Paper feeding device of numerical control automatic taping machine

A technology of a paper feeding device and a tape wrapping machine, which is applied in the directions of packaging, transportation and packaging, and thin material handling, can solve problems such as affecting coil quality and potential safety hazards, and achieve the effects of precise operation, high work efficiency, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

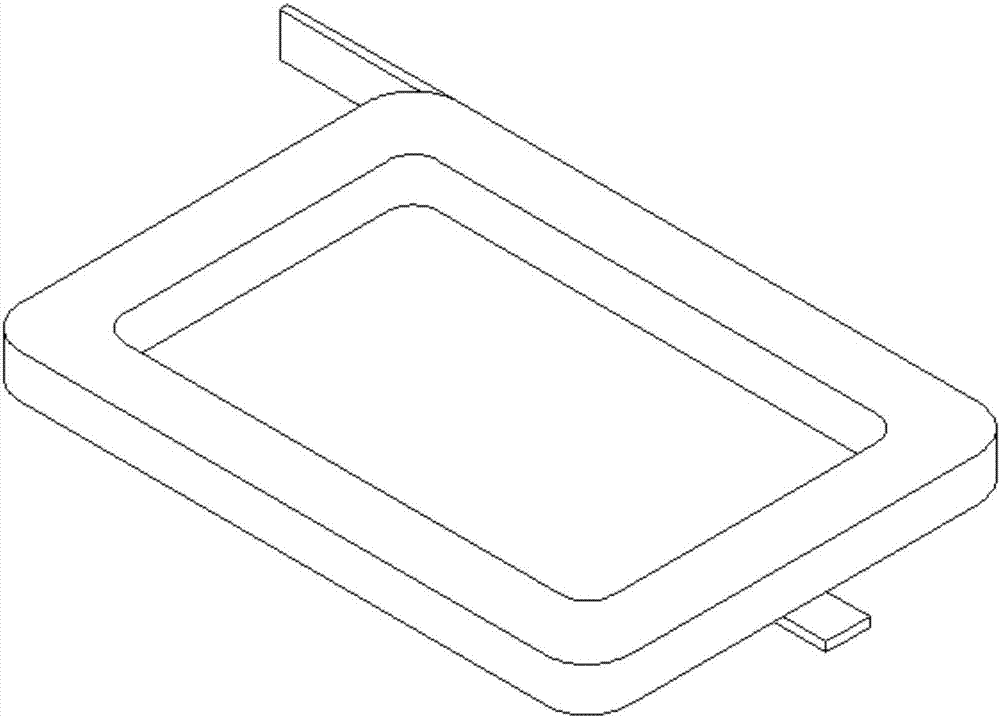

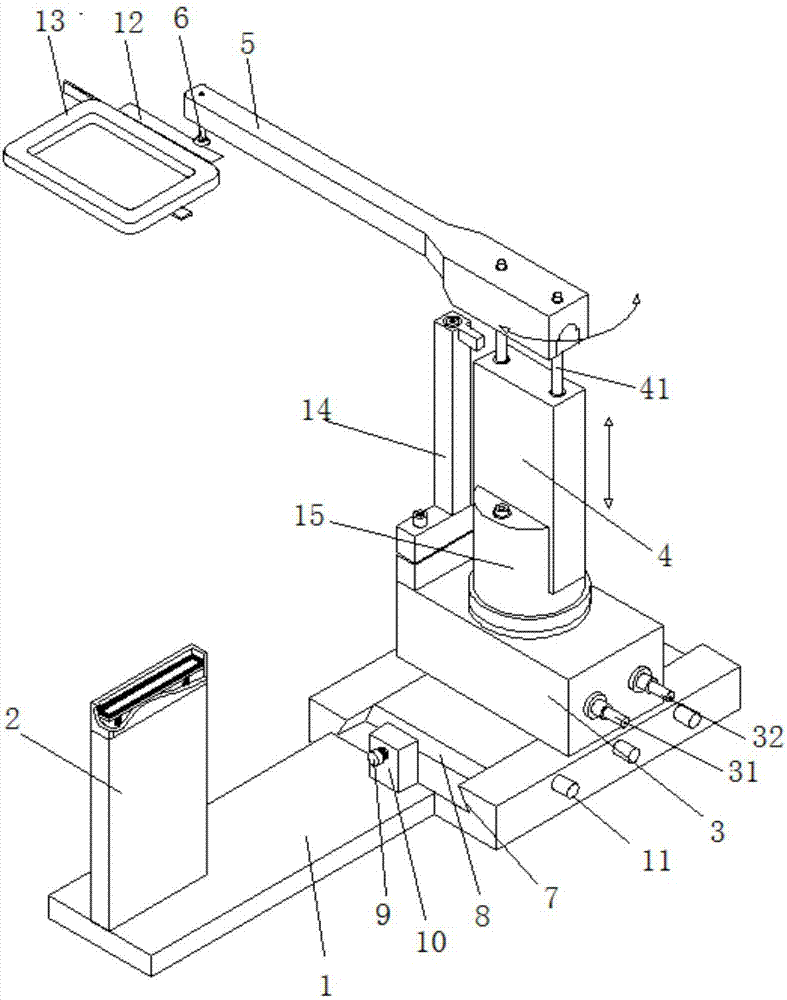

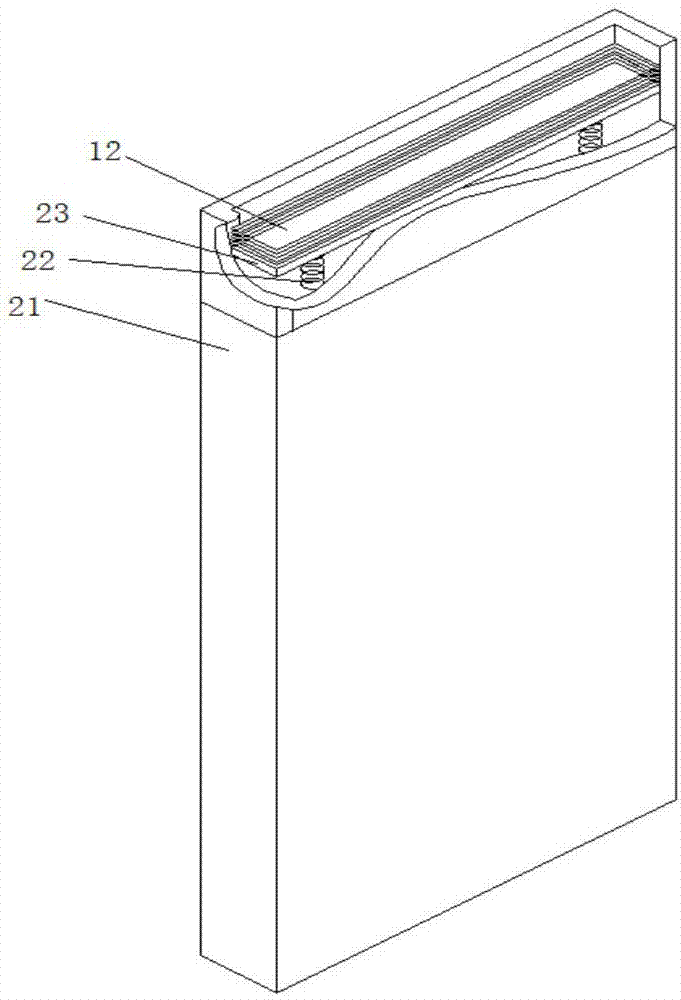

[0033] like Figure 2-4 As shown, the paper feeding device of the numerical control automatic taping machine includes: a paper storage mechanism 2, which stores a number of sheets of paper 12 and is set close to the tape wrapping station of the workpiece 13. In this embodiment, the tape wrapping station of the workpiece 13 is located at The right front of the paper storage mechanism 2; the paper feeding mechanism has a paper feeding structure that transports the paper sheet 12 in the paper storage mechanism 2 to a predetermined position on the workpiece 13 and a paper feeding structure that drives the movement of the paper feeding structure. The first driving structure 3. The first driving structure 3 is a rotary cylinder, and the side of the rotary cylinder is provided with a left-handed regulator 31 and a right-handed regulator 32 that can adjust the leftward rotation angle and rightward rotation angle of the rotary cylinder. The paper structure is pivotally connected to re...

Embodiment 2

[0046] The paper storage mechanism 2 and the wrapping station of the workpiece 13 are at the same horizontal position, and the rotating arm 5 does not need to be lifted up and down and rotated when taking and putting paper, but only needs to be translated after the paper storage mechanism 2 takes paper It only needs to reach the predetermined position of the workpiece 13, and at the same time, no limit mechanism 14 is required in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com