Demolishing construction method for pipeline with thermal-insulating and abrasion-resistant lining

A technology of heat-insulating and wear-resistant lining and construction method, which can be applied in building maintenance, construction, building construction and other directions, can solve the problems of high construction cost, long construction period, high labor intensity, etc., so as to reduce construction cost and shorten construction period. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

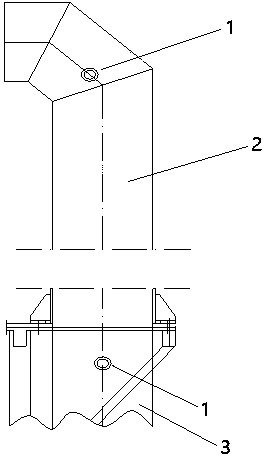

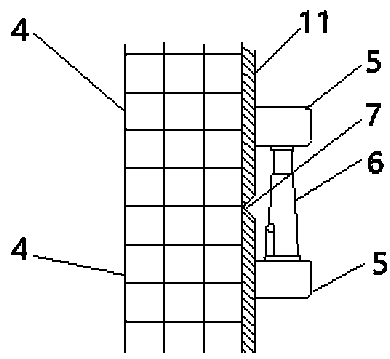

[0044] Figure 1 to Figure 6 It is the schematic diagram of the construction method of this implementation. The pipelines removed in this example are high-altitude vertical pipelines 2 and low-altitude vertical pipelines 3. There are refractory brick linings 4 in the high-altitude vertical pipelines 2 and low-altitude vertical pipelines 3. The nominal diameter of the pipeline is 2400mm. The total height of the pipeline is 40 meters, the specific steps are as follows,

[0045] (1) Removal of high-altitude vertical pipeline 2:

[0046] Construction workers work on the cage platform,

[0047] a. If figure 1 As shown, install lugs 1 on the high-altitude vertical pipeline 2 and the low-altitude vertical pipeline 3;

[0048] b. If figure 2 As shown, 2 pairs of stoppers 5 are installed on both sides of the section 7 to be cut on the high-altitude vertical pipeline 2, and 2 pairs of stoppers are distributed at the two ends of the diameter of the high-altitude vertical pipeline 2,...

Embodiment 2

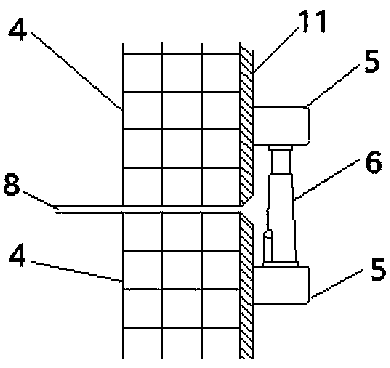

[0059] Figure 7 to Figure 8 It is a schematic diagram of the construction method implemented in this example. The pipeline to be demolished in this example is a high-altitude horizontal pipeline with a refractory brick lining 4 inside the pipeline. The nominal diameter of the pipeline is 800mm, and the total length of the pipeline is 300 meters. The demolition is divided into 8 to 10 sections ,Specific steps are as follows,

[0060] Construction workers work on the cage platform,

[0061] a. Install lifting lug 1 on the high-altitude horizontal pipeline;

[0062] b. Install 2 pairs of stoppers 5 on both sides of the section 7 to be cut on the high-altitude horizontal pipeline, 2 pairs of stoppers are distributed at both ends of the diameter of the high-altitude horizontal pipeline, and a jack 6 is installed between each pair of stoppers 5;

[0063] c. Pre-cut the high-altitude horizontal pipeline 13 along the circumference of the section 7 to be cut, and the pre-cut depth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Nominal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com