Patents

Literature

38results about How to "Orderly process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

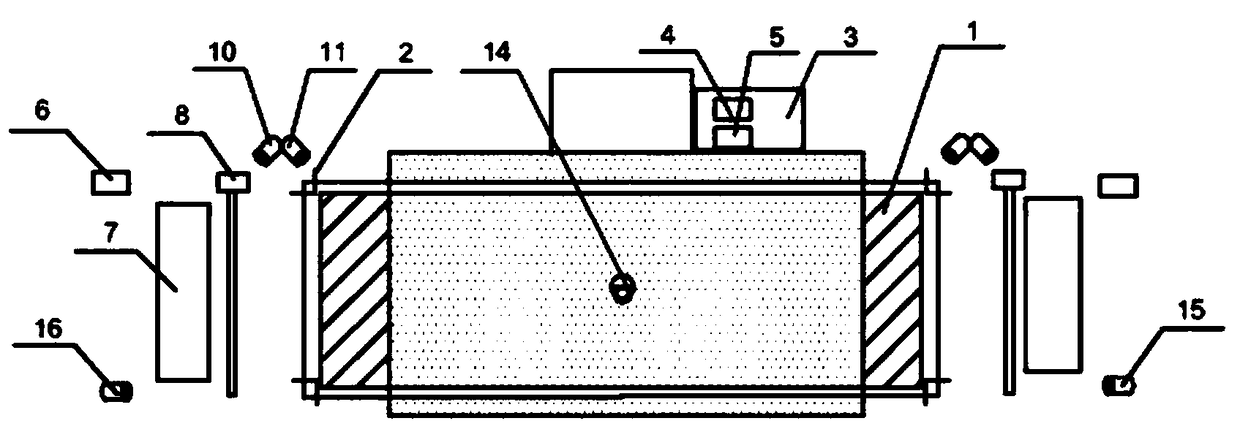

Automatic weighing metering system and method for granary

ActiveCN105241533AImprove accuracyImprove efficiencyData processing applicationsCo-operative working arrangementsParking areaComputer science

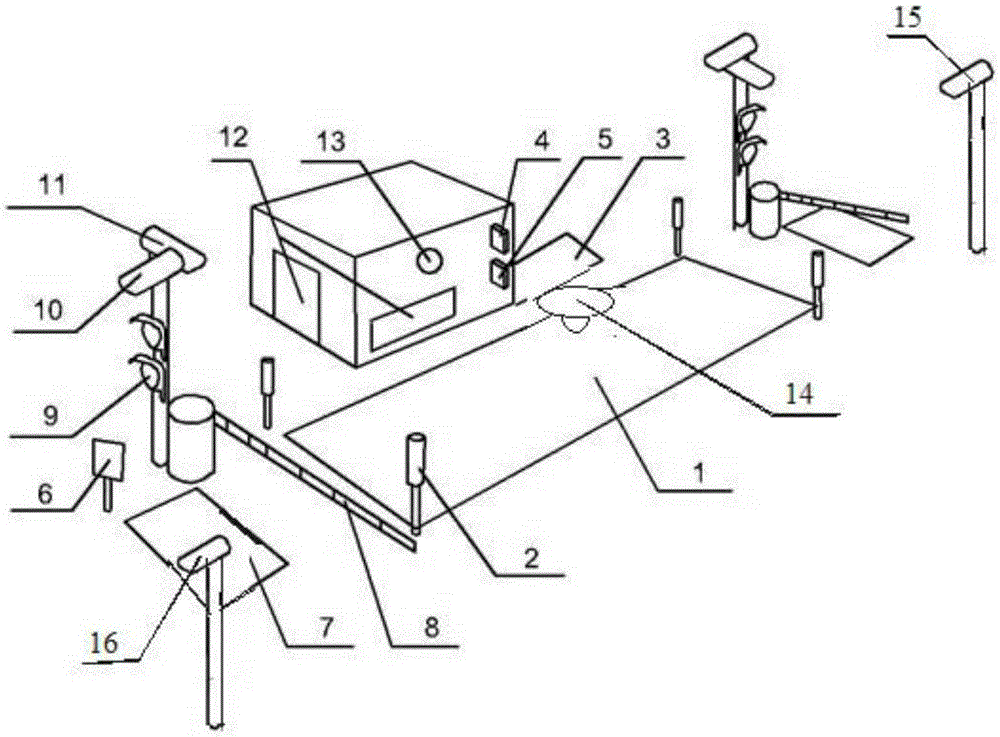

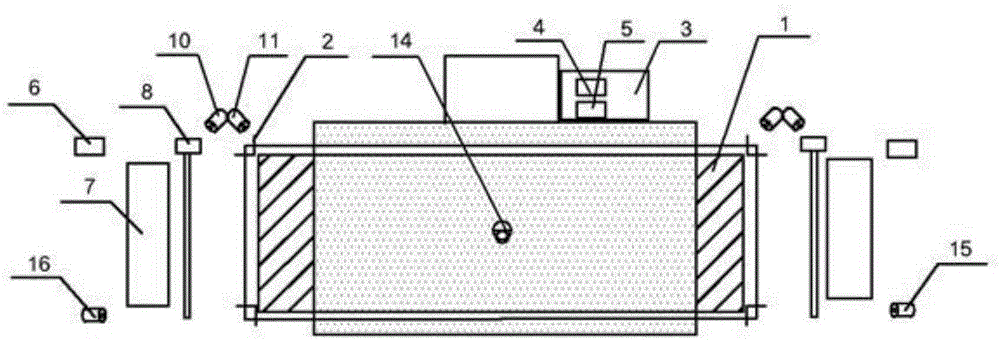

The invention discloses an automatic weighing metering system for a granary. The system comprises a weighbridge. Multiple infrared light curtain detectors limit a vehicle parking area. A host computer, a waiting area and a camera unit are arranged near the weighbridge. The host computer is configured in a way that after a grain carrier worker stays in the waiting area and the face information of the worker is verified, an RFID card is swiped, the weighbridge records weighing data and the camera unit captures current video frames at the same time after a grain carrying vehicle stays in the vehicle parking area, the camera unit does not capture the face and the weighing data by the weighbridge is steady, and the data and the video frames are uploaded to the host computer; and if the grain carrying vehicle does not stay in the vehicle parking area, or the camera unit captures the face or the weighing data by the weighbridge is not steady, the weighbridge does not have a weighing effect and will emit reminding sound. The invention also discloses an automatic weighing metering method for a granary. Man-made cheating can be prevented in many ways, smooth information operations of a whole course during which a grain carrying vehicle enters a granary and exits from the granary can be achieved, the number of workers can be reduced, operating procedures can be standardized, and highly efficient and automatic weighing metering is achieved.

Owner:HUBEI YE WEI INTELLIGENT TECH

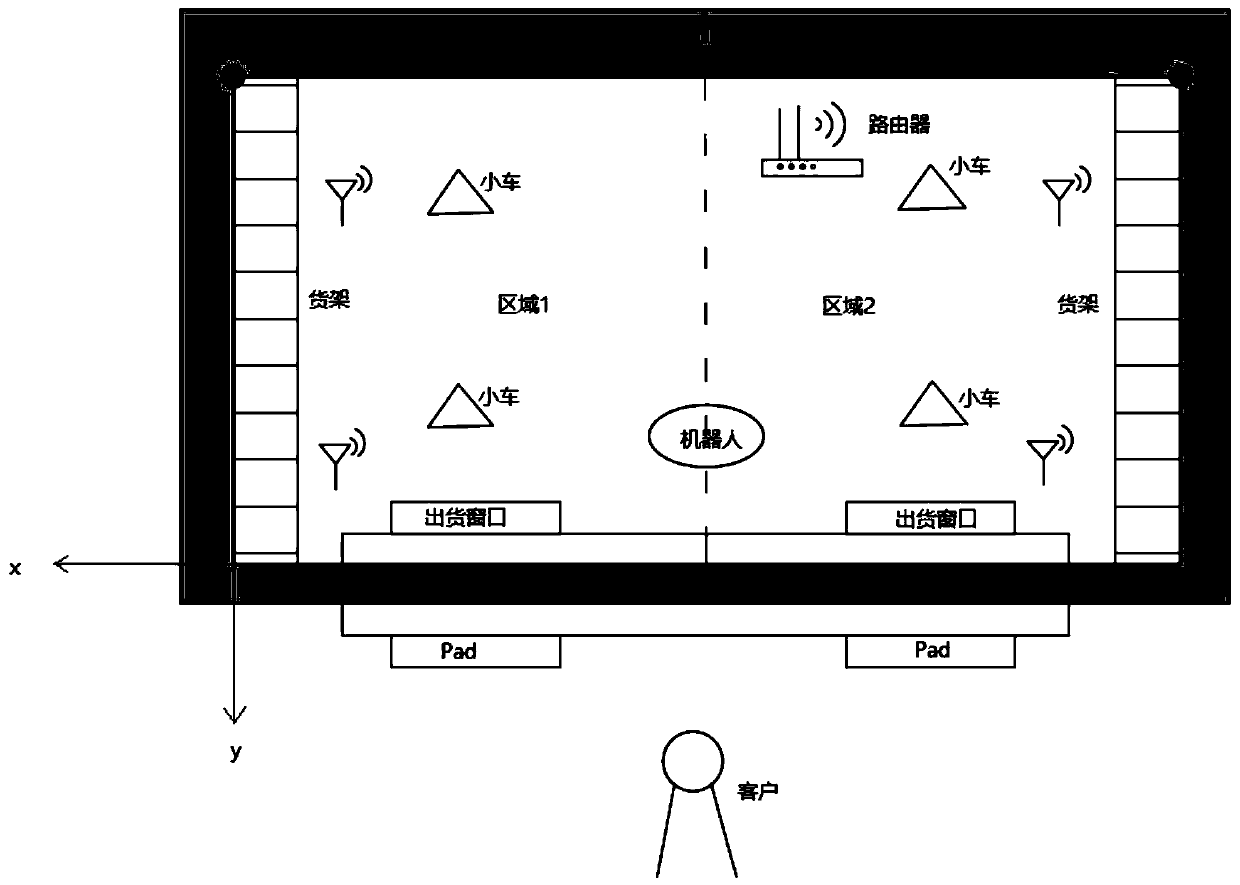

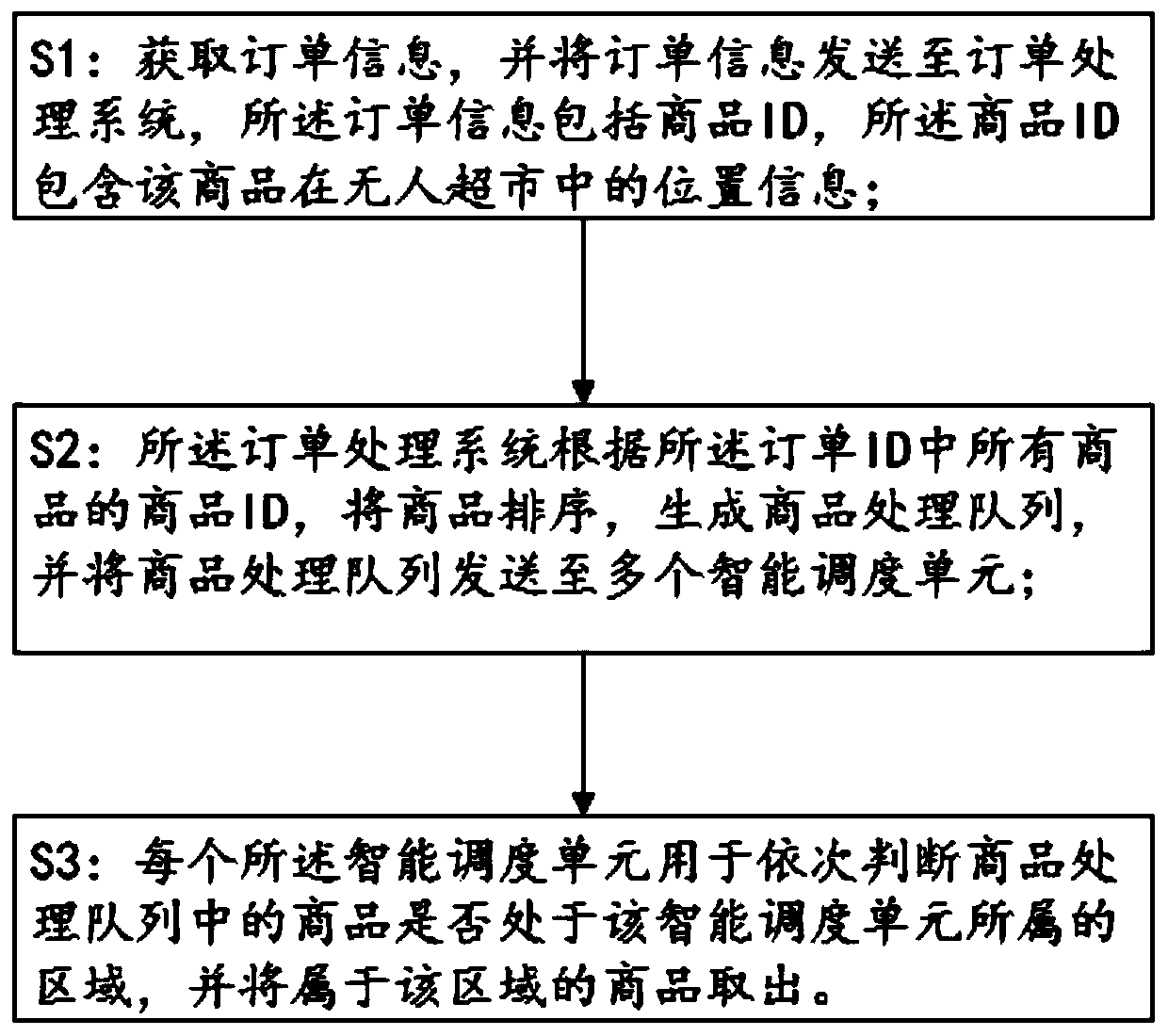

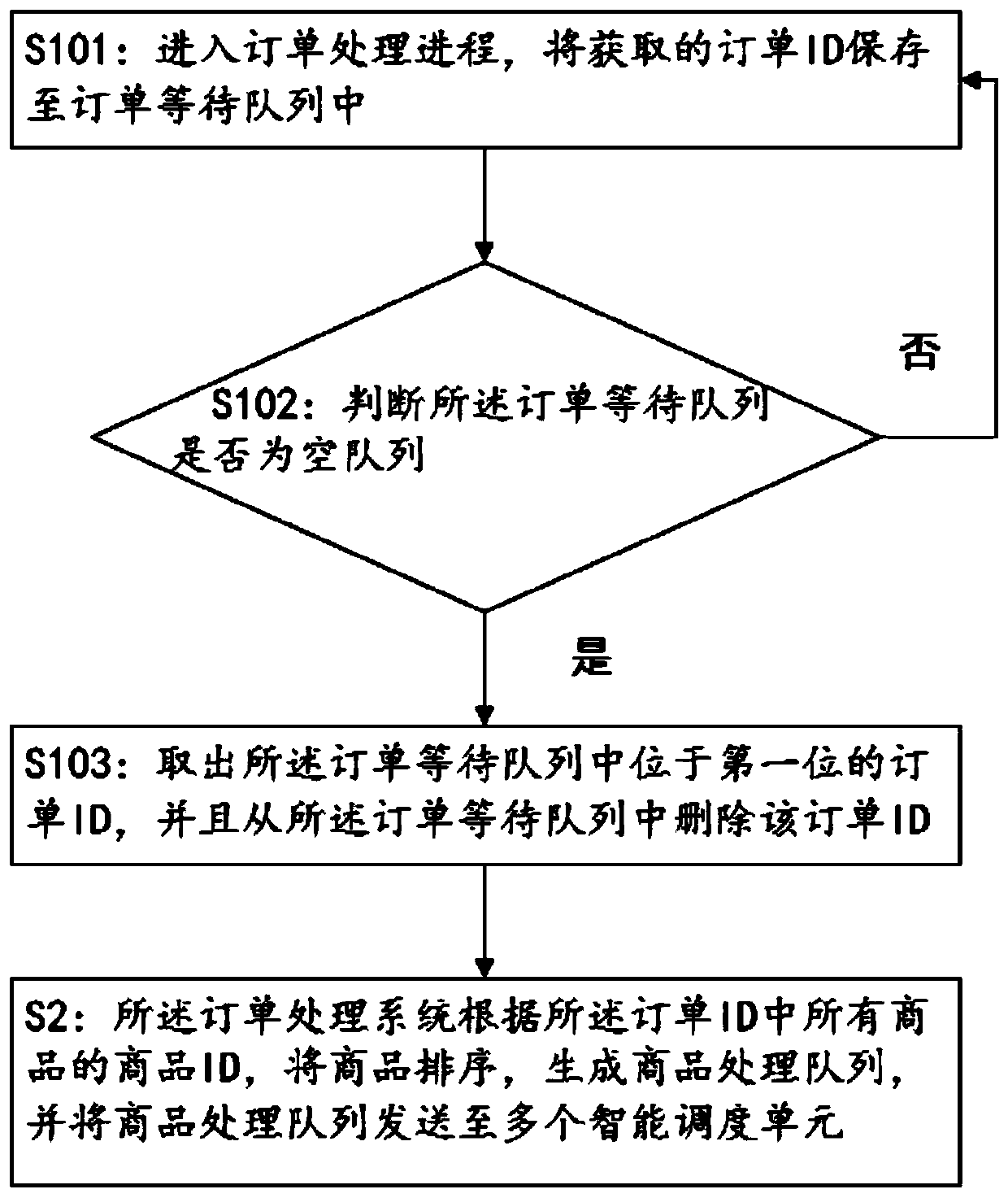

Full-automatic unmanned supermarket vending system and method

InactiveCN110992133AHigh degree of automationEasy shoppingCash registersBuying/selling/leasing transactionsOrder processingComputer science

The invention provides a full-automatic self-service supermarket vending system and method. The system comprises a client, a self-service supermarket, an order processing system and a self-service supermarket goods taking scheduling system. The order processing system communicates with the client and the unmanned supermarket goods taking scheduling system. The unmanned supermarket goods taking scheduling system comprises a plurality of intelligent scheduling units, and the plurality of intelligent scheduling units are used for respectively executing allocation and transportation of goods in different areas of an unmanned supermarket; the order processing system is used for processing the order information according to the commodity IDs of all commodities in the order information, sorting the commodities to generate a commodity processing queue, and sending the commodity processing queue to multiple intelligent scheduling units; and the intelligent scheduling units are used for sequentially judging whether the commodities in the commodity processing queue are located in an area to which the intelligent scheduling units belong or not and taking out the commodities belonging to the area. The automation degree is high, the shopping process is easy and simple, and the system is suitable for wide application.

