Patents

Literature

127results about How to "Improve loading effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

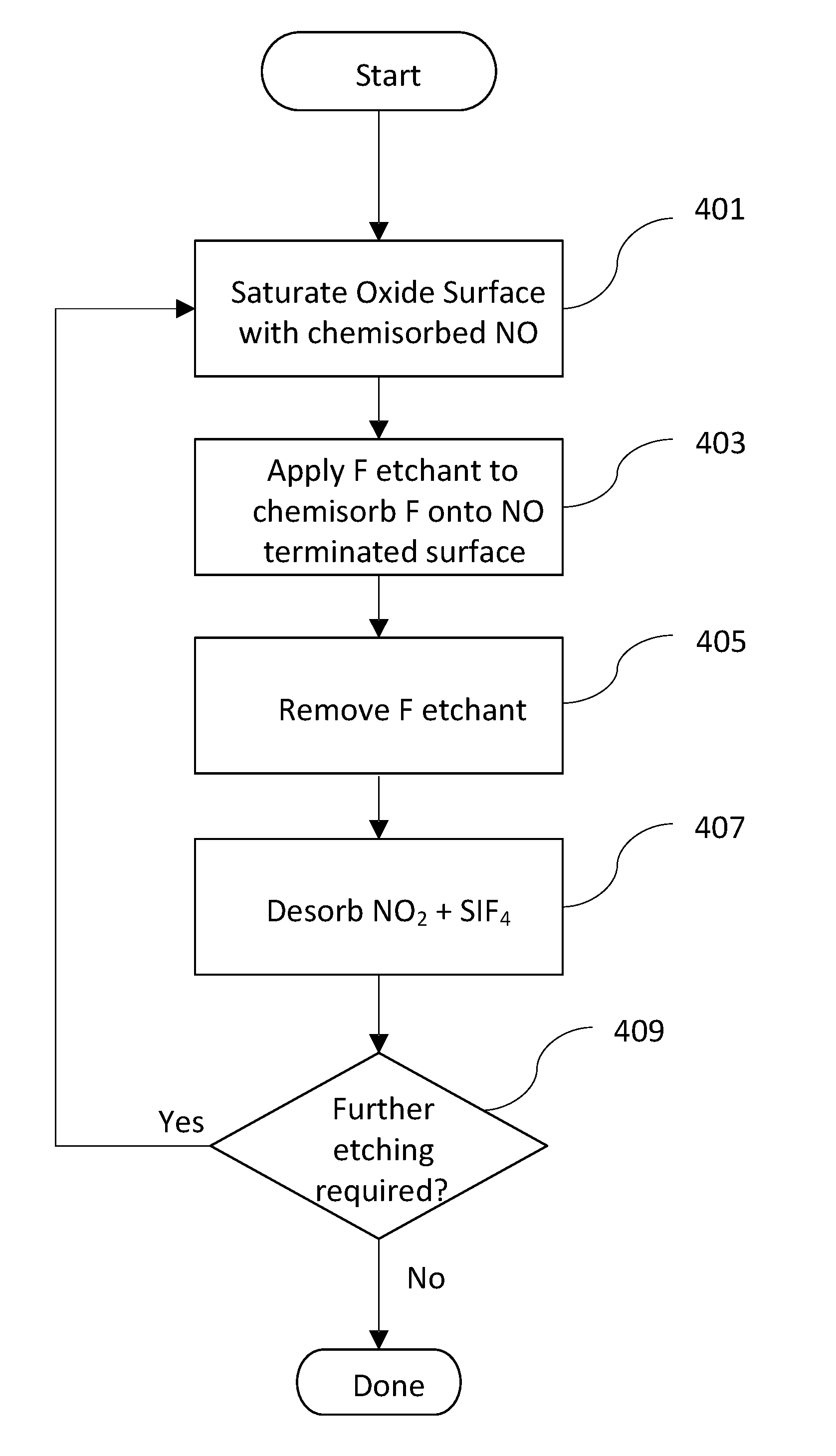

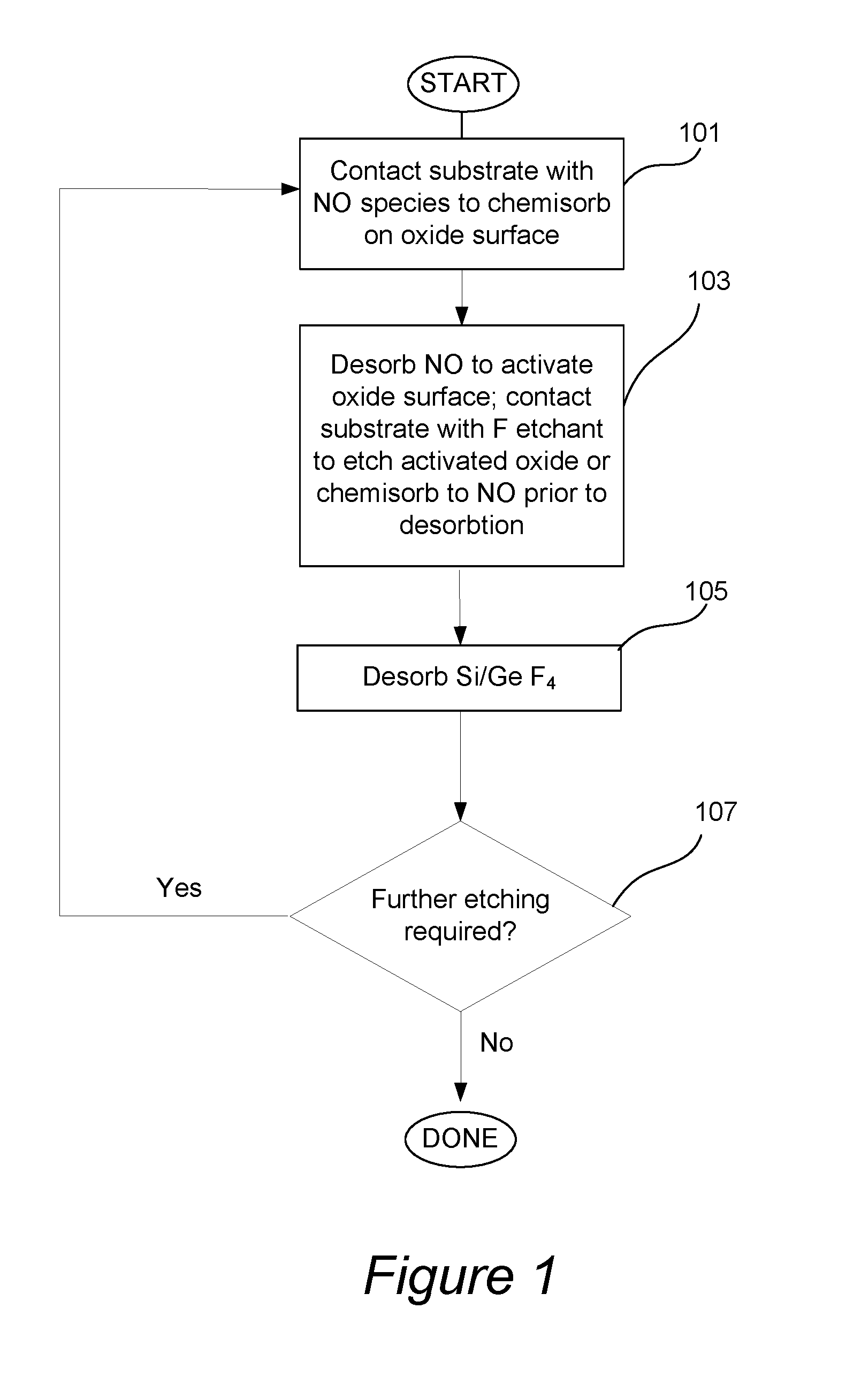

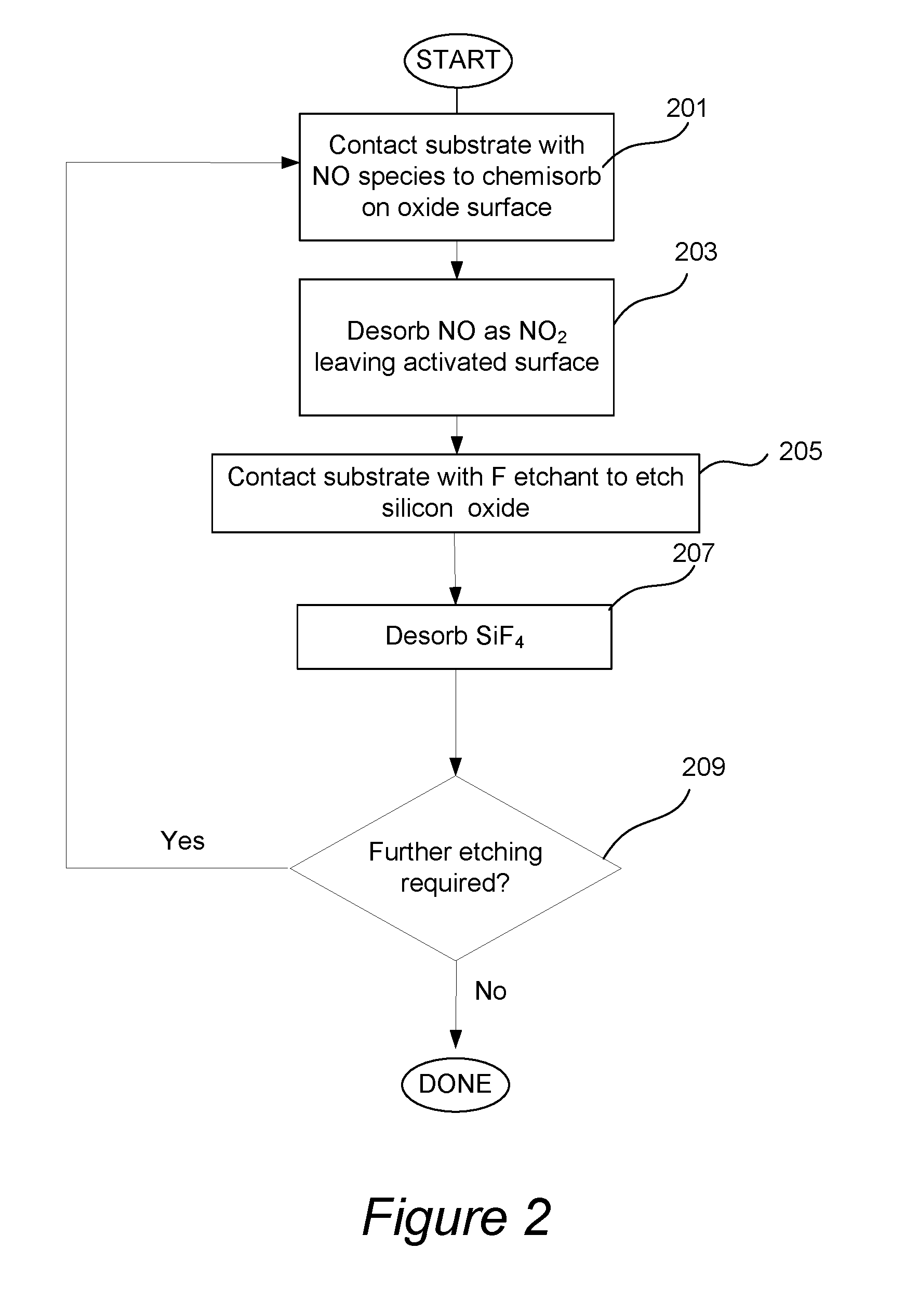

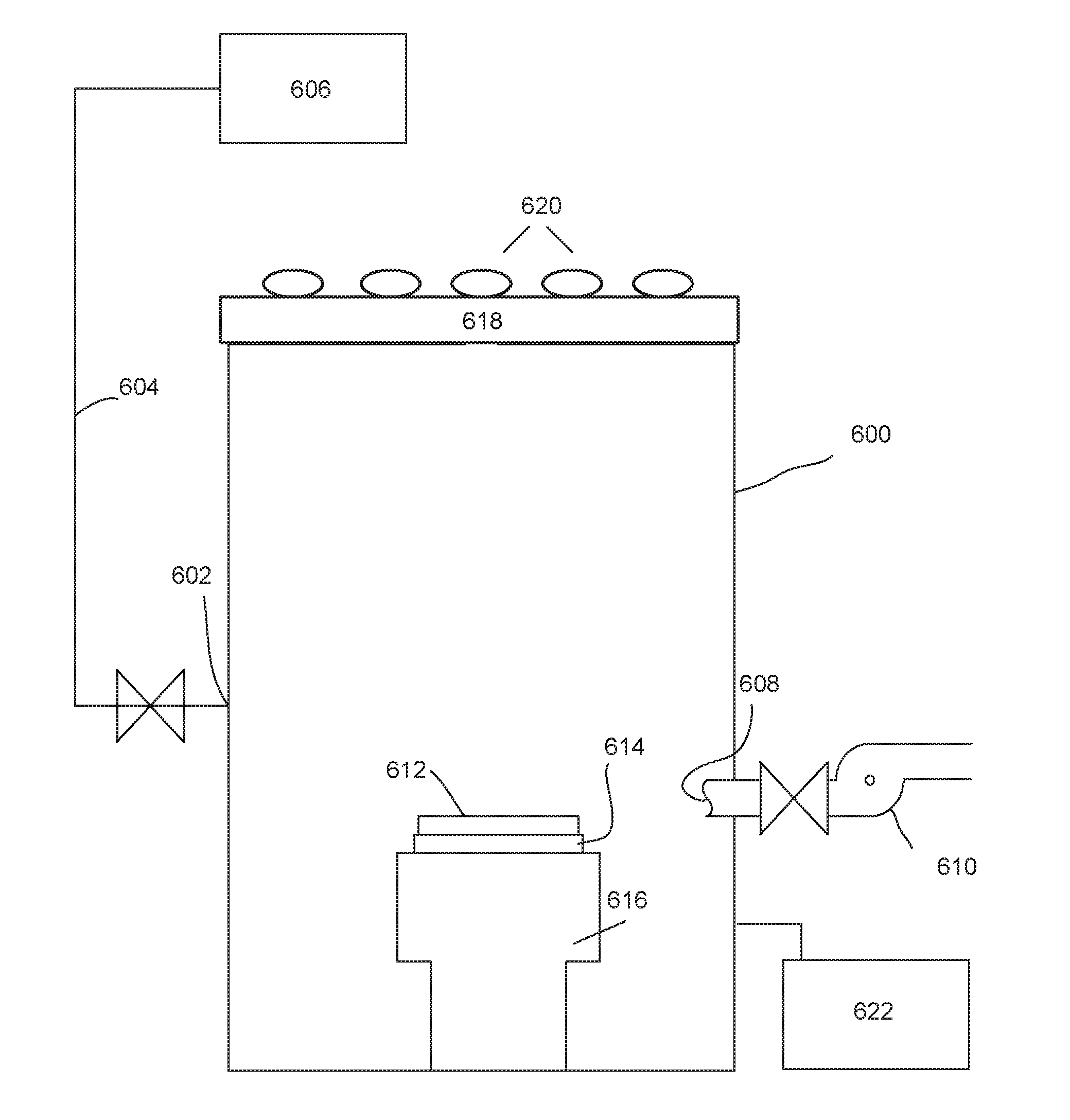

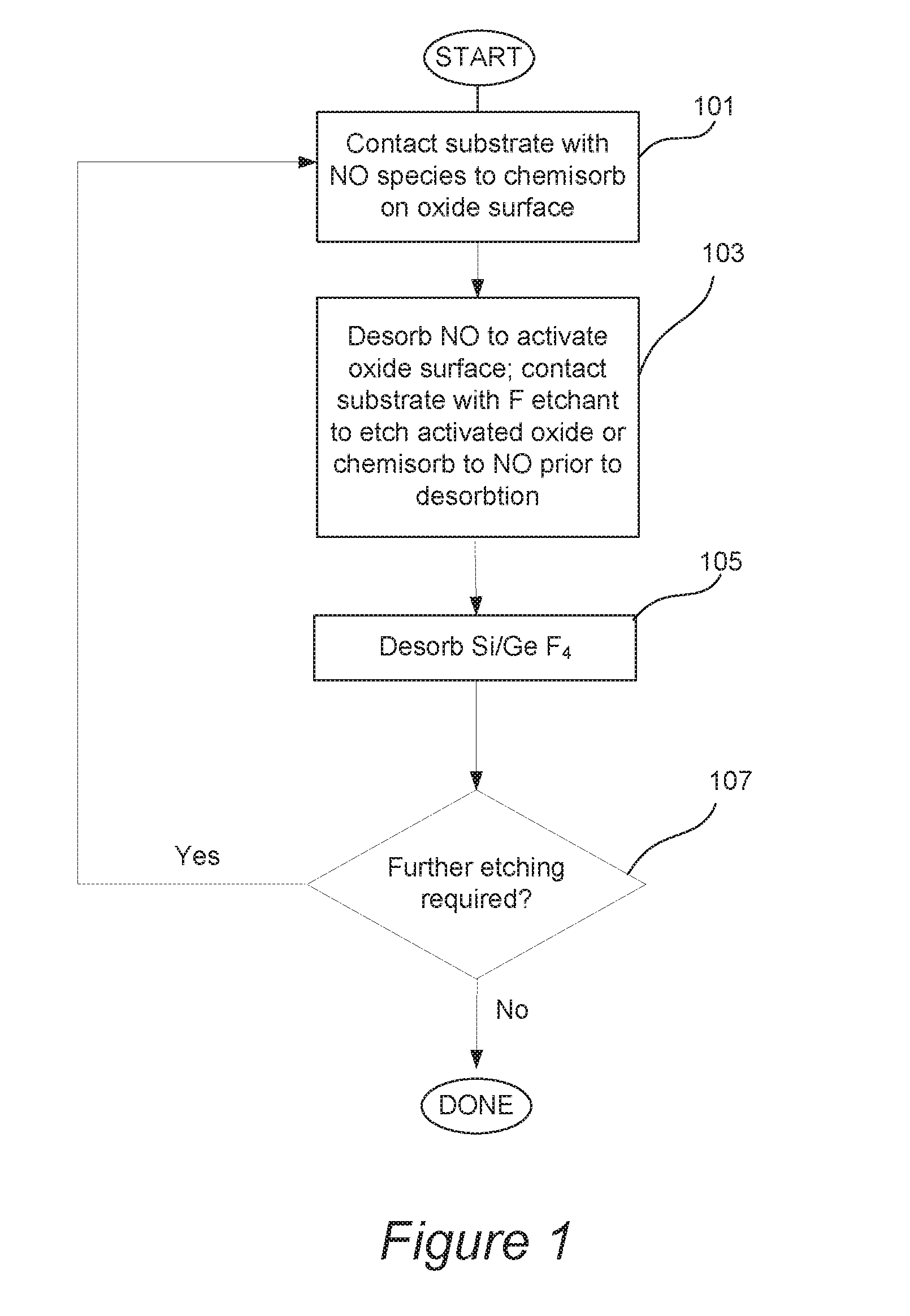

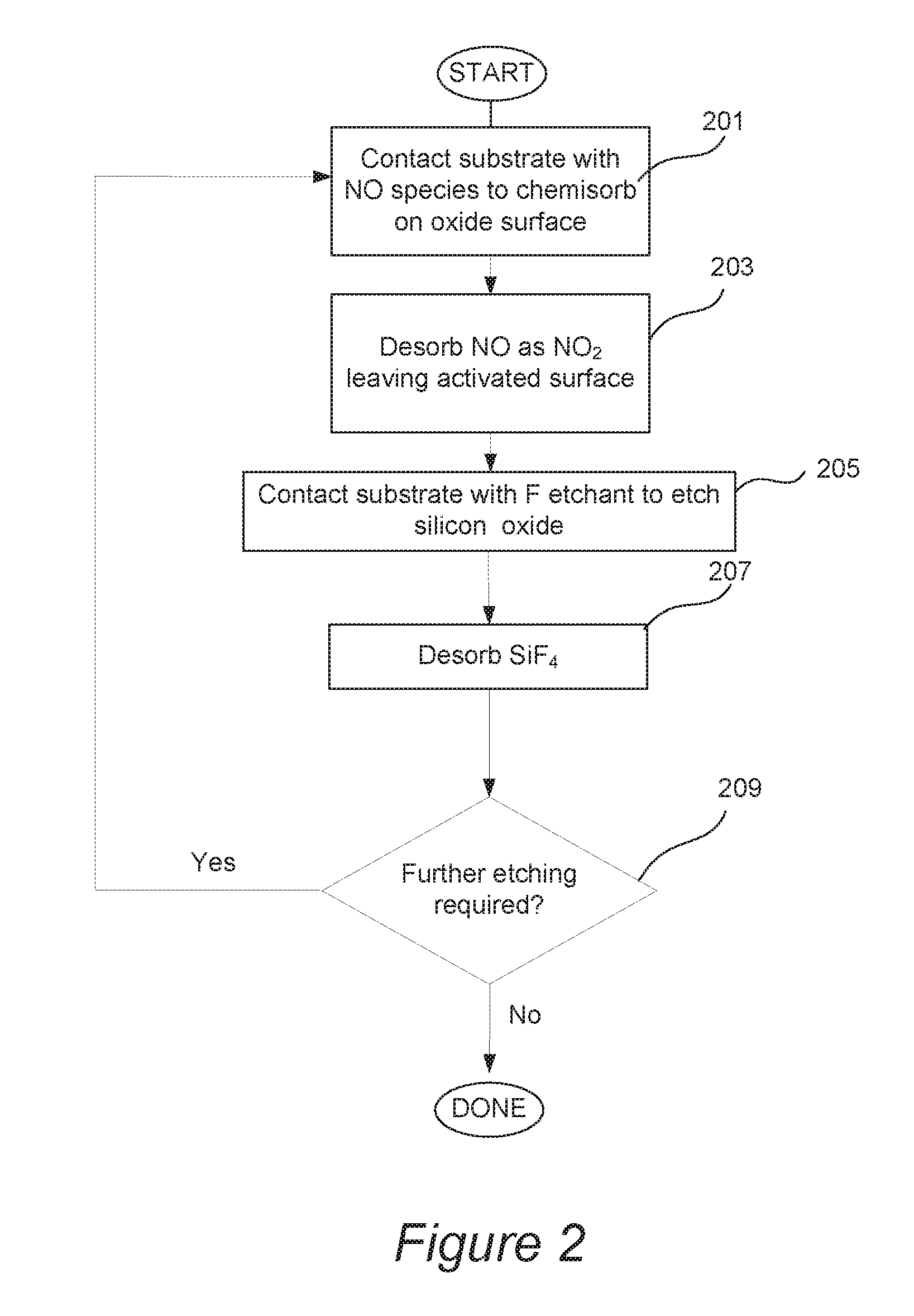

Isotropic atomic layer etch for silicon oxides using no activation

ActiveUS9425041B2High selectivityReduce defective rateElectric discharge tubesSemiconductor/solid-state device manufacturingGate dielectricSilicon oxide

Methods for controlled isotropic etching of layers of silicon oxide and germanium oxide with atomic scale fidelity are provided. The methods make use of NO activation of an oxide surface. Once activated, a fluorine-containing gas or vapor etches the activated surface. Etching is self-limiting as once the activated surface is removed, etching stops since the fluorine species does not spontaneously react with the un-activated oxide surface. These methods may be used in interconnect pre-clean applications, gate dielectric processing, manufacturing of memory devices, or any other applications where accurate removal of one or multiple atomic layers of material is desired.

