Method for sending vertical continuous casting rigid dummy bars upwards

A dummy rod and rigid technology, applied in the field of vertical continuous casting rigid dummy rod feeding, to achieve the effect of safe operability, complete process and orderly action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing.

[0028] A method for feeding rigid dummy rods for vertical continuous casting, comprising the following steps:

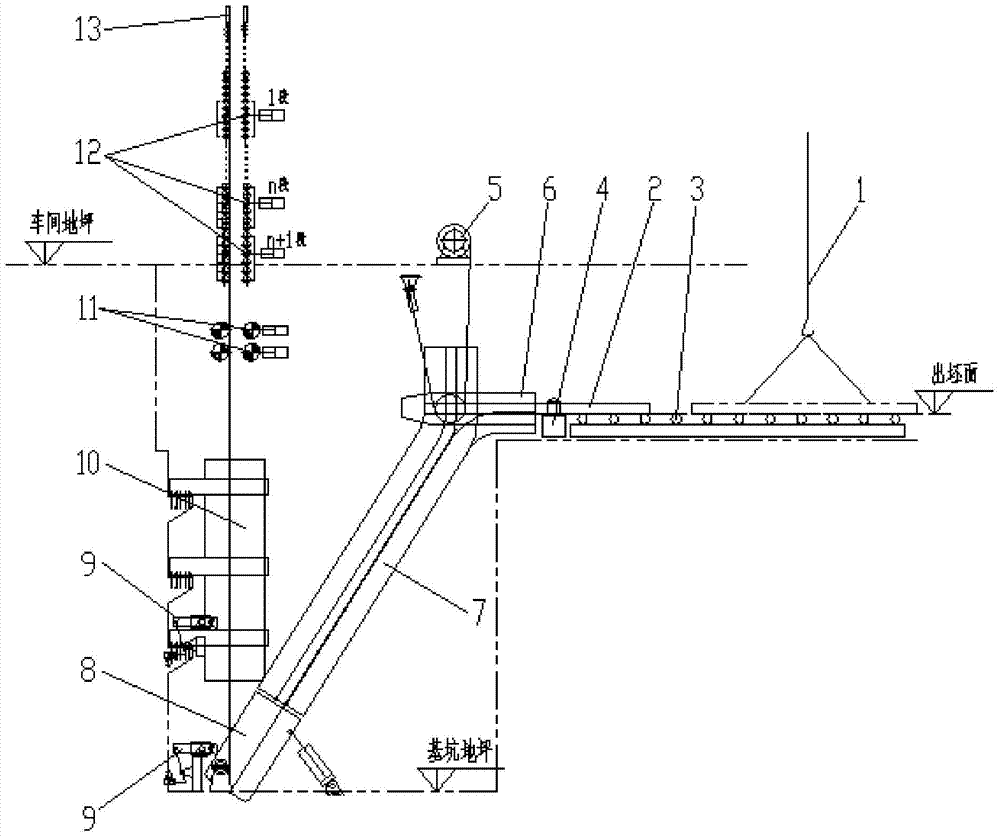

[0029] refer to figure 1 , step 1, in the casting preparation mode, the rigid dummy bar 2 is placed on the billet roller table 3 by the workshop crane 1, the billet roller table 3 runs counterclockwise, and the two billet pinch vertical rollers 4 run simultaneously, and the The rigid dummy rod 2 is sent into the blank receiving trolley 6 which is waiting horizontally;

[0030] The arrangement of the two slab pinch vertical rollers 4 is convenient for the rigid dummy bar 2 to accurately enter the slab receiving trolley 6, and is also suitable for continuous casting machine short-length billet discharge.

