Waste paper regenerating process and apparatus thereof

A waste paper and process technology, applied in the field of papermaking, can solve problems such as pollution, fiber loss, and re-pollution, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

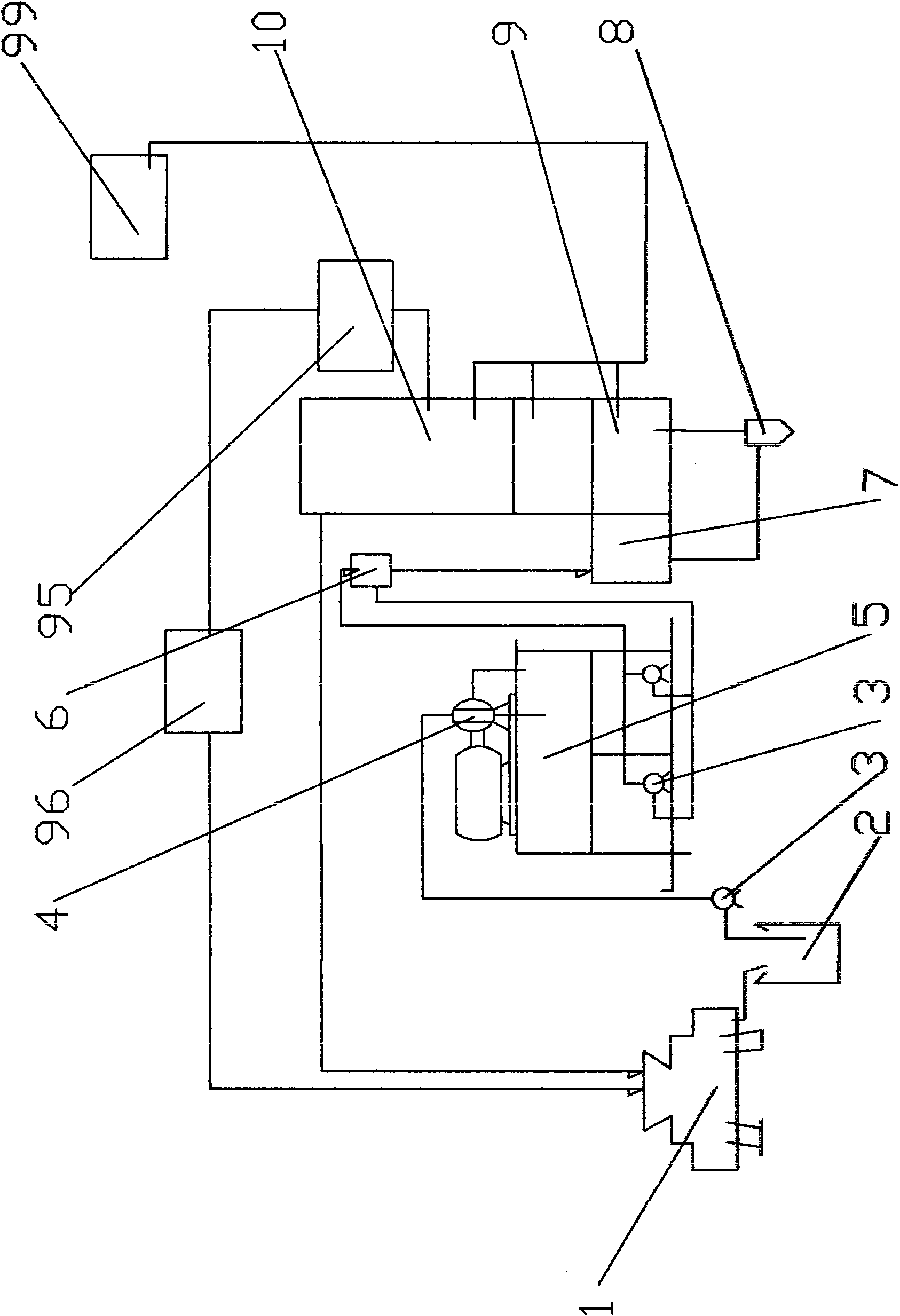

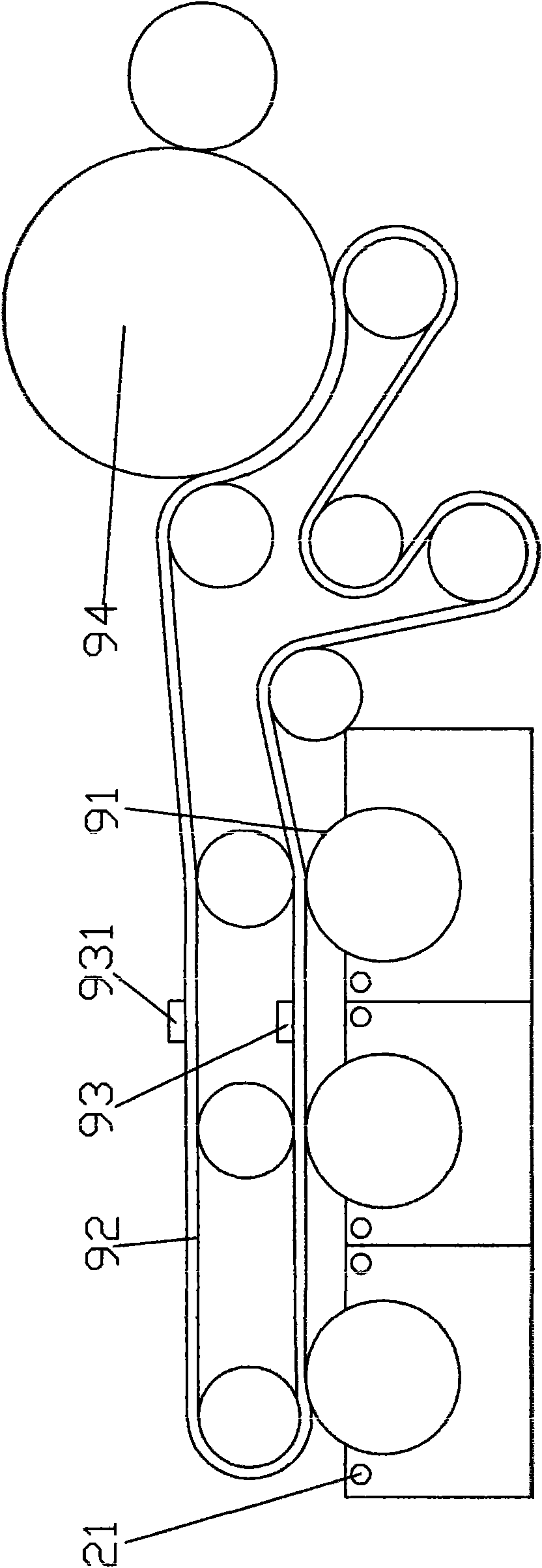

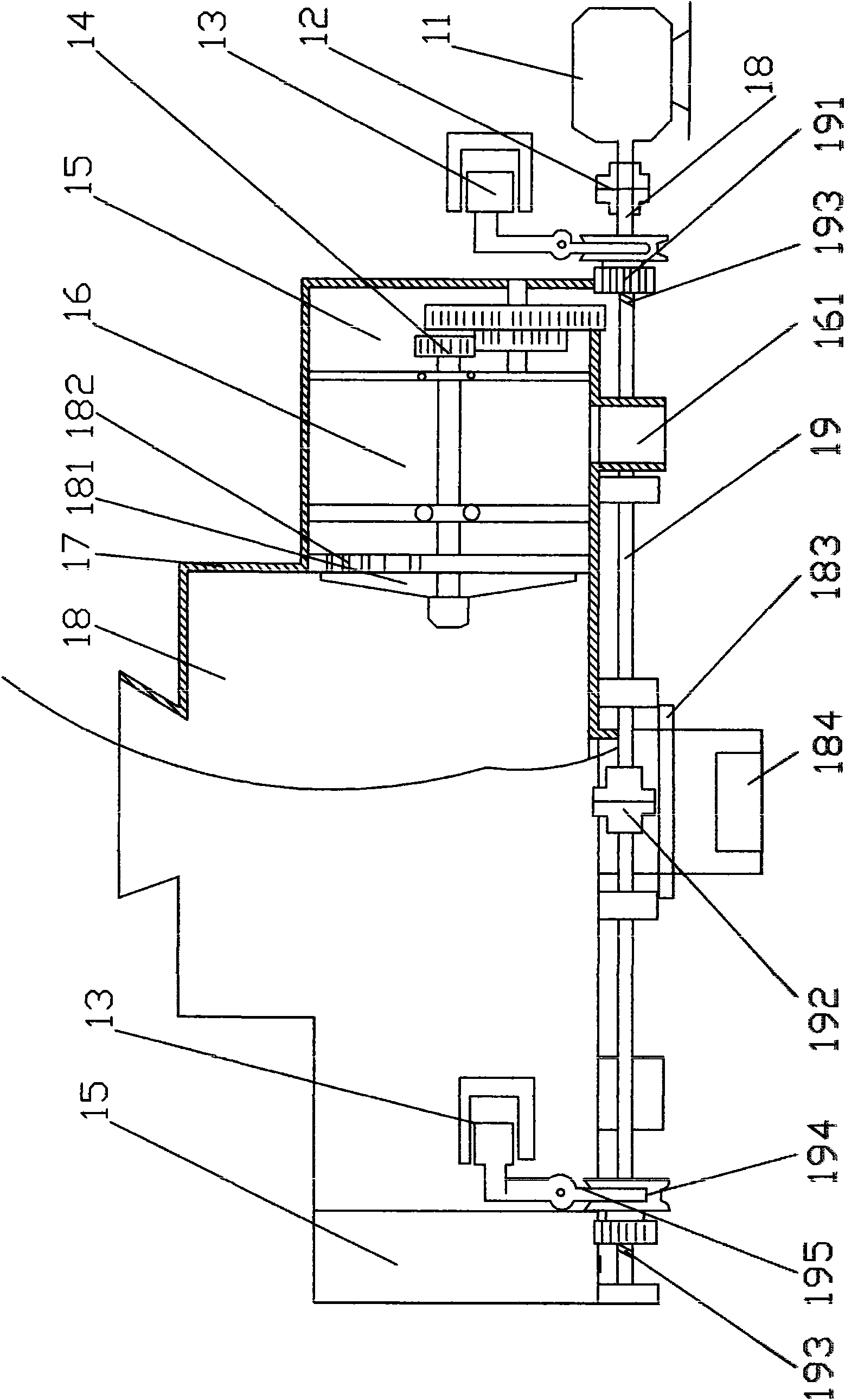

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a waste paper regeneration process, the waste paper is cleaned and prepared in the stockyard, and then decomposed by the fiber disintegrator 1, the decomposed pulp is discharged in the pulp tank 2, and the pulp is pumped by the pulp pump 3 to the refiner 4 for further processing. Rub the pulp, enter the pulping pool 5 after rubbing, the pulp is pumped to the material box 6 by the pulp pump 3, and then fed to the mixing tank 7 by a fixed amount from the material box 6, and the pulp is desanded by the sand remover 8, and then enters The net cage 91 of the net cage 9 is formed into a paper page, and the net cage 9 is provided with a special water spray device 21 to clean the net cage 91, and then the paper page is printed on the felt 92 and vacuum dehydrated in a vacuum machine 93. , in the press 931, the paper is squeezed and squeezed, and then enters the drying cylinder 94 to dry to obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com