Owner:LAM RES CORP

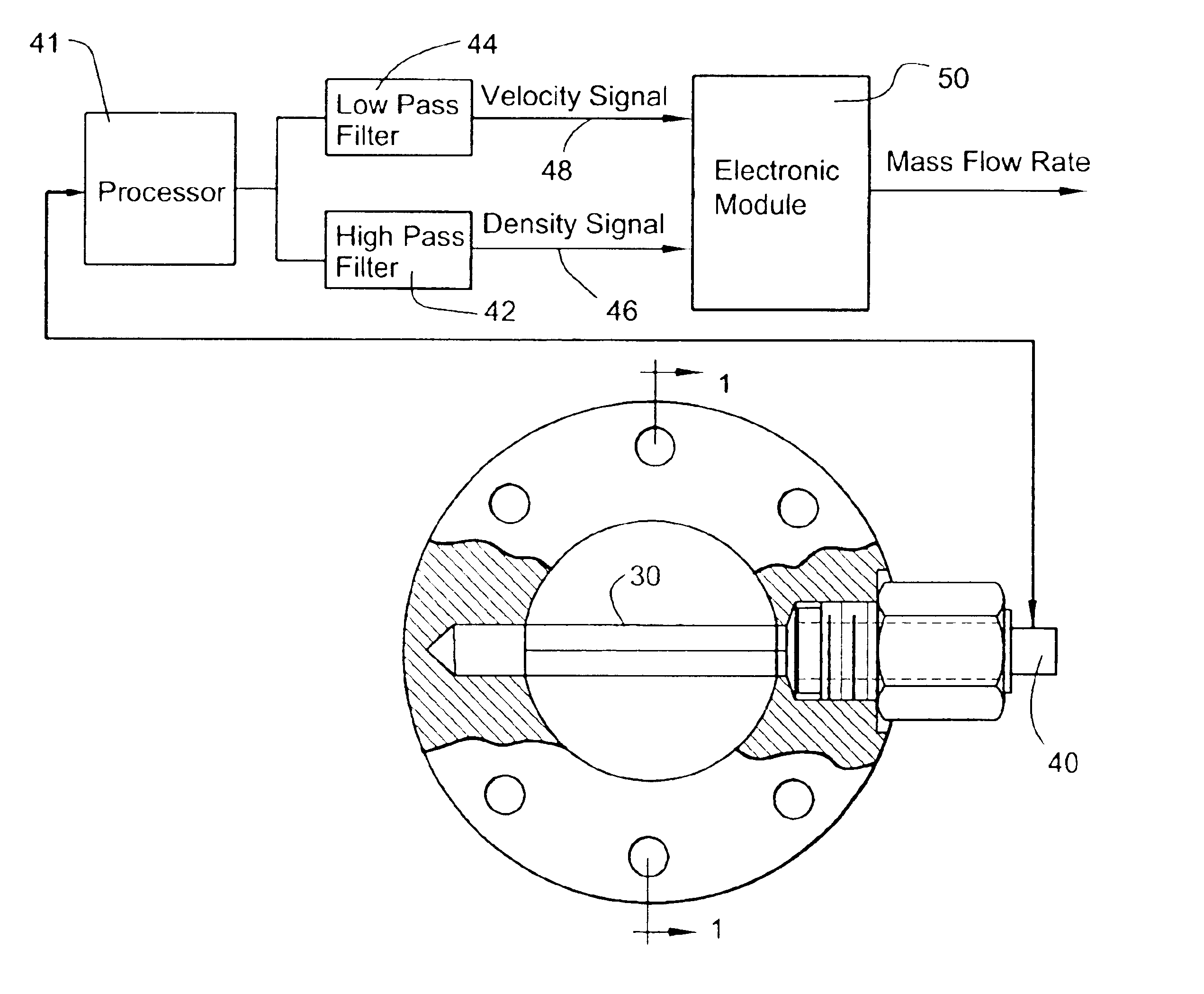

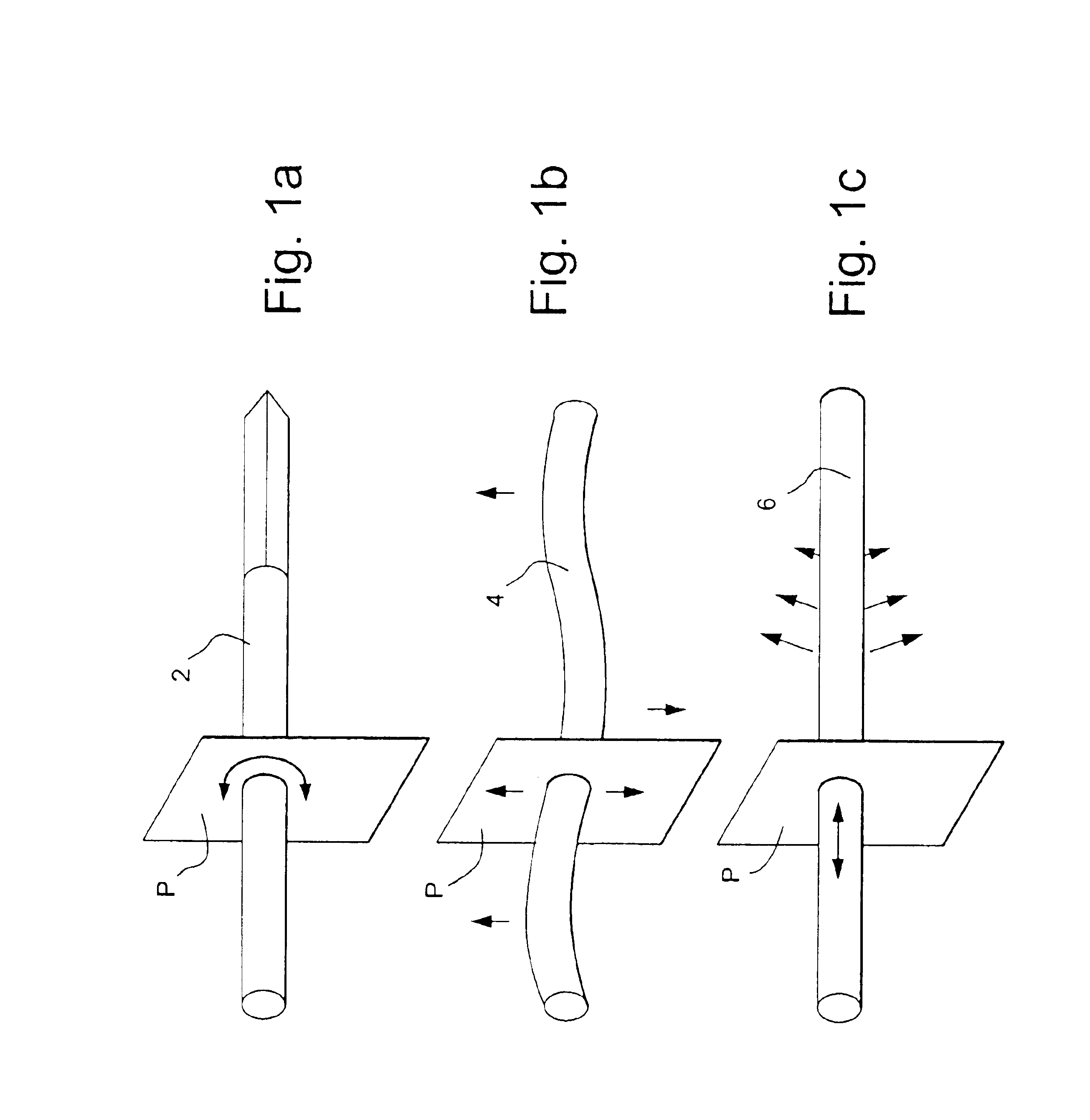

Mass flow sensor and methods of determining mass flow of a fluid

ActiveUS6912918B1Prevent leakageAvoid radiationVolume/mass flow by dynamic fluid flow effectSpecific gravity measurementSonificationUltrasonic beam

The mass flow rate sensor includes a waveguide disposed in a flow passage having a bluff body facing in an upstream direction. Waves are pulsed along the waveguide for interaction with the fluid. A receiver is coupled to the waveguide to detect a propagated wave and provides a first output signal proportional to the transit time of the propagated wave for determining fluid density. The receiver also provides a second output signal proportional to the shedding frequency of vortices from the waveguide to determine velocity. An electronics module calculates mass flow rate from the velocity times density times area of the flow passage and a constant. In other forms, the velocity is ascertained by transmitting an ultrasonic beam through the shedding vortices to determine vortex frequency which is proportional to velocity.

Owner:BAKER HUGHES INC

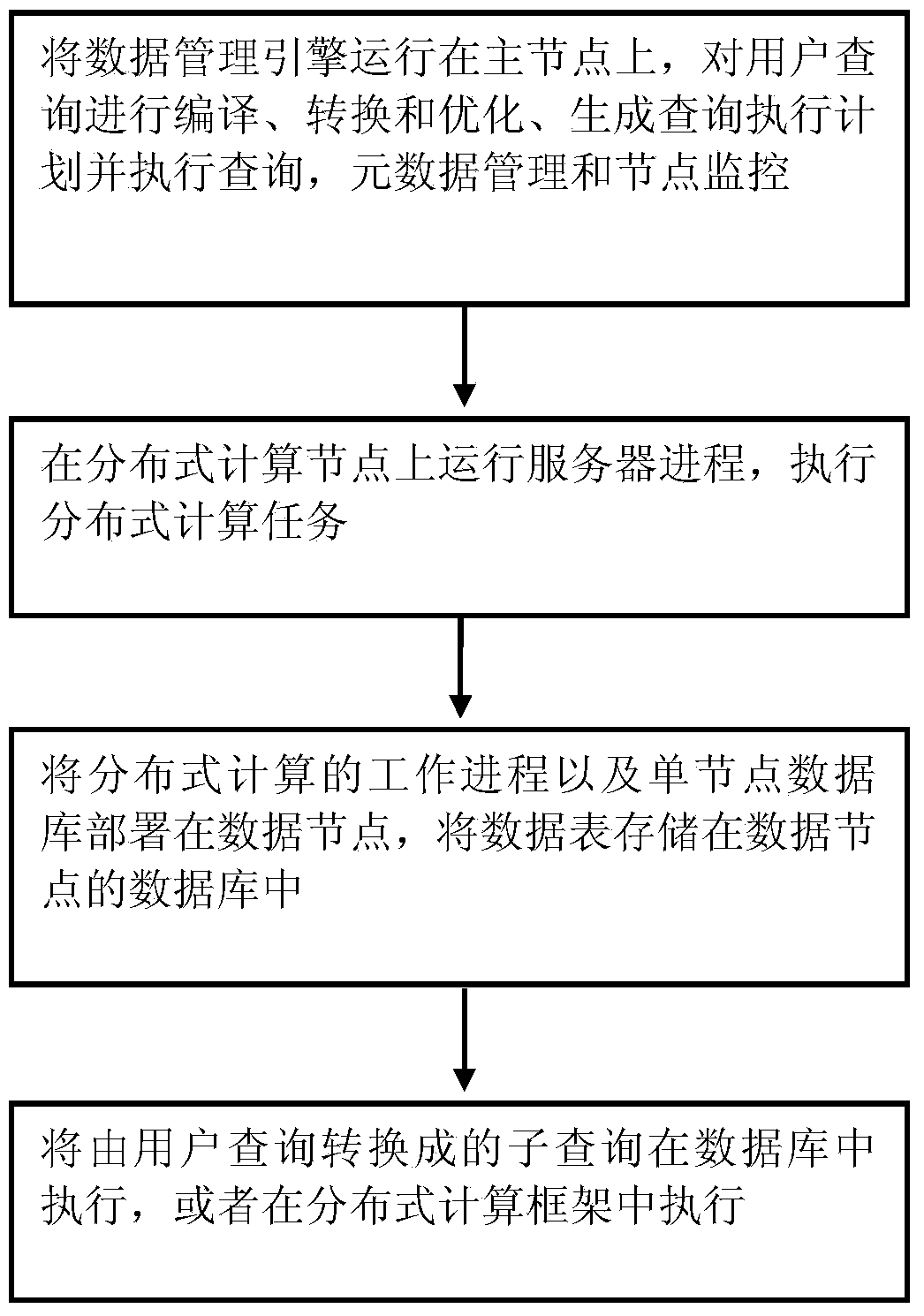

Big data distributed storage method and system

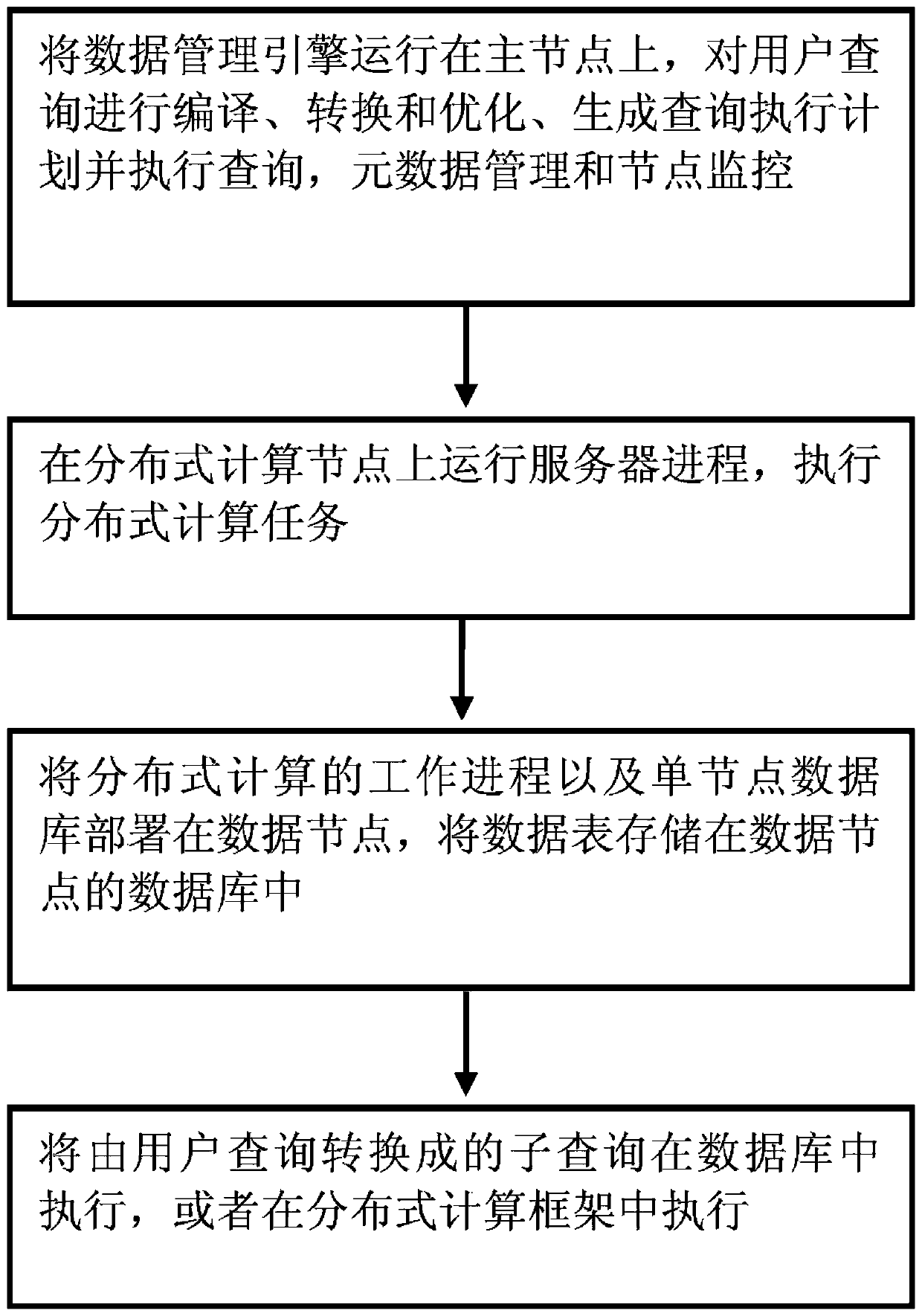

InactiveCN104063486AAvoid transmission costsImproved distributed storage methodSpecial data processing applicationsExecution planMetadata management

The invention provides a big data distributed storage method and system. The method comprises the steps of operating a data management engine on a main node, conducting compiling, conversion and optimization on user queries, generating and executing a query executing plan, and conducting metadata management and node monitoring; operating server processes on a distributed computational node and executing a distributed computation task; deploying the working processes of distributed computation and a single-node database on a data node; executing a subquery in the database or in a distributed computation frame. According to the big data distributed storage method and system, the opportunities that the queries are pushed down to the database to be executed are increased, data transmission cost caused by cross-node connection is avoided, and query performance is improved.

Owner:SICHUAN FEDSTORE TECH

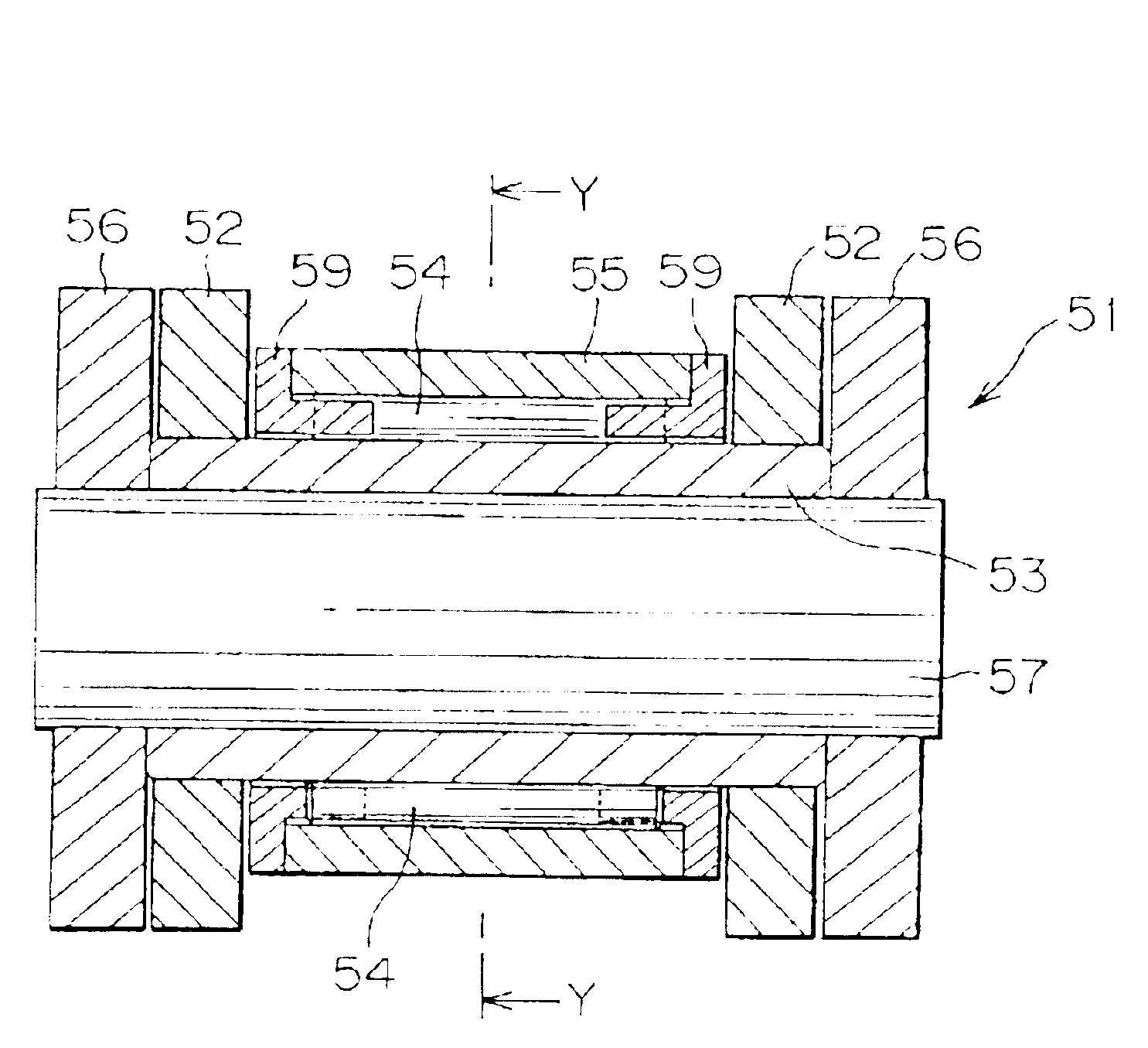

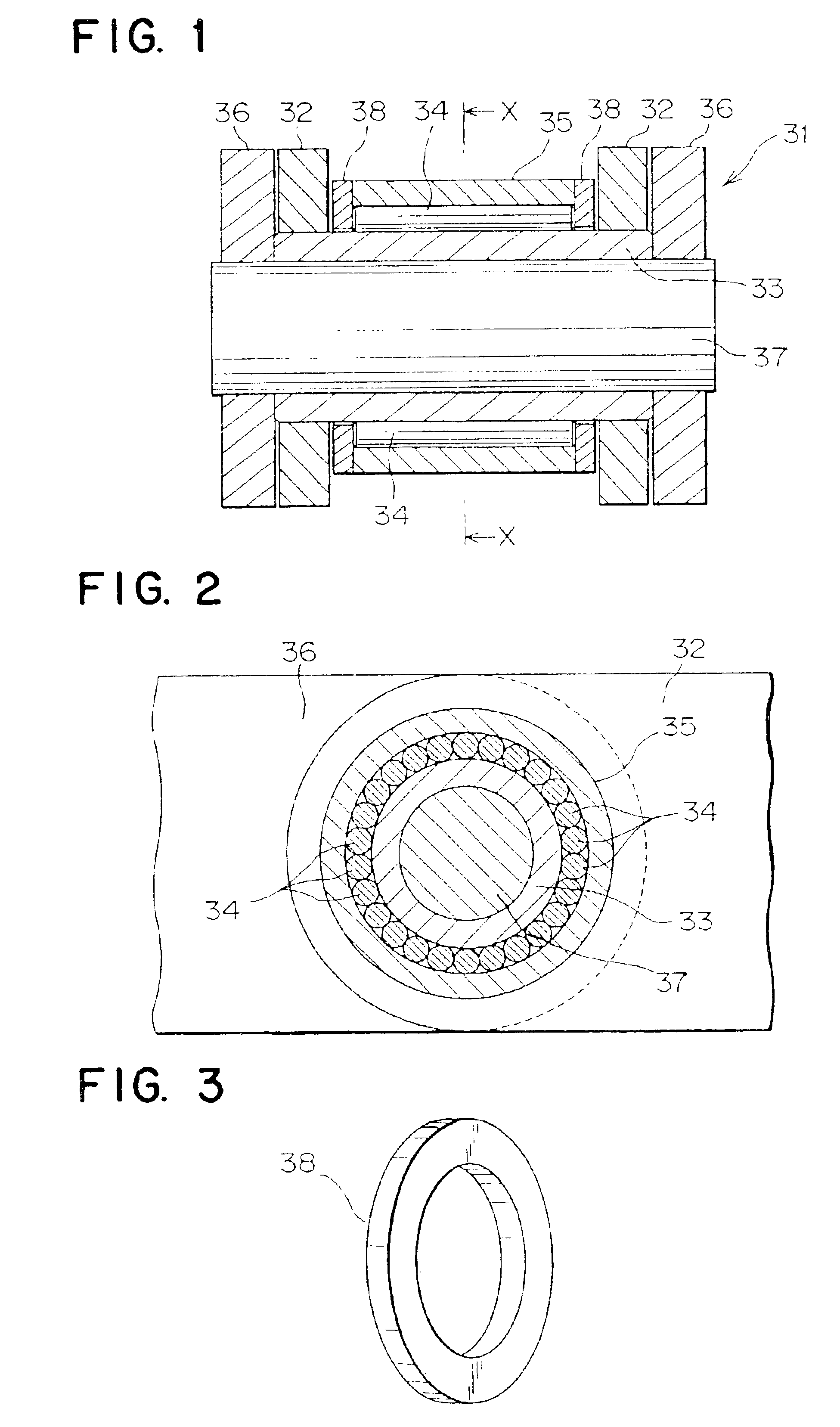

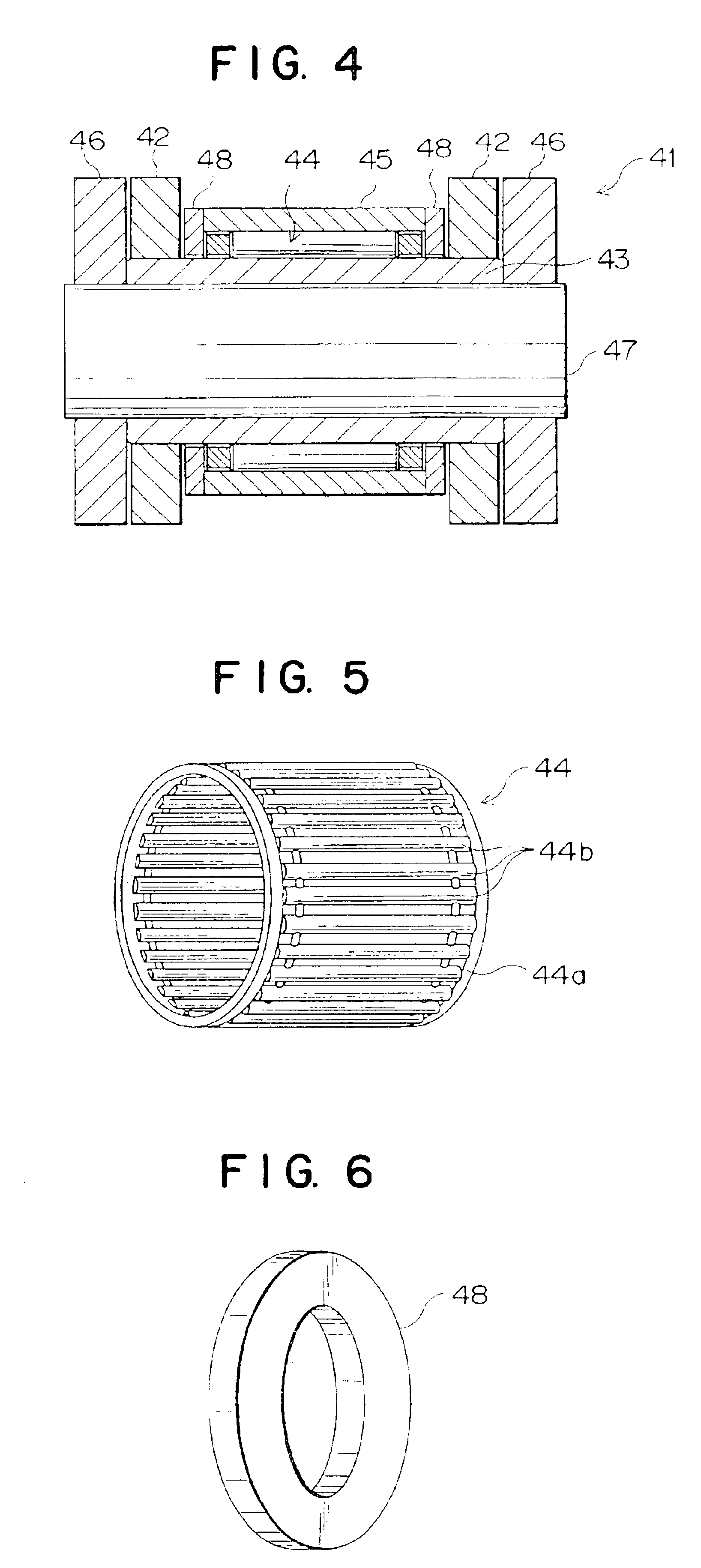

Chain

InactiveUS6855080B2Improve loading effectReduce weightRotary combination bearingsConveyorsProject areaThrust bearing

A roller chain incorporates a plurality of rolling members between a roller and a bushing. A thrust bearing plate is provided between the end surfaces of the roller and inside surfaces of inner link plates. The outer diameter of the roller is smaller than the widths of the inner link plates and the outer link plates and the roller is accomodated in a projected area of the widths of the inner link plates and the outer link plates.