Owner:武汉诺得佳科技有限公司

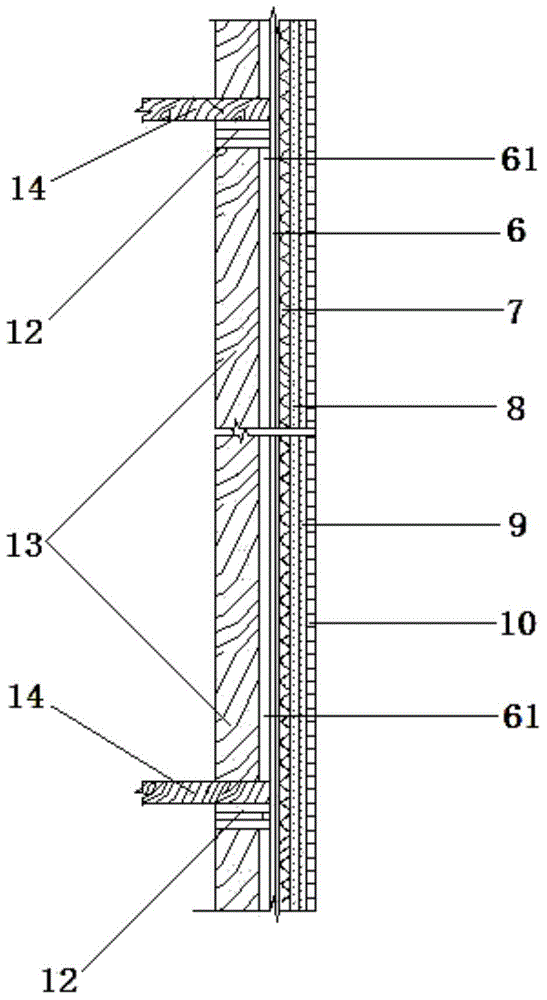

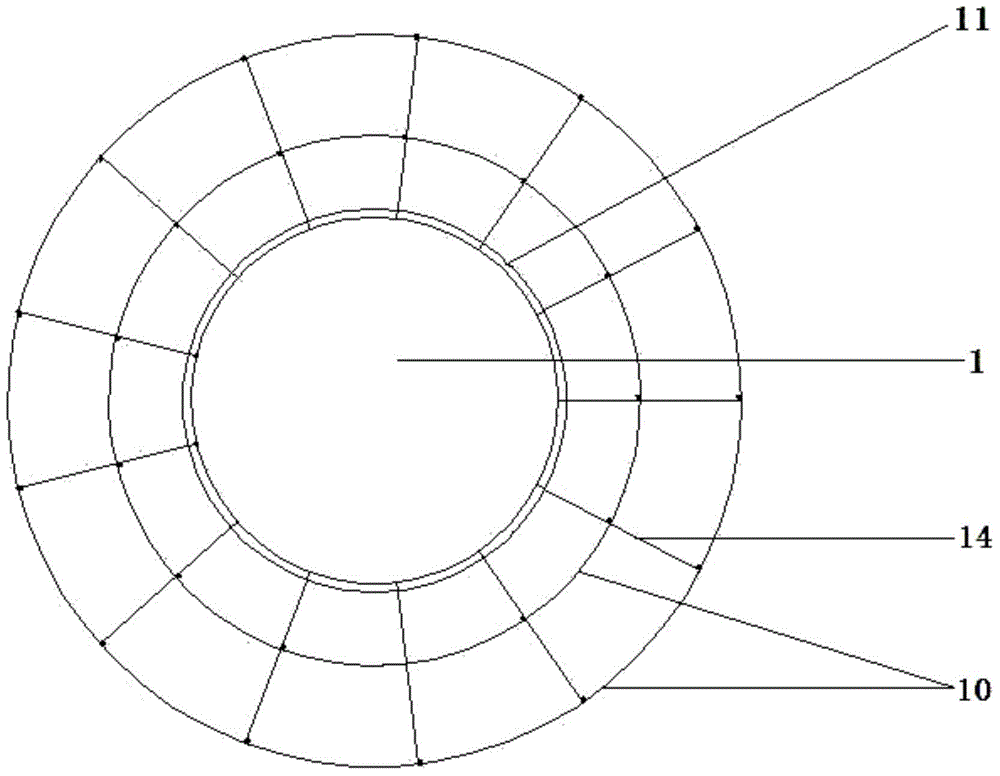

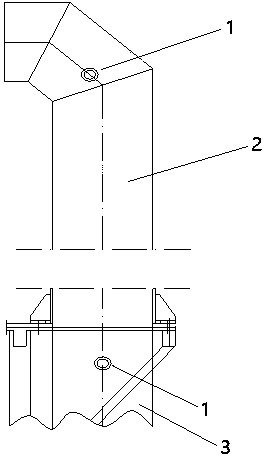

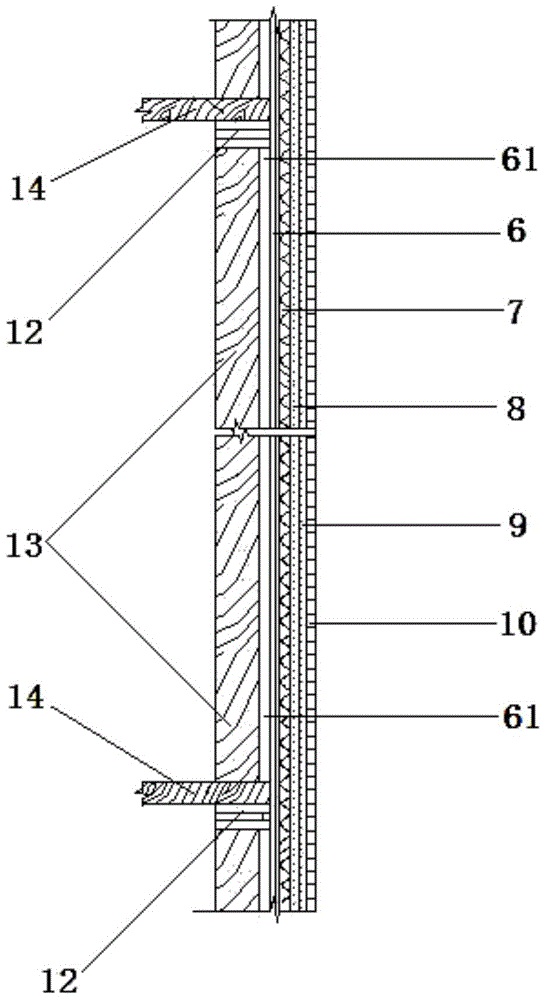

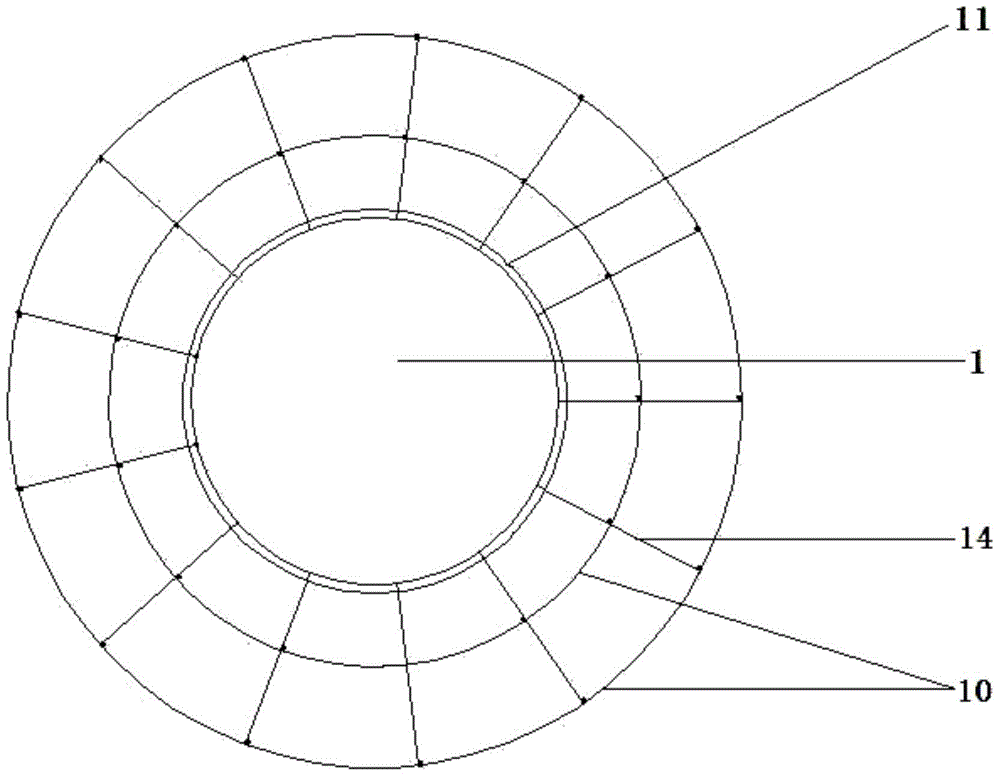

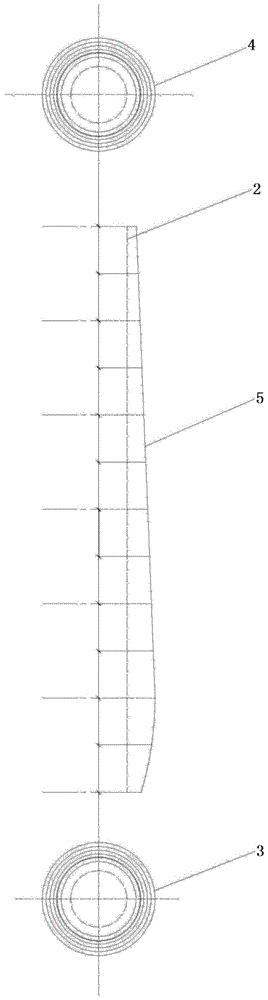

Construction method of irregular decorative column facing with variable cross section

ActiveCN104594582AEasy typesetting and cuttingSmooth connectionCovering/liningsStructural engineering

The invention discloses a construction method of an irregular decorative column facing with a variable cross section. The method comprises a series of ordered construction and operation steps of paying off accurately throughcarrying out three-dimensional (3D) model building and 3D composing, accurately surveying and lining, positioning drill holes, nailing a wooden sleeper, producing and installing a wood frame, installing a composite board seal ring, paving a glass grid, leveling and painting a circular arc camber, composing the facing, positioning and snapping a line, and paving a face brick surface layer. The construction of the irregular decorative column facing with the variable cross section with low construction difficulty, ordered process and lower cost can be realized, a bowling type cylindrical deformed surface paved with wavy colorful patterns can be modeled, and the construction facing is smooth, the patterns can be connectedjoined smoothly, the radian feeling is good, and camber lines are smooth; furthermore, the decorative column is strong in modeling plasticity, easy to trim, reliable in quality and short in construction duration, the factory prefabrication of face bricks can be realized without the cutting again on the site, cost saving can be realized, and the patterns on the facing can be continuous uniform and corresponded continuously, uniformly and symmetricallycorresponding and symmetrical, therefore the perfect and uniform facing modeling effect can be reached.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

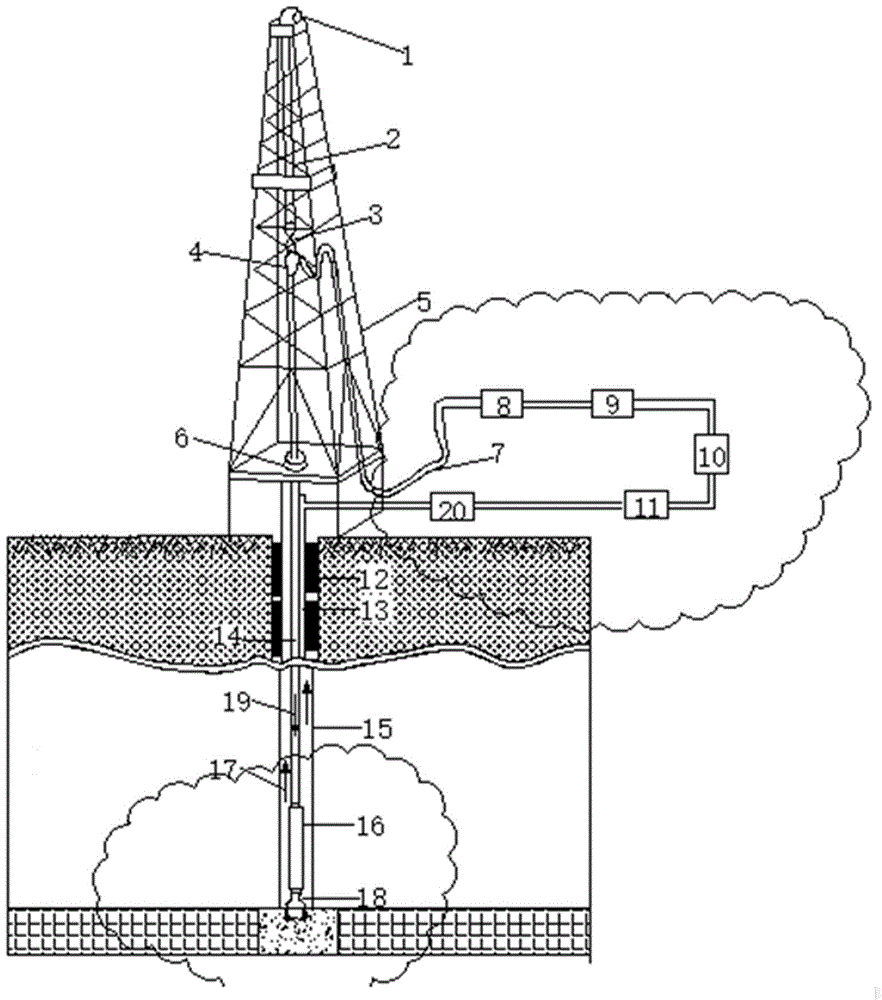

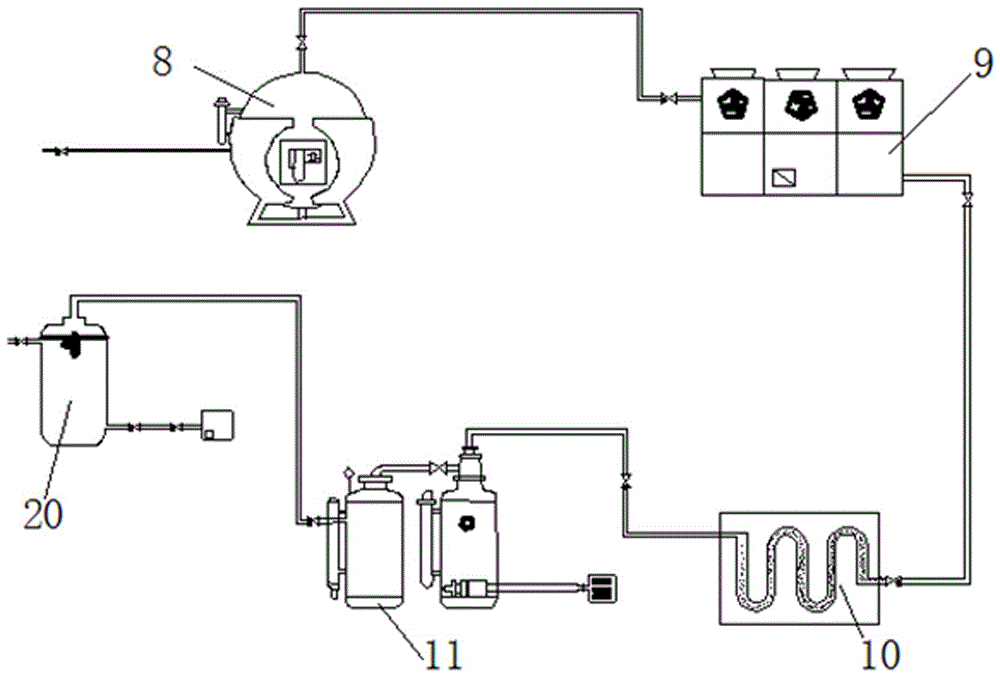

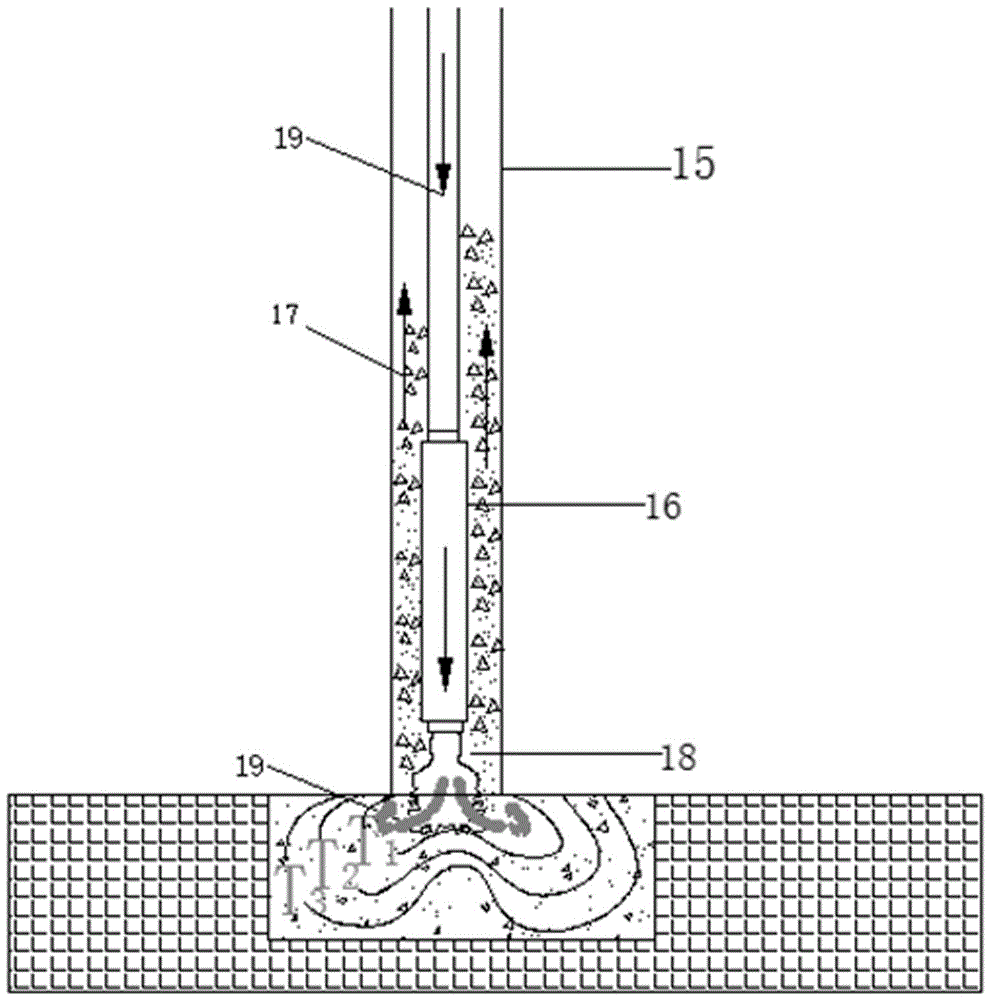

Well drilling method for using dry ice drilling fluid to assist in rock breaking

ActiveCN106246101AGuarantee capacityEnsure rock breaking efficiencyInsulationFlushingHigh pressureHigh heat

The invention provides a well drilling method for using dry ice drilling fluid to assist in rock breaking and belongs to the technical field of hot dry rock geothermal well drilling construction. Granular dry ice serves as drilling fluid, heat absorption during different phase state changes of carbon dioxide is sufficiently utilized to cool a drilling tool, temperature gradient is generated on rock mass in front of a drill bit, the rock mass is subjected to thermal fracture, then the properties of the rock mass are weakened, and the rock breaking assisting function is achieved. In the circulation process of the dry ice drilling fluid, the functions including (1) drill bit cooling and lubricating, (2) rock breaking assisting, (3) rock waste carrying and (4) well wall system stability maintaining are brought into full play. Meanwhile, cyclic utilization of the dry ice drilling fluid is achieved on the ground. Through the well drilling method, the difficult problem of well drilling under high temperature and high pressure conditions can be solved, the technical problems that due to the high-temperature and high-pressure environment, the drilling tool stability is poor, the performance of the drilling fluid is poor, the drillability of a rock stratum is poor, the stability of a drill hole is poor, and the well drilling construction cost is high are solved, and the technical defects of hot dry rock geothermal development well drilling construction are effectively overcome.

