Well drilling method for using dry ice drilling fluid to assist in rock breaking

A drilling fluid and dry ice technology, applied in drilling equipment and methods, drilling equipment, wellbore/well parts, etc., can solve the problems of poor high temperature resistance of drilling fluid, high drilling construction cost, and poor drillability of rock formations. The effect of improving rock breaking efficiency, increasing drilling speed and reducing drilling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

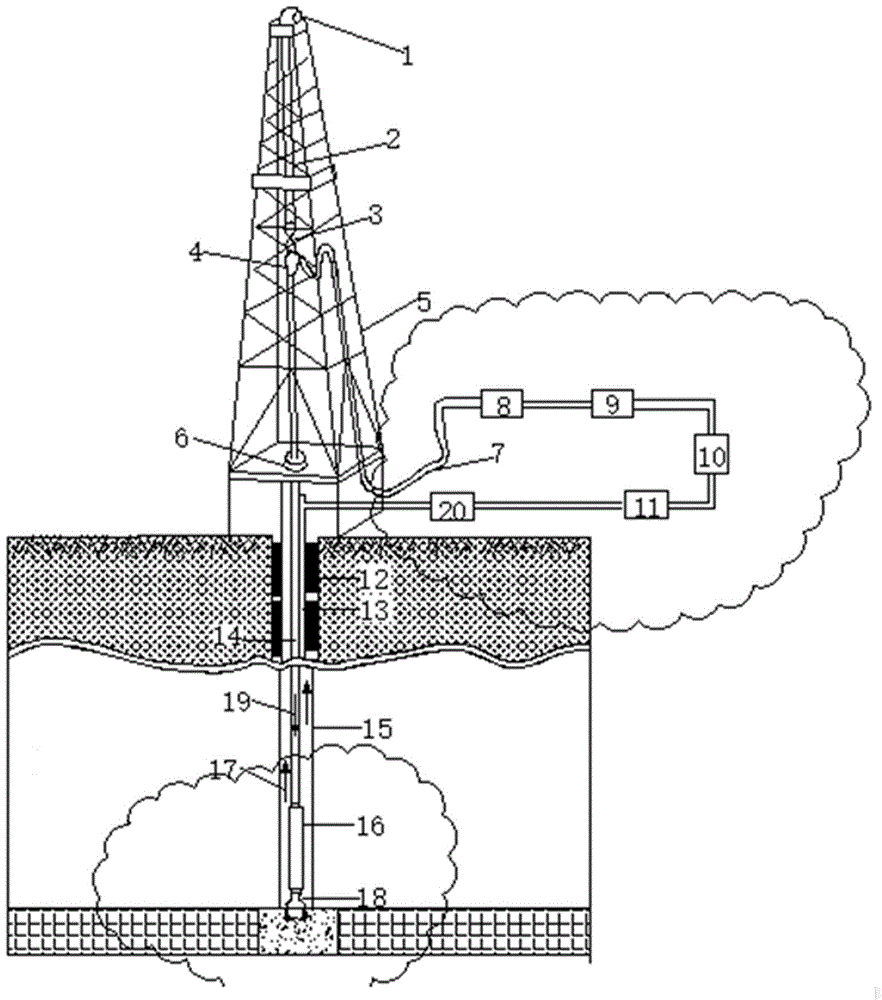

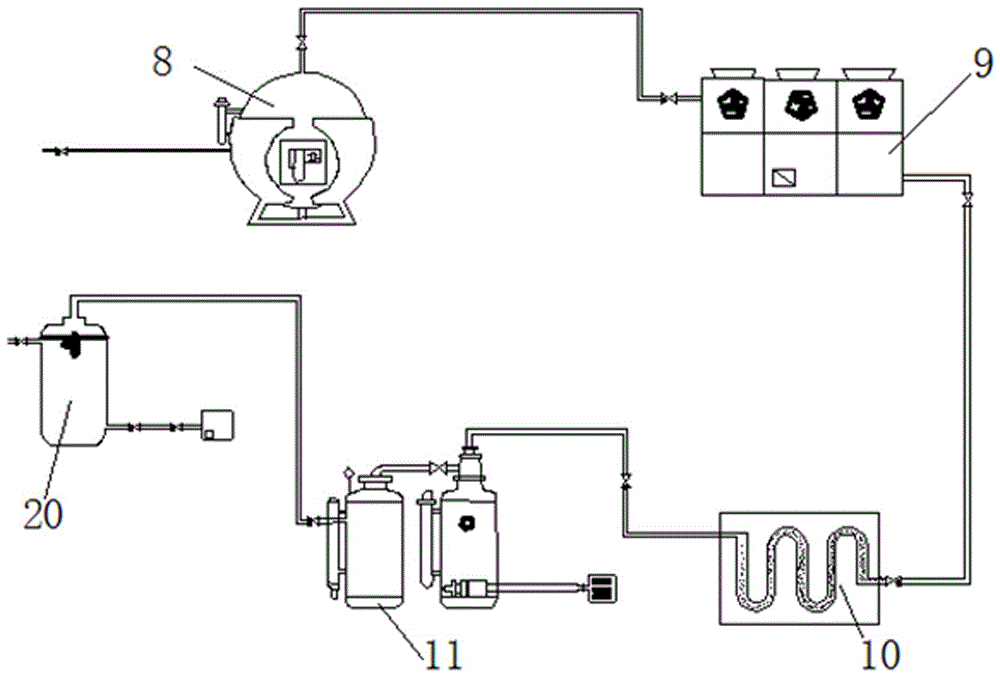

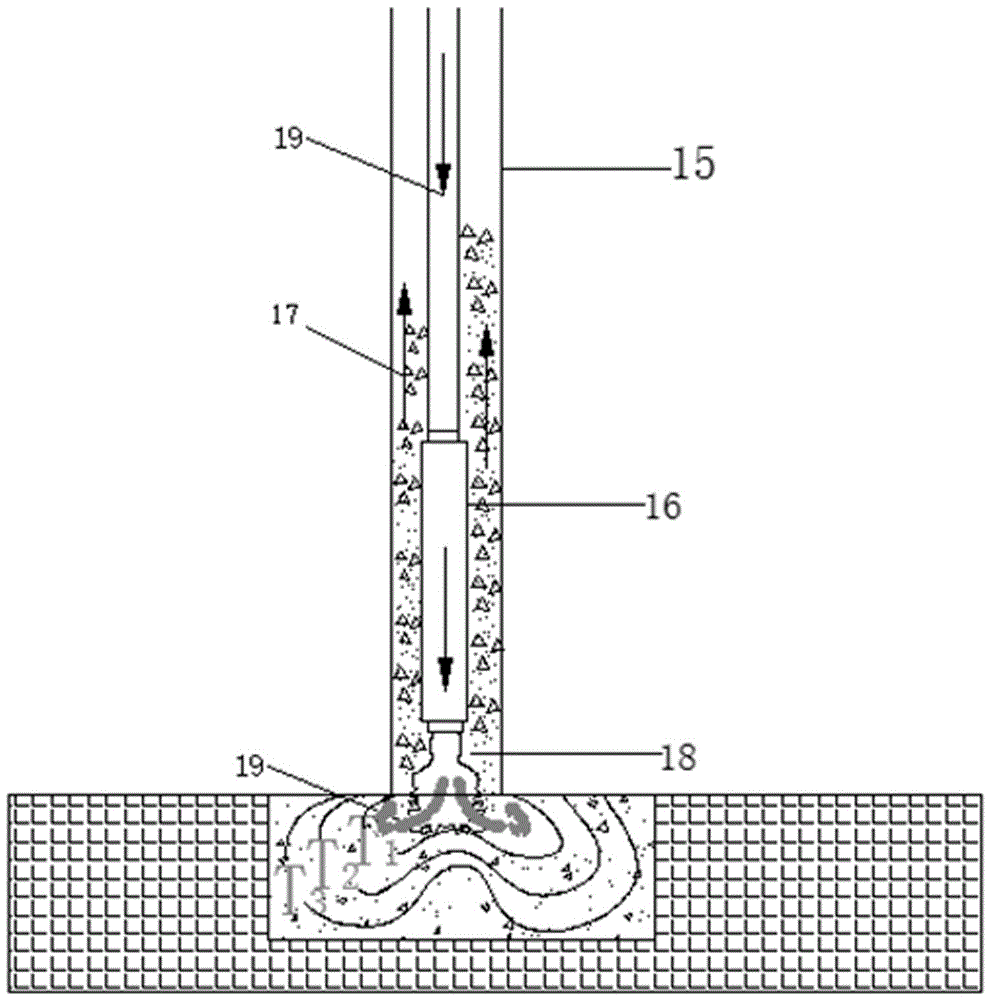

[0023] Attached below figure 1 , figure 2 , image 3 The present invention will be further described.

[0024] Injection wells and production wells are constructed in a delineated hot dry rock geothermal development area. During the construction process, granular dry ice is used as drilling fluid to assist rock breaking drilling methods. The specific steps are as follows:

[0025] (1) According to the exploration results of geological conditions, it is decided to arrange the injection well and production well in the granite layer with a depth of 2000m and a temperature of 200°C. The drilling fluid is granular dry ice, and the injection pressure is greater than 50MPa.

[0026] (2) Complete the preparatory work before drilling construction, such as well hole positioning, drilling rig in place, etc. Firstly, the wellbore positioning is carried out according to the well group layout plan and spacing, and then the drilling equipment is installed. Assemble the derrick 5 accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com