Owner:TSUBAKIMOTO CHAIN CO

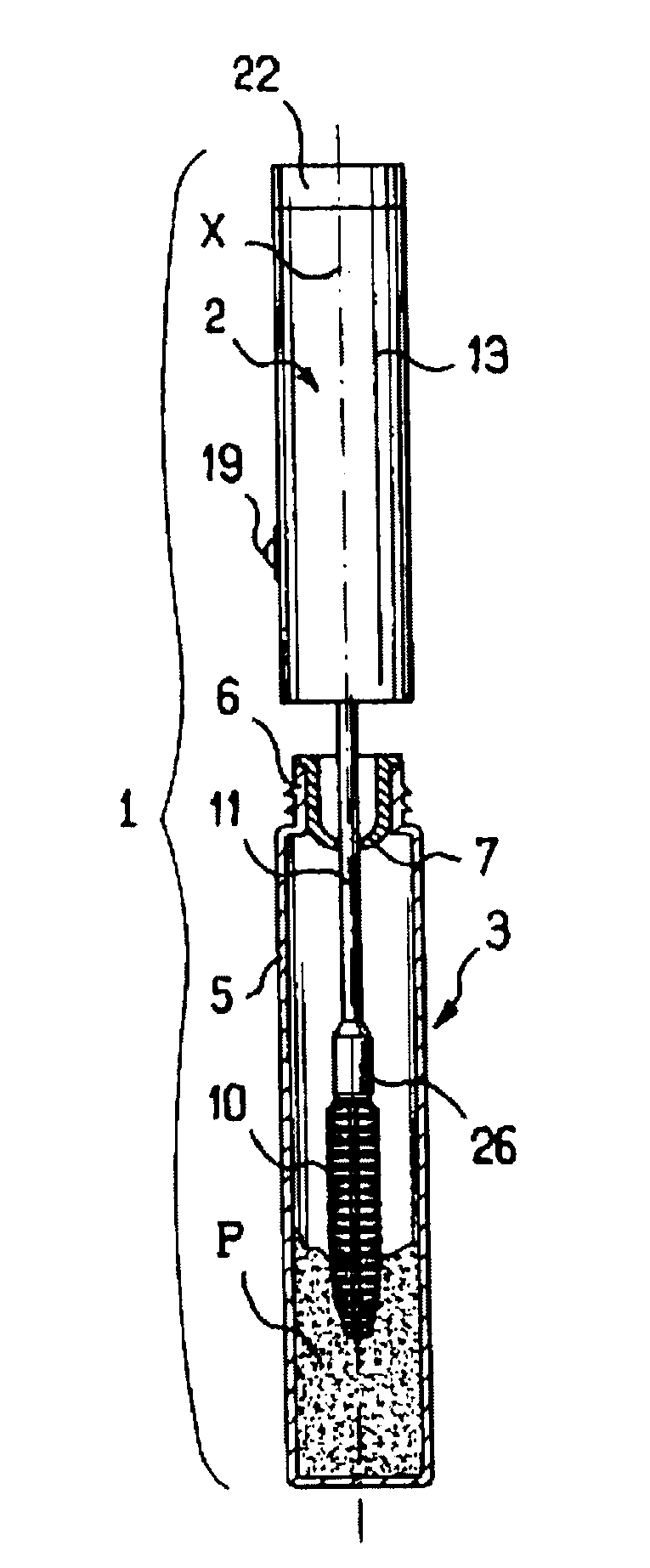

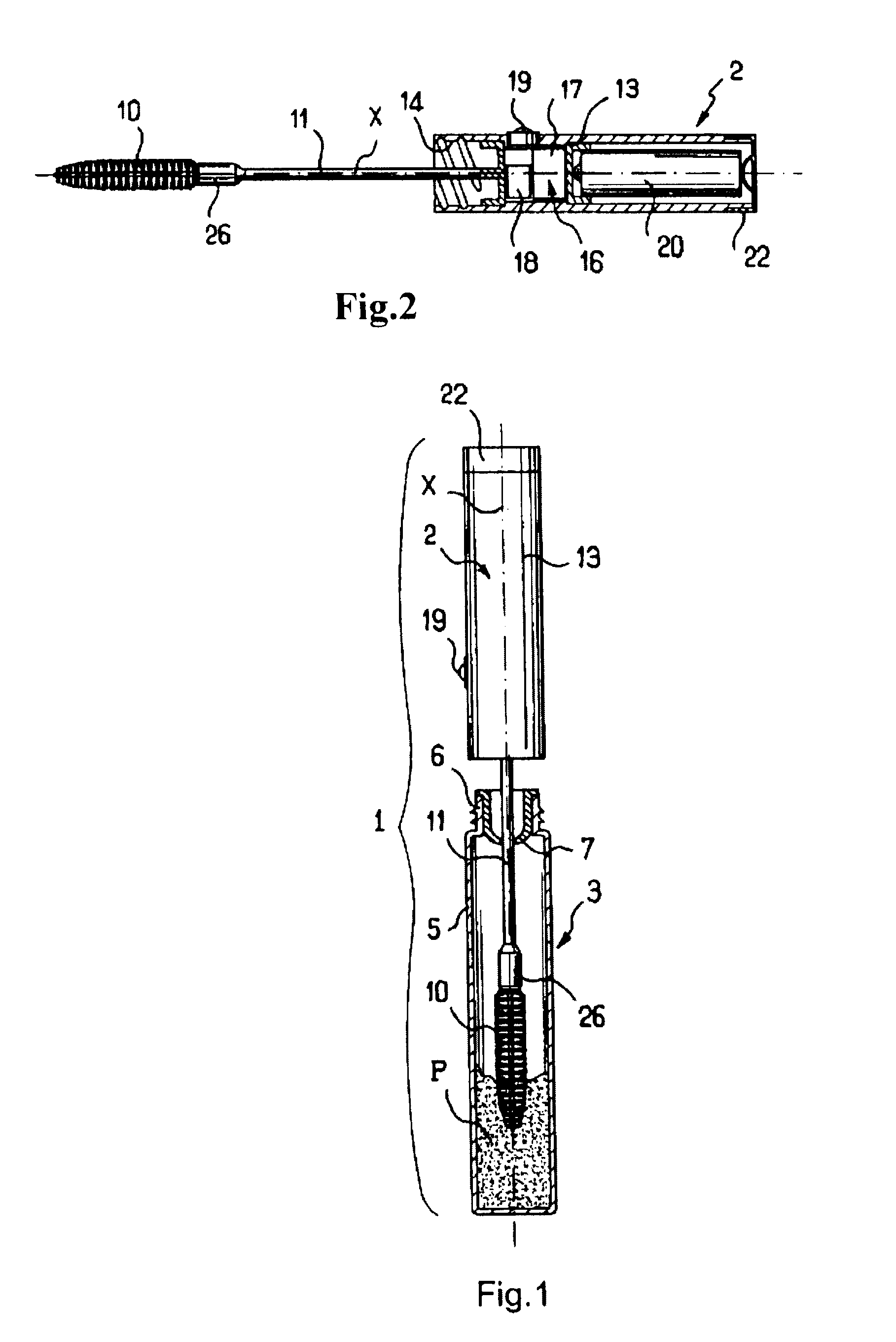

Eyelash makeup and/or care assembly

InactiveUS20100031969A1Optimization definitionImprove loading effectCosmetic preparationsHair removalEyelashSURFACTANT BLEND

Assembly and method for making up and / or caring for keratin material, the assembly containing:at least one composition containing platelet-shaped particles, at least one nonionic surfactant and / or at least one ionic surfactant and / or at least one polymeric surfactant, or at least one fatty-phase rheological agent, andat least one applicator having an application member and a vibrating source for making the application member vibrate.

Owner:LOREAL SA

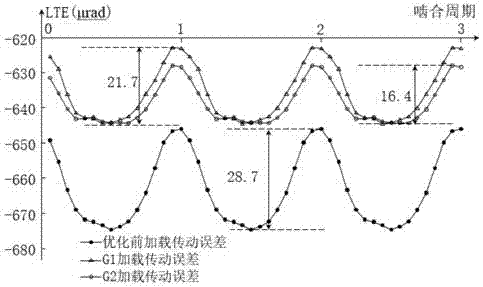

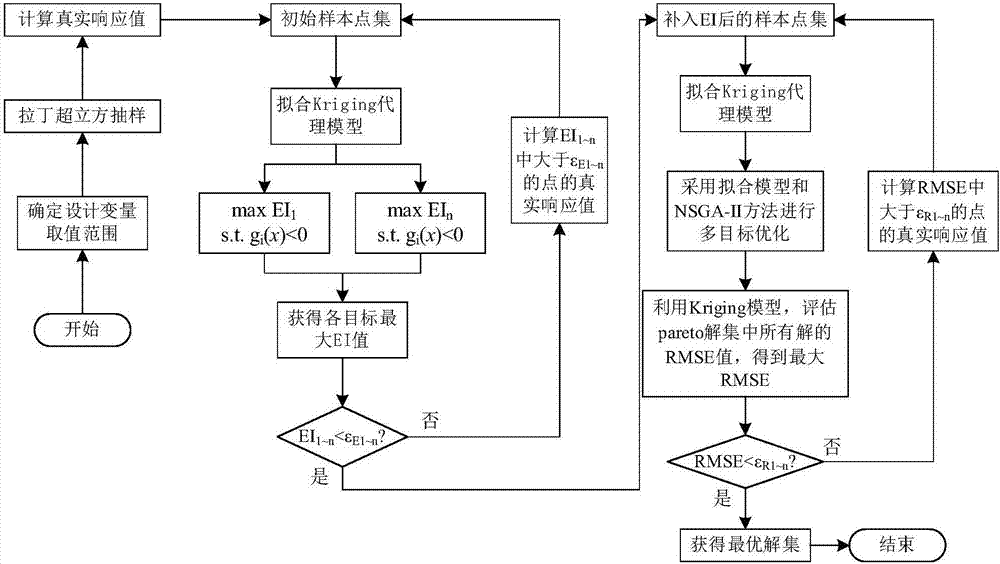

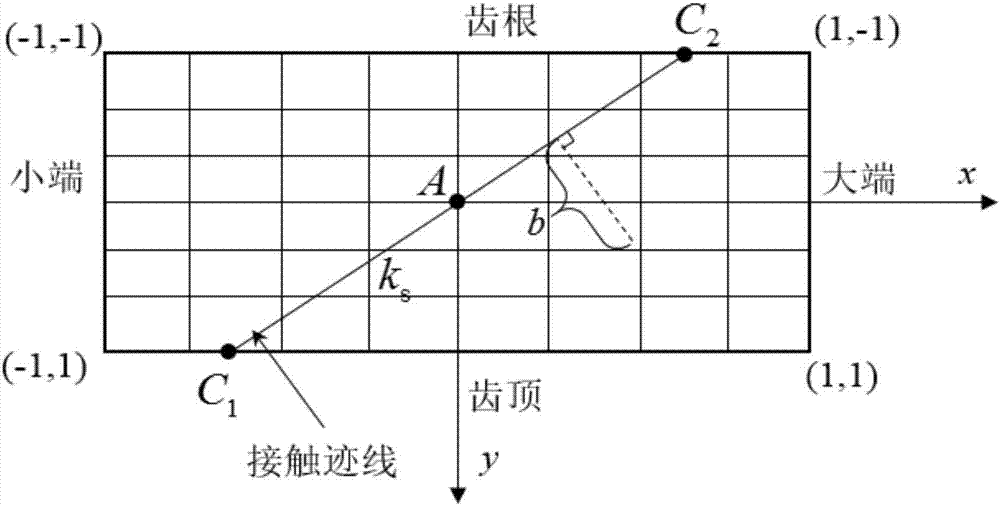

Spiral bevel gear tooth surface loading performance multi-objective optimization method

ActiveCN107577876AImprove loading effectAvoid broken teethSpecial data processing applicationsMathematical modelRooted tooth

The invention relates to a spiral bevel gear tooth surface loading performance multi-objective optimization method. The method is characterized by comprising the following steps that firstly, a mathematical model of a spiral bevel gear tooth surface loading performance multi-objective optimization problem is established, and test design sample points are obtained; secondly, a tooth surface loadingcontact analysis method considering tooth root bending stress is established, tooth surface loading contact analysis is conducted on the test design sample points, target functions corresponding to the test design sample points and response values of the target functions are obtained, and then an initial sample point set including the test design sample points and the corresponding response values is obtained; thirdly, a Kriging proxy model is fitted on the basis of the initial sample point set, the mathematical model of the spiral bevel gear tooth surface loading performance multi-objectiveoptimization problem is solved, and the optimal solution set of the spiral bevel gear tooth surface loading performance multi-objective optimization problem is obtained. The method is high in calculation efficiency, high in calculation accuracy and capable of being widely applied to spiral bevel gear tooth surface loading performance multi-objective optimization.