Owner:TAIYUAN UNIV OF TECH

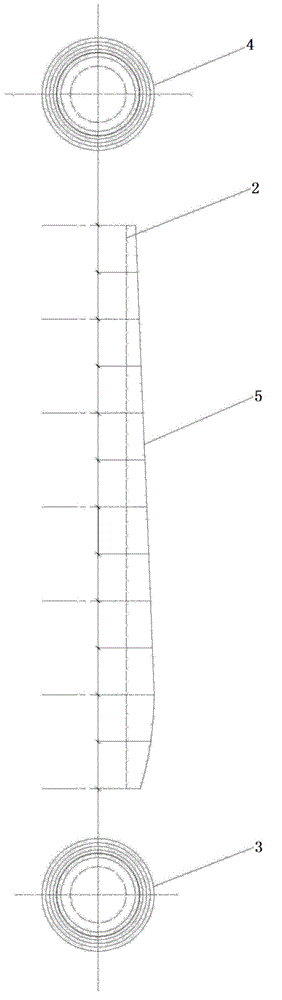

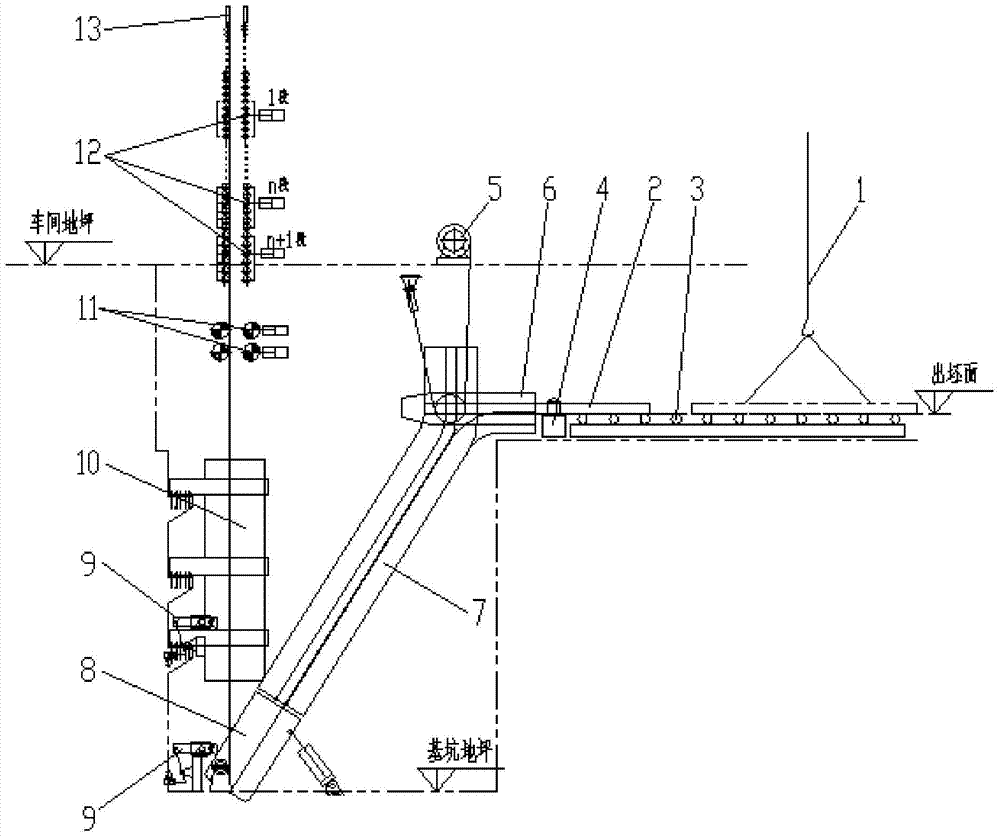

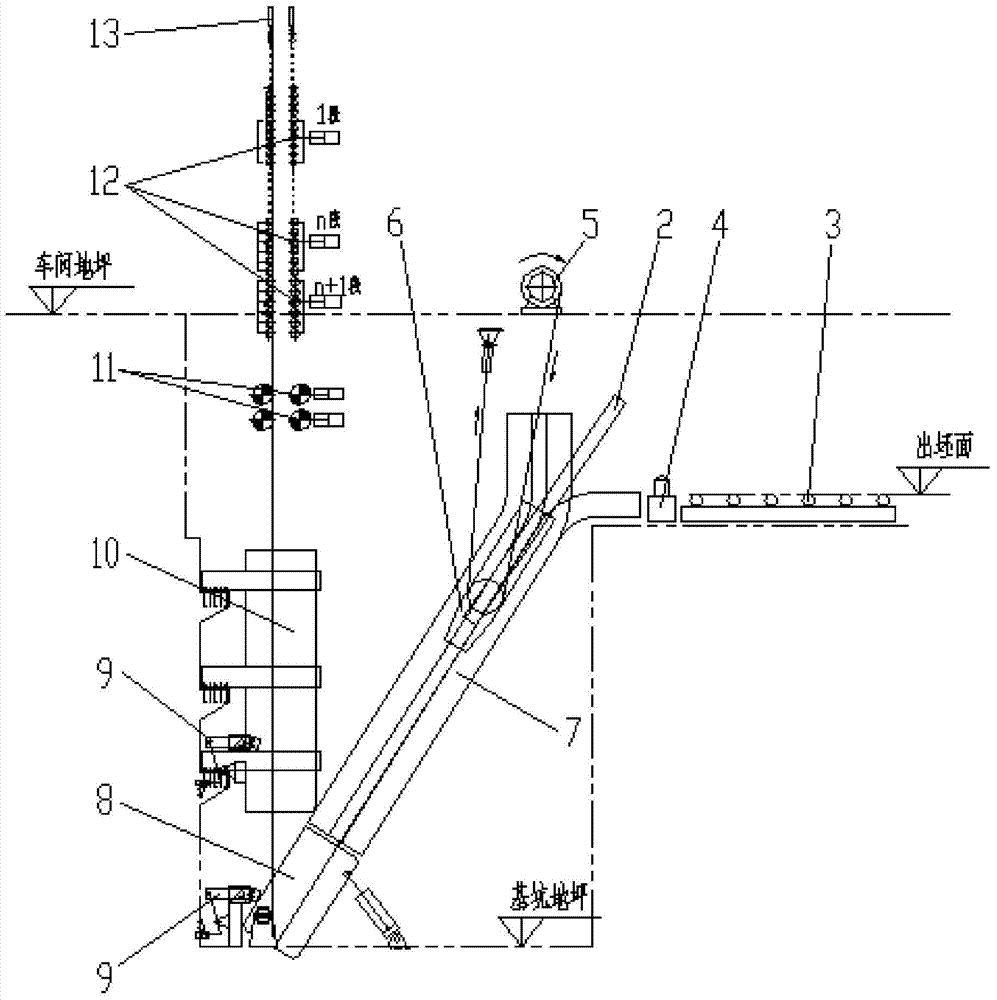

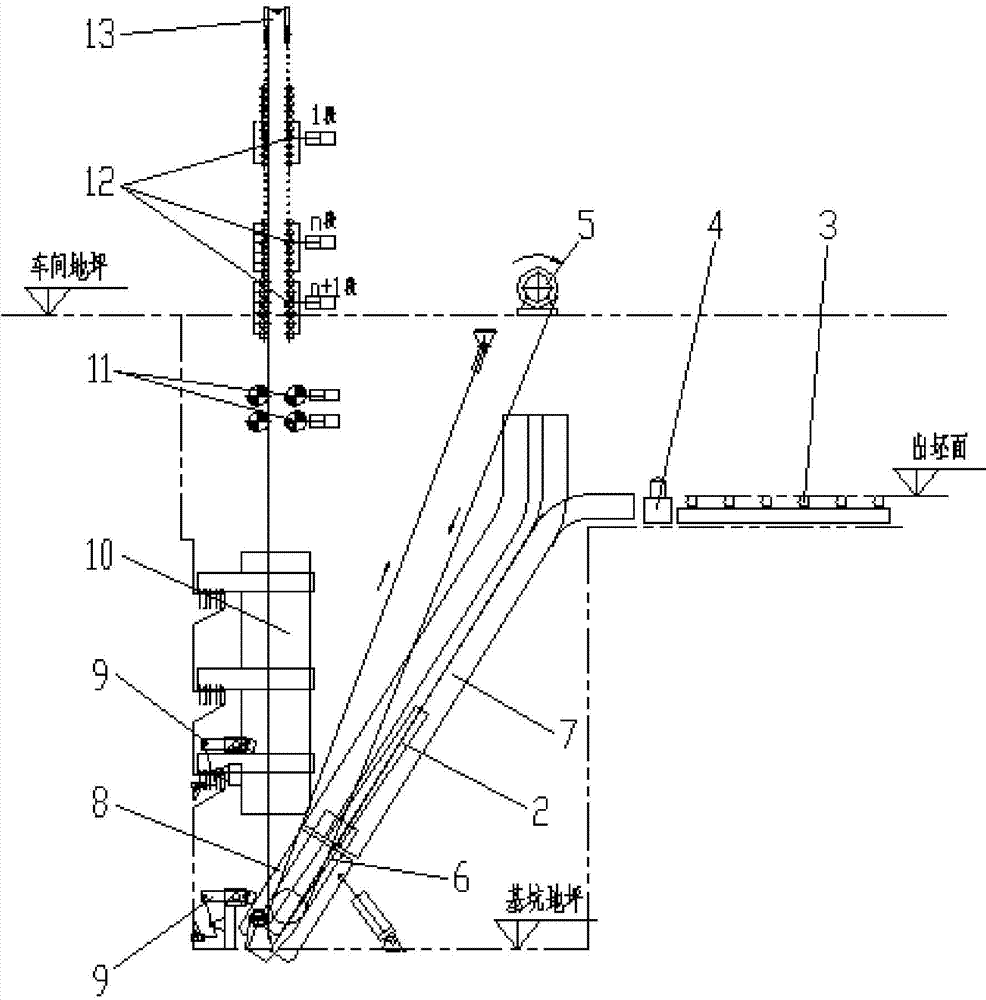

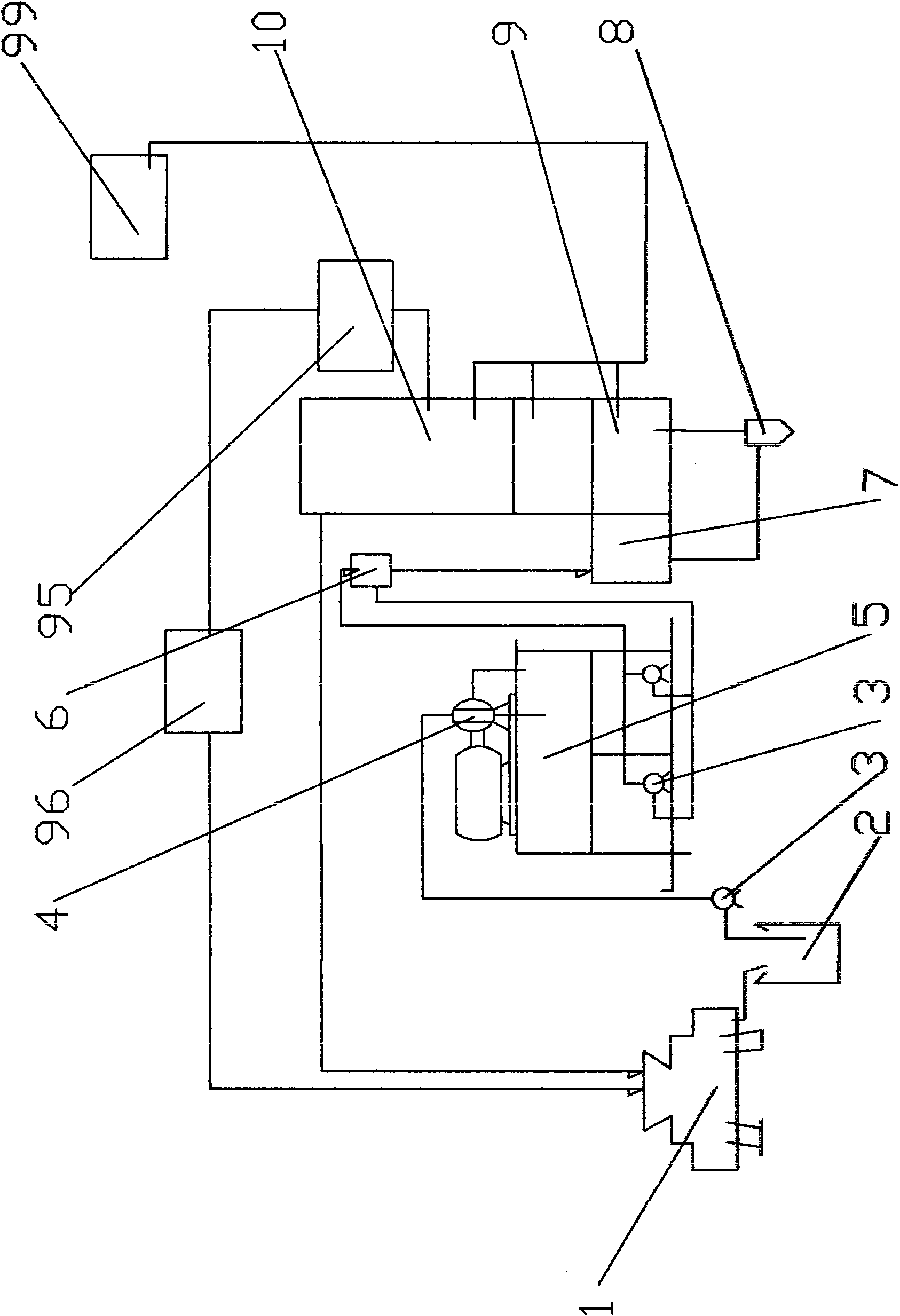

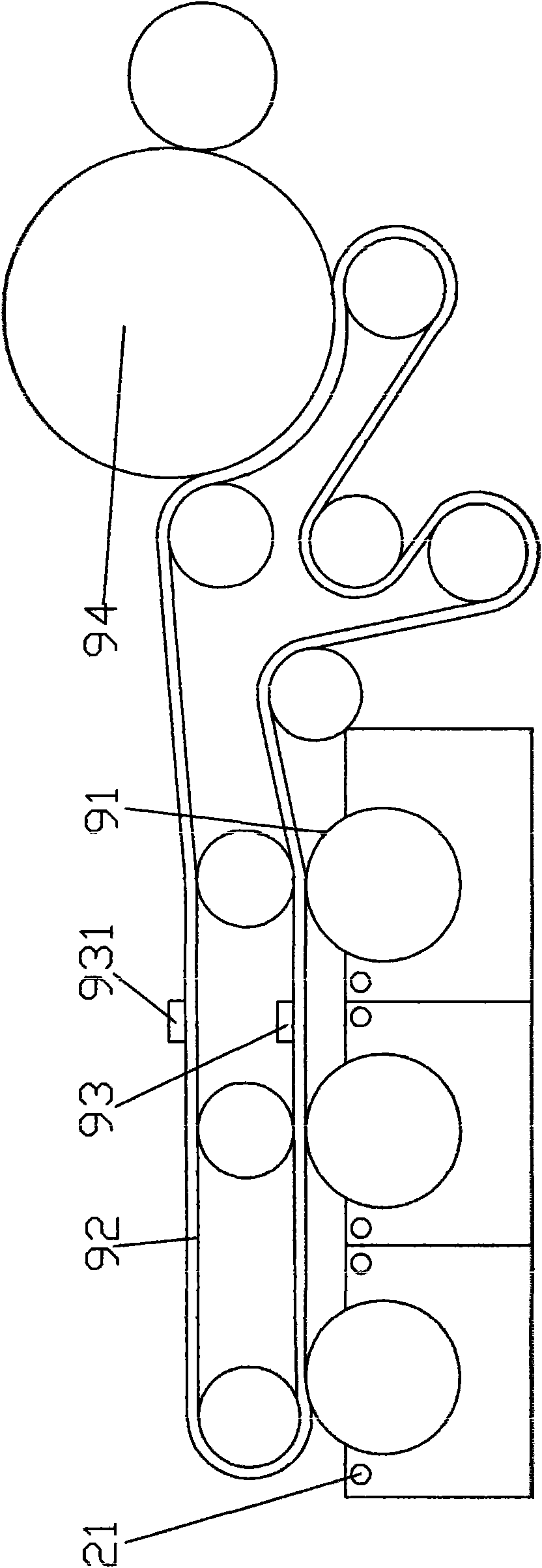

Method for sending vertical continuous casting rigid dummy bars upwards

The invention discloses a method for sending vertical continuous casting rigid dummy bars upwards. Under a casting preparing mode, the rigid dummy bars are placed on a blank outlet roller table through a workshop crane and are sent into a horizontal waiting blank receiving trolley; a coiling block of a winding plant runs clockwise, and the blank receiving trolley is pulled by a steel rope to obliquely enter a fixed oblique rail; the winding plant runs clockwise to enable the blank receiving trolley to enter a swinging track; the winding plant stops running and carries the blank receiving trolley and the rigid dummy bars to swing anticlockwise to a vertical position; a hydraulic electromagnetic positioning mechanism acts simultaneously to push and pull the rigid dummy bars to a stand state; the coiling block of the winding device runs anticlockwise, the rigid dummy bars are sent upwards to a crystallizer under the successive relay running of a plurality of sector-shaped driving rollers with the hydraulic cylinder clamping function and are clamped by the three sector-shaped driving rollers at the topmost part to keep static, and then the dummy bars are sent upwards. The method solves the problem of loading of the continuous casting rigid dummy bars, is safer and has higher maneuverability.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

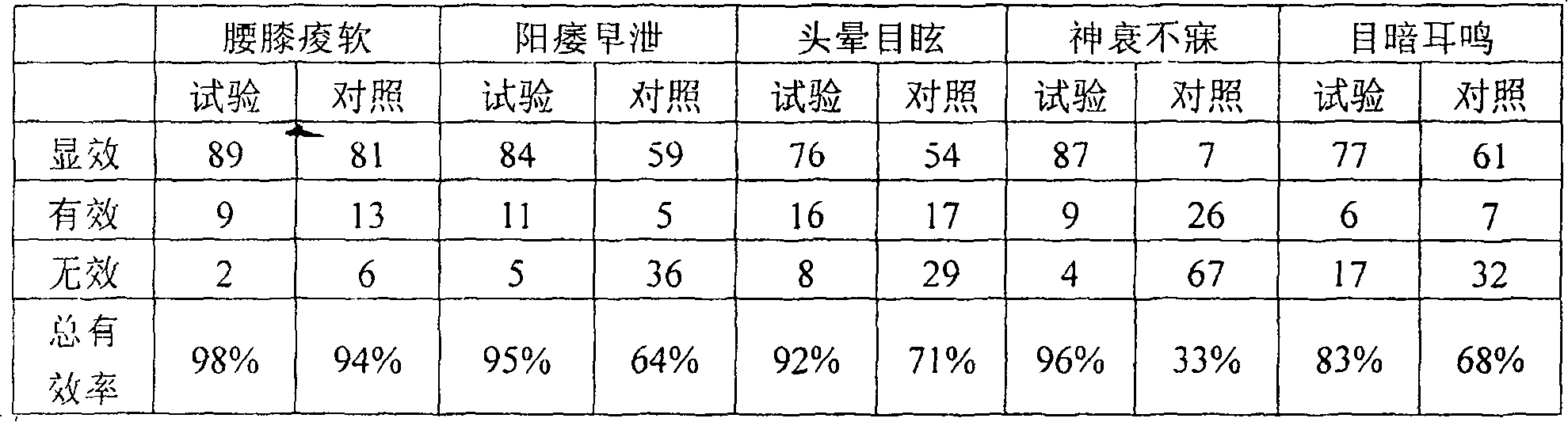

Anti-senility medicine and its preparing method

InactiveCN1899486AAnti-aging function is completePrecise and proper treatmentAntinoxious agentsPlant ingredientsEpimediumLycium barbarum fruit

The present invention is a kind of anti-senility Chinese medicine possessing the functions of invigorating kidney, liver and spleen, benefiting qi, promoting blood circulation, dredging meridians, etc. The anti-senility Chinese medicine is prepared with fleece flower root, wolfberry fruit, dodder seed, epimedium, Indian mulberry and other seven kinds of medicine-food material, and through pre-treatment, decocting, filtering, sterilizing and other steps to form honeyed bolus, tablet or capsule. The anti-senility Chinese medicine has obvious anti-senility effect.

Owner:陈昊 +2

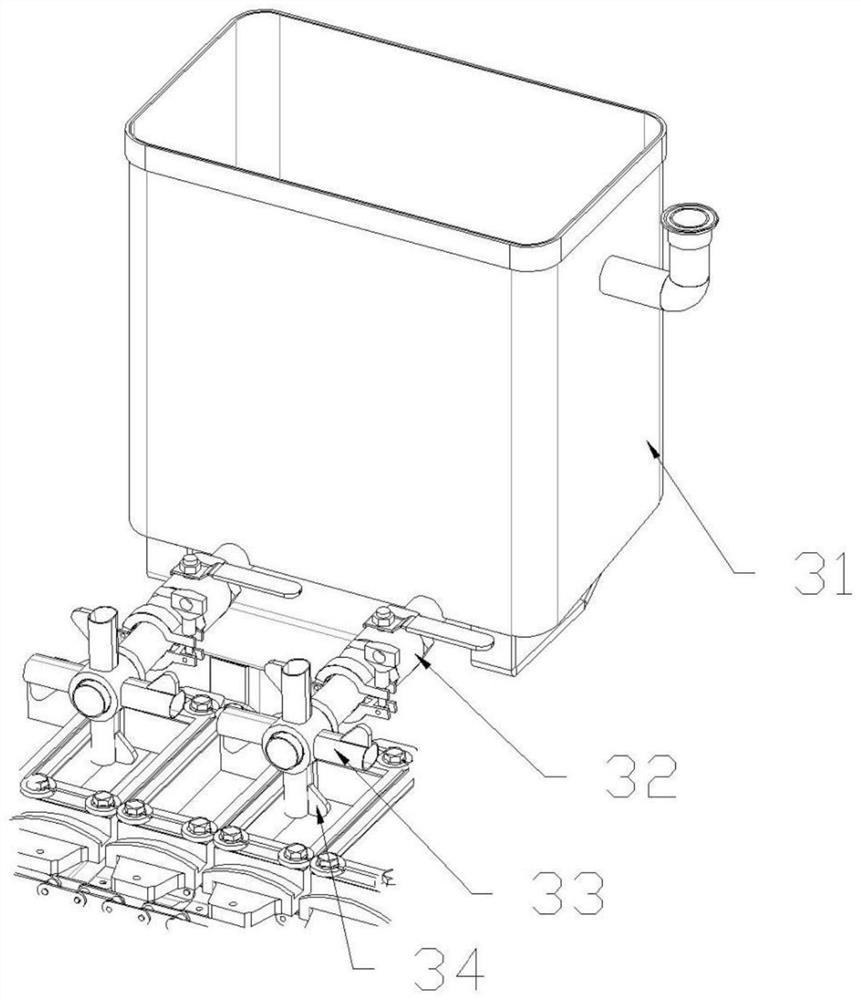

Waste paper regenerating process and apparatus thereof

InactiveCN101570944ASimple processOrderly processPaper recyclingMachine wet endDecomposerPaper sheet

The invention relates to the field of paper making, in particular to a waste paper regenerating process. Waste paper is cleaned in a stockyard for standby use and then decomposed by a fiber decomposer. Decomposed paper pulp is discharged in a pulp pond, pumped by a stock pump to a pulping machine for kneading, and then enters another pulp pond. The paper pulp is pumped by the stock pump to a material box and is fed into a mixing pond in a rated manner from the material box. The paper pulp then undergoes sand removal performed by a desander and enters a net cage of a net box so as to be shaped to be a paper sheet. A special water spraying device is arranged in the net box for cleaning the net cage. Then, the paper sheet is printed on a blanket and undergoes vacuum dehydration in a vacuum machine. After the vacuum dehydration, the paper sheet undergoes pressing and water extrusion in a presser and then enters a drier for drying, and a finished product is obtained. Steam water is generated in the drier, the blanket is cleaned by the water spraying device, and white water is generated and recycled to the fiber decomposer. The process is simple and ordered, realizes that waste paper regeneration does not generate pollution again, saves 85 percent of water, 20 percent of electricity and 80 percent of chemicals, achieves 100 percent fiber utilization rate and directly reduces 15 percent of production cost.

