Fresh air haze remover with energy-saving effect

A fresh air fan and fresh air technology, which is applied in home appliances, ventilation systems, mechanical equipment, etc., can solve the problems of high resistance on the fresh air side and poor energy-saving effect, so as to reduce the energy consumption of the whole machine, reduce the development cost, and reduce the types of development Effect

Pending Publication Date: 2019-12-13

GREE ELECTRIC APPLIANCES INC

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to solve the technical problem of poor energy-saving effect caused by the high resistance of the fresh air side of the existing fresh air haze remover, an energy-saving device with an energy-saving effect that reduces the energy consumption of the whole machine and reduces the cost is provided on the premise of ensuring the capacity of the fresh air haze remover Fresh air haze remover

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

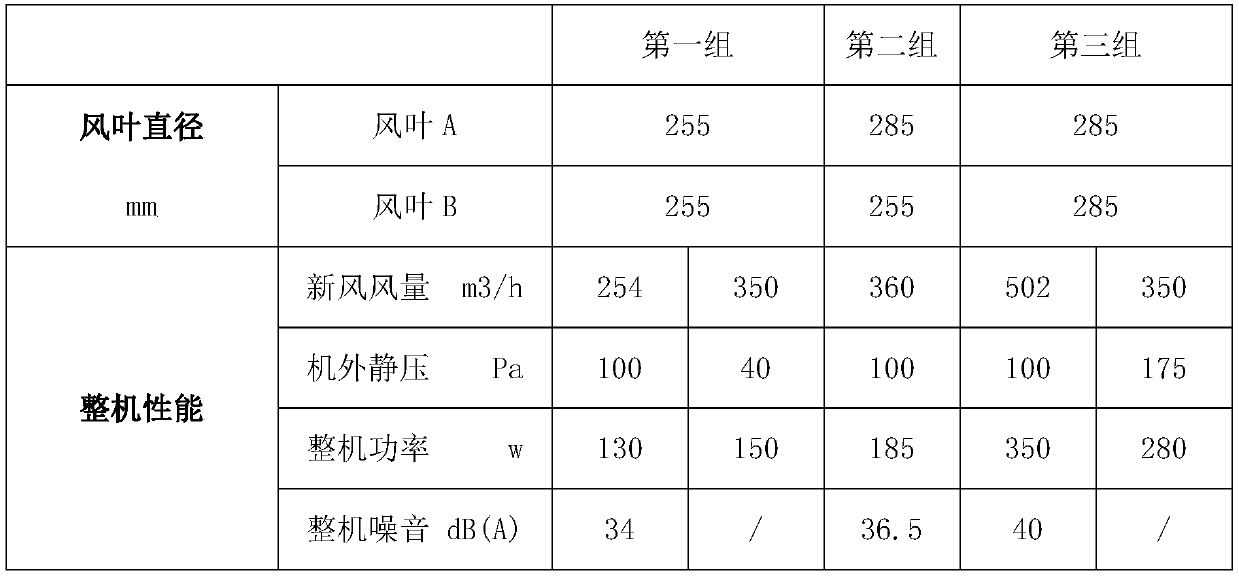

[0051] The static pressure of the fresh air haze removal machine is required to meet 100pa;

[0052] The air volume of the whole machine meets 350m 3 / h;

[0053] The specifications of the fresh air fan and exhaust fan are two specifications: the diameter of the fan blade is 255mm and the diameter of the fan blade is 285mm;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