Owner:TSINGHUA UNIV +1

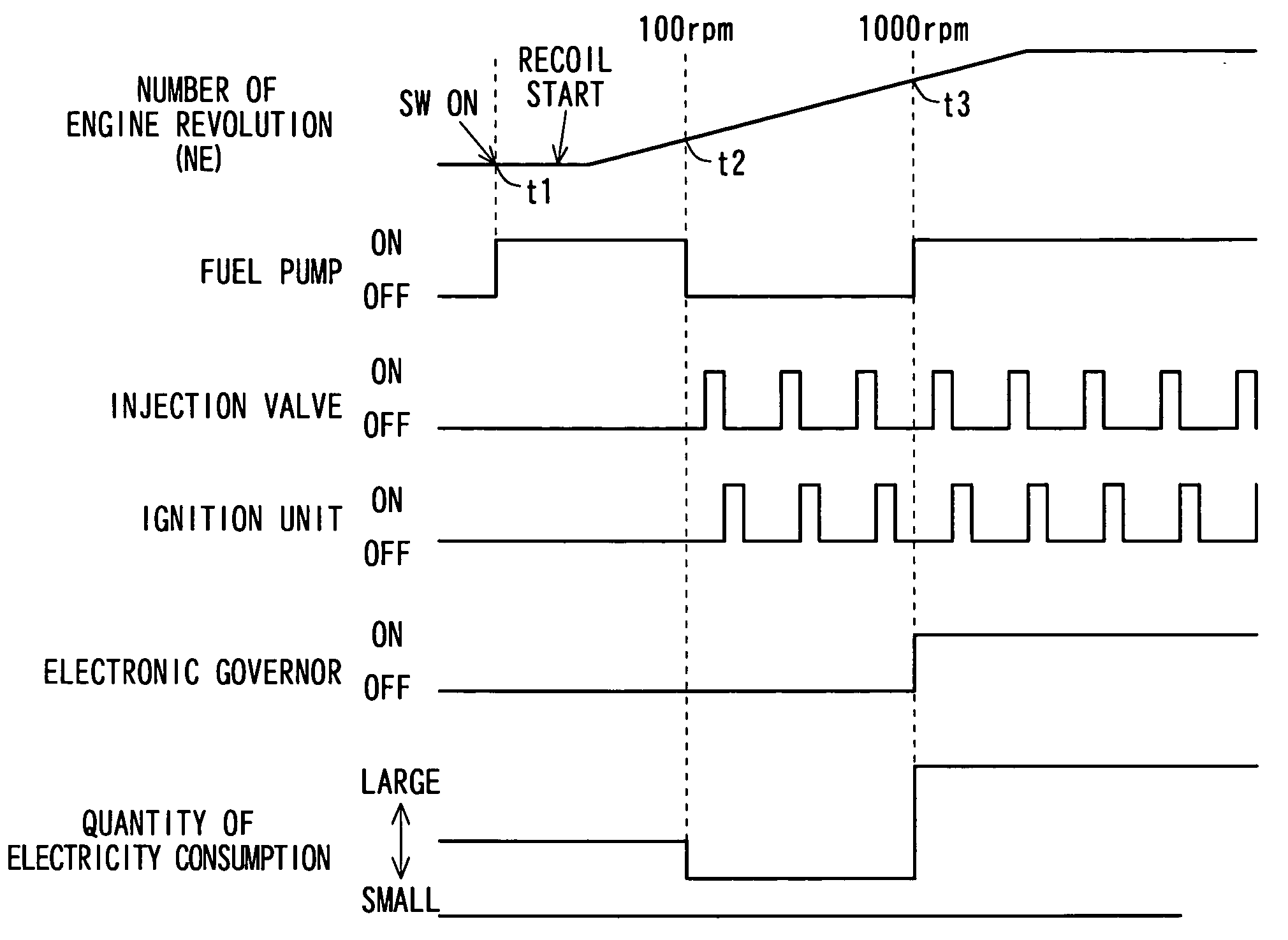

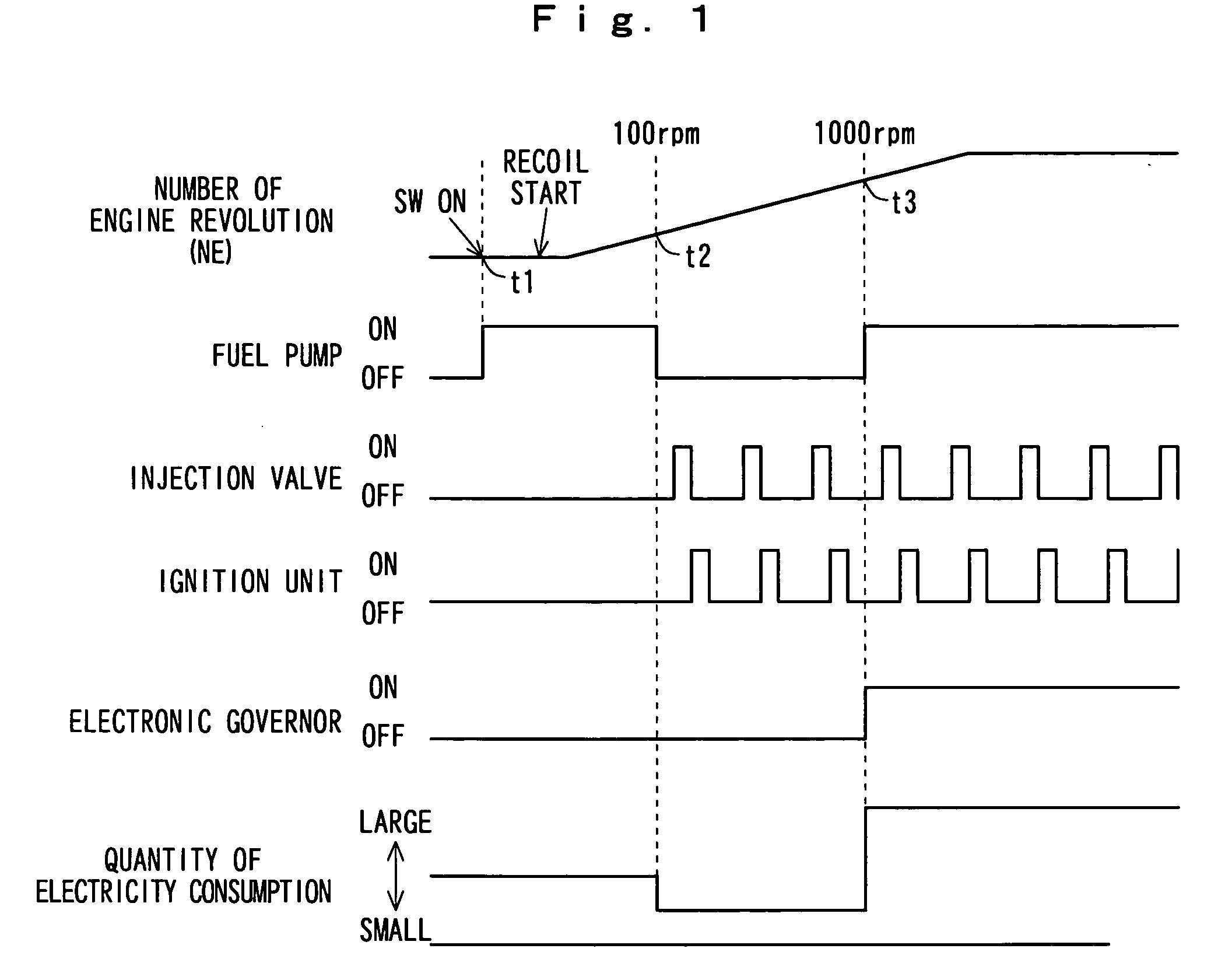

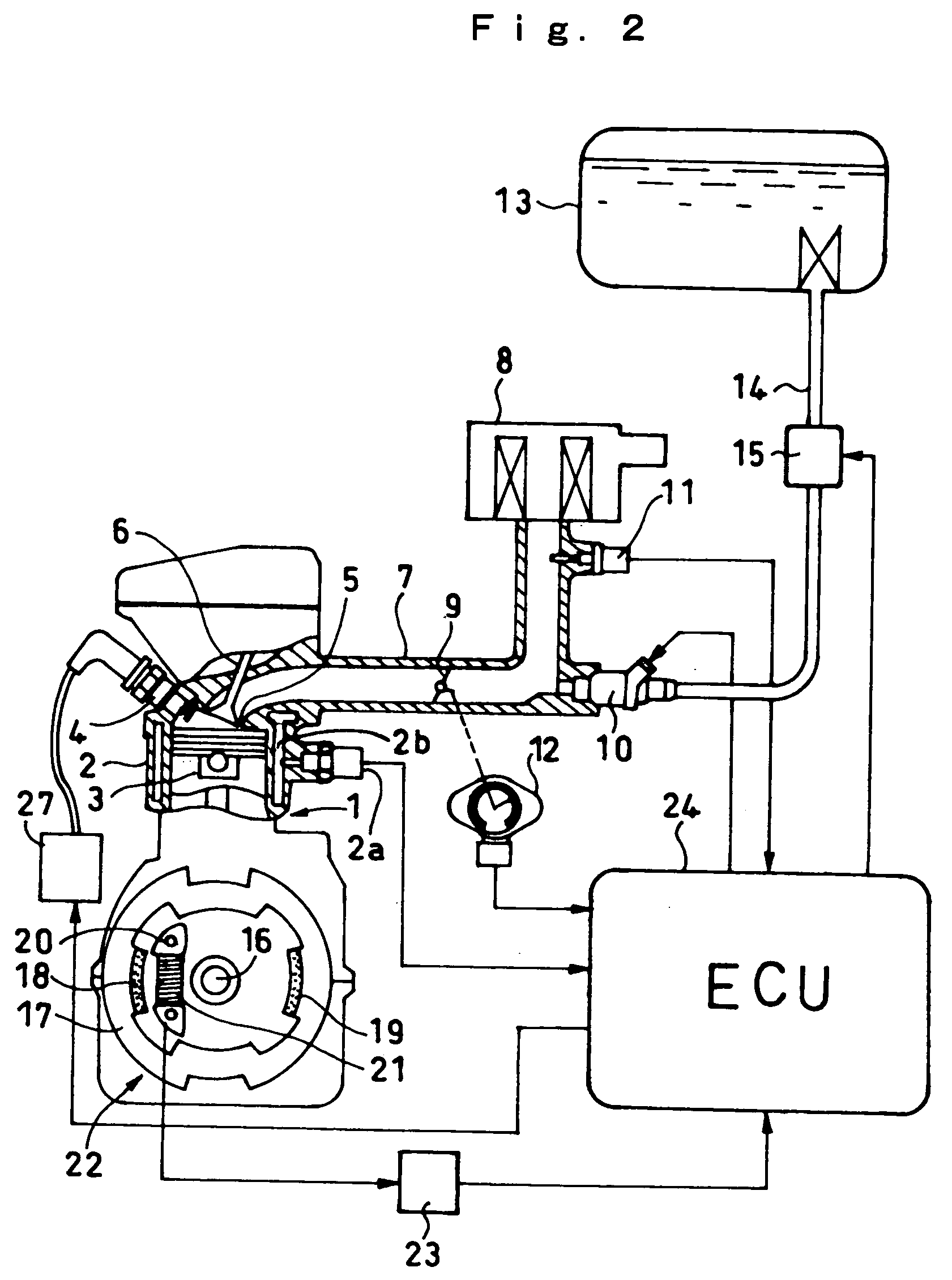

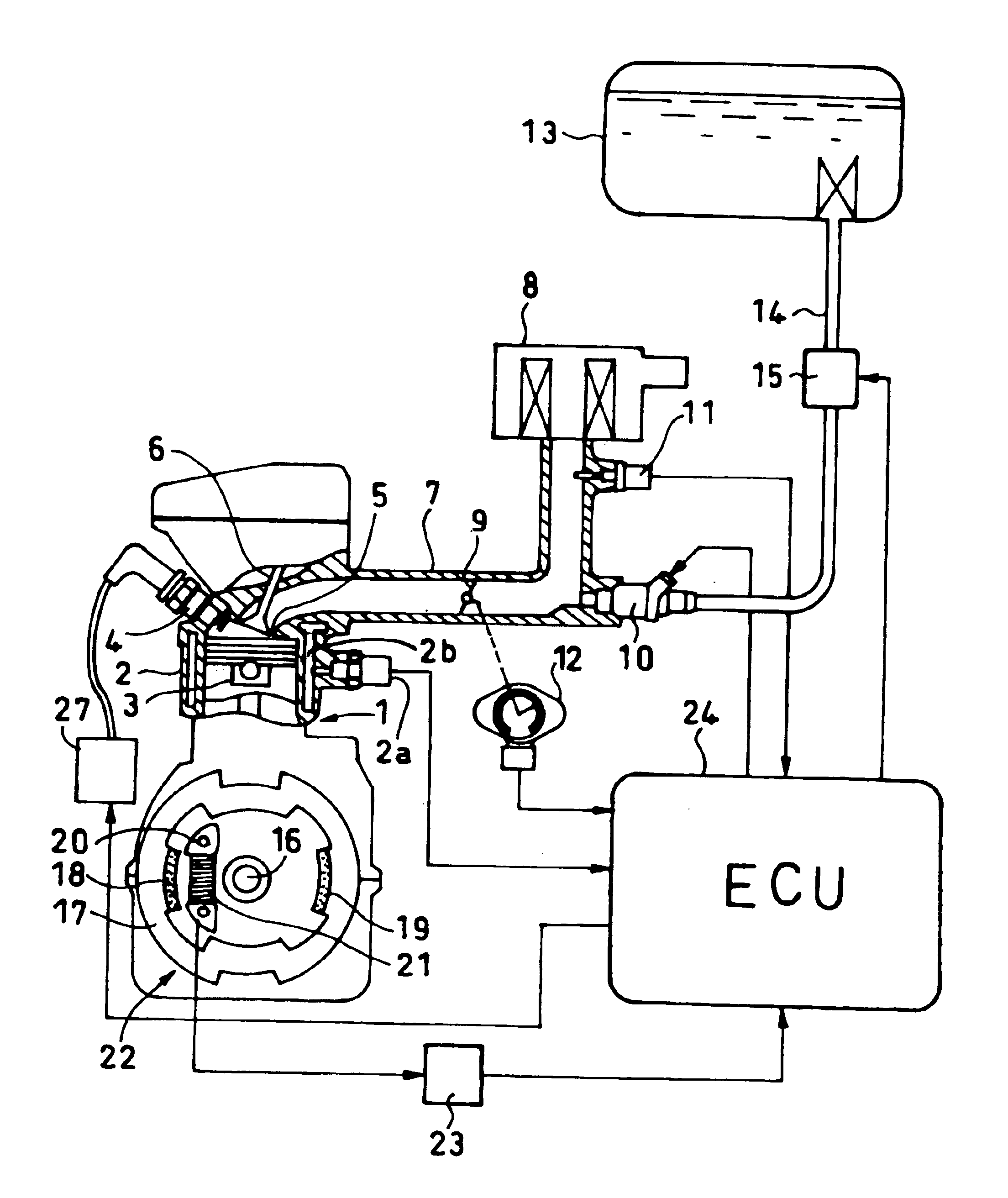

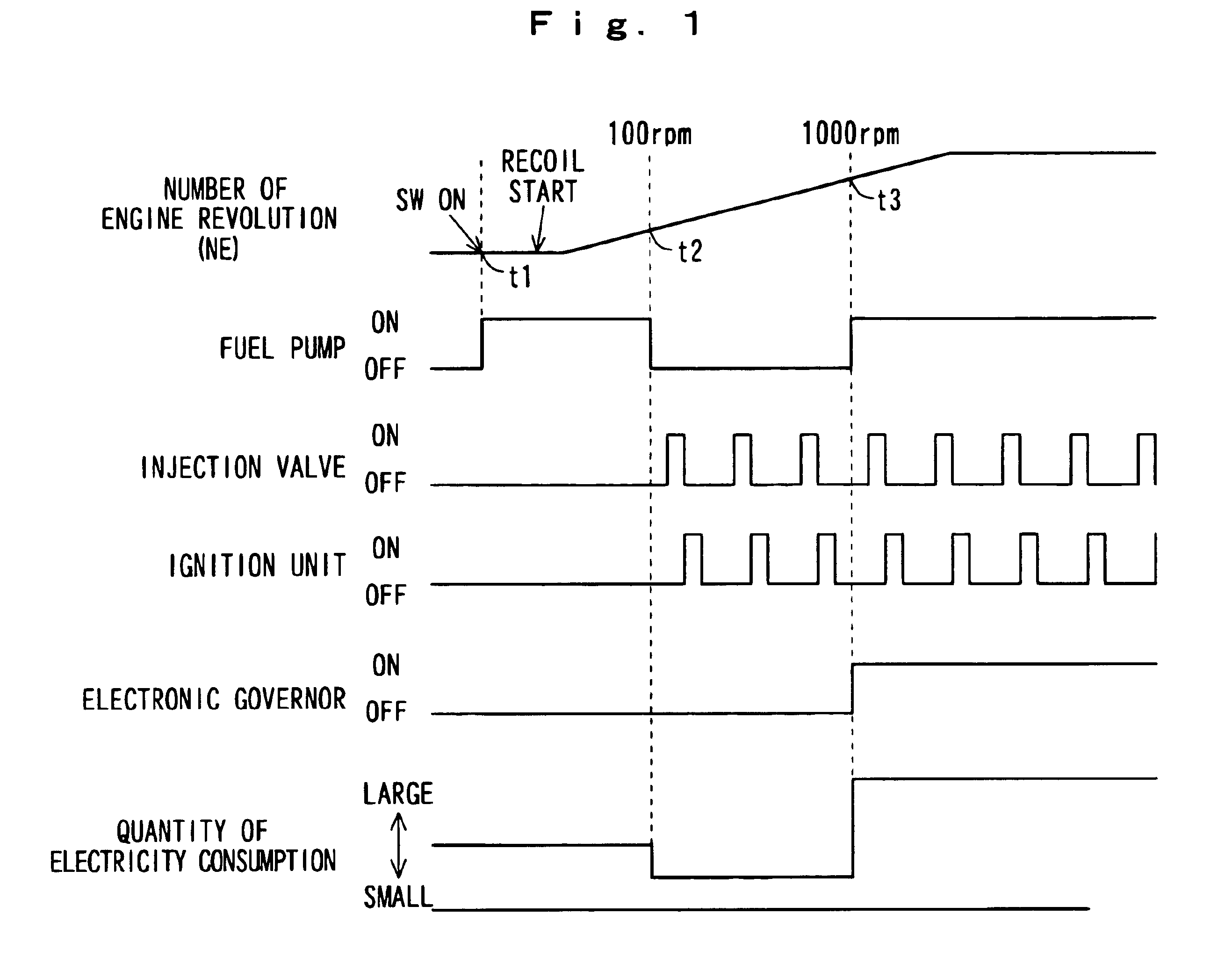

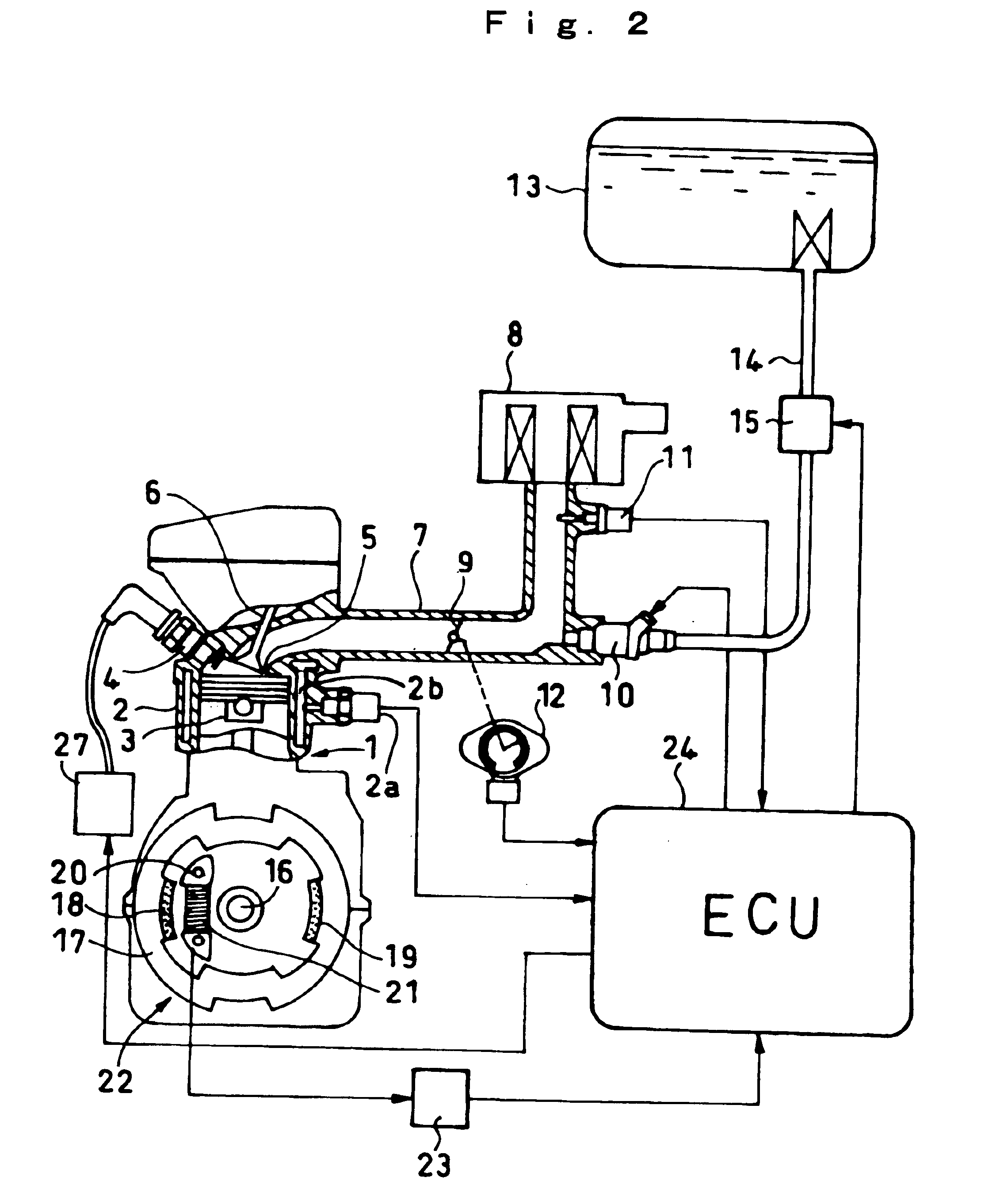

Electronic controlled fuel injection apparatus of internal combustion engine

InactiveUS20050005914A1Improve loading effectImprove charging effectElectrical controlMuscle operated startersGeneral purposeElectricity

The invention intends to downsize a general-purpose engine generator and make operability thereof easy. A backup battery (233) is provided for the generator (22). The battery supplies electricity to an electronic controlled device such as a fuel pump for starting the engine. When the engine (1) carries out a rating operation, electricity is supplied from the generator (22). When the engine speed is in a low speed range, only a pump (15) is driven. When the engine speed is exceeds the low speed range, the pump (15) is stopped, and an injectors (10) and (27) are driven to be prevented from lapping over each other. When the engine speed reaches a high-speed range, the pump (15) is again driven. Electricity consumption at a time of starting is restricted by driving the electronic controlled devices at different timings until the engine (1) executes a self-sustaining.

Owner:HONDA MOTOR CO LTD

Isotropic atomic layer etch for silicon oxides using no activation

ActiveUS20160329221A1High selectivityReduce defective rateElectric discharge tubesSemiconductor/solid-state device manufacturingActivation methodSelf limiting

Methods for controlled isotropic etching of layers of silicon oxide and germanium oxide with atomic scale fidelity are provided. The methods make use of NO activation of an oxide surface. Once activated, a fluorine-containing gas or vapor etches the activated surface. Etching is self-limiting as once the activated surface is removed, etching stops since the fluorine species does not spontaneously react with the un-activated oxide surface. These methods may be used in interconnect pre-clean applications, gate dielectric processing, manufacturing of memory devices, or any other applications where accurate removal of one or multiple atomic layers of material is desired.

Owner:LAM RES CORP

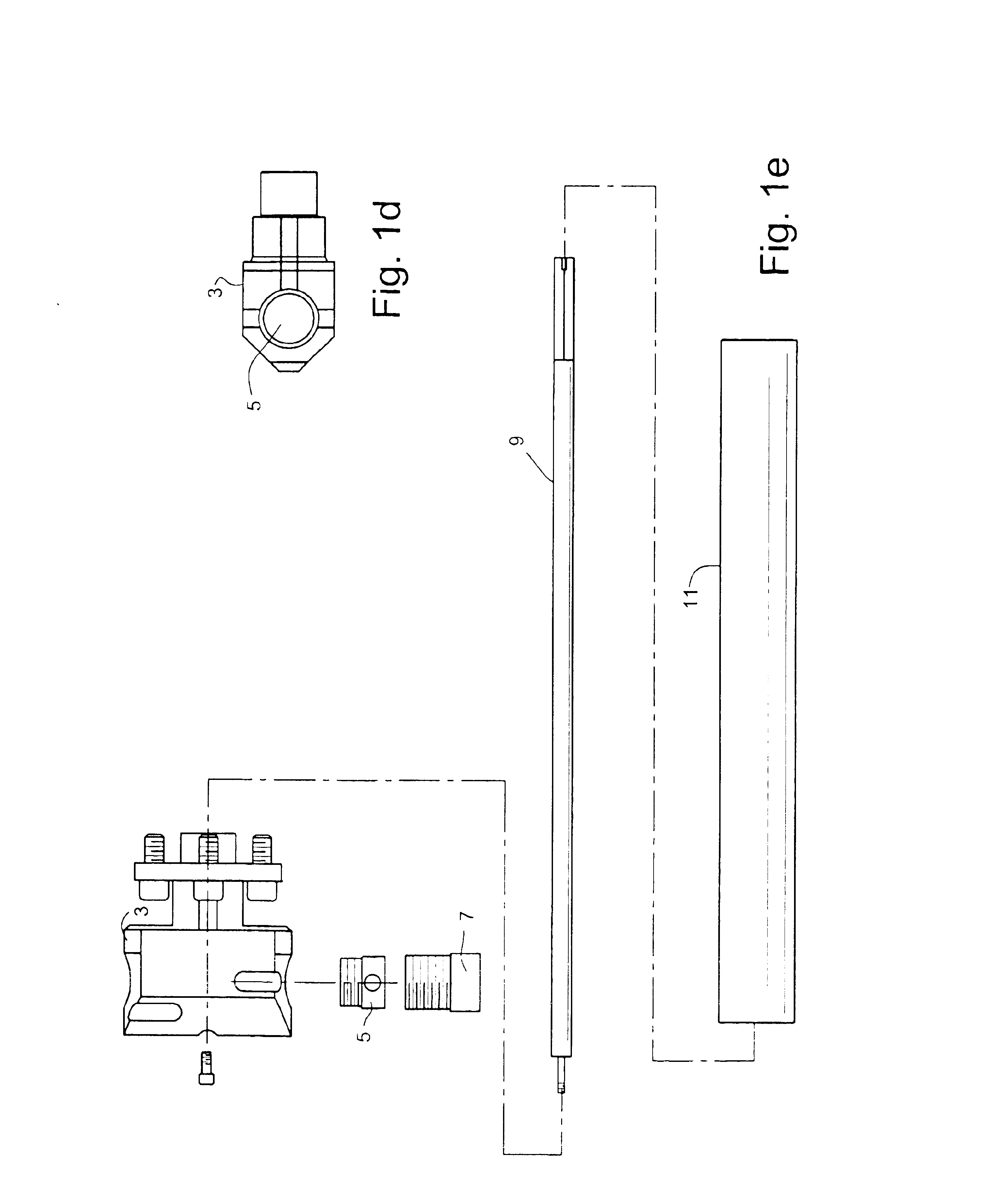

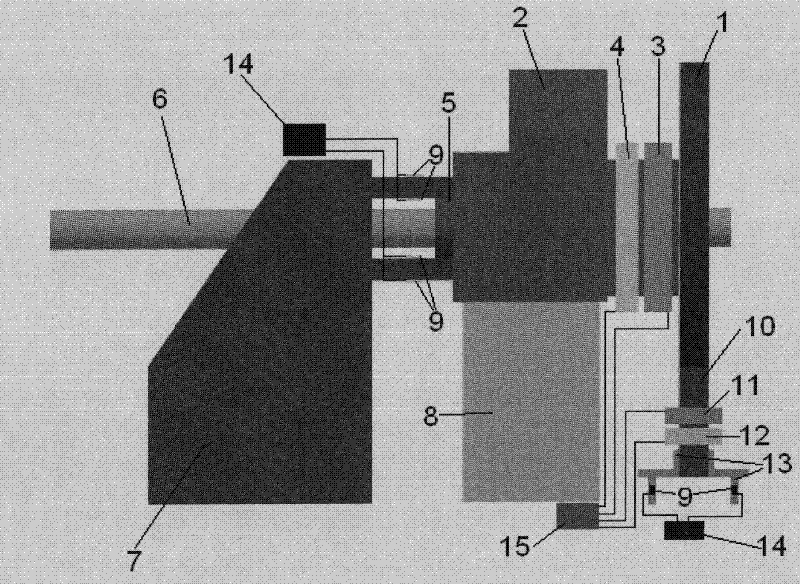

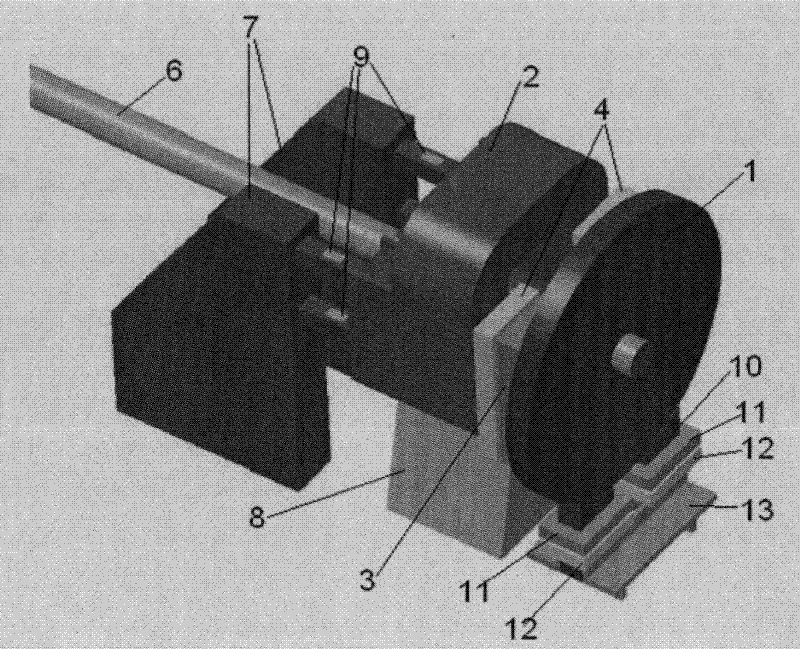

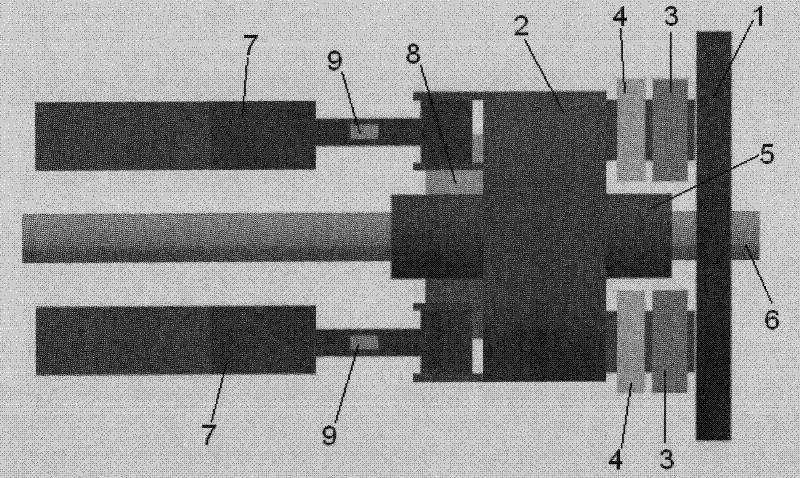

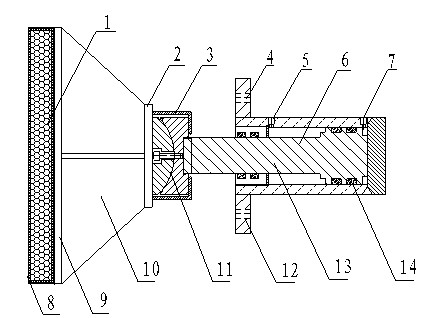

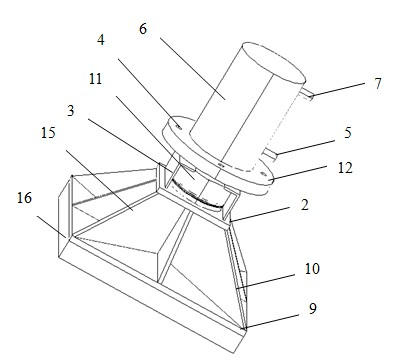

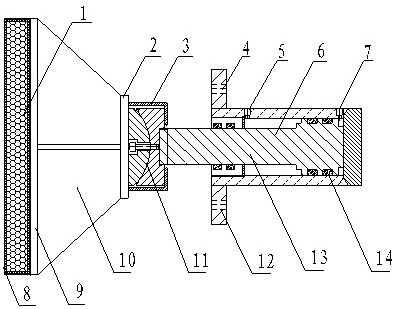

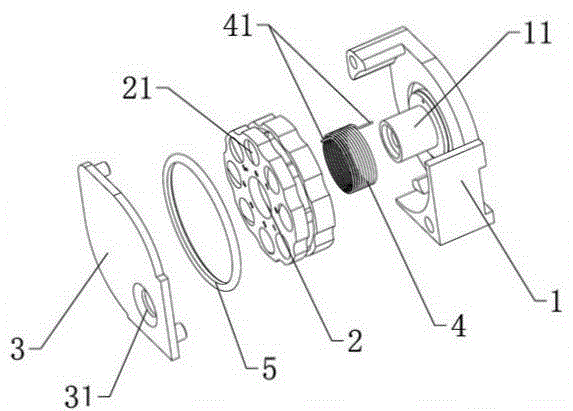

Electromagnetic excitation shaft loading device

The invention discloses an electromagnetic excitation shafting loading device. The electromagnetic excitation shafting loading device is composed of an axial loading device, a radial loading device, an armature, a current generating device and a load measuring device. The axial loading device and the radial loading device are respectively used for exerting the axial and radial loads on the shafting. The static and dynamic loads can be simultaneously loaded by using the electromagnet principle, and the static load also can be only loaded. The loaded load is controlled by the input current; the loaded dynamic load can be a single-frequency exciting force, and can be the combination of a plurality of exciting forces. The invention provides a new technical approach for simulating ship shafting vibration and ship stern vibration caused by the ship propeller exciting force and the ship structure noise caused by these vibrations, realizes the contact-free and friction-free purpose of the shafting; the loading of the precise single-frequency sine wave exciting force and the loading of the combined waveform exciting force are mainly used for the excitation experiment of the ship shafting experiment table or ship shafting berth, and can be further used for the excitation experiment underwater.