Owner:傅承祖

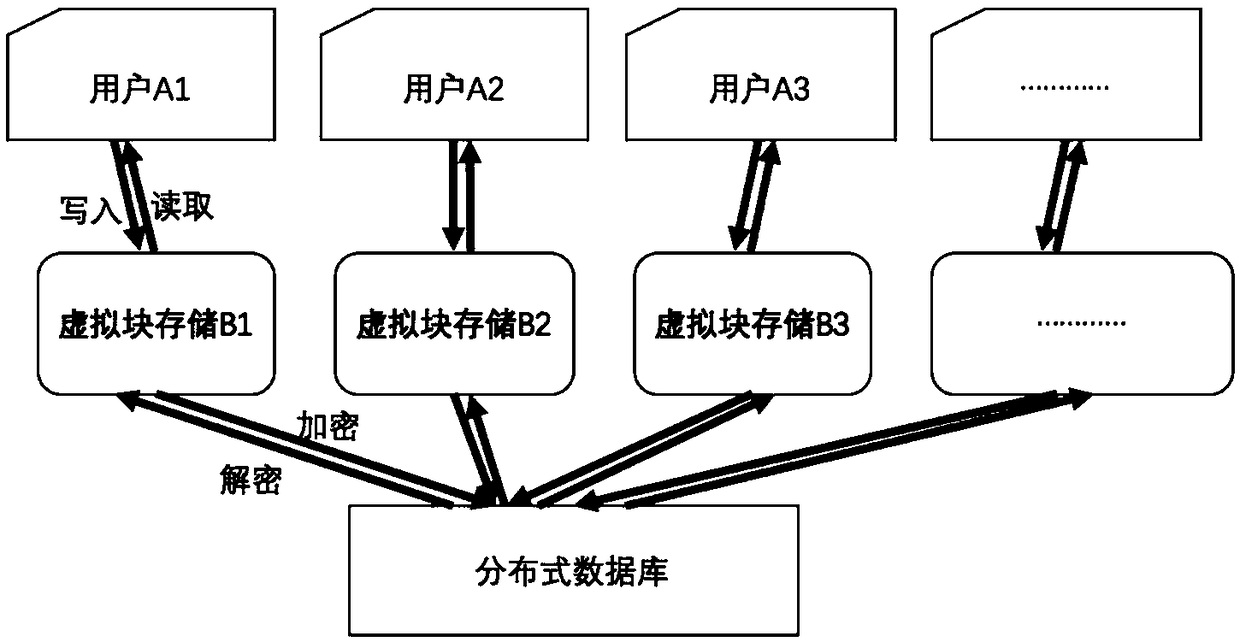

User data storage method based on cloud platform distributed block storage

Owner:浙江远算科技有限公司 +1

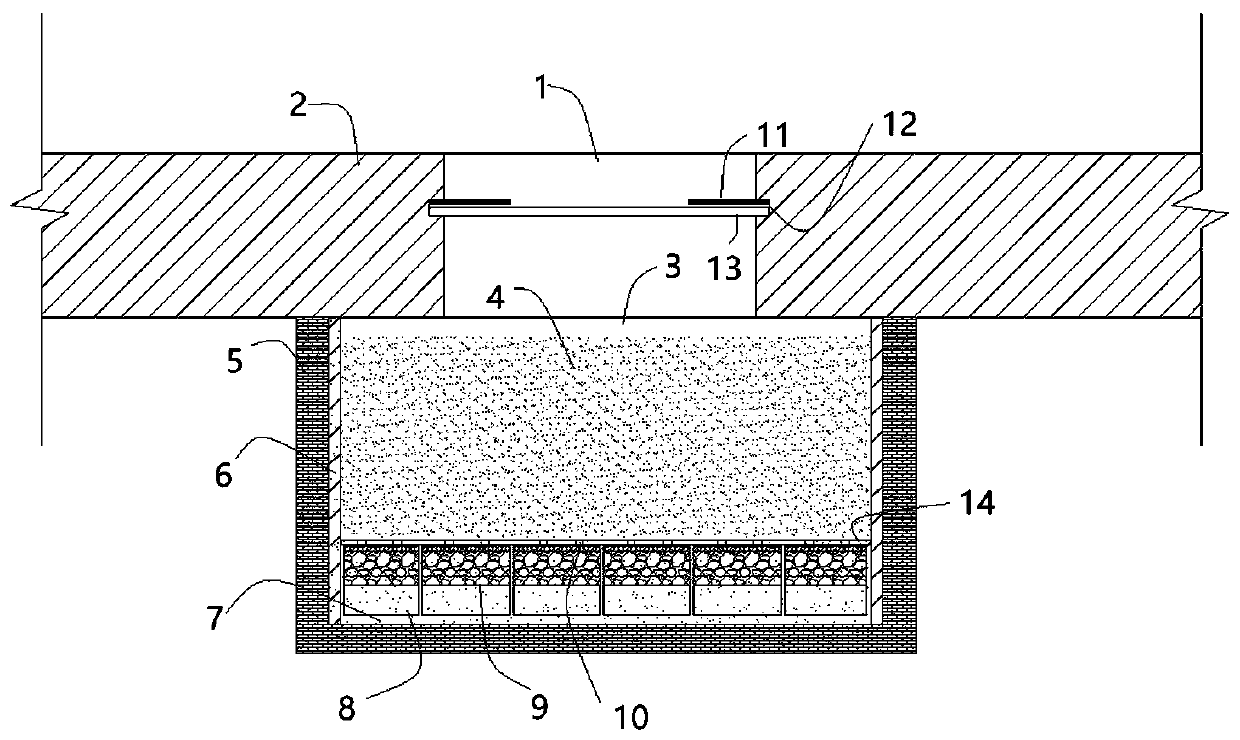

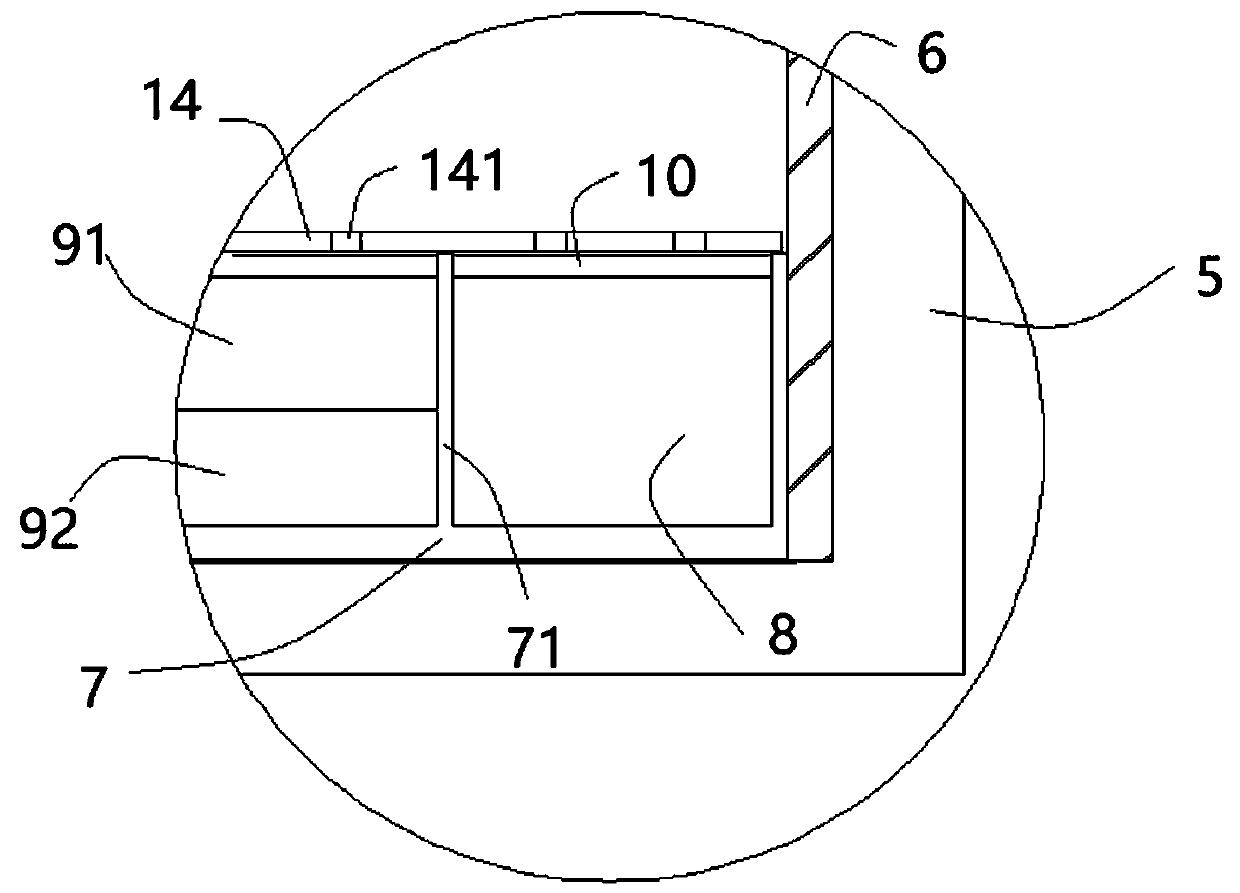

Basement post-cast strip anti-leakage construction method

ActiveCN110158664AEasy to pourEasy to shapeArtificial islandsProtective foundationBasementReinforced concrete

The invention discloses a basement post-cast strip anti-leakage construction method. A basement post-cast strip anti-leakage structure is used in the method; the structure comprises a water absorptionexpansion layer, a water stop strip, a concrete cushion layer, a reinforced concrete layer and a water absorption layer arranged on a post-cast strip, and can achieve an excellent anti-permeation effect; meanwhile, through the concrete cushion layer, the subsequent concrete casting and molding are more facilitated, and the stability and the firmness of the whole structure are guaranteed; a waterproof steel plate is arranged on the concrete cushion layer on the side wall of a groove body of the post-cast strip; the concrete cushion layer at the bottom of the groove body is provided with a baseplate and isolation plates arranged on the base plate; the steel plate butts against the isolation plates at two ends of the base plate; the thickness of the steel plate can be designed according toactual demands to guarantee total occupation of the bottom area (the concrete cushion layer can be extruded) of the groove body after installation with the base plate; and the base plate and the waterabsorption layer therein can be installed in the groove bottom after ahead manufacturing, so that the efficient and ordered implementation of whole procedures is guaranteed.

Owner:浙江大东吴集团建设有限公司

Electrical piping and in-pipe threading construction method in power distribution cabinet installation construction process

InactiveCN111525427AImprove installation and construction efficiencySimple processSwitchgearApparatus for laying cablesPipingStructural engineering

The invention discloses an electrical piping and in-pipe threading construction method in a power distribution cabinet installation and construction process. The method comprises: construction procedures of concealed pipe laying: construction preparation, prefabricated processing pipe hot bending, box measurement, box position measurement, box fixing, box and pipeline connection, deformation jointtreatment and grounding treatment; the construction procedure of exposed pipe laying comprising the steps of construction preparation, prefabricated machined pipe simmer bending, support and hangingbracket determination, box, box and fixing point position determination, support and hanging bracket fixation, box and box fixation, pipeline laying and connection, deformation joint treatment and grounding treatment; in-pipe threading construction procedure comprising the steps of construction preparation, wire selection, wire threading and pulling, pipeline cleaning, paying off and wire breaking, binding of a wire and a strip wire, connection of the wire with a protective opening, wire welding, wire binding and line inspection insulation remote measurement. The method is orderly in operation, easy to master, high in construction efficiency and low in error rate.

Owner:WUHU ZHUOYA ELECTRIC

Automatic Grain Depot Weighing and Measuring System and Method

ActiveCN105241533BImprove accuracyImprove efficiencyData processing applicationsCo-operative working arrangementsParking areaGrain storage

Owner:HUBEI YE WEI INTELLIGENT TECH

Demolishing construction method for pipeline with thermal-insulating and abrasion-resistant lining

ActiveCN108049655AReduce labor intensityImprove securityBuilding repairsArchitectural engineeringBuilding construction

The invention provides a demolishing construction method for a pipeline with a thermal-insulating and abrasion-resistant lining. The demolishing construction method comprises the following steps thata hanging lug is mounted on the pipeline; paired stop blocks are mounted on the two sides of a to-be-cut section of the pipeline, and a jack is mounted between each pair of stop blocks; precutting isconducted on the pipeline along the circumference of the to-be-cut section; the jacks are started, so that the pipelines on the two sides of the cut section are initially separated; deep cutting is conducted along an initially separated clearance of the pipelines, so that the pipelines on the two sides of the cut section are completely separated; blocking plates are inserted in the cur clearance during deep cutting; the jacks are removed, and reinforcing ribbed plates are mounted on the stop blocks where the jacks are removed; the reinforcing ribbed plates and the blocking plates are welded, so that openings of the cut pipelines are closed through the blocking plates; and the cut pipelines are moved away through a crane. According to the demolishing construction method for the pipeline with the thermal-insulating and abrasion-resistant lining, the labor intensity is advantageously reduced, construction safety is improved, the construction period is shortened, and the construction costis reduced.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

