Grain Depot Automatic Sampling System

A sampling and automatic technology, which is applied in the field of automatic sampling system of grain depots, can solve problems such as inability to sample grain, and achieve the effects of avoiding information verification difficulties, prolonging service life, and extending functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

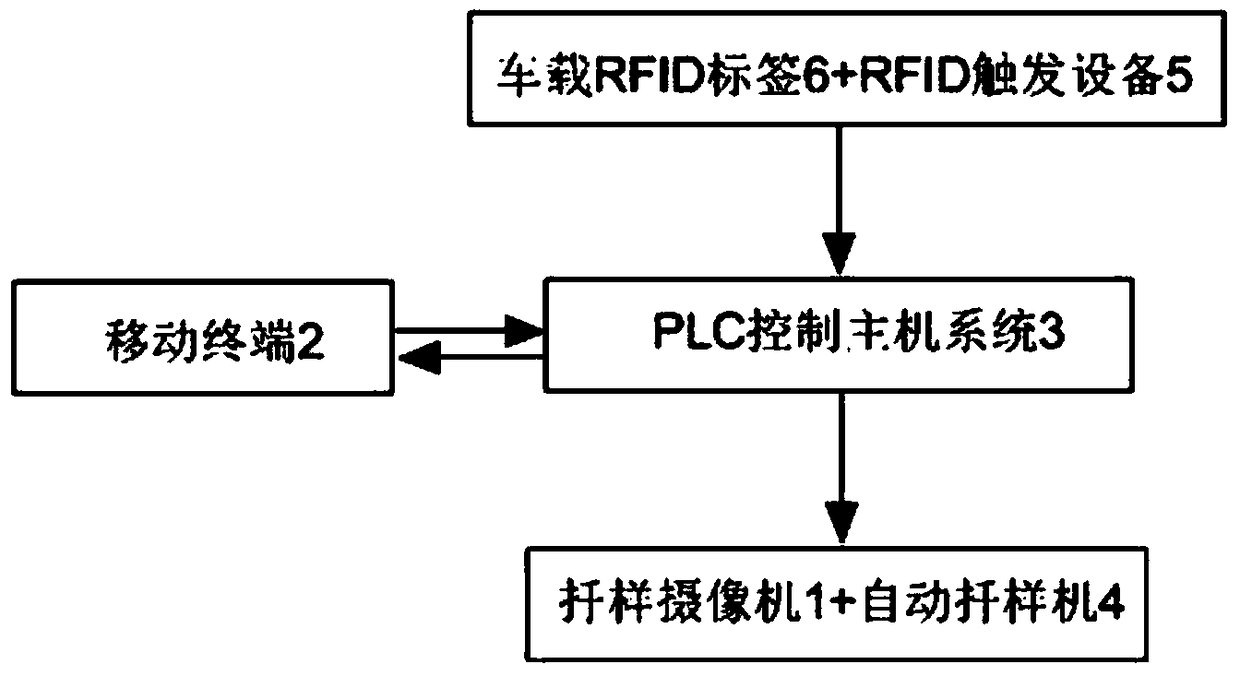

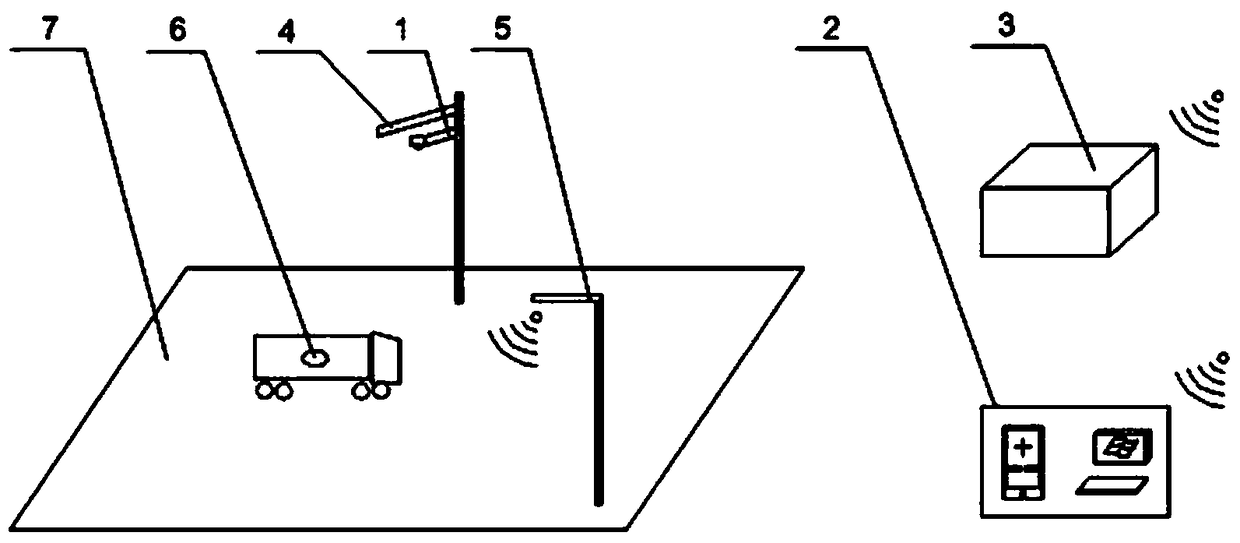

[0034] Such as Figure 1~2 As shown, the present invention provides an automatic sampling system for grain depots, including an automatic sampling machine 4, and also includes:

[0035] Sampling camera 1, which records and sends video signals of vehicles in the sampling operation area 7;

[0036] Terminal 2, which communicates with the sampling camera 1, the terminal 2 receives the video signal, manually determines the sampling area, and sends and controls the automatic sampling machine 4 to perform a specified sampling action in the sampling area instructions,

[0037] The PLC controls the host system 3, which communicates with the sampling camera 1 and the terminal 2. The PLC controls the host system 3 to receive the instructions and controls the automatic sampling machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com