Owner:周其斗 +2

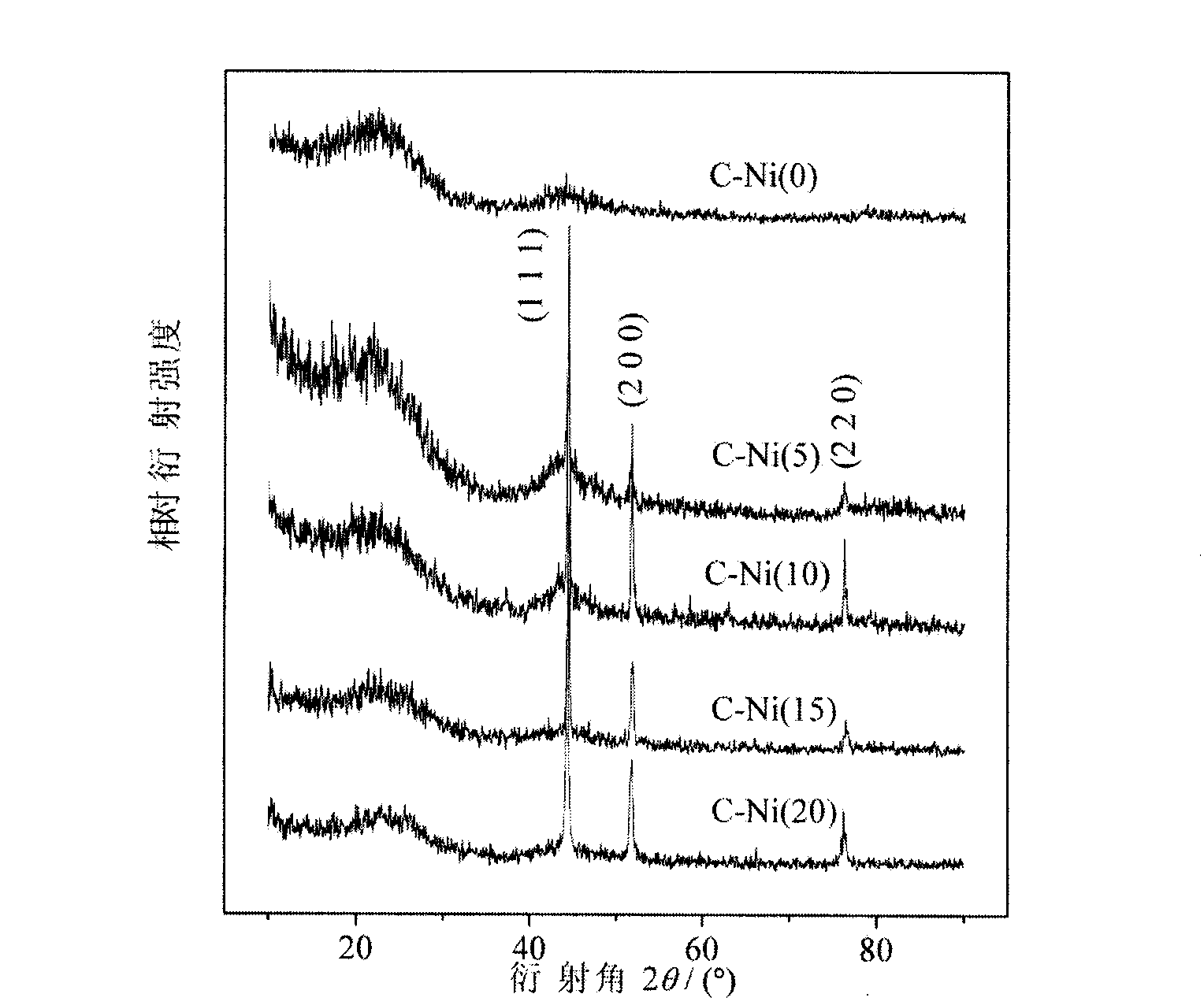

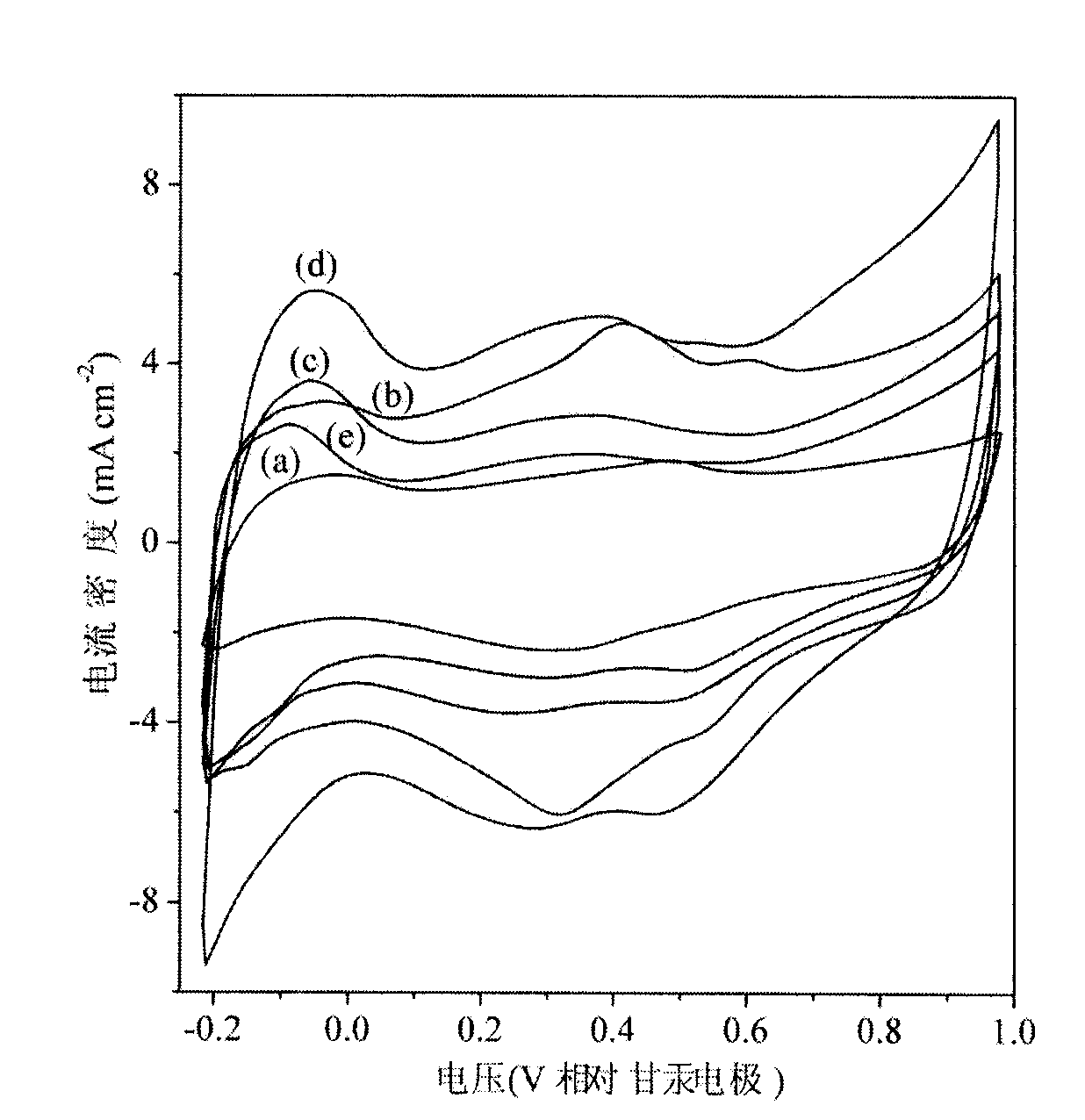

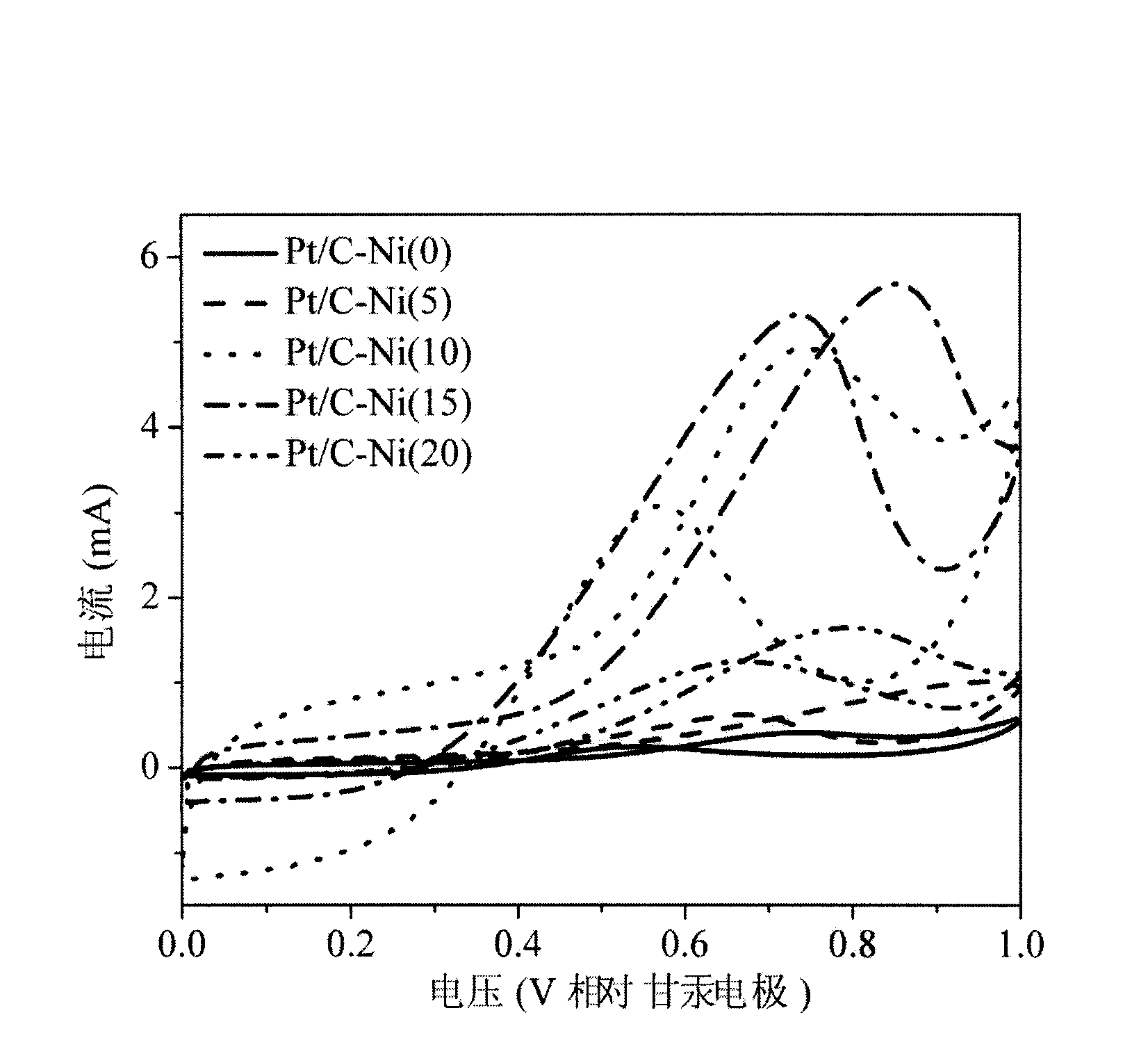

Nickelous chloride assisted synthesis method of fuel cell catalyst carrier ordered mesoporous carbon

InactiveCN101491777APrevent collapseImprove conductivityCatalyst carriersCell electrodesChemistryMetallic Nickel

The invention relates to a method for the nickel chloride-aided synthesis of fuel cell catalyst carrier ordered mesoporous carbon, which belongs to a preparation process of a direct methanol fuel cell catalyst. The method can produce carbon-carried Pt catalyst with excellent performance by adopting in-situ carbon thermal reduction technique and a unique binary metal loading method and is applicable to oxyhydrogen proton exchange membrane fuel cells and direct methanol fuel cells. The method produces a binary electrocatalyst by using a metal chloride as an additive, synthesizing the ordered mesoporous carbon with a modified soft template self-assembly method, forming a metal nanocrystal through carbon thermal reduction, and loading Pt nano particles with a microwave heating glycol reduction method. The catalyst has excellent electrocatalysis performance and substantially increases the catalytic activity and utilization rate of Pt, thereby having enormous application prospect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

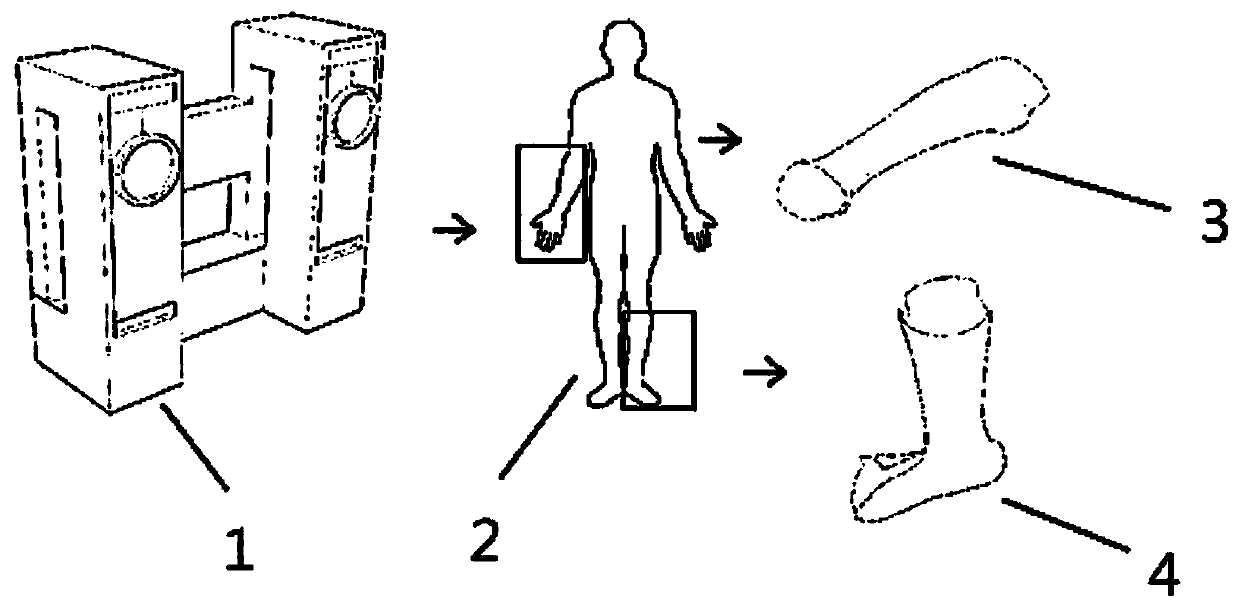

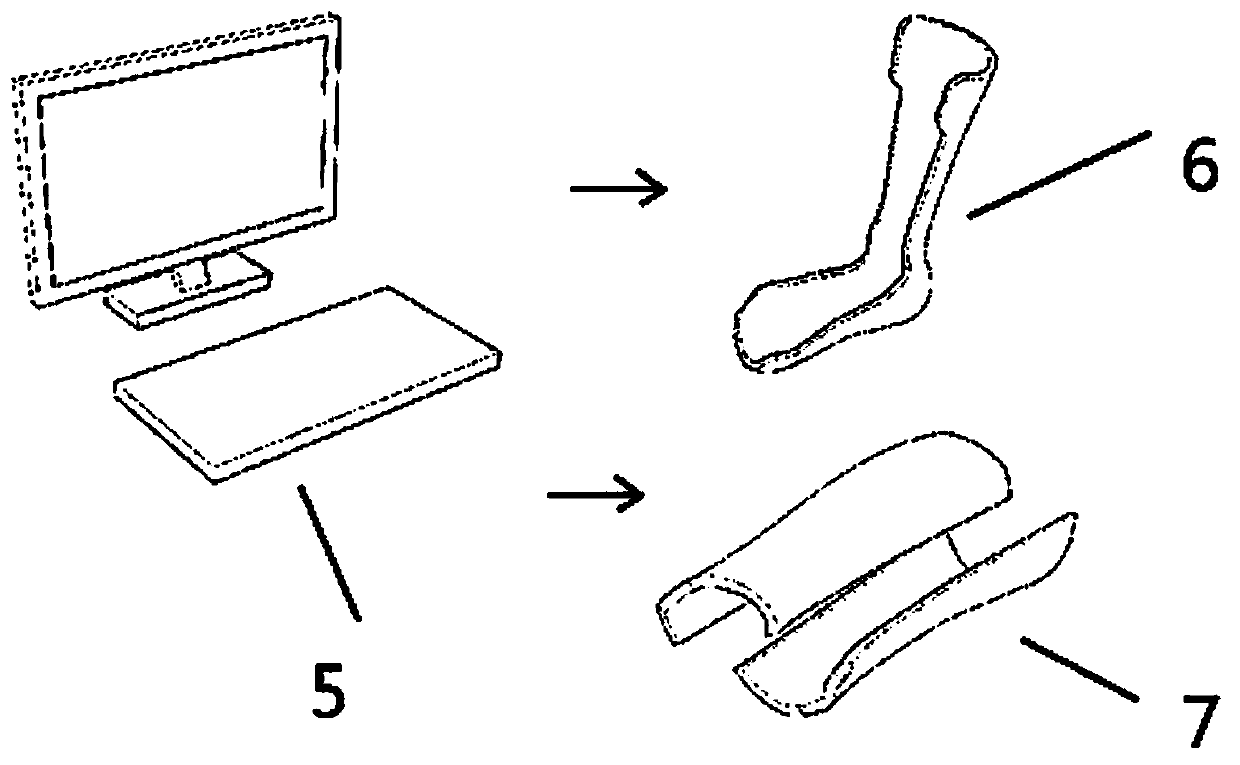

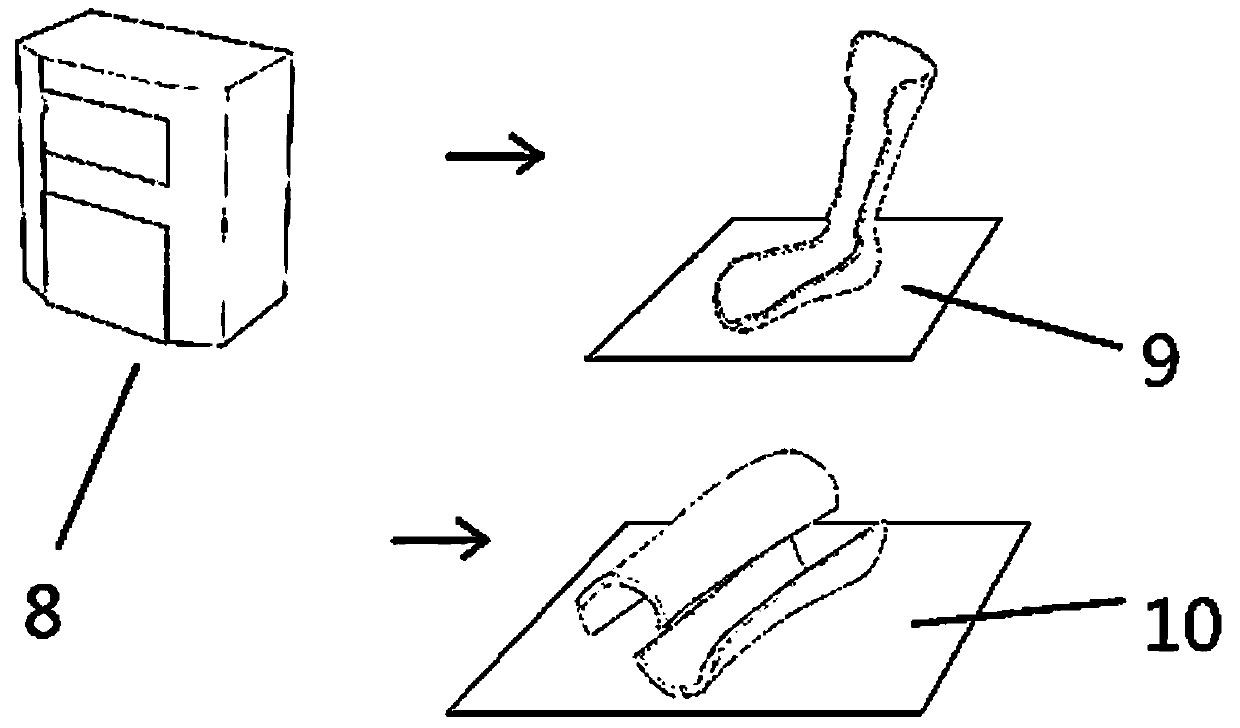

Combined machining method for SLA orthosis formed by three-dimensional printing

ActiveCN104814808A3D scanning is convenientDigital prosthetic orthopedic preciseProsthesisDigital mockup3 dimensional printing

The invention discloses a combined machining method for a SLA orthosis formed by three-dimensional printing. The method comprises the following steps: in the digital model design stage of an orthosis, the wall thickness of the orthosis is set to be 0.7-1.0 mm, and the digital model is molded through a three-dimensional printing process; the inner side of an orthosis SLA housing is coated with a release agent which serves as a demoulding layer, and a semi-water fibrous plaster is injected and serves as an internal support after curing; the outer side of the orthosis SLA housing is coated with a resin fiber coating layer to form a composite reinforcing layer; and finally, heating is performed to cure the resin fiber coating layer, and then the only requirement is to remove the plaster support. The combined machining method solves the problem that a pure SLA material has high probability of ageing and brittle rupture and is relatively high in cost and high in probability of deformation once heated; the consumption of a SLA material is reduced by 40-65%, and both resin and fibers are low in price, so that the cost is greatly reduced; the softening temperature of the orthosis subjected to combined machining is increased by 15-25 DEG C; and the combined machining material is favorable in ductility and the loading performance of the combined machining material is increased by 3 to 5 times compared with that of the pure SLA material.