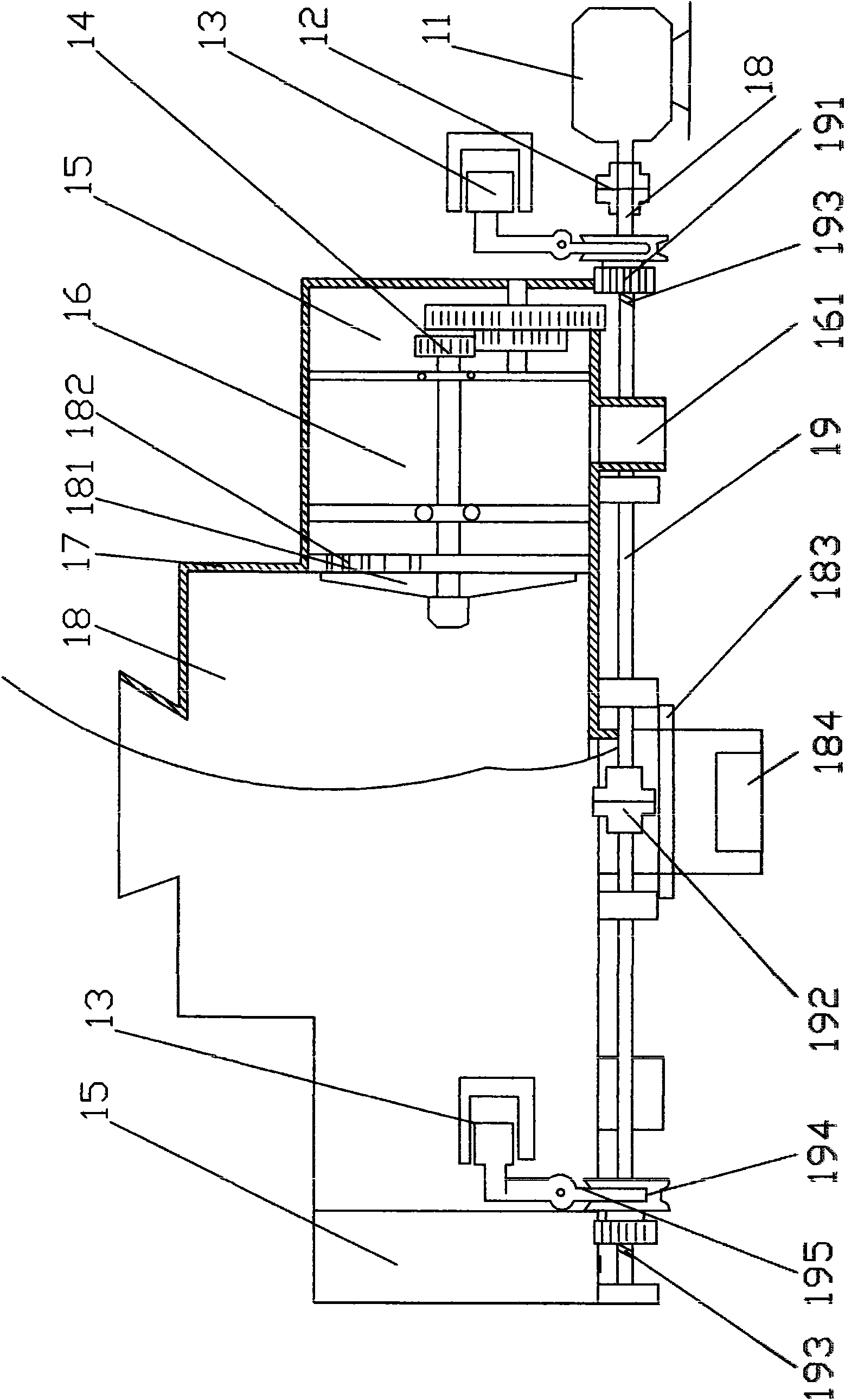

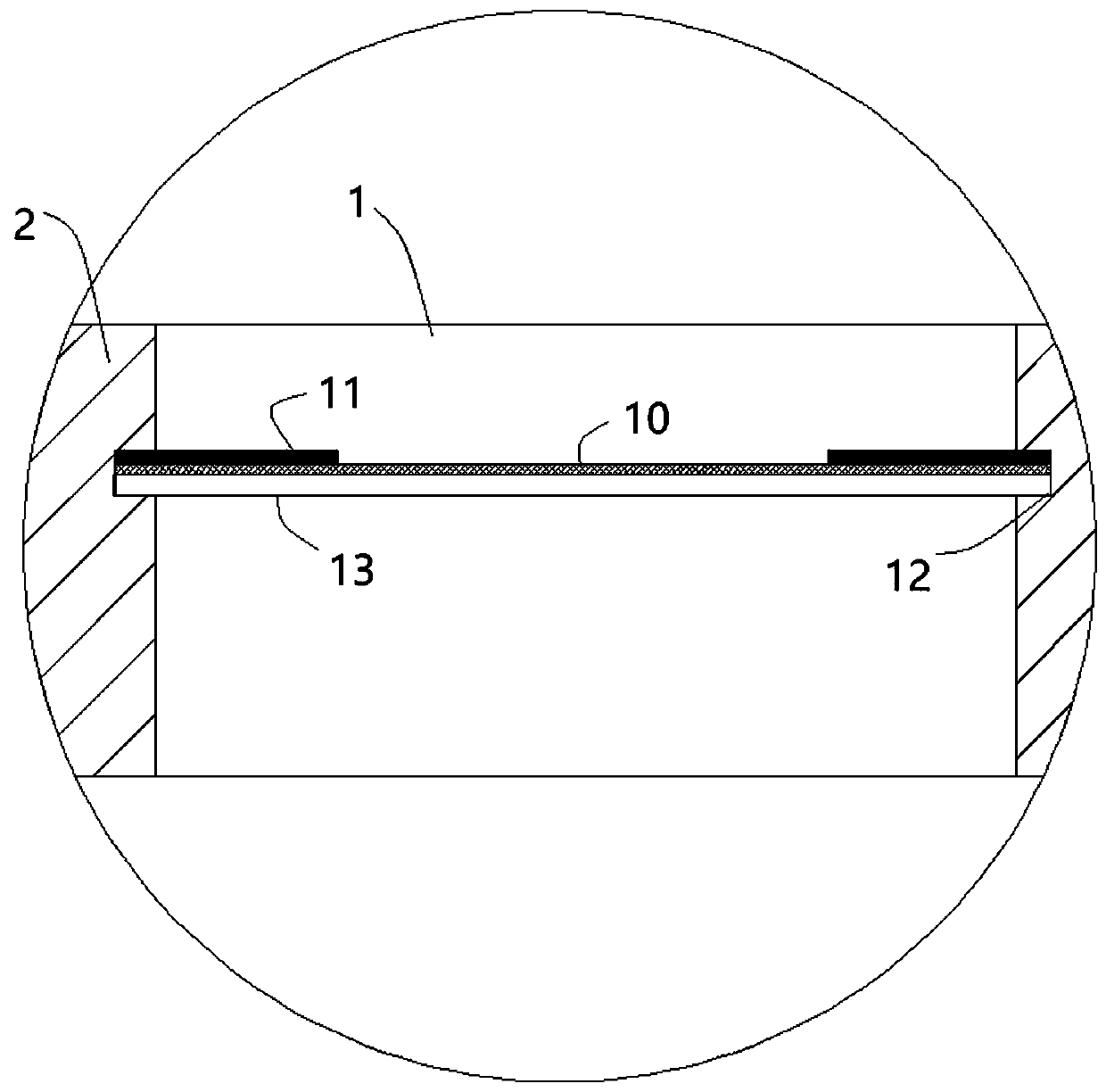

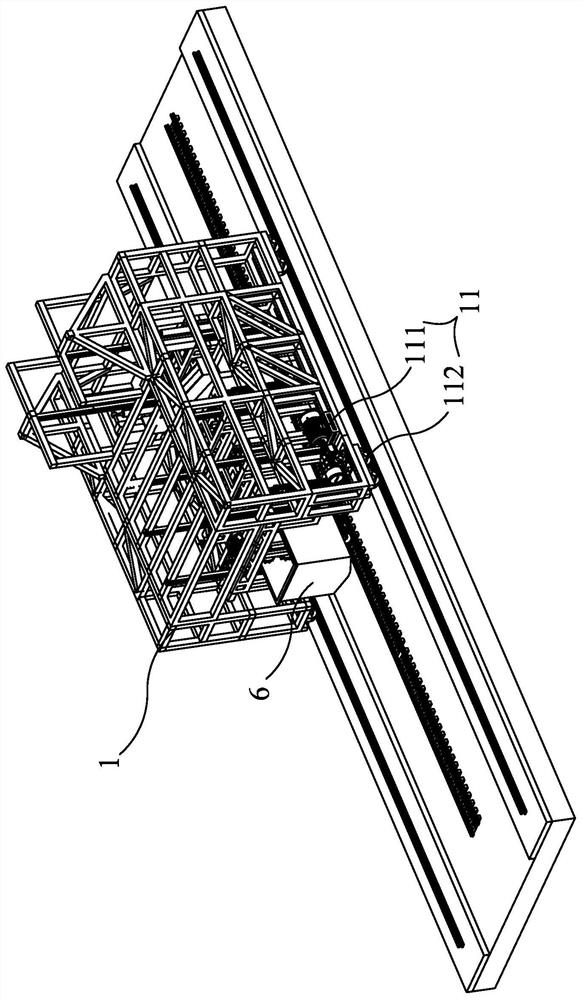

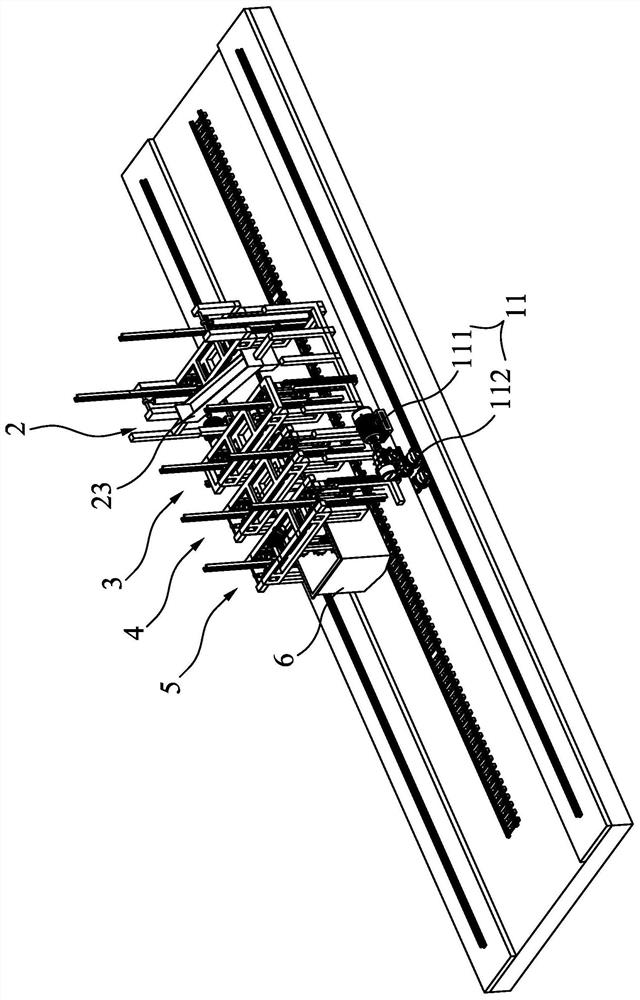

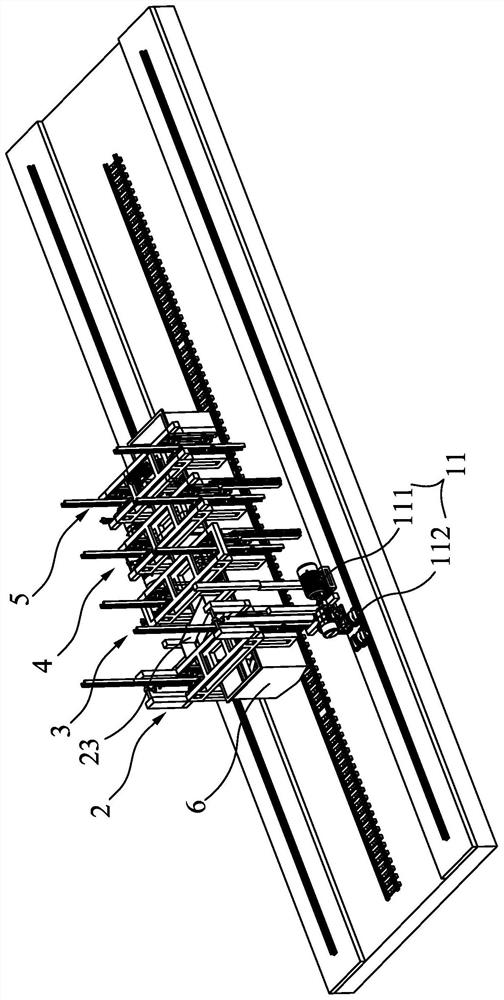

Paper feeding device of numerical control automatic taping machine

ActiveCN107472607AAccurate placementWon't wrinklePackagingArticle feedersNumerical controlPulp and paper industry

The invention discloses a paper feeding device of a numerical control automatic taping machine. The paper feeding device comprises a paper storage mechanism and a paper feeding mechanism, wherein multiple papers are stored in the paper storage mechanism; the paper storage mechanism is arranged bear a workpiece taping station; the paper feeding mechanism is provided with a paper conveying structure for conveying the papers in the paper storage mechanism to preset positions on workpieces and a first driving structure for driving the paper conveying structure to move; in the process of matching the device with the taping machine to wind insulation tapes, the papers in the paper storage mechanism are conveyed onto the workpieces by the paper conveying structure and the first driving structure in the paper feeding mechanism; the papers are wrapped by using the insulation tapes; the device is matched with the taping machine to realize full-automatic production of winding the insulation tapes so as to achieve safety, high speed and precise operation; and the papers can be accurately put in the preset positions, and cannot be crumpled in the winding process of the insulation tapes, so that the working efficiency and the product pass percent are improved.

Owner:温州市桑德拉自动化科技有限公司

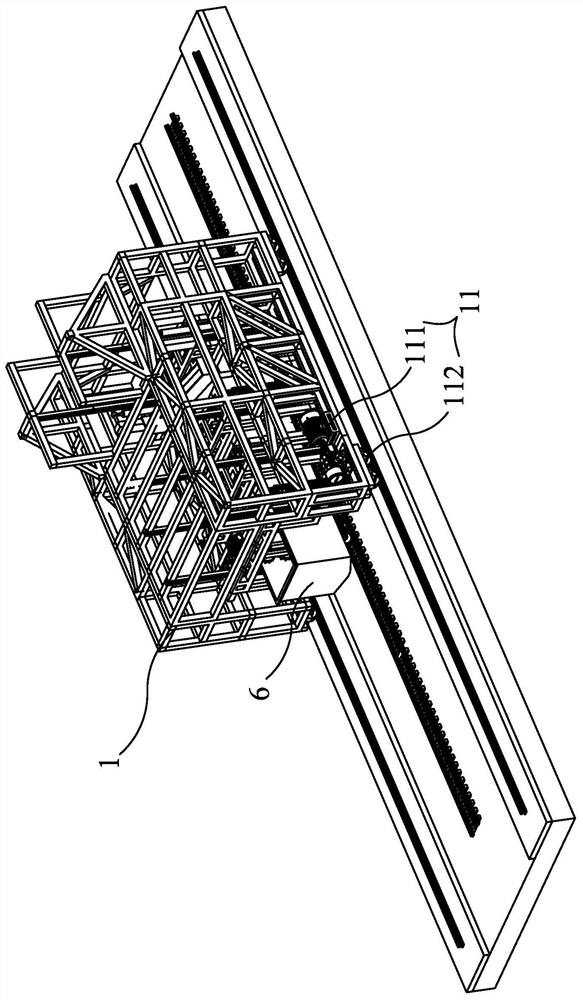

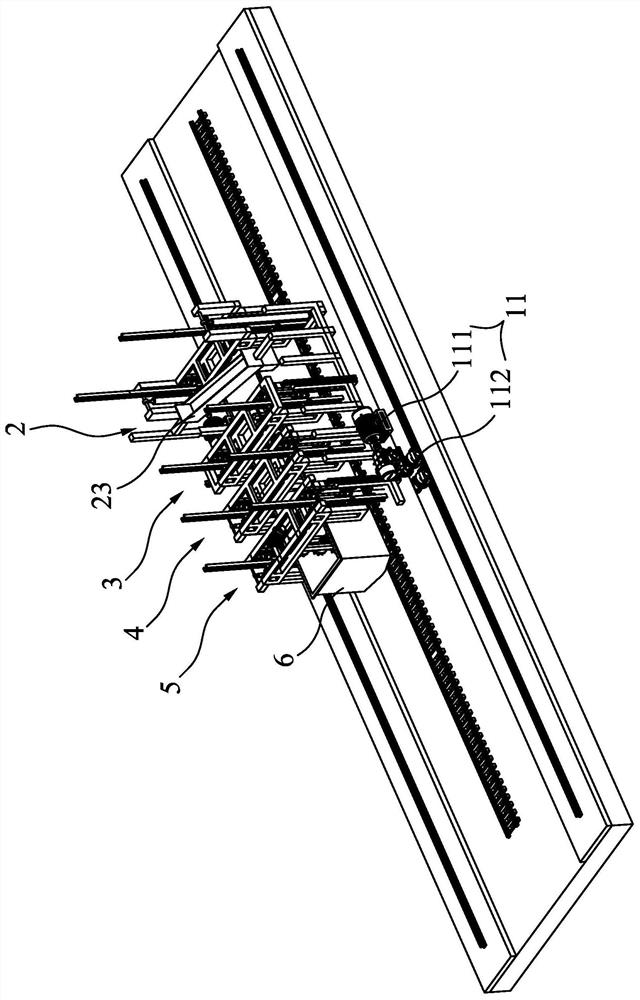

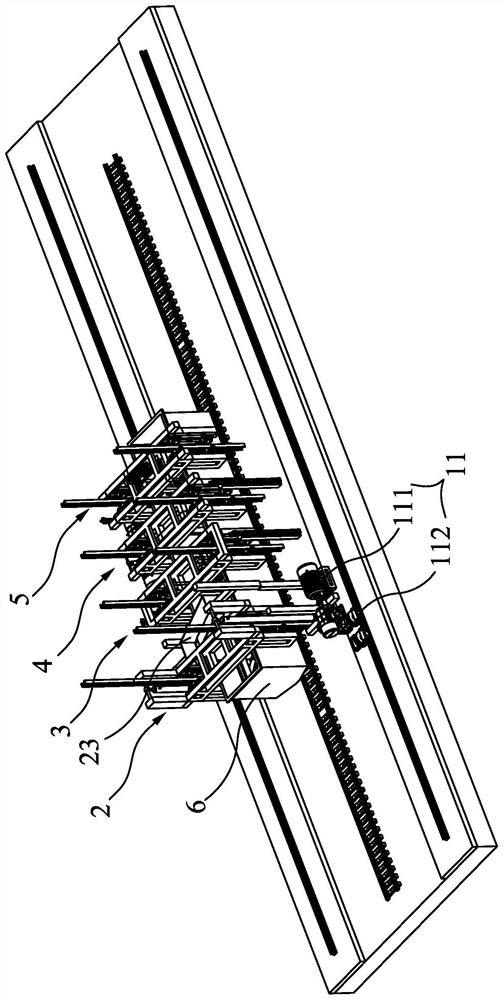

Intelligent sweeper for railway wagon

ActiveCN111715644AImprove cleanlinessImprove cleaning efficiencyHollow article cleaningCleaning apparatus for vehicle interiorsAssembly linePortal frame

The invention discloses an intelligent sweeper for a railway wagon. The intelligent sweeper comprises a portal frame, a material loosening mechanism, a material shoveling mechanism, a cleaning mechanism, a clearing and transporting mechanism and lifting and lowering mechanisms, wherein the portal frame can move front and back relative to the railway wagon; the material loosening mechanism, the material shoveling mechanism, the cleaning mechanism and the clearing and transporting mechanism are arranged in sequence along a direction from the front end and the rear end of the railway wagon and are independently installed on the portal frame through the lifting and lowering mechanisms; the material loosening mechanism can carry out material loosening processing on materials deposited on the bottom of the railway wagon; the material shoveling mechanism pushes materials subjected to material loosening by the material loosening mechanism to the front end of the railway wagon; the cleaning mechanism cleans residual materials generated after the material shoveling mechanism works; and the clearing and transporting mechanism shovels and discharges the materials on the front end position of the railway wagon. The intelligent sweeper is mainly used for the cleaning work of the materials on the bottom of the railway wagon, and finishes cleaning independently through four steps, i.e., material loosening, material shoveling, cleaning as well as clearing and transporting, assembly line type cleaning is used for replacing manpower cleaning, so that cost is greatly saved, and in addition, the intelligent sweeper can carry out comprehensive cleaning.

Owner:ZHONGBEI UNIV

High-fiber sesame balls and preparation method thereof

InactiveCN107372743AGolden colorUniform internal textureDough treatmentDeep-fried productsNutrientRice flour

