Motion control method for office swivel chair production

A motion control, swivel chair technology, applied in the direction of comprehensive factory control, program control manipulators, manufacturing tools, etc., can solve problems such as lack of standardization, and achieve the effect of improving the level of intelligent motion control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below through specific embodiments.

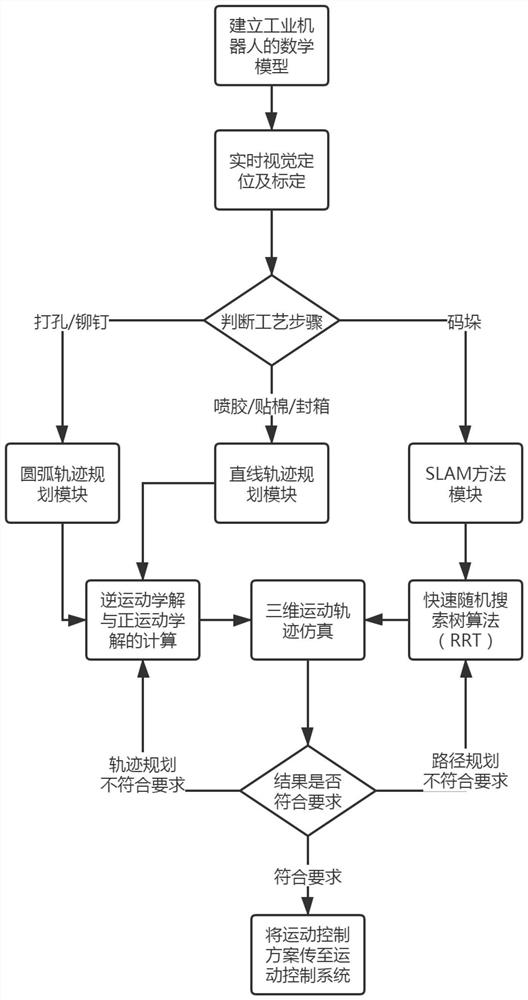

[0030] Such as figure 1 As shown, it is the implementation flow chart of the motion control scheme for the office swivel chair provided in the embodiment of this application, and the specific implementation scheme includes:

[0031] (1) Establishing the mathematical model of the industrial robot is mainly to determine the torsion angle, distance, length and angle range of each joint of the robot according to the D-H parameter determination rules. Usually, the D-H parameter table can be obtained from the specific model of the industrial robot operation manual; optionally, This application can use the Yaskawa MH12 robot as the operating robot in the production process of the swivel chair. The robot has 6 series rotating joints. The four types of parameters (twist angle, distance, length and Angle range), the relevant details of the connecting rod transformation matrix expression of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com