Owner:REGENOVO BIOTECH

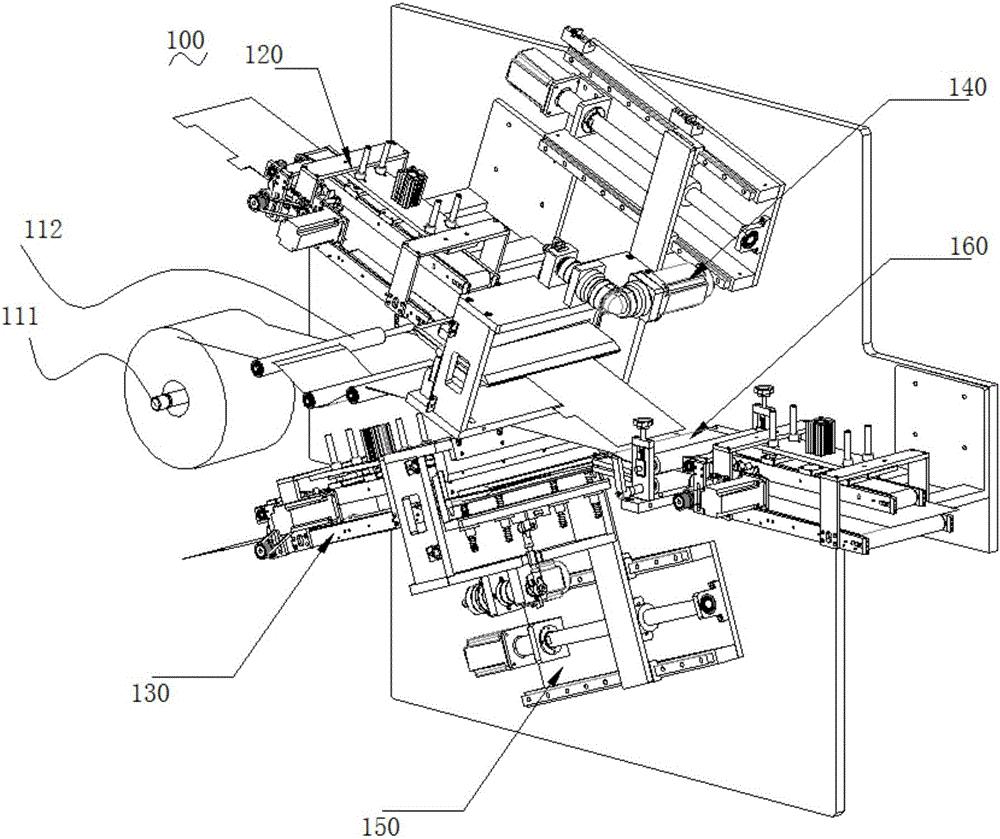

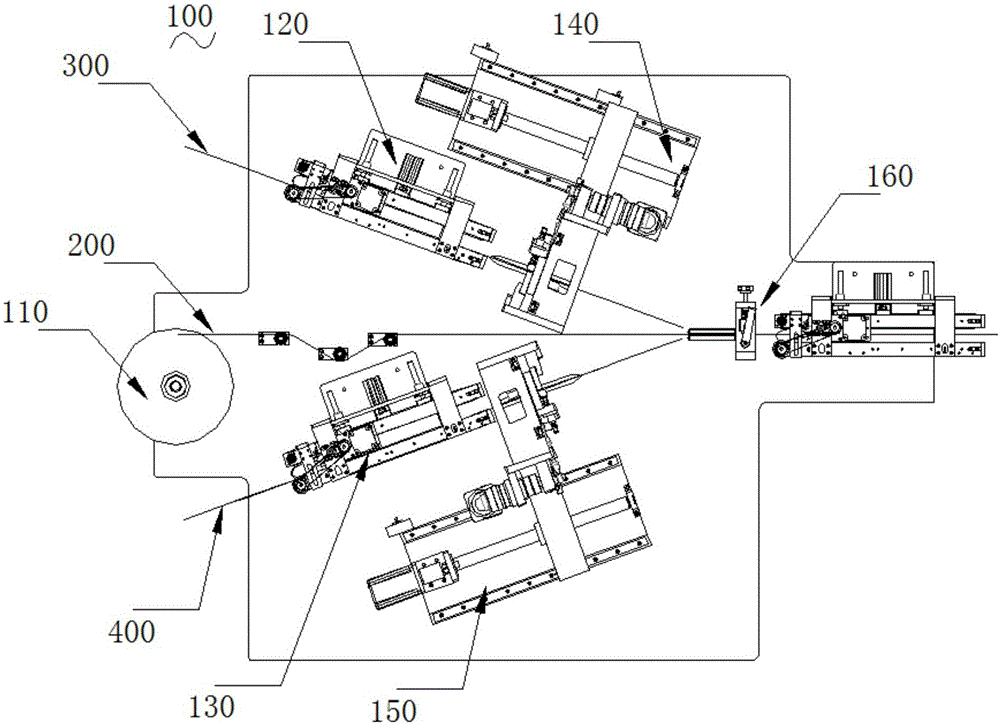

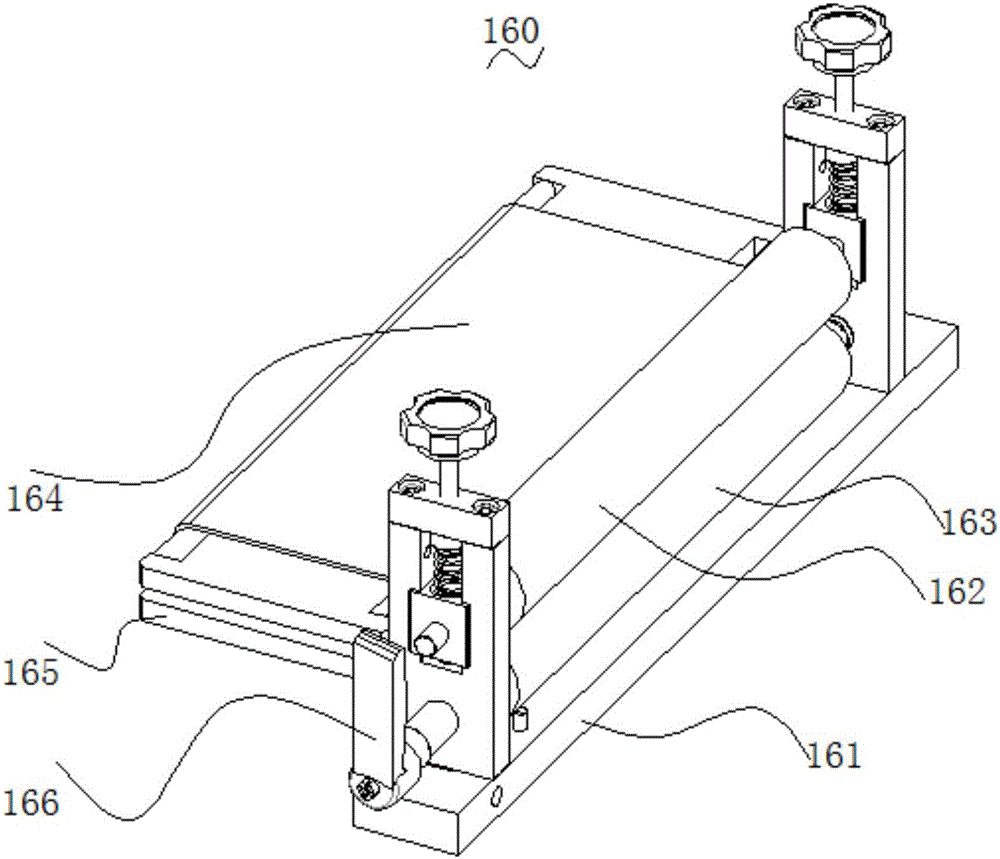

Pole piece loading device for battery cell winding lamination stacking machine

ActiveCN105789678AGuaranteed alignmentAvoid short circuitLamination ancillary operationsFinal product manufactureStack machineEngineering

The invention relates to the technical field of battery pole piece processing equipment, in particular to a pole piece loading device for a battery cell winding lamination stacking machine. The pole piece loading device comprises a diaphragm loading assembly, a positive electrode loading assembly, a negative electrode loading assembly, a positive electrode cutting assembly, a negative electrode cutting assembly and a hot-pressing fusion assembly for integrating a positive electrode piece, a negative electrode piece and a diaphragm as a whole, wherein an output end of the diaphragm loading assembly is connected to the hot-pressing fusion assembly; the positive electrode loading assembly and the negative electrode loading assembly are correspondingly arranged on two sides of a connecting line between the diaphragm loading assembly and the hot-pressing fusion assembly; the positive electrode cutting assembly and the negative electrode cutting assembly are correspondingly arranged on two sides of the connecting line between the diaphragm loading assembly and the hot-pressing fusion assembly; the positive electrode cutting assembly is located behind the positive electrode loading assembly; the negative electrode cutting assembly is located behind the negative electrode loading assembly; the hot-pressing fusion assembly is located behind the positive electrode cutting assembly and the negative electrode cutting assembly. The pole piece loading device provided by the invention is simple in structure, high in efficiency, stable to operate and good in lamination effect.

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

High-strength network structured nano-carrier material and preparation method and application thereof

A high-strength network structured nano-carrier material and a preparation method and application thereof. A nano-cellulose solution and graphene are mixed and ultrasonication is performed in an ultrasonic pulverizer to obtain a nano-cellulose / graphene suspension. The suspension with a phenolic resin adhesive is mixed and stirred to obtain a nano-cellulose / graphene / phenolic resin suspension. The nano-cellulose / graphene / phenolic resin suspension is injected into a mold. The mold is placed in a freeze dryer for freezing and vacuum dried in two stages to obtain a nano-cellulose / graphene / phenolic resin aerogel. The aerogel is preheated and cured in a muffle furnace, then subjected to a high-temperature thermal decomposition treatment in a tube furnace to obtain a nano-carrier material having a high-strength network structure. The preparation method is simple and convenient, low in cost, environmentally friendly and green. The obtained carrier material has a good water resistance and a high mechanical property, and can carry more active substances.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

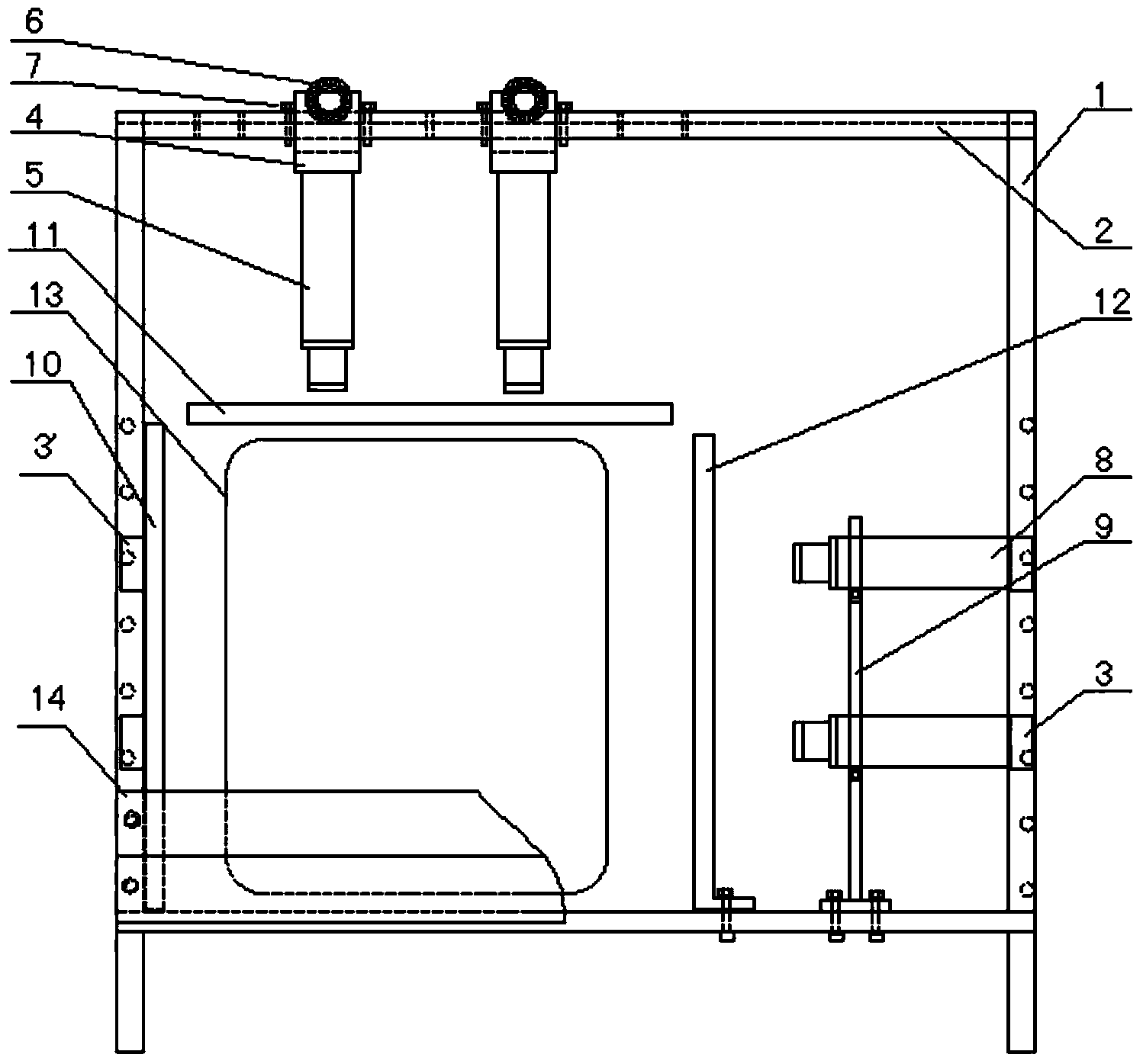

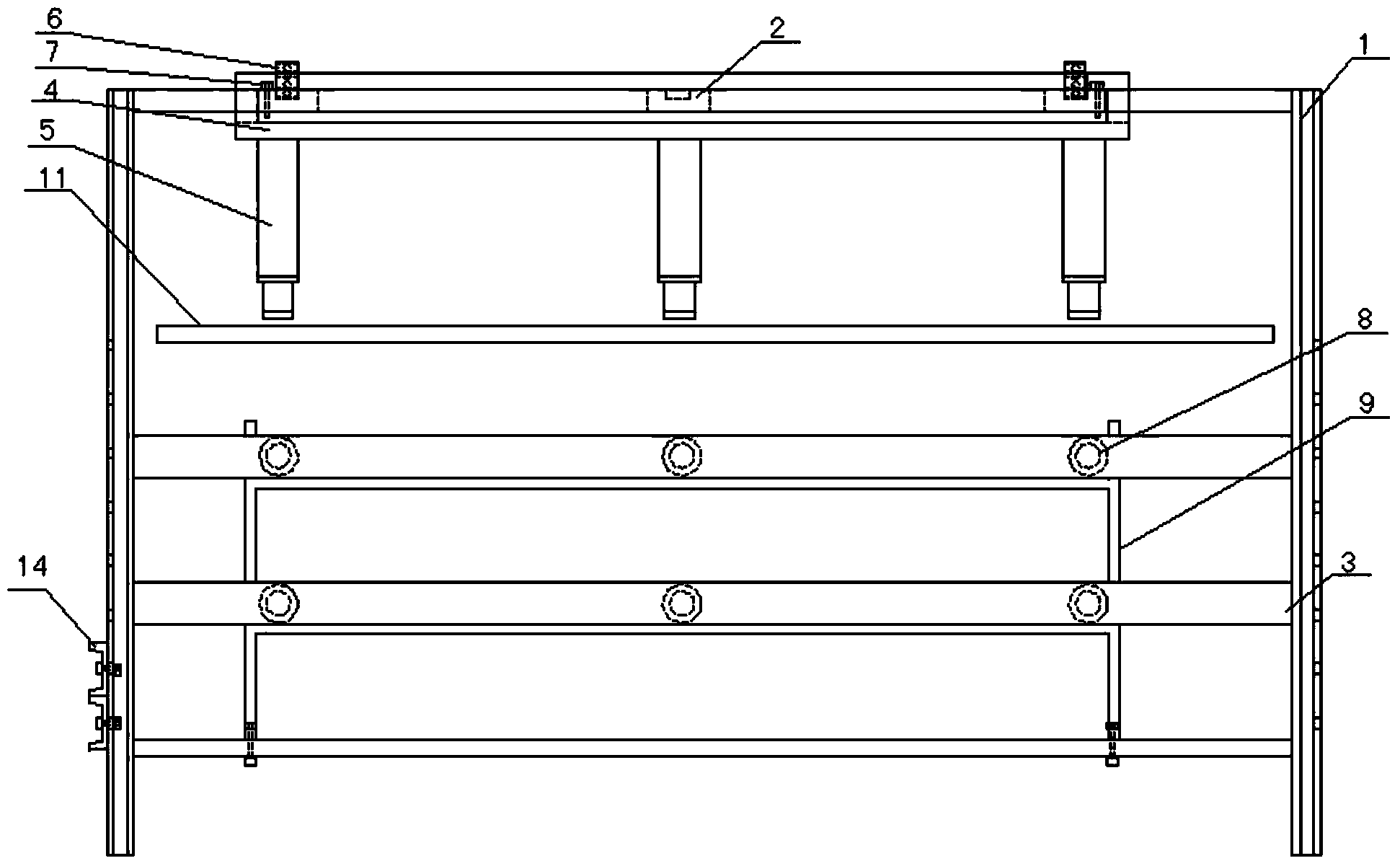

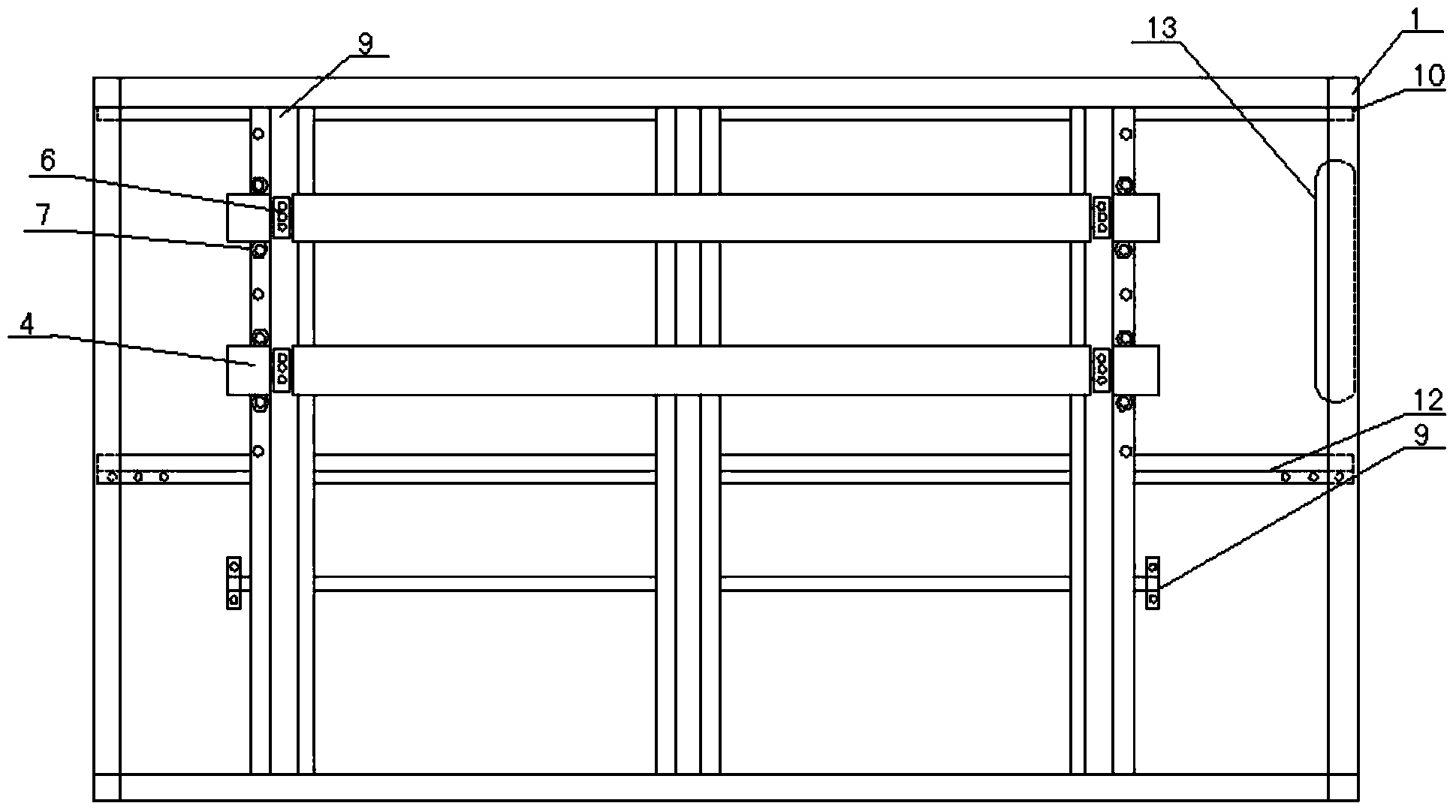

Pressurizing device for anchor rod pull-out test for simulating surrounding rock stress of anchoring body

InactiveCN103512805AOvercome the phenomenon of large deviation of forceReasonable designMaterial strength using tensile/compressive forcesFree stateStress variation

A pressurizing device for an anchor rod pull-out test for simulating surrounding rock stress of an anchoring body comprises a rectangular framework with a closed bottom, wherein a bearing cross beam is welded at the top of the framework; a left bearing longitudinal beam and a right bearing longitudinal beam are welded on the left side and the right side of the framework respectively; a sliding beam is connected onto the bearing cross beam; an upper jack is connected onto the sliding beam; an upper loading plate is arranged below the upper jack; a lateral jack is connected onto the right bearing longitudinal beam; a lateral loading plate is arranged on the left side of the lateral jack; a pressure bearing plate is connected onto the left bearing longitudinal beam. The pressurizing device has the characteristics of reasonable design, simple structure, convenience in operation and good loading effect; a phenomenon that in the anchor rod pull-out test, the anchoring body is in a free state and a real surrounding rock stress state cannot be simulated, so that an experimental result has very big deviation from the anchor rod stress in the practical engineering application is overcome; the change condition of the surrounding rock stress can be simulated; and a condition is provided for testing relevant parameters of an anchor rod under the dynamic pressure condition.

Owner:ANHUI UNIV OF SCI & TECH

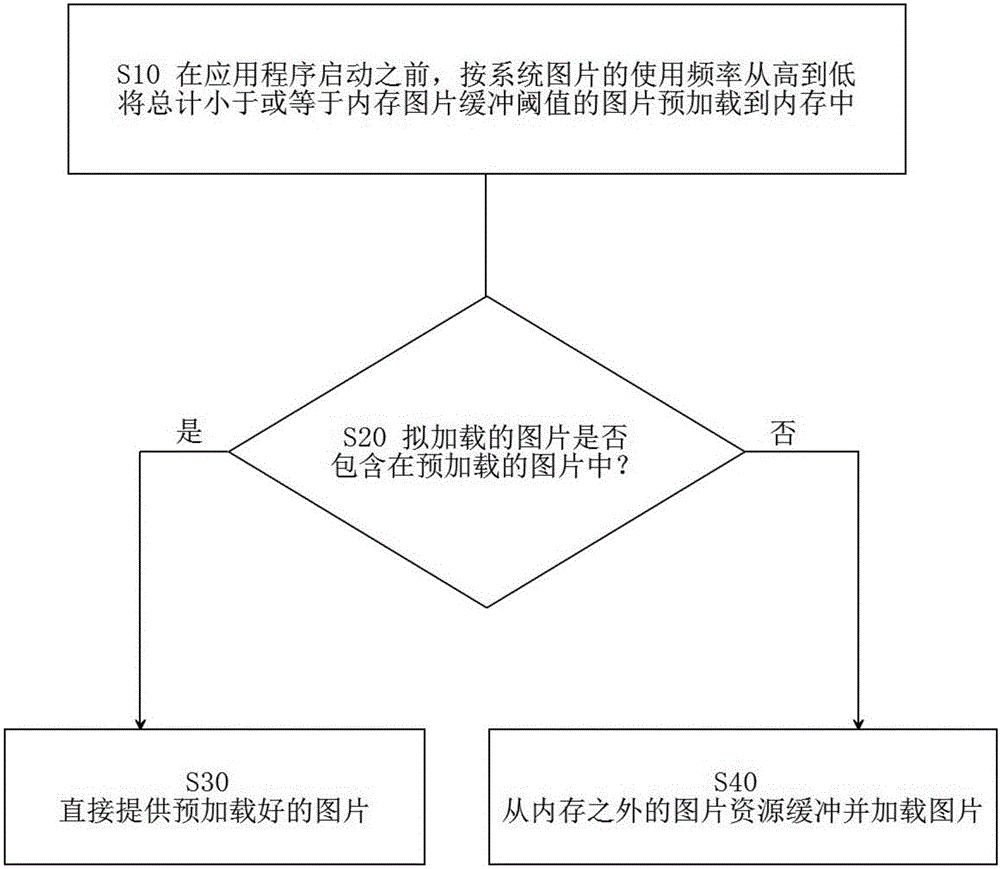

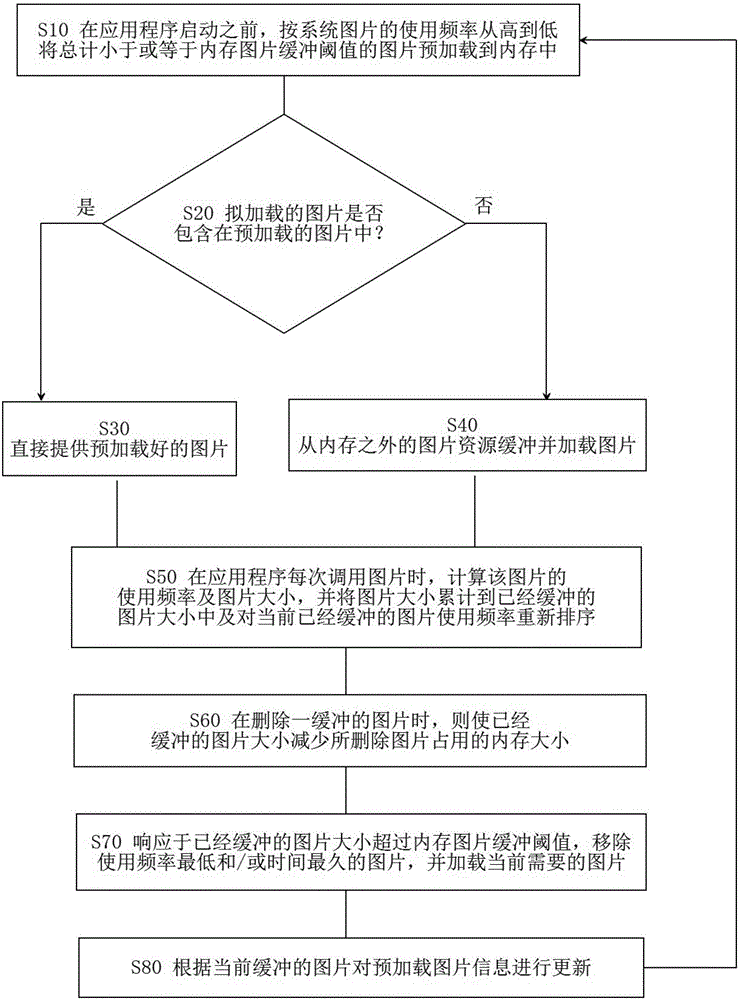

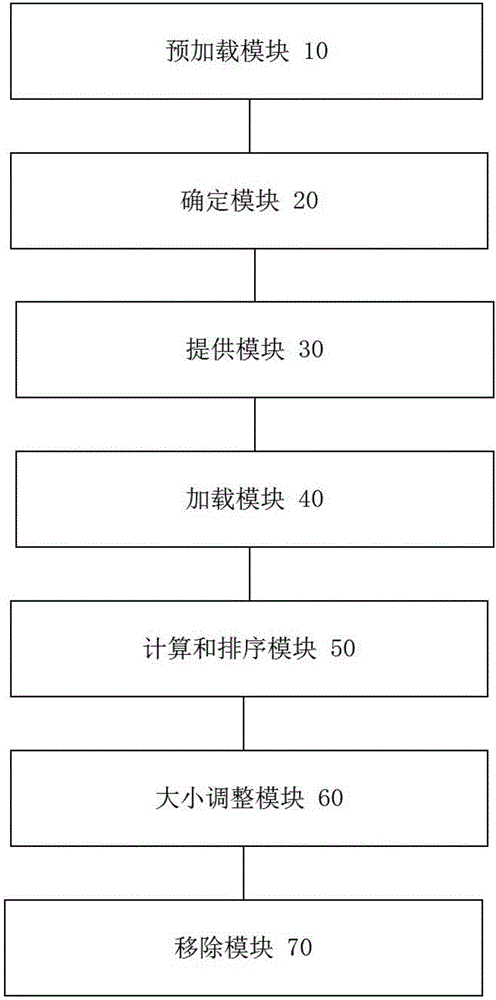

Picture loading method and system

InactiveCN106569894AImprove loading effectImprove application loading speedResource allocationFrequency of useComputer engineering

The invention discloses a picture loading method and system. The method comprises the following steps: before starting an application, pre-loading pictures which are less than or equal to a memory picture buffer threshold in total to a memory according to the use frequency of system pictures from high to low; in response to the application, starting the loaded pictures, and determining whether a quasi-loaded picture is included in the pre-loaded pictures; in response to that the quasi-loaded picture is included in the pre-loaded pictures, directly providing the pre-loaded pictures; and in response to that the quasi-loaded picture is not included in the pre-loaded pictures, buffering and loading the pictures from picture resources except the memory. The picture loading method provided by the invention can improve the picture loading speed of the application, optimize the experience and improve the picture loading effect.