Owner:BENGBU COLLEGE

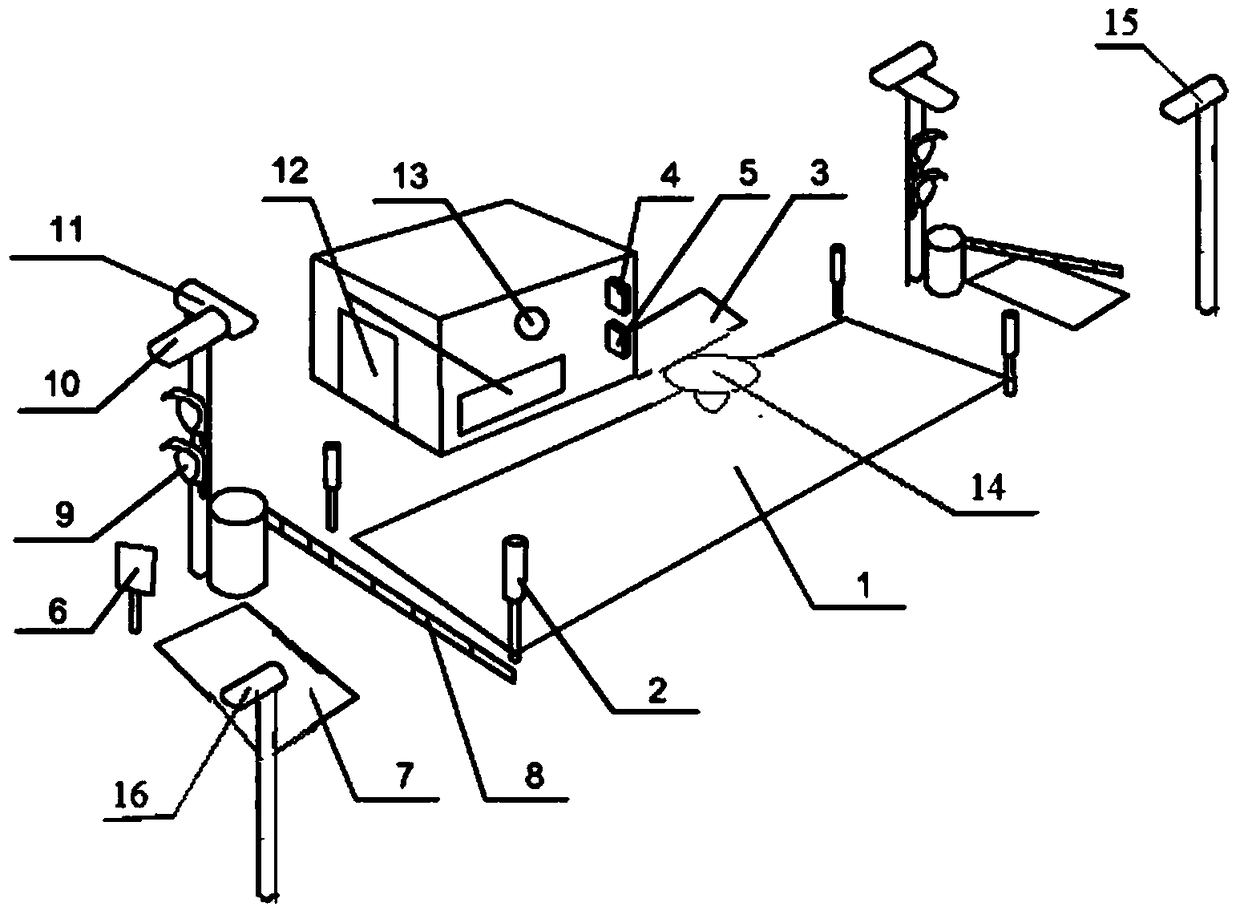

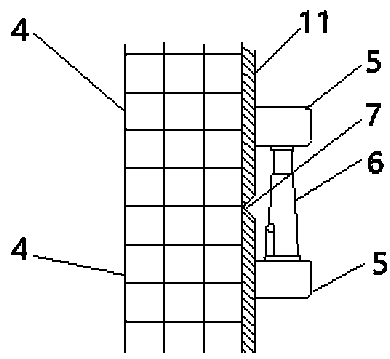

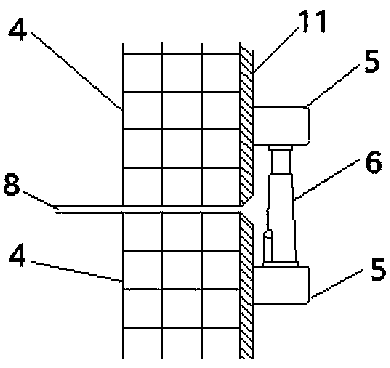

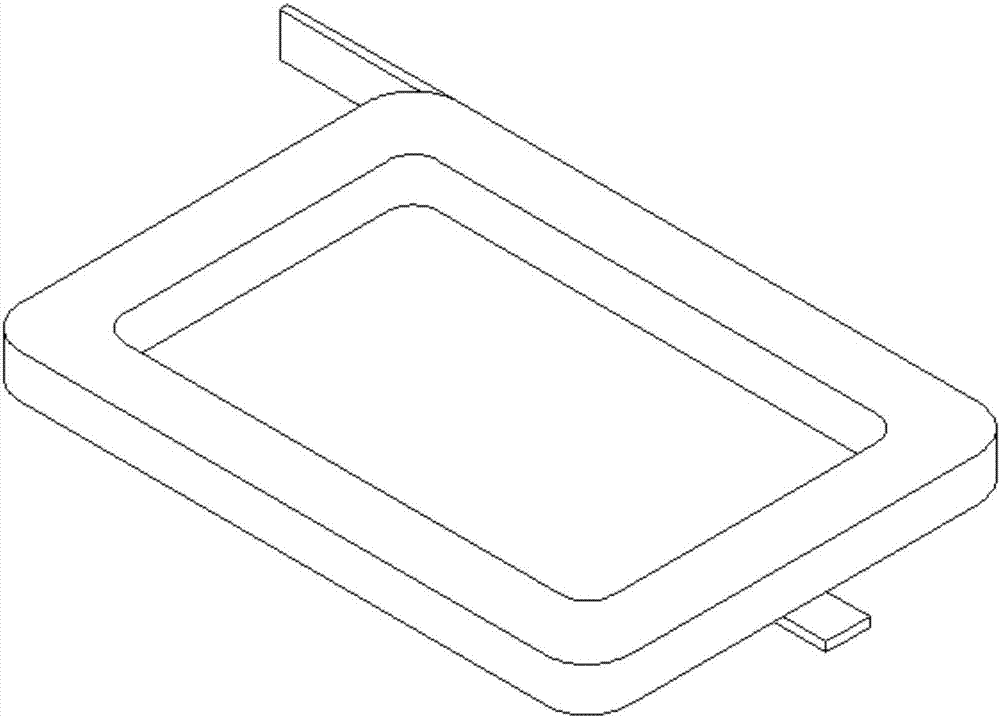

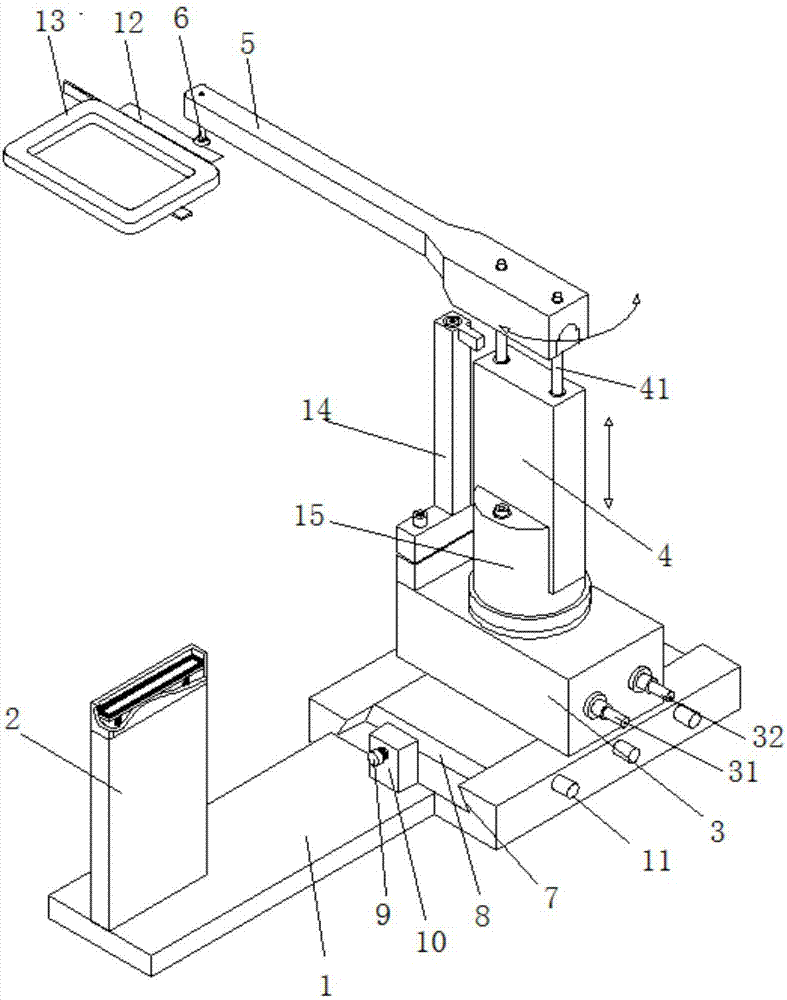

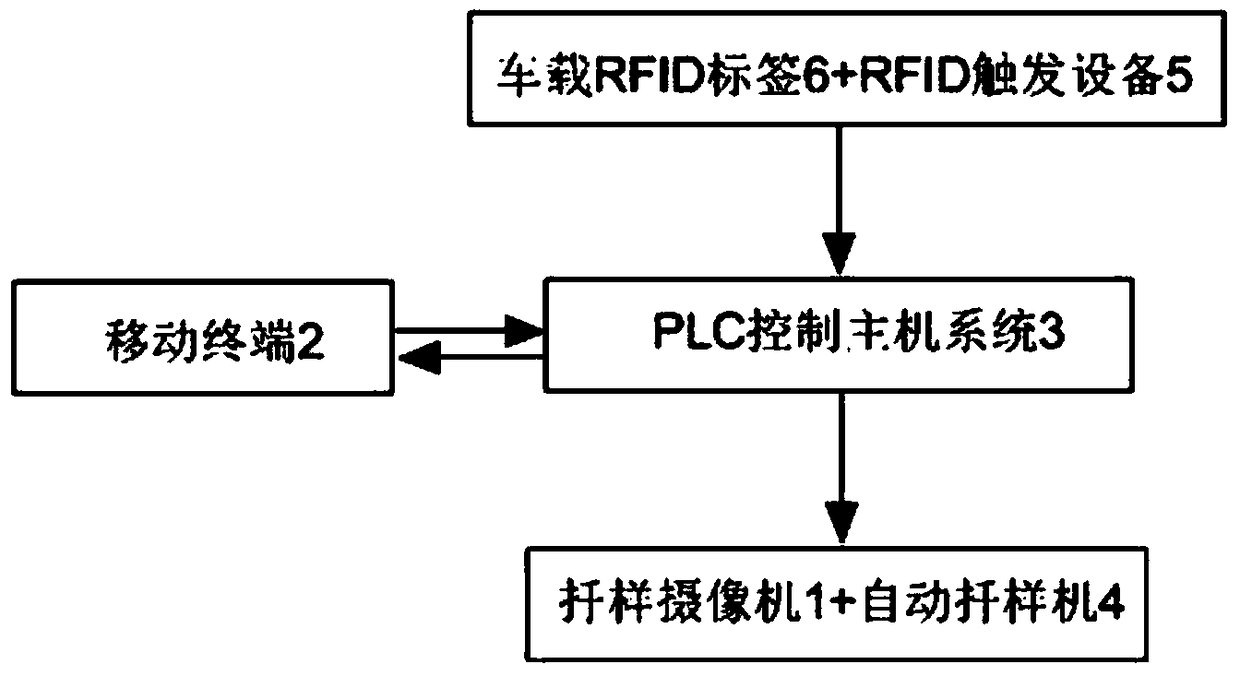

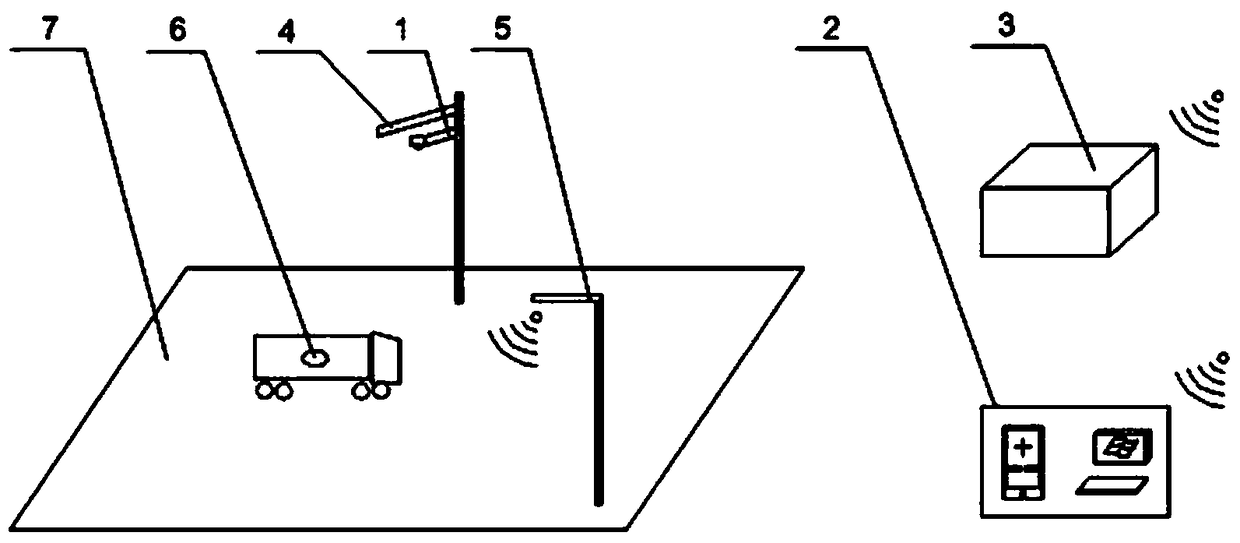

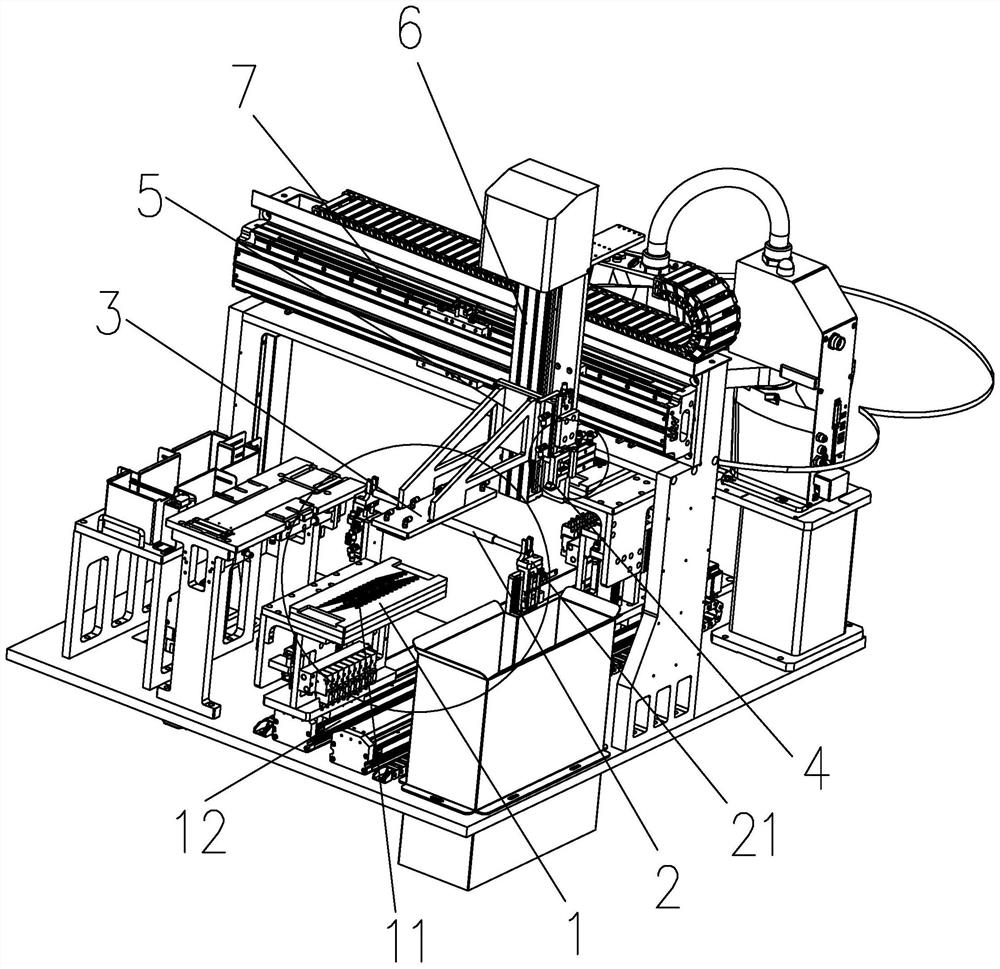

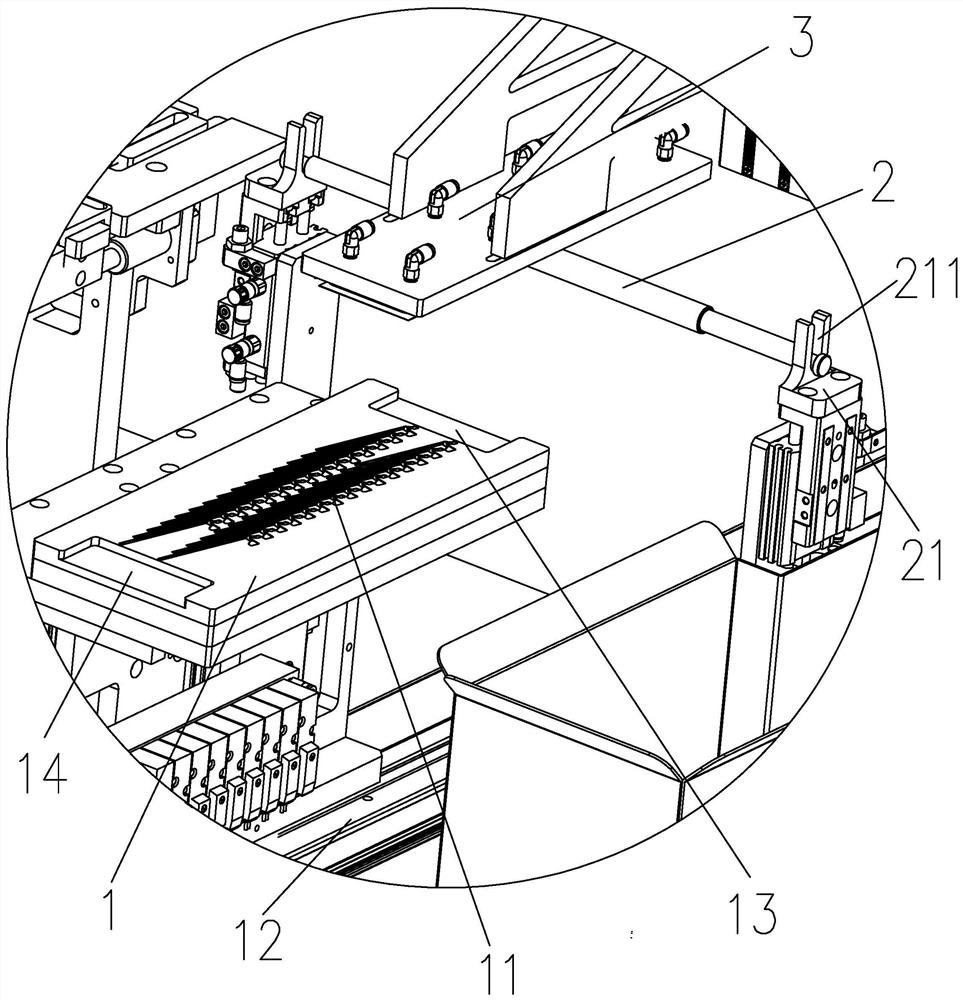

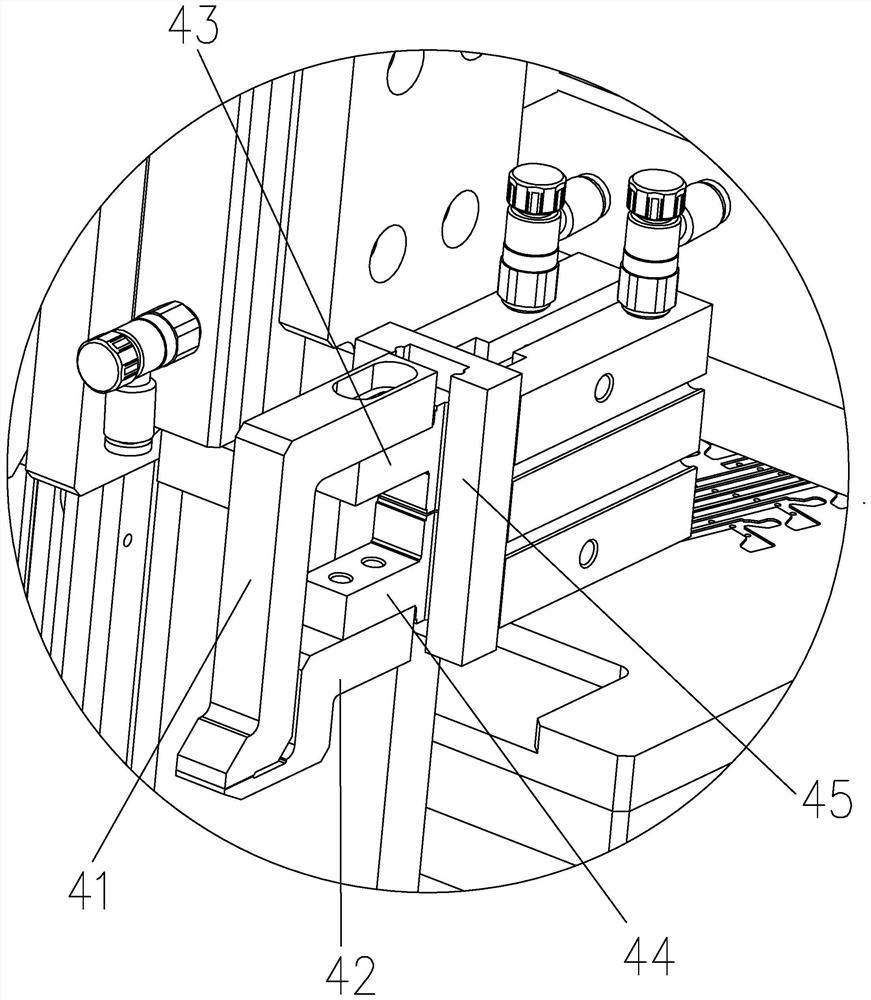

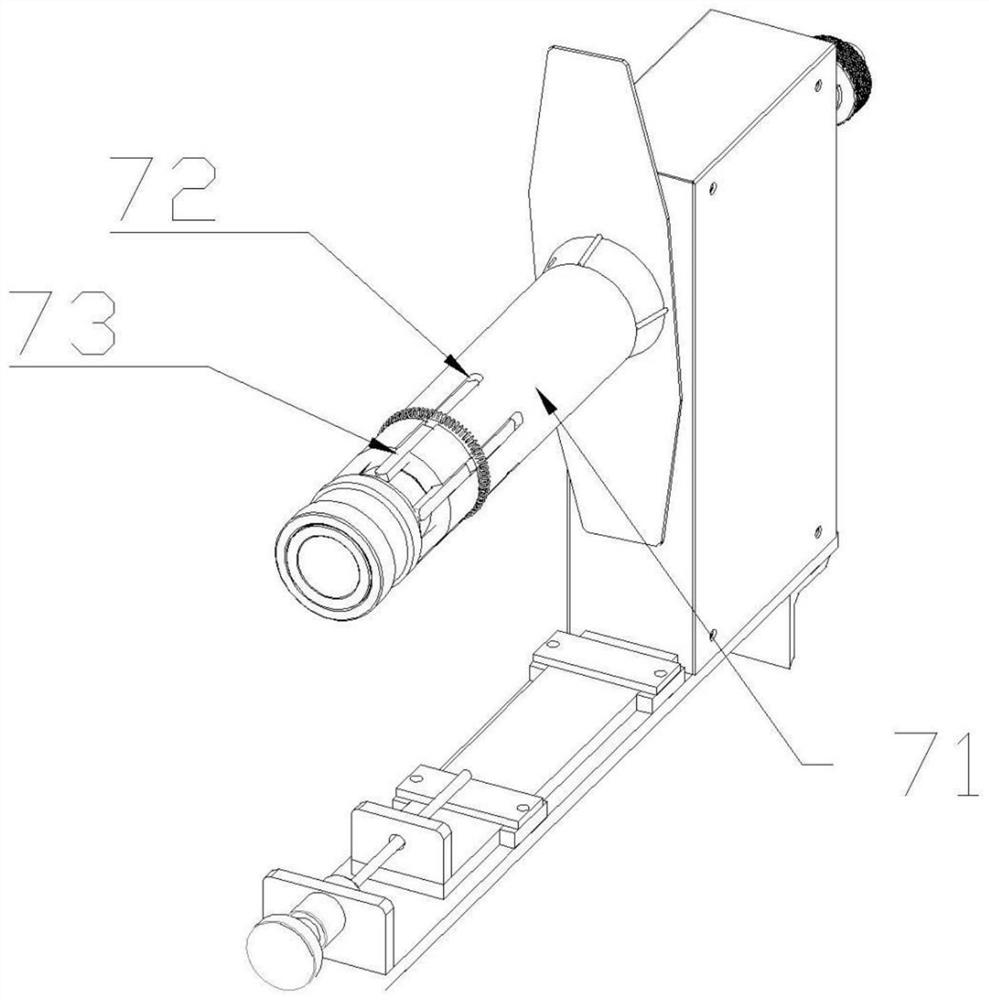

Grain Depot Automatic Sampling System

ActiveCN105158012BExtended service lifeFunction increaseWithdrawing sample devicesClosed circuit television systemsGrain storageComputer terminal

The invention discloses an automatic sampling system for a grain depot, which includes an automatic sampling machine, and further includes: a sampling camera, which records and sends video signals of vehicles in the sampling operation area; a terminal, which communicates with the sampling camera connected, the terminal receives the video signal, manually determines the sampling area, sends an instruction to control the automatic sampling machine to perform a specified sampling action in the sampling area, and the PLC controls the host system, which is connected to the sampling area The camera is connected to the terminal by communication, and the PLC control host system receives the instruction and controls the automatic sampling machine to perform sampling work. The present invention can realize the intelligent operation or remote operation of the automatic cutting machine according to the different models and sizes of the vehicles. The staff can observe the situation of the cutting on the spot, intervene in the cutting process at any time, and paste the serial number sheet representing the attribute of the detection sample. The detection process is the whole process Indoor camera monitoring to ensure absolute security and intelligence.