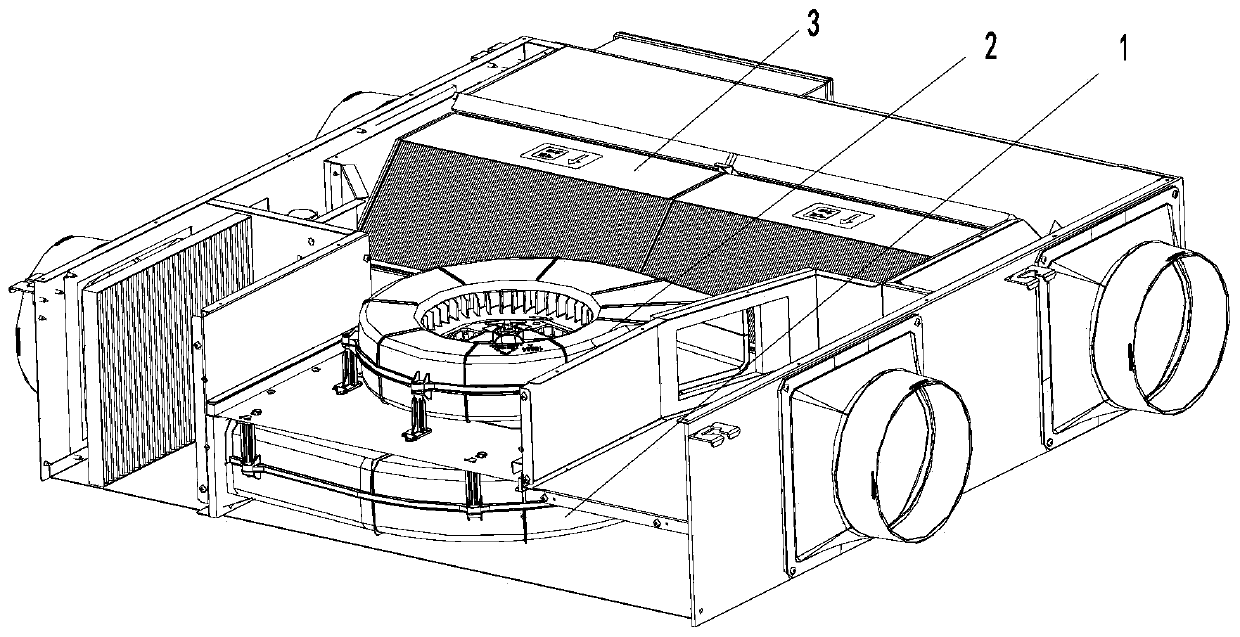

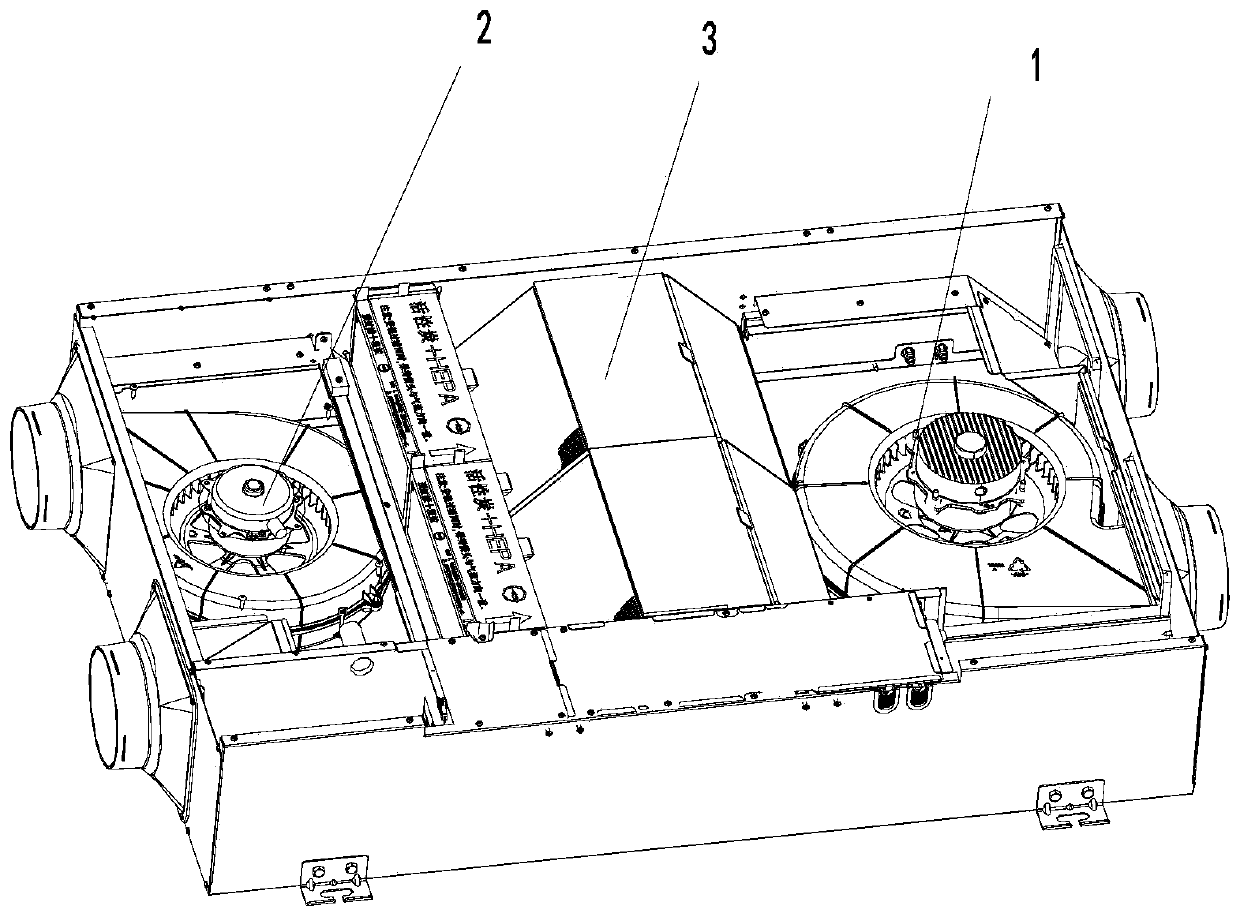

The invention provides a fresh air haze remover with an energy-saving effect. The fresh air haze remover comprises a fresh air pipeline and an air exhaust pipeline, wherein a fresh air fan is arrangedin the fresh air channel; an air exhaust fan is arranged in the air exhaust channel; and the fan blade diameter of the fresh air fan is greater than that of the air exhaust fan. The fresh air haze remover with the energy-saving effect provided by the invention has system characteristics of combining great fresh air side resistance with small air exhaust side resistance, so that the fan blade diameter of the fresh air fan is greater than that of the air exhaust fan, and therefore, energy consumption of the fresh air haze remover is reduced and the cost is reduced on the premise of guaranteeingability of the fresh air haze remover; and moreover, the fan blades can be matched, so that development types of the fans are reduced to the greatest extent on the premise of meeting product needs, and therefore, development cost is further reduced.

Description

technical field [0001] The invention relates to the technical field of fresh air processing equipment, in particular to a fresh air haze removal machine with energy-saving effect. Background technique [0002] For the full heat exchange fresh air haze removal system, the fresh air side needs to purify the outdoor fresh air, and at the same time protect the full heat exchange core and prolong its service life. Usually, a purification component is installed in the fresh air inlet chamber to achieve a higher primary filtration. Efficiency, usually using HEPA high-efficiency physical filters. On the exhaust side, in order to protect the total heat exchange core and prolong its service life, a purification component is usually installed in the exhaust air inlet cavity. Because the indoor air quality is better, the purification component on the exhaust side is generally a coarse-effect filter. The filter has less resistance. Due to the characteristics of HEPA itself, its resista...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F24F7/08F24F13/24F24F13/30F04D25/08F04D25/16F04D29/28F04D29/66

CPCF24F7/08F24F13/30F24F13/24F04D25/08F04D25/166F04D29/281F04D29/661F24F2013/247

Inventor 刘莹薛寒冬杨力詹朝永古展彰

Owner GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com