Owner:BEIJING YUANXIN SCI & TECH

Flexibility uniform distribution pressure loading device applicable to geomechanical model test

InactiveCN102012337AImprove performanceLarge load concentrationMaterial strength using tensile/compressive forcesHydraulic cylinderAutomatic control

The invention relates to a flexibility uniform distribution pressure loading device applicable to a geomechanical model test, comprising a hydraulic cylinder thrustor, wherein the upper end of the hydraulic cylinder thrustor is connected with a hydraulic cylinder by virtue of a spherical hinge, and the bottom of the hydraulic cylinder thrustor is provided with a flexible force-transfer cushion layer. The loading device can be connected with a counter-force frame by virtue of a preposition flange or a postposition flange of a hydraulic cylinder, the maximum load of 50t can be applied, the maximum load intensity on the model surface is 4.5MPa, the load intensity deviation is less than or equal to 5%, the stress on the model surface is uneven, and the depth is less than 100mm. The invention can realize flexible uniform distribution pressure loading on the model surface; the structure is simple, the assembling is flexible, the operation is easy, the size of single loading unit is reasonable, and the loading and unloading can be realized when the hydraulic cylinder is combined with a hydraulic station and a hydraulic automatic control system; and meanwhile multiple loading devices can be combined in different arrangements, and the gradient loading is realized. The invention integrates the hydraulic cylinder, the spherical hinge, the thrustor and the flexible force-transfer cushion layer, and the uniform distribution loading effect is better.

Owner:SHANDONG UNIV

Electronic controlled fuel injection apparatus of internal combustion engine

InactiveUS6868832B2Large storage capacityReduce power outputElectrical controlMuscle operated startersLow speedEngineering

Owner:HONDA MOTOR CO LTD

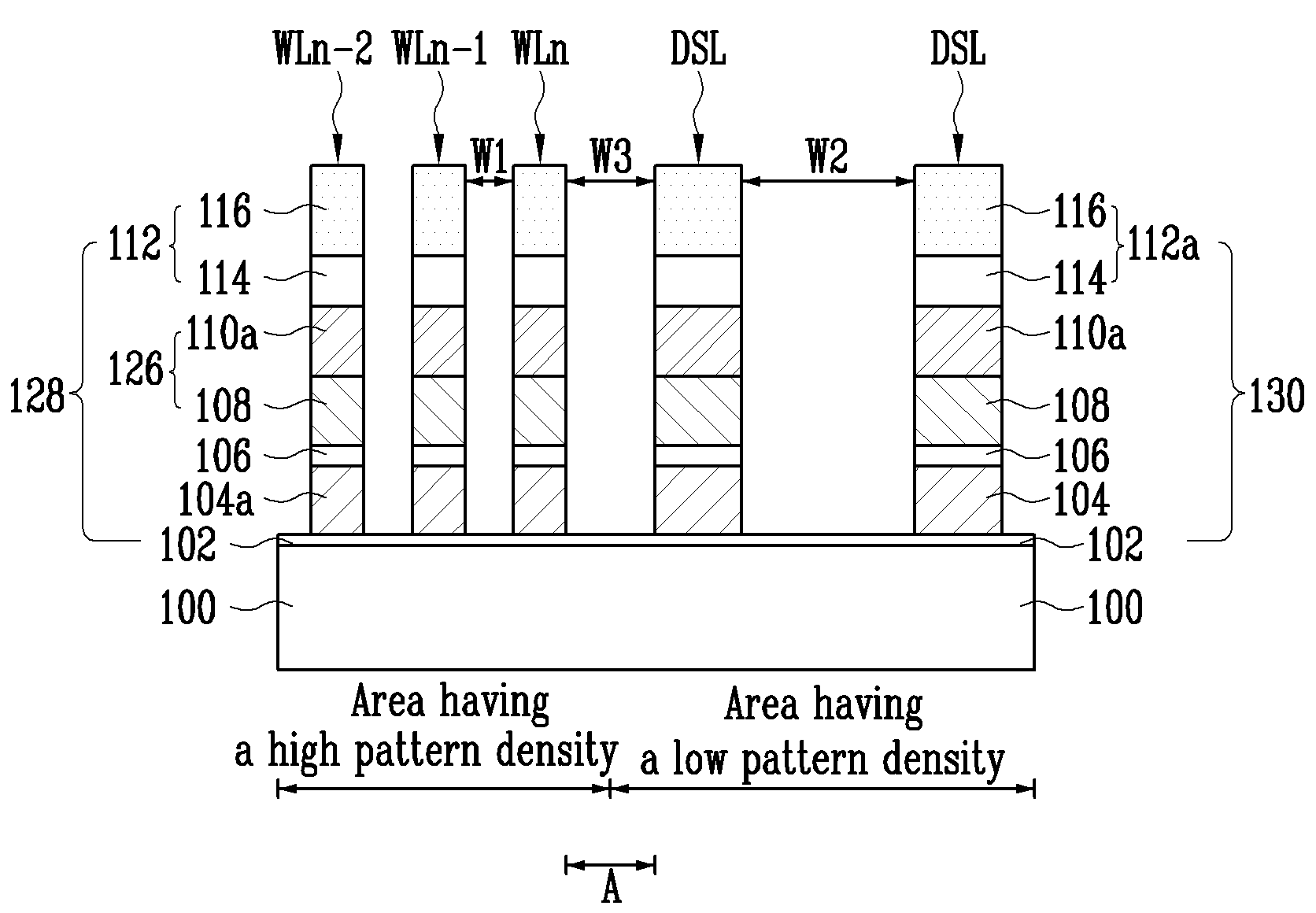

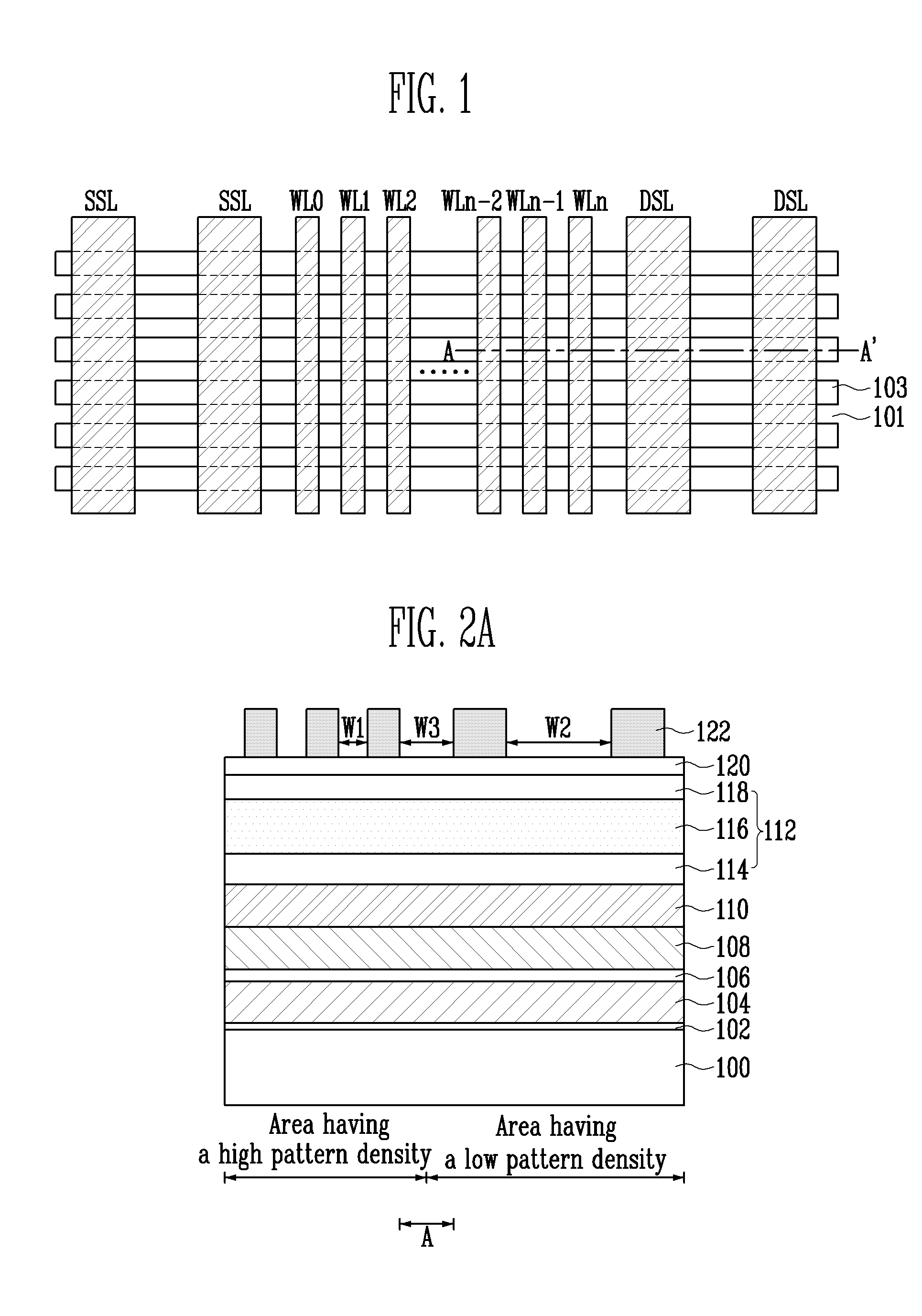

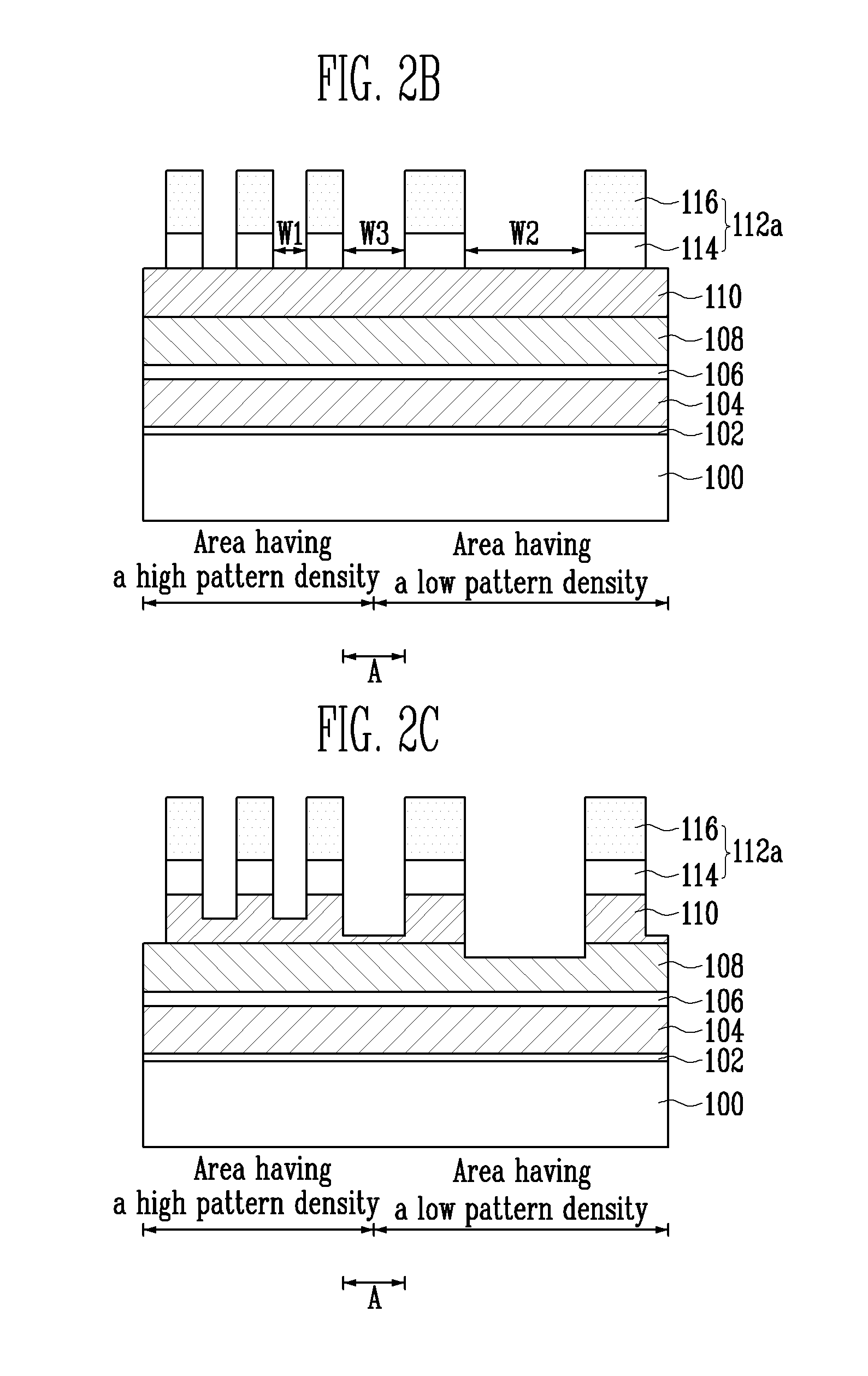

Method of manufacturing semiconductor device

InactiveUS20090068829A1Improve loading effectHigh pattern densitySemiconductor/solid-state device manufacturingSemiconductorMetal

A method of manufacturing a semiconductor device comprising forming a conductive layer on a semiconductor substrate; forming a metal layer on the conductive layer; performing a first etching process for patterning the metal layer on a first area to form first metal layer patterns at relatively wide intervals until the conductive layer of the first area is exposed; performing a second etching process for forming an etching-obstructing layer on the first area and patterning the metal layer on a second area to form second metal layer patterns at relatively narrow intervals until the conductive layer of the second area is exposed; removing the etching-obstructing layer; and removing an exposed area of the conductive layer to form a conductive pattern.