Owner:HUBEI YE WEI INTELLIGENT TECH

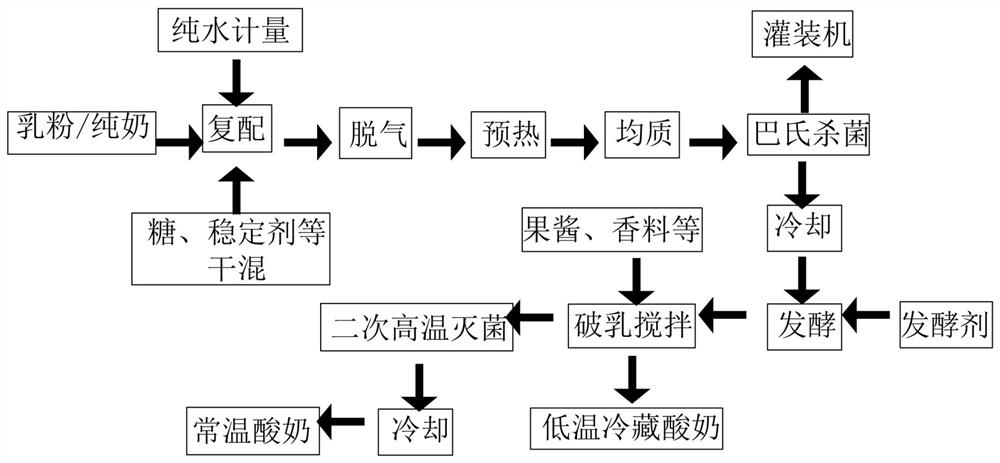

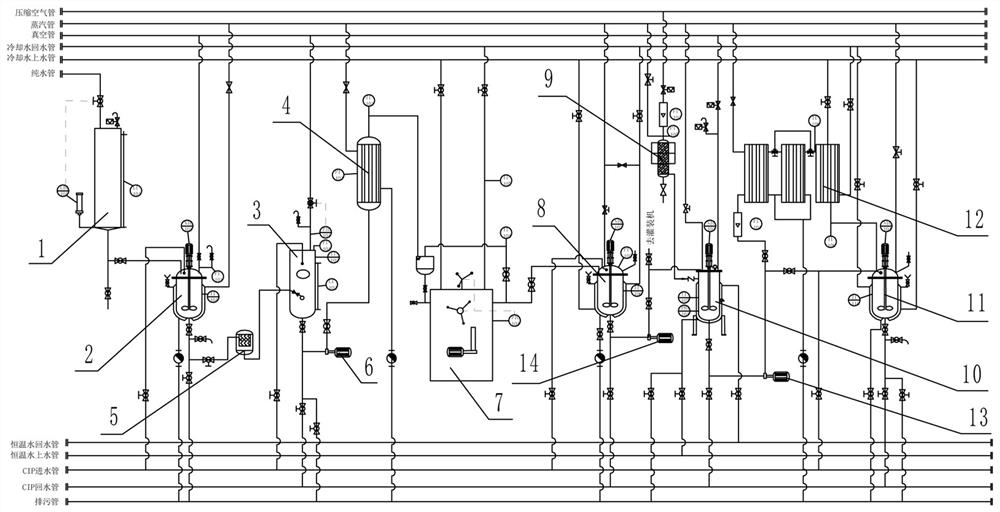

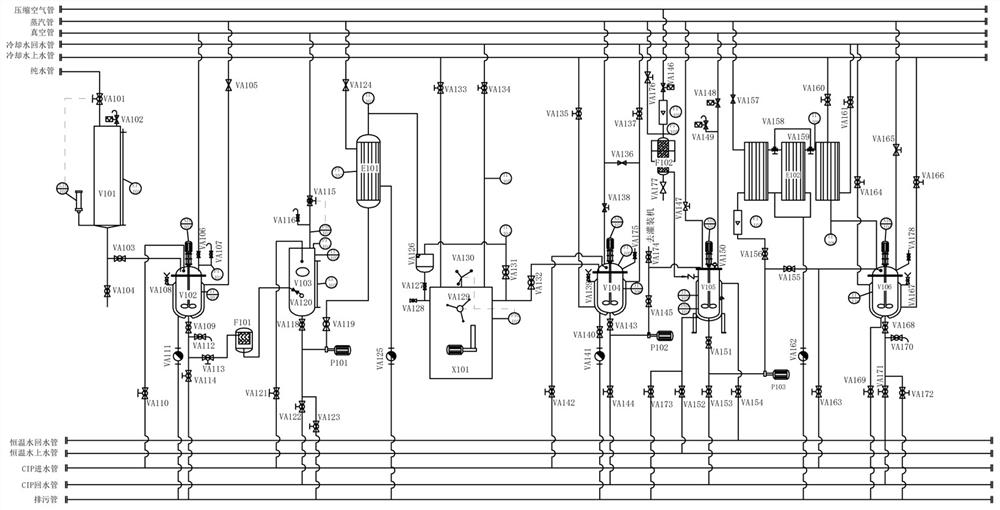

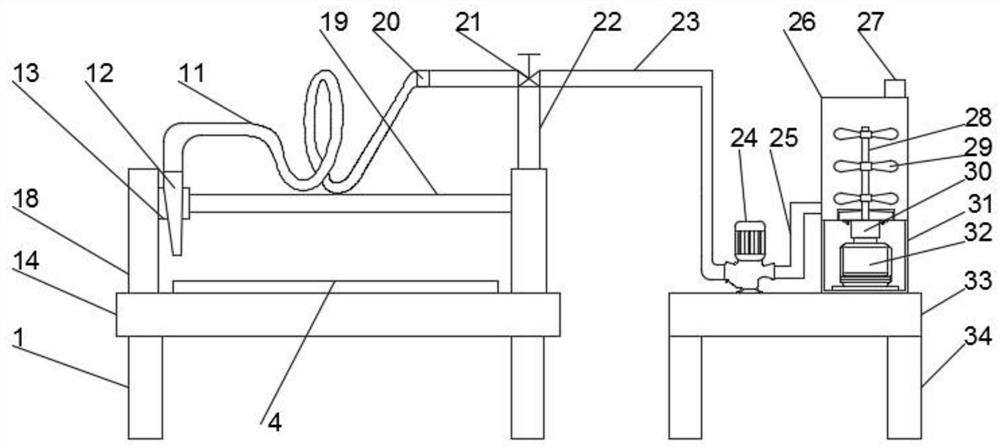

Normal-temperature and low-temperature yoghourt teaching practice device

PendingCN112471255AReduce usageDeepen the awareness of distinctionMilk preparationMilk preservationPlate heat exchangerProcess engineering

The invention provides a normal-temperature and low-temperature yoghourt teaching practice device which comprises a pipe gallery area, a power area and a static equipment area. The bottom of a metering tank in the static equipment area is connected with a feed port of a top cover of the compounding tank, and a discharge port at the bottom of the compounding tank is communicated with a bag filter;the bag filter is connected to a feeding hole in the side wall of the degassing tank, and the degassing tank is connected with the tubular heat exchanger through the first milk guide pump; a dischargeport of the tubular heat exchanger is connected with the homogenizer; a discharging port of the homogenizer is respectively connected to a feeding port of the homogenizer and a feeding port of a topcover of the pasteurization tank; the pasteurization tank is connected to a feeding port of the fermentation tank through a second milk guide pump; the fermentation tank is respectively connected witha feeding port of the product storage tank and the plate heat exchanger through a third milk guide pump; a discharge port of the plate heat exchanger is communicated with a feed port of the product storage tank. The device can be used for carrying out small-scale production and experimental research on normal-temperature yoghourt, low-temperature yoghourt and milk-containing beverages, can effectively solve the problem that college students lack actual operation manipulative ability, and can make the college students contact industrial control knowledge in advance.

Owner:HENAN LABPARK CHEM EQUIP MFG

Construction method of decorative column veneer with special-shaped variable section

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

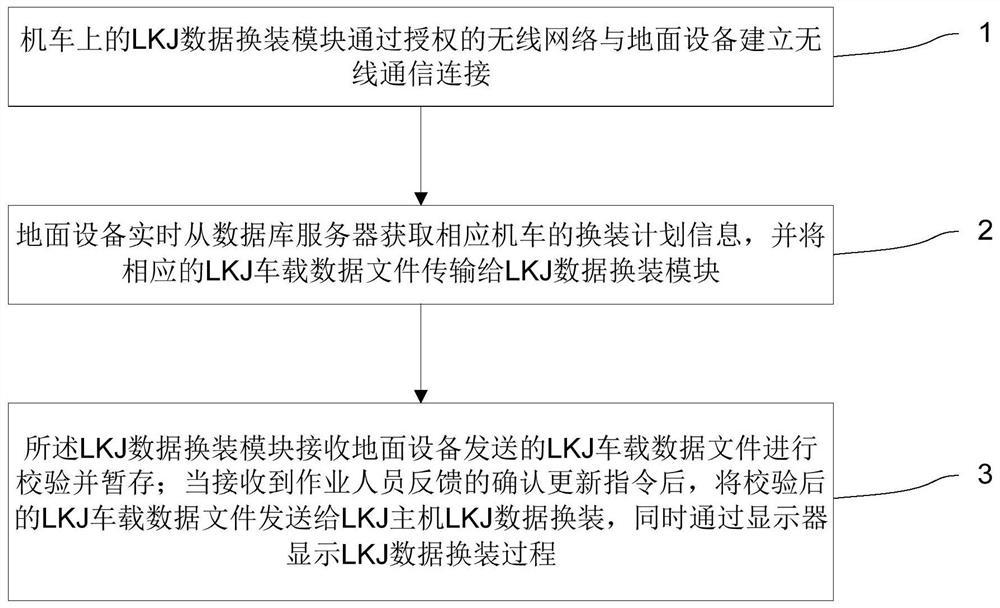

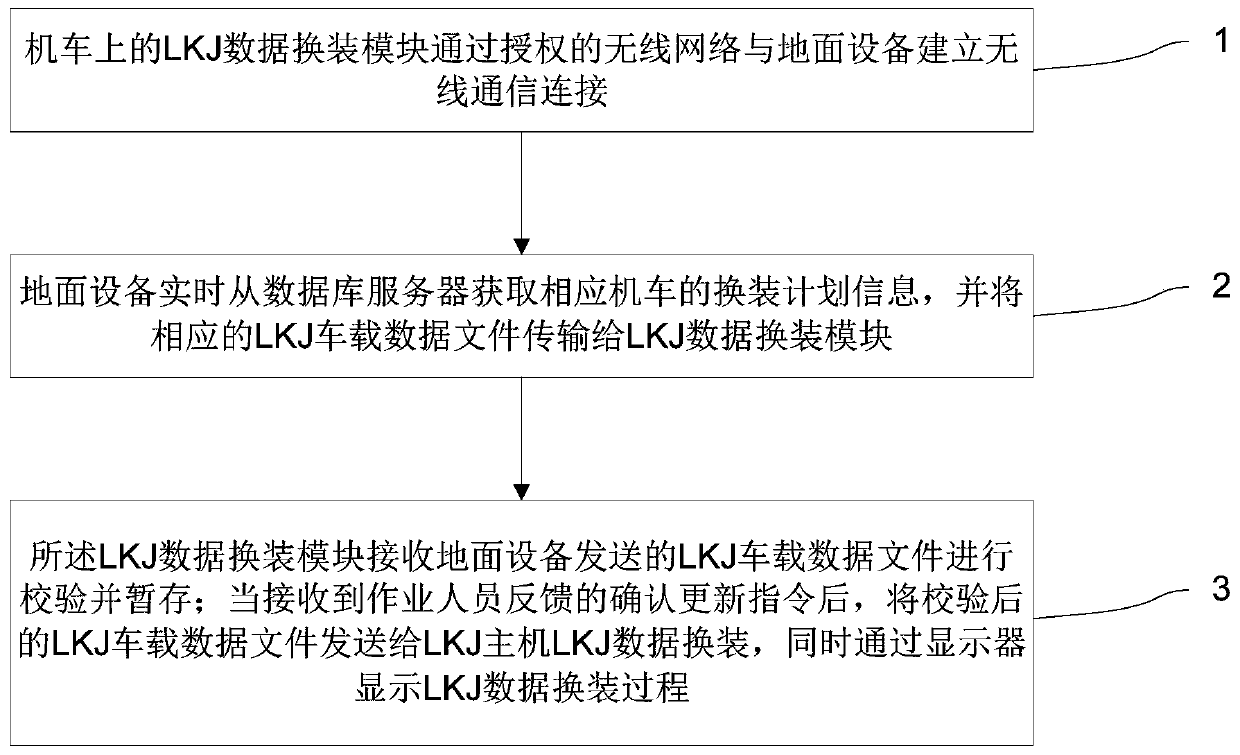

Method for realizing lkj data replacement by adopting information processing technology and wireless communication technology

ActiveCN110022232BReduce workloadReal-time display of changing statusParticular environment based servicesFor mass transport vehiclesData exchangeReal time display

Owner:SIGNAL & COMM RES INST OF CHINA ACAD OF RAILWAY SCI +3

Anti-senility medicine and its preparing method

InactiveCN100409878CSafe to takeNo yin and yang biasAntinoxious agentsPlant ingredientsPharmaceutical drugSpleen

The present invention is a kind of anti-senility Chinese medicine possessing the functions of invigorating kidney, liver and spleen, benefiting qi, promoting blood circulation, dredging meridians, etc. The anti-senility Chinese medicine is prepared with fleece flower root, wolfberry fruit, dodder seed, epimedium, Indian mulberry and other seven kinds of medicine-food material, and through pre-treatment, decocting, filtering, sterilizing and other steps to form honeyed bolus, tablet or capsule. The anti-senility Chinese medicine has obvious anti-senility effect.

Owner:陈昊 +2

Method for realizing LKJ data reloading by adopting informatization technology and wireless communication technology

ActiveCN110022232AReduce misplacementReduce riskParticular environment based servicesFor mass transport vehiclesInformatizationWorkload

The invention discloses a method for realizing LKJ data reloading by adopting an informatization technology and a wireless communication technology, the remote reloading of LKJ data is achieved by adopting the informatization technology and the wireless communication technology, and the reloading state can be displayed in real time, so that the whole reloading process is ordered and controllable;meanwhile, a traditional manual reloading mode is changed, so that the workload of reloading the LKJ basic data of the electric power section is reduced, the labor cost is reduced, the safety risks ofwrong reloading and missing reloading in the data reloading process are reduced, and it can be ensured that the reloading work of the LKJ basic data is completed within the specified time.

Owner:SIGNAL & COMM RES INST OF CHINA ACAD OF RAILWAY SCI +3

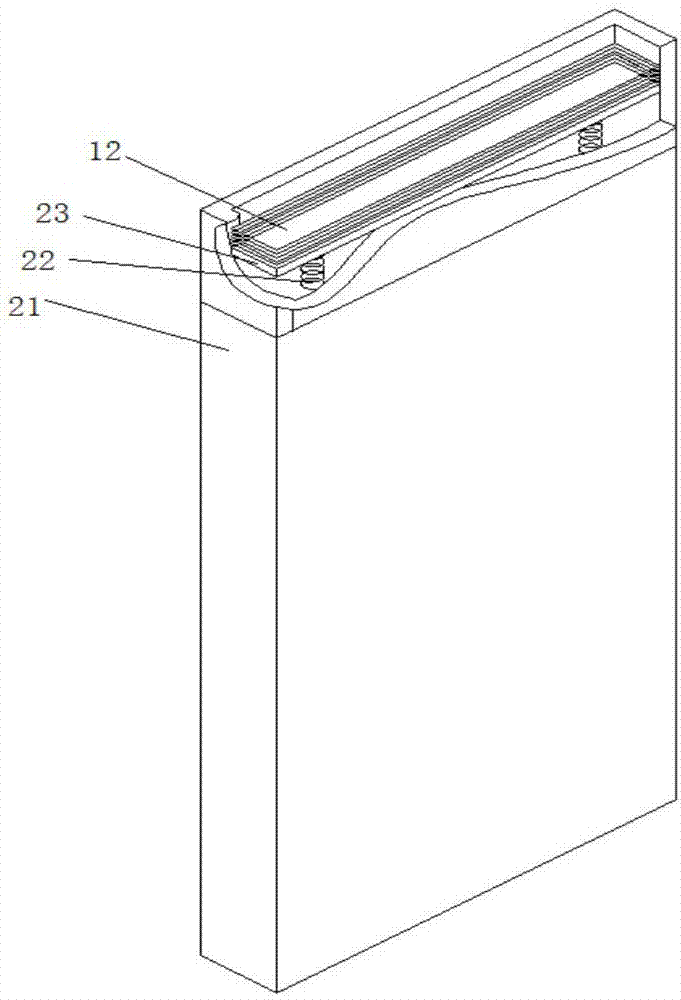

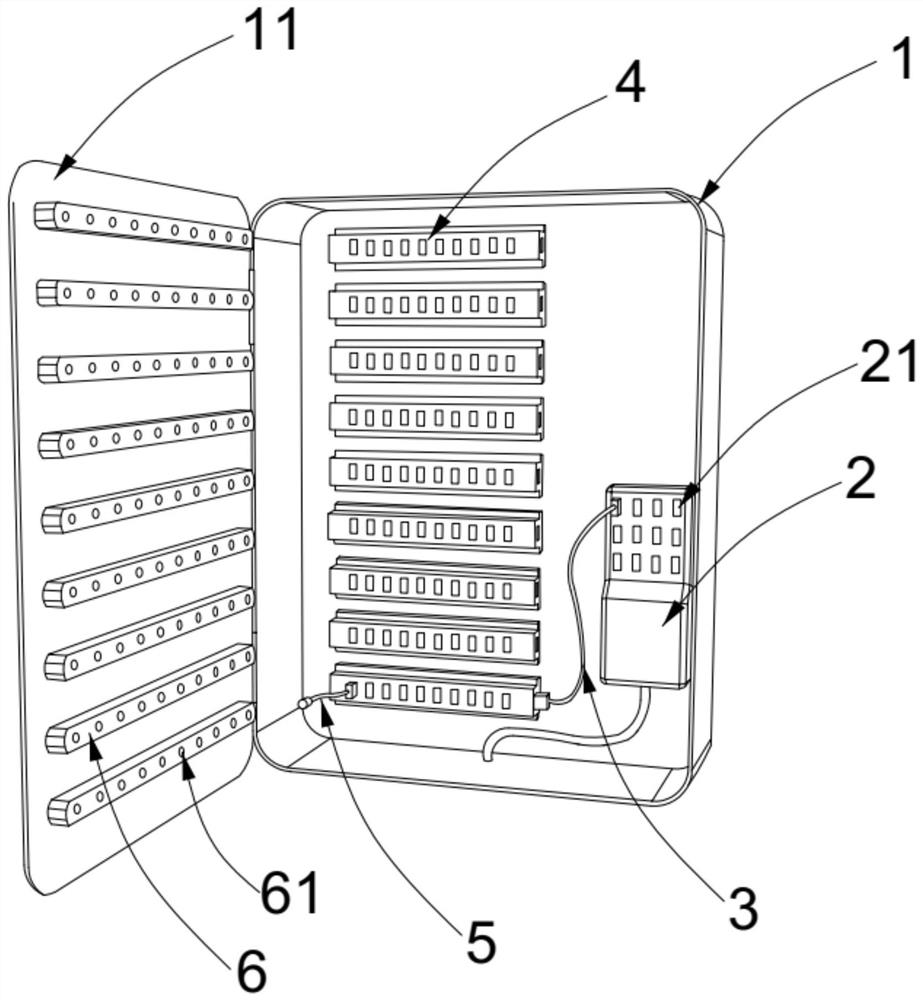

A kind of fpc feeding machine

ActiveCN113301722BImprove feeding efficiencyGuaranteed PrescriptivePrinted circuit manufactureMechanical engineeringManufacturing engineering

The present invention provides a kind of FPC loading machine, comprises stripping platform, Z-axis assembly, roller assembly; Described stripping platform is connected with first moving guide rail, and FPC assembly is placed on described stripping platform, and described roller assembly includes Roller shaft; the Z-axis assembly includes a suction cup assembly and a stripping jaw; the stripping platform is provided with an adsorption device for absorbing the FPC assembly placed on the stripping platform; during work, the roller shaft is set On the peeling platform and press one end of the film on the FPC assembly, the peeling jaw clamps the part of the film that is not provided with the FPC assembly; the peeling platform is on the first moving guide rail The upward movement causes the film to be taken away from the FPC assembly by the peeling jaws with the movement of the peeling platform and under the pressure of the roller shaft. The application of this technical solution can improve the standardization of the FPC tear film, and improve the production efficiency and yield of the product.