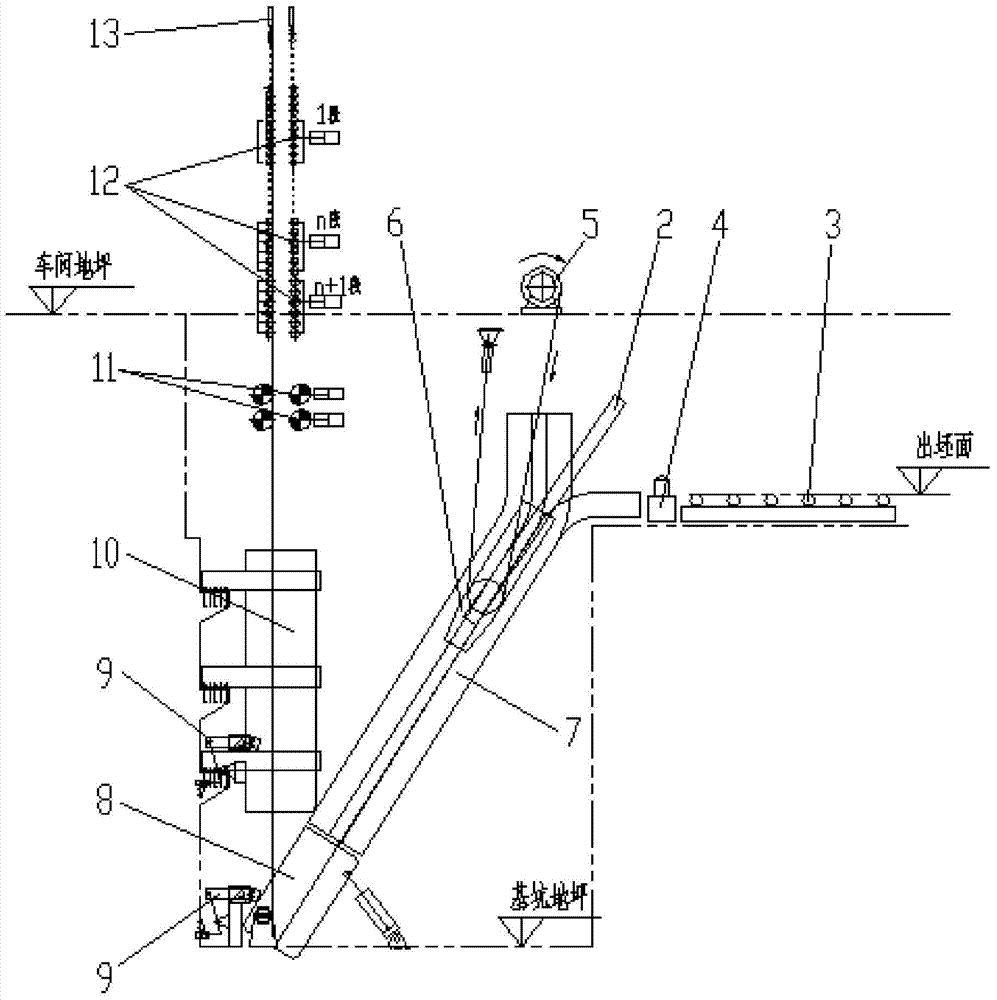

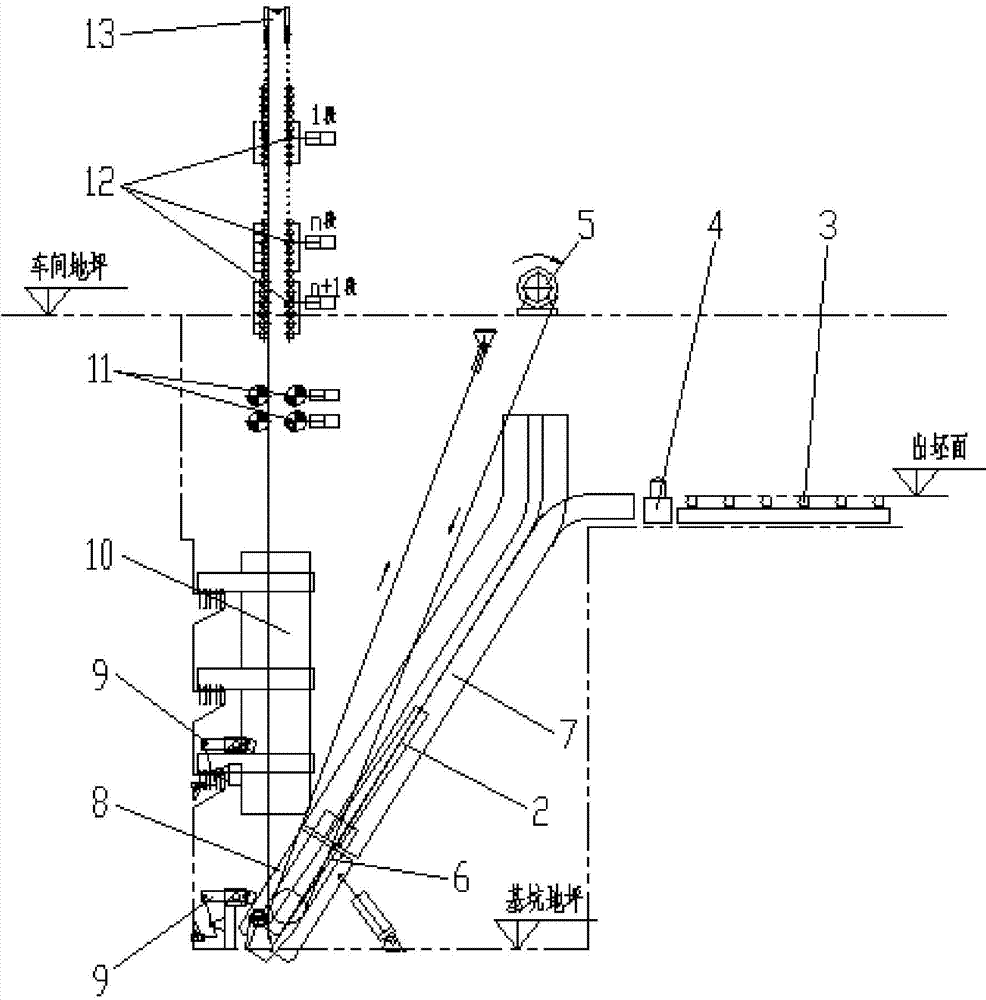

[0031] refer to figure 2 , step 2, the reel of hoisting device 5 rotates clockwise, so that the blank receiving trolley 6 loaded with rigid dummy bar 2 is inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com