Owner:厦门普诚科技有限公司

Porous magnetic attraction charging device

PendingCN113972723AExtended service lifeReduce charging costsEngagement/disengagement of coupling partsElectric powerTransformerEngineering

Owner:海南世电科技有限公司

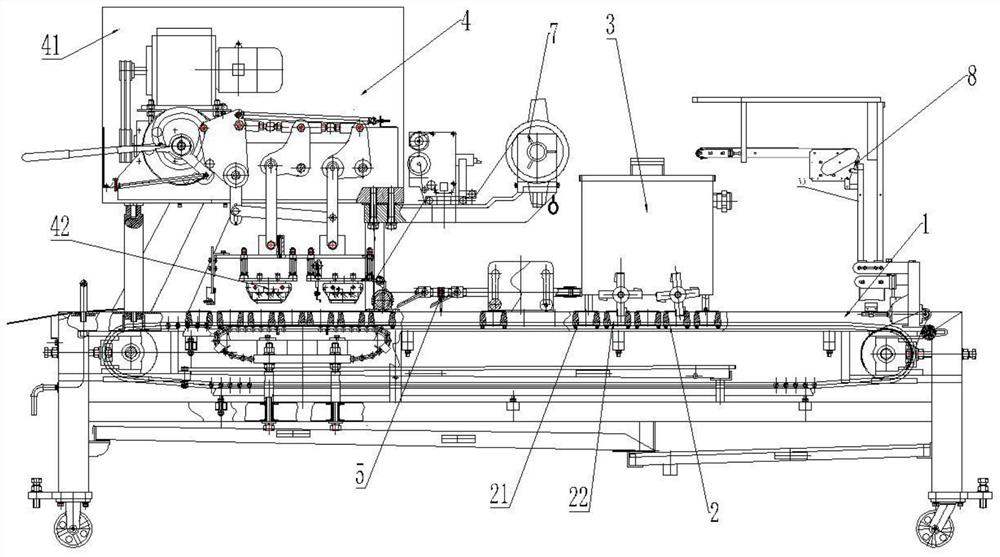

Seven-type plastic box packaging sealing machine

InactiveCN112249435AReduce labor lossIncrease productivityWrapper twisting/gatheringLiquid materialProcess engineeringMechanical engineering

The invention discloses a seven-type plastic box packaging sealing machine. According to the seven-type plastic box packaging sealing machine, integration of the steps of material conveying, equivalent feeding, sealing, defoaming and the like is achieved, the labor loss is greatly reduced, and the production efficiency is improved. According to the seven-type plastic box packaging sealing machine,through the arrangement of a multi-hole discharging device of a feed mechanism, equivalent feeding can be achieved on the feeding mechanism without adding an electric valve, and therefore adding of an operating system can be omitted, and the device cost is greatly reduced.

Owner:SHANGHAI WANGXIN BEAN PRODS EQUIP

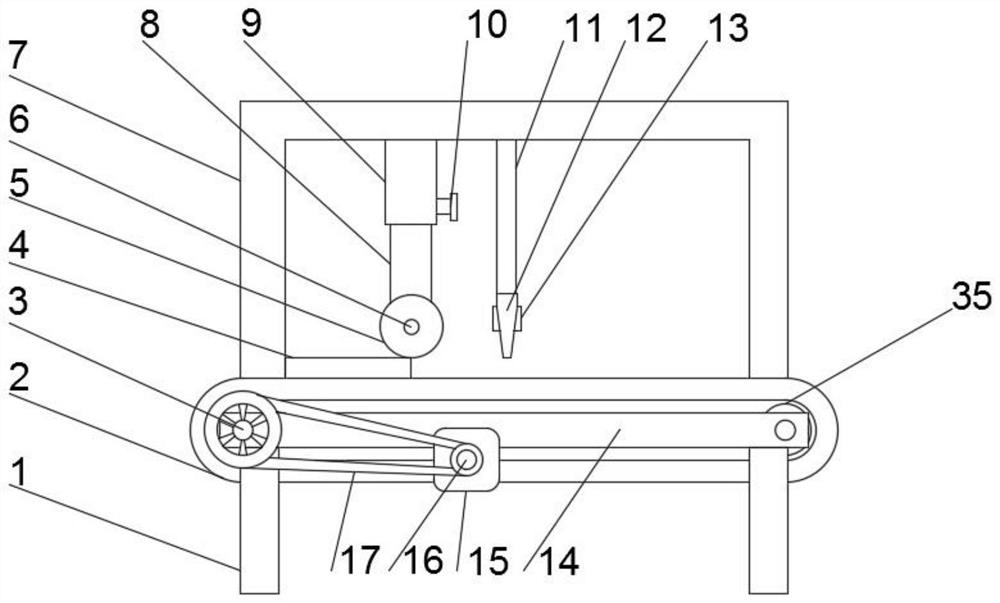

High-efficiency and high-quality embossing and spraying device for aluminum gusset plate, and using method

PendingCN111940166AAvoid liftingEasy to operateLiquid spraying apparatusGusset plateTransmission belt

The invention discloses an high-efficiency and high-quality embossing and spraying device for an aluminum gusset plate, and belongs to the technical field of aluminum gusset plate production. The embossing and spraying device comprises a conveyor belt, and roll shafts are arranged on the two inner sides of the conveyor belt; and connecting plates penetrate through the front ends of the roll shafts, and two groups of connecting plates are provided; belt pulleys a are arranged at the front ends of the roll shafts. Support columns a are installed on the right and left sides of the bottoms of theconnecting plates, and a motor a is fixedly connected with the surfaces of the connecting plates; a belt wheel b is installed at the front end of the motor a, and a belt pulley b is installed at the front end of the motor a; a belt is installed between the surface of the belt pulley a and the surface of the belt pulley b, and a frame is fixedly connected with the top ends of the connecting plates;and an aluminum gusset plate is arranged on the surface of the conveyor belt. The inner side wall of the frame is fixedly connected with a pair rod. The embossing and spraying device has a stirring function, and paint can be stirred and then coated by spray; stirring with other devices is not required before spray coating, and meanwhile embossing is conducted on a rolling wheel under the conveying effect of the conveyor belt; and in this way, the overall operation is easy, and the whole process is orderly and effective.

Owner:嘉兴市爱玛电器有限公司

Railway wagon intelligent cleaning machine

ActiveCN111715644BImprove cleanlinessImprove cleaning efficiencyHollow article cleaningCleaning apparatus for vehicle interiorsMachineShovel

The invention discloses an intelligent cleaning machine for railway wagons, which includes a gantry that can move back and forth relative to the railway wagon, a loosening mechanism, a shoveling mechanism, a cleaning mechanism, a cleaning mechanism and a lifting mechanism, the loosening mechanism, the shoveling mechanism, and the cleaning mechanism 1. The clearing mechanism is arranged in sequence along the direction from the front end to the rear end of the railway wagon, and is respectively installed on the gantry through the lifting mechanism. The loosening mechanism can loosen the deposited material at the bottom of the railway wagon, and the shovel The material mechanism pushes the material loosened by the loosening mechanism to the front end of the railway wagon, the cleaning mechanism cleans the remaining material after the shoveling mechanism works, and the cleaning mechanism scoops up and discharges the material at the front end of the railway wagon. The invention is mainly used for cleaning the bottom materials of railway wagons. The cleaning is completed through four steps of loosening, shoveling, cleaning and cleaning, and the cleaning is completed by assembly line cleaning instead of manual cleaning, which greatly saves costs and is cleaner. ,More comprehensive.

Owner:ZHONGBEI UNIV

Household garbage collecting device convenient to seal

PendingCN113387080AGood sealingLifting way is stableRefuse receptaclesStructural engineeringMechanical engineering

The invention discloses a household garbage collecting device convenient to seal. The device comprises a garbage collecting box and a lifting assembly; a sealing plate is connected to the top of the garbage collecting box in a sliding and penetrating mode, and a pressing assembly is arranged on one side of the bottom end of the sealing plate; the pressing assembly comprises bearing plates, the two bearing plates are horizontally and symmetrically arranged on one side of the bottom end of the sealing plate, and an extrusion roller is arranged between the two bearing plates; and the lifting assembly is arranged at the bottom of the garbage collecting box and comprises a bearing box, a power control assembly is arranged in the bearing box, a connecting cover is arranged at the top end of the bearing box, and supporting mechanisms are fixedly connected to the two sides of the top end of the connecting cover. The device has the beneficial effects that according to the garbage collecting device, through the design of the top of the garbage collecting box and the design of the structure of the sealing plate, the sealing plate can easily seal the garbage collecting box; and the sealing plate is provided with the extrusion assembly, so that operation of the sealing plate can be smooth.

Owner:唐纪会

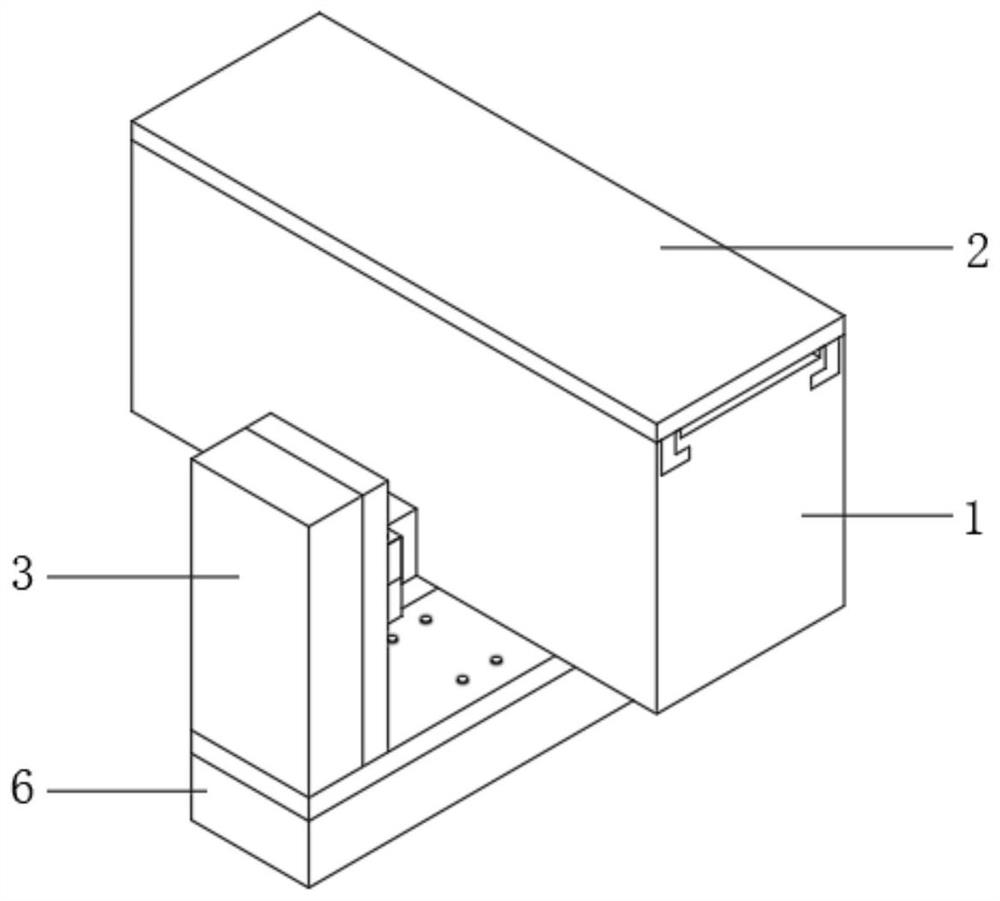

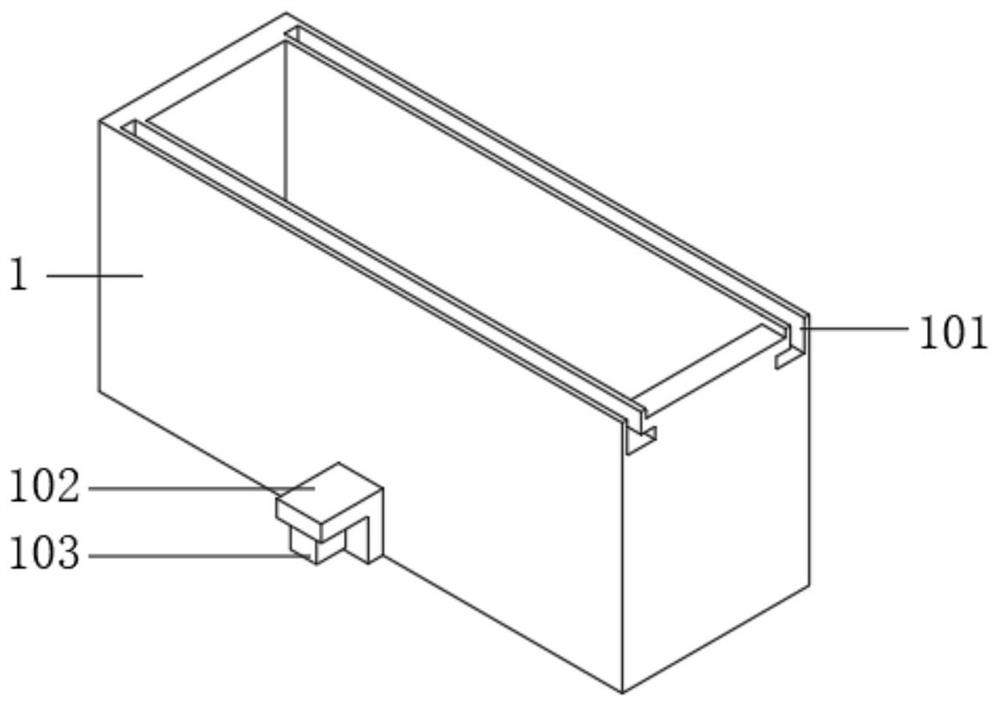

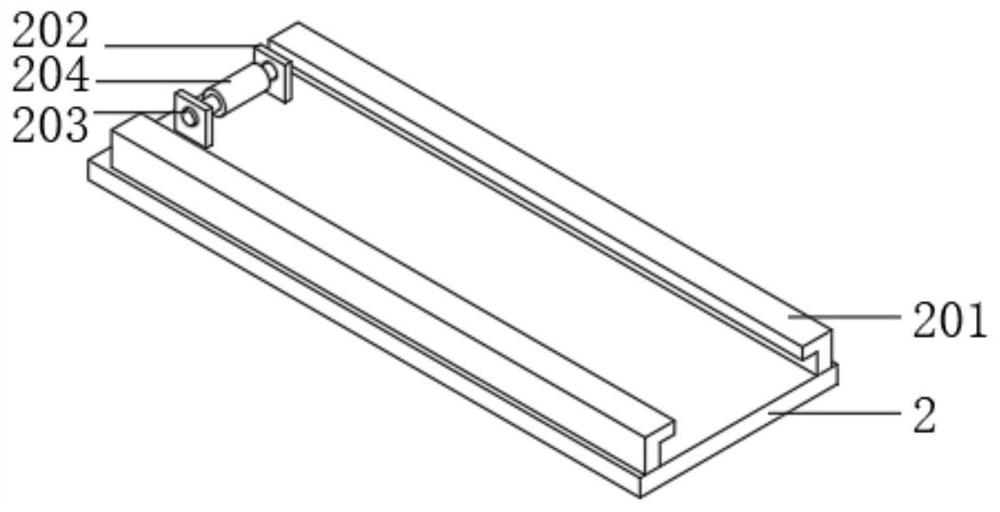

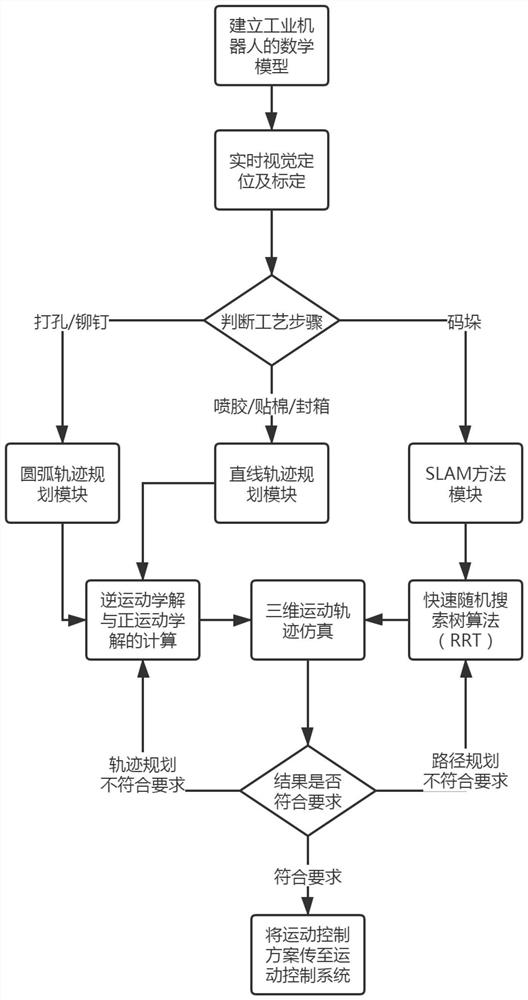

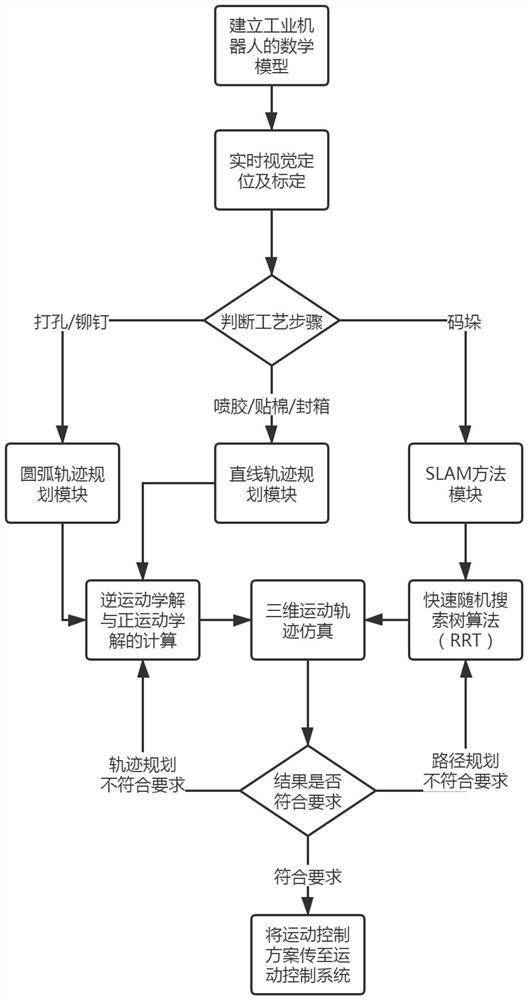

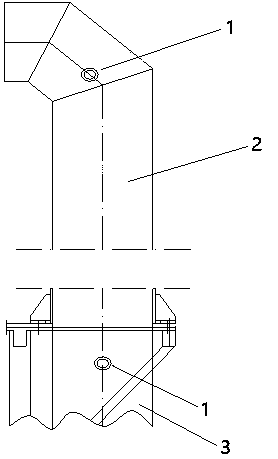

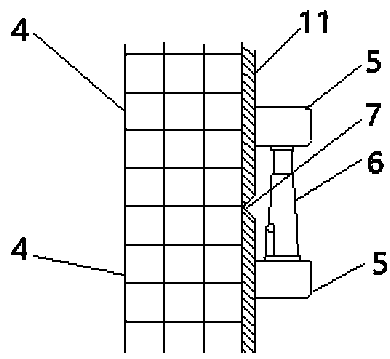

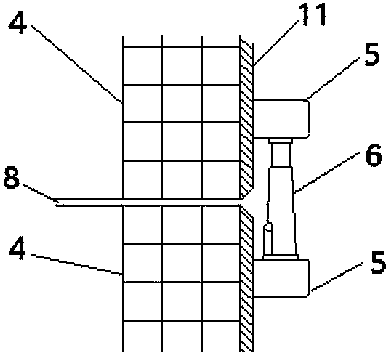

Motion control method for office swivel chair production

ActiveCN113119123AComplete and accurate process operationImprove the level of intelligent motion controlProgramme-controlled manipulatorTotal factory controlMathematical modelPalletizer

The invention provides a motion control method for office swivel chair production. The method specifically comprises the following steps: determining the torsion angle, distance, length and angle range of each joint of an industrial robot according to a D-H parameter determination rule, and establishing a mathematical model of the industrial robot; carrying out on-line positioning of a punching position, a connecting point position, a glue spraying area and a cotton pasting area according to a calibration parameter matrix; in an acquisition process step, if in a swivel chair wood board punching and riveting process, a swivel chair armrest connecting piece locking process, a swivel chair wood board glue spraying and cotton pasting process and a swivel chair finished product box sealing process, solving a track path and joint information of a tail end mechanical arm of the industrial robot; if in a swivel chair finished product stacking process, determining a motion path of a stacking robot; and verifying whether the track path and the motion path meet requirements or not. The method provided by the invention is favorable for completing accurate control of automatic production of office swivel chairs, and various technological processes of automatic production of the office swivel chairs are efficiently and orderly completed.

Owner:XIAMEN UNIV

A motion control method for the production of office swivel chairs

ActiveCN113119123BComplete and accurate process operationImprove the level of intelligent motion controlProgramme-controlled manipulatorTotal factory controlRobotic armPalletizer

Owner:XIAMEN UNIV

A construction method for dismantling pipelines with heat-insulating and wear-resistant linings

ActiveCN108049655BReduce labor intensityReduce construction costsBuilding repairsArchitectural engineeringStructural engineering

Owner:CHINA NAT CHEM ENG THIRD CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com