Owner:SK HYNIX INC

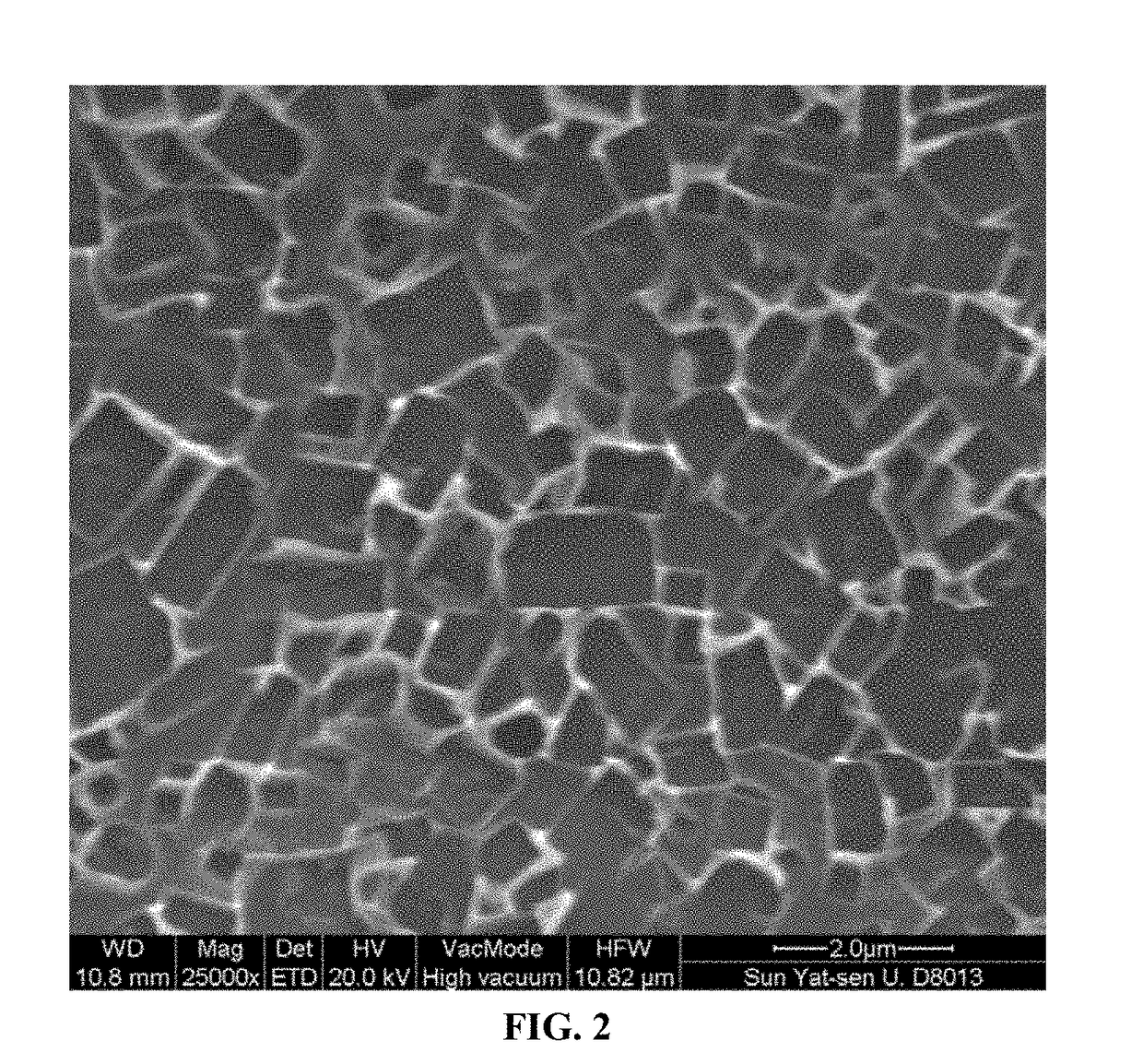

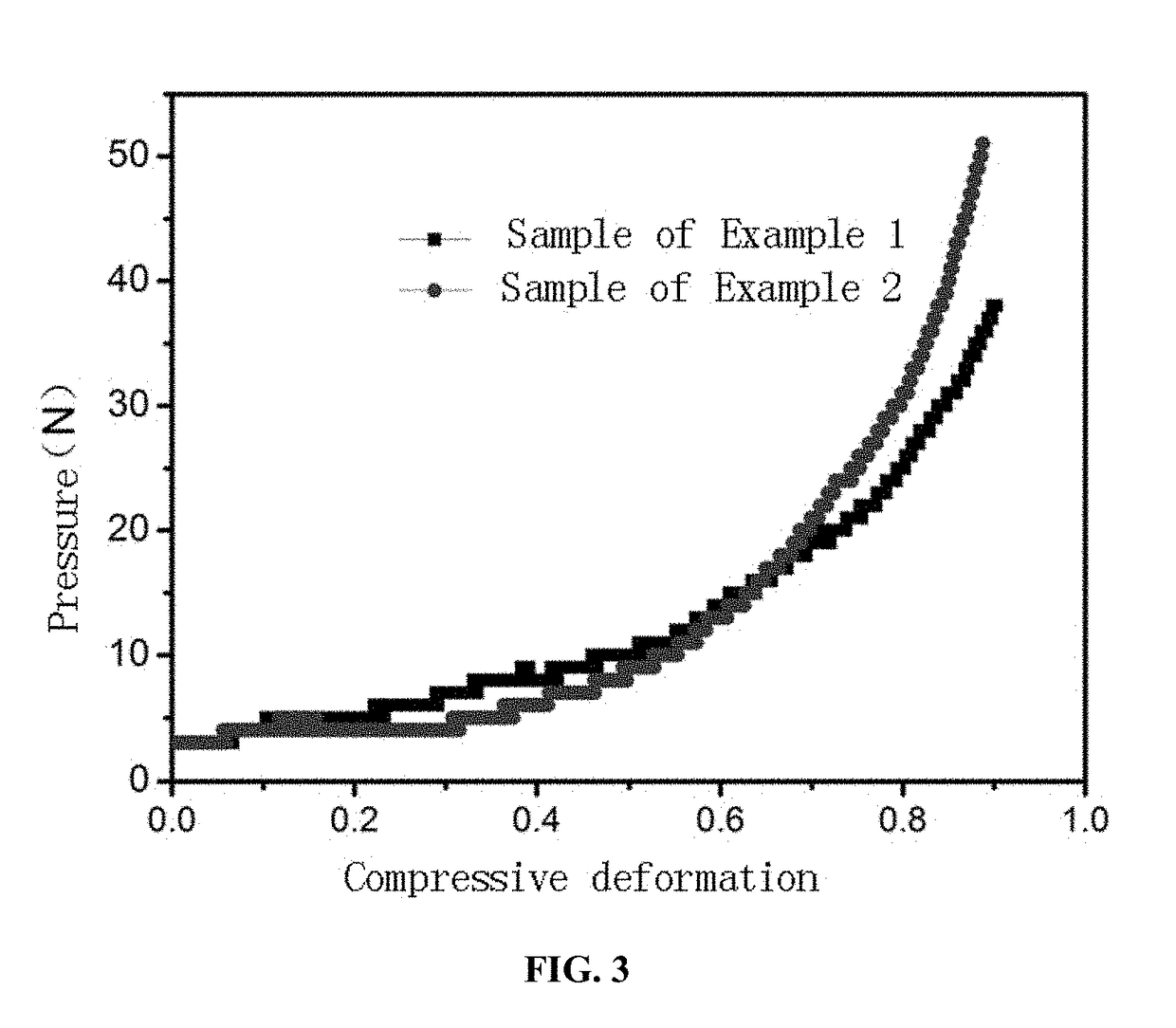

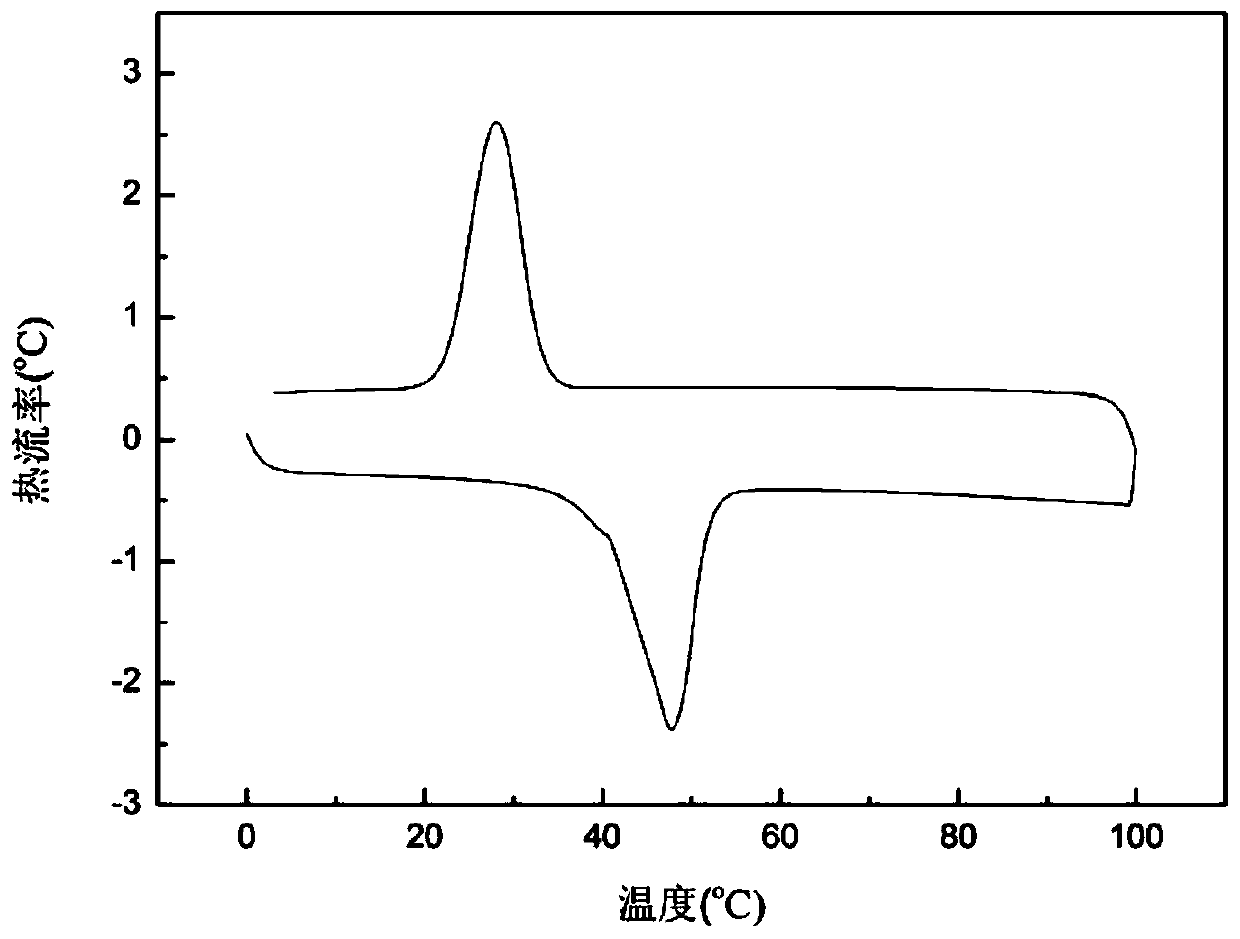

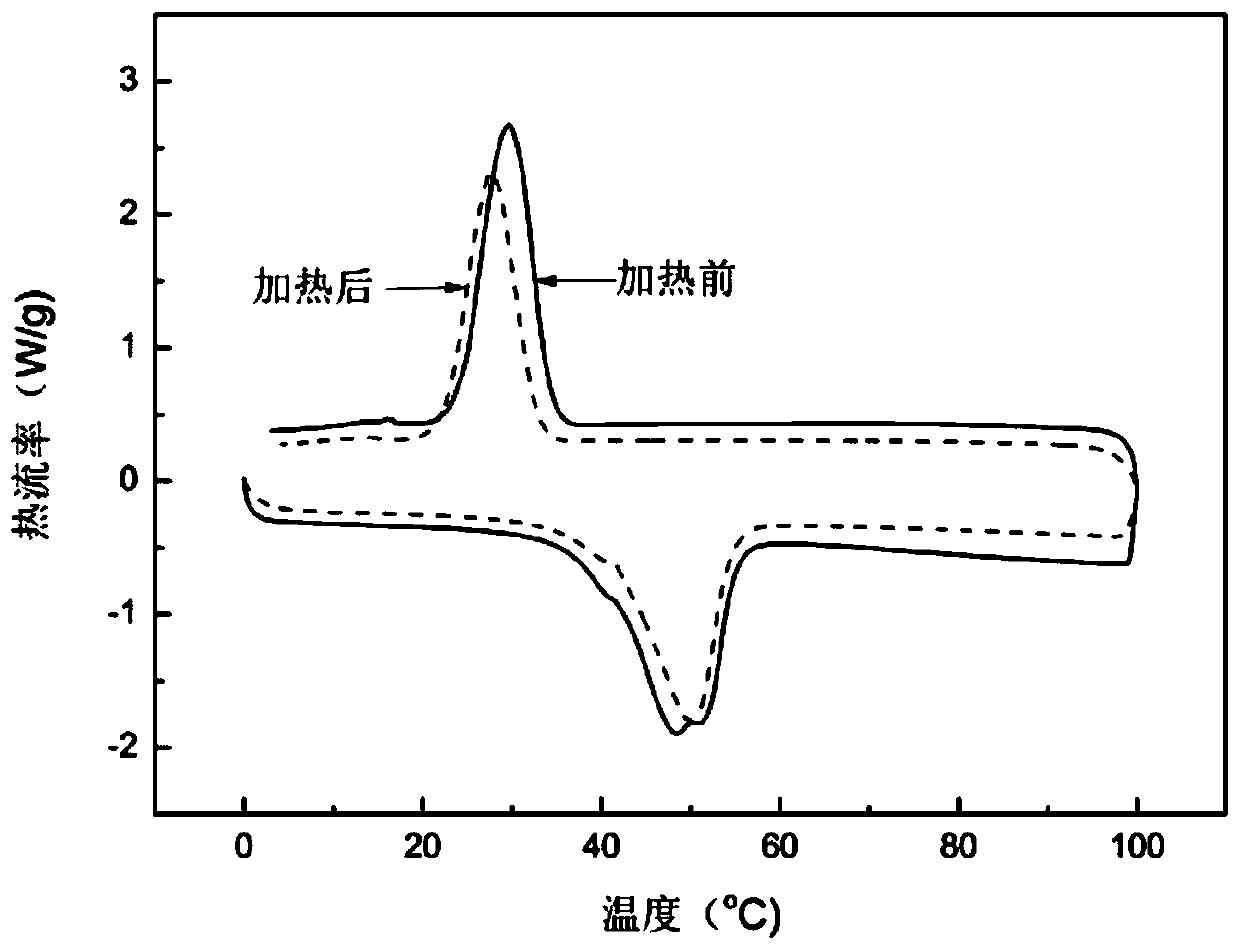

Double-network phase change aerogel and preparation method thereof

ActiveCN111187598AImprove heat resistanceHigh yieldHeat-exchange elementsThermodynamicsHeat conservation

The invention discloses a double-network phase change aerogel and a preparation method thereof. The double-network phase change aerogel is prepared through emulsion polymerization. The prepared phase-change aerogel not only reserves rich pore structures of aerogel, but also realizes dual functions of a phase change material and an aerogel material, so a basis is provided for more functionalizationpurposes. The phase change aerogel can effectively realize the immobilization of PEG; a phase change temperature can be regulated and controlled by the molecular weight of PEG; phase change enthalpyreaches 90 J / g or above; a specific surface area reaches 230 m<2> / g or above; an aperture ratio reaches 90% or above; a heat-resistant temperature reaches 350 DEG C or above. The phase change aerogelcan be applied to the fields of intelligent textiles, heat preservation and insulation materials, protective materials, intelligent adsorbents, industrial waste heat utilization and the like. Based onthe regulation and control mechanism of the chemical structure and the morphological structure of the phase change aerogel, different dual-network immobilization components can be selected to realizemore functions in optical and electrical aspects and other aspects.

Owner:DALIAN POLYTECHNIC UNIVERSITY

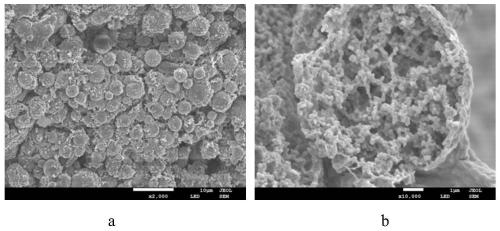

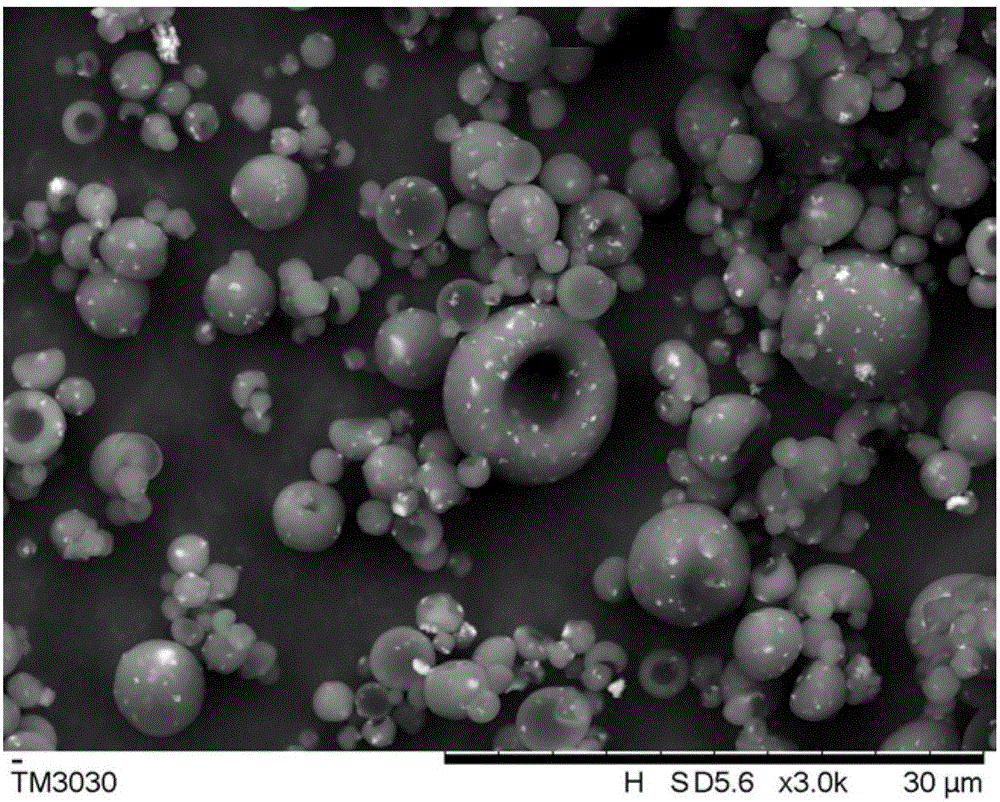

Antibacterial carboxymethyl chitosan/nano zinc oxide composite microsphere and preparation method thereof

InactiveCN106390175AGood antibacterial effectLow biological toxicityInorganic non-active ingredientsAbsorbent padsMicrosphereStaphyloccocus aureus

The invention belongs to the technical field of bio-medical composite materials, and discloses an antibacterial carboxymethyl chitosan / nano zinc oxide composite microsphere as well as a preparation method and an application thereof. The preparation method comprises the following steps: adding nZnO to a water solution of carboxymethyl chitosan, conducting ultrasonic oscillation so that the nZnO is uniformly dispersed, and conducting standing by so as to obtain a mixed suspension of the carboxymethyl chitosan and the nZnO; and spray-drying the suspension by virtue of a spray-dryer, so that the carboxymethyl chitosan / nano zinc oxide composite microsphere is obtained. The carboxymethyl chitosan / nano zinc oxide composite microsphere provided by the invention is small in grain size and obvious in antibacterial activity, and an antibacterial rate on staphylococcus aureus and escherichia coli reaches 80% or above; and the carboxymethyl chitosan / nano zinc oxide composite microsphere is low in biotoxicity, and the survival rate of NIH-3T3 cells within 24h is higher than 90% when the concentration of the composite microsphere is less than or equal to 125mg / mL; therefore, the carboxymethyl chitosan / nano zinc oxide composite microsphere can be applied to wound repair materials, food / drug packaging materials and drug carrier materials.

Owner:JINAN UNIVERSITY

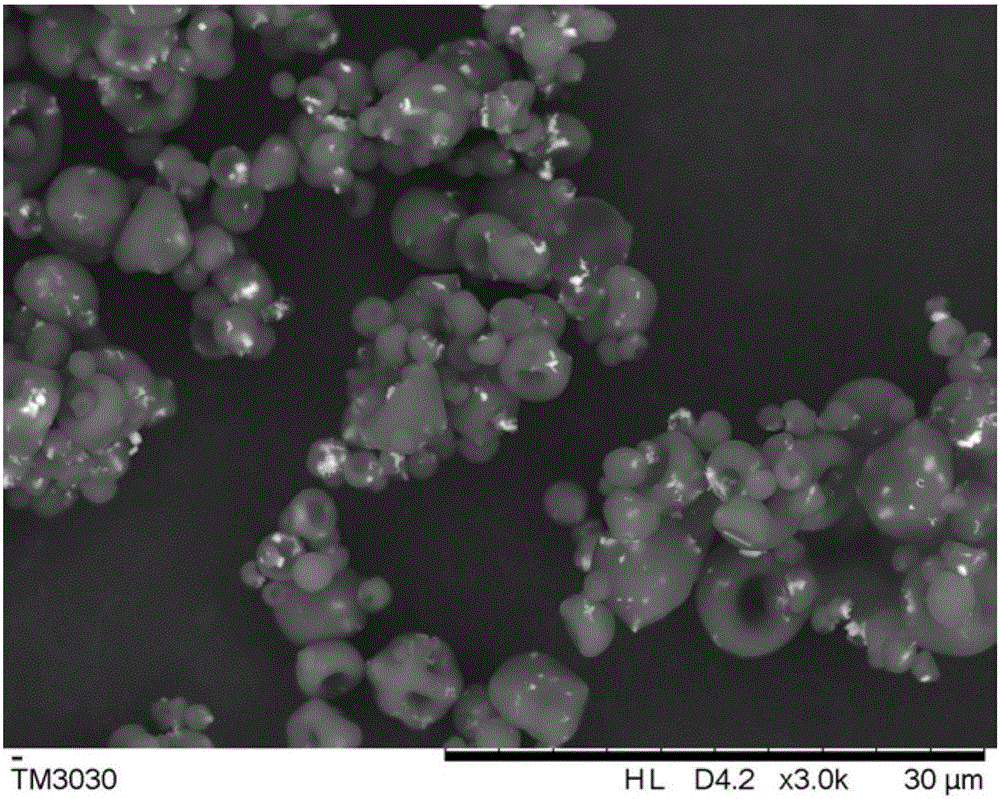

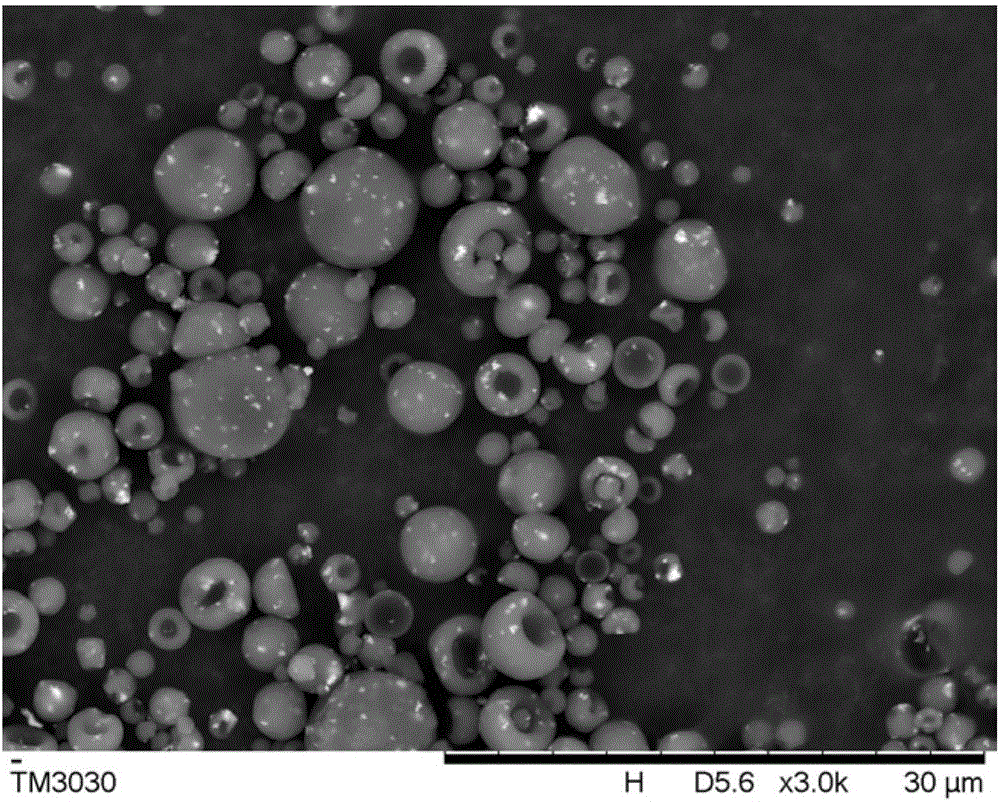

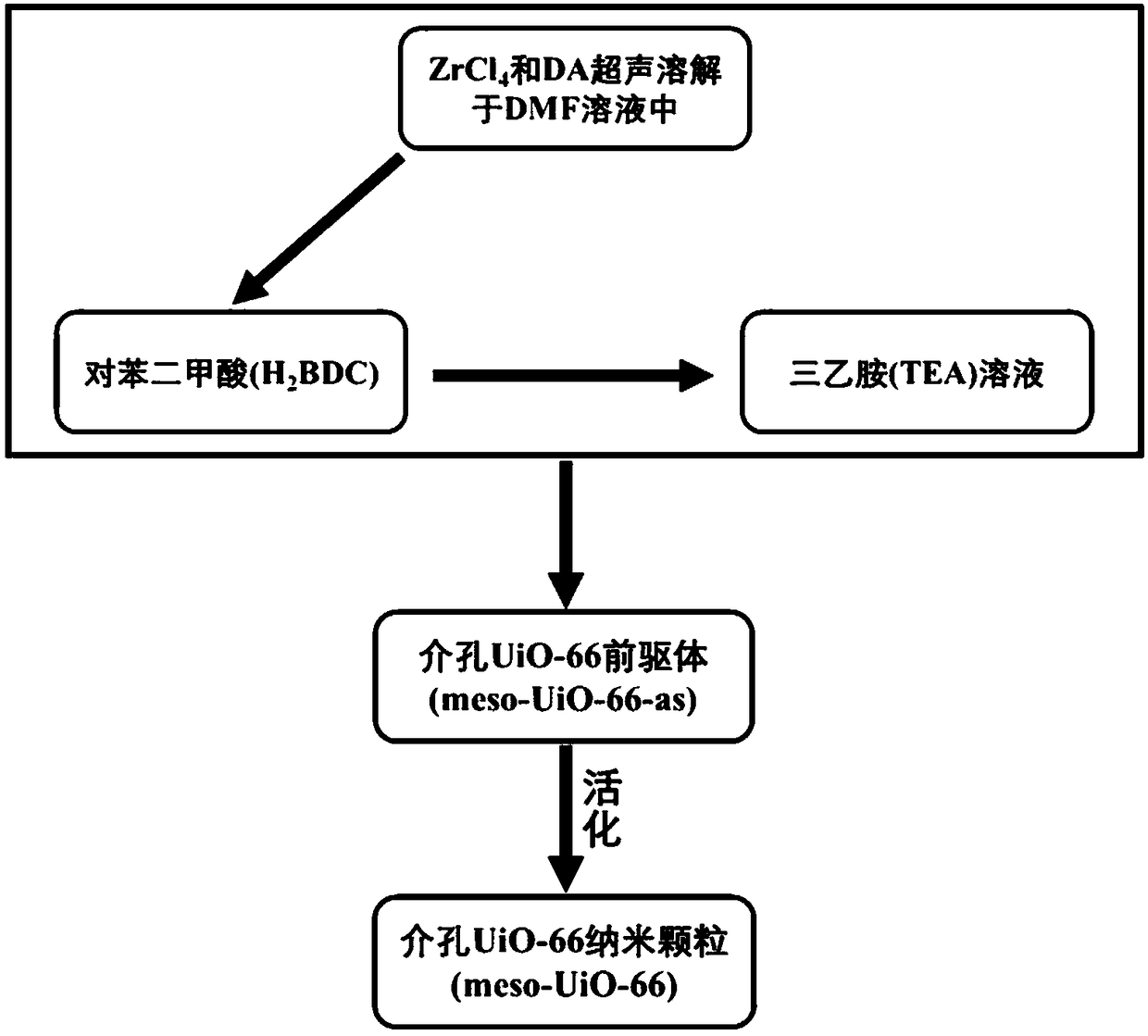

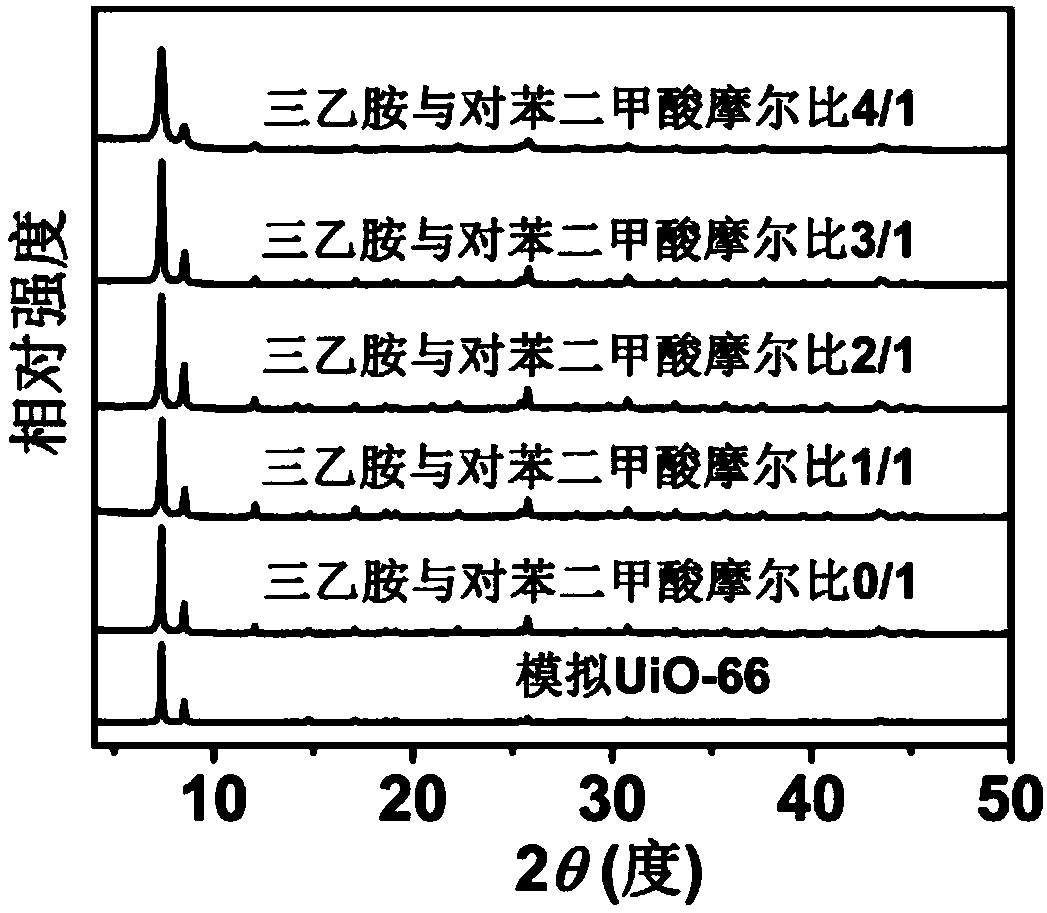

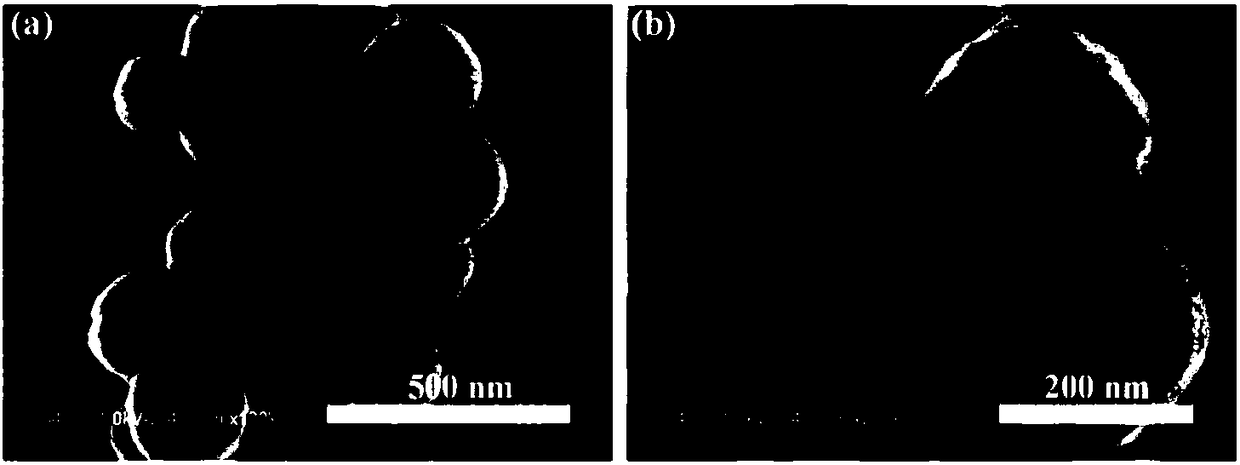

Preparation method of particle size adjustable mesoporous metal organic framework nanomaterial and nanomaterial prepared by method

ActiveCN108066773AImprove loading effectGood biocompatibilityNanomedicinePharmaceutical non-active ingredientsDispersityOrganic base

The invention relates to a preparation method of a particle size adjustable mesoporous metal organic framework nanomaterial, which comprises the steps of dissolving zirconium tetrachloride and monoacid in a solvent, adding a dicarboxylic acid ligand and organic base for reaction to form a mesoporous metal organic framework precursor, taking a zirconia cluster provided by zirconium tetrachloride asa node, allowing monoacid and the dicarboxylic acid ligand to perform competition coordination with zirconium tetrachloride to form the zirconia cluster, allowing the dicarboxylic acid ligand to be coordinated with zirconium tetrachloride to serve as a connector of a metal organic framework, inserting monoacid into hole channels of the metal organic framework via a coordination bond, dispersing the mesoporous metal organic framework precursor in a mixed solution of the solvent and inorganic acid to remove monoacid to form the particle size adjustable mesoporous metal organic framework nanomaterial, wherein inorganic acid damages the coordination bond between monoacid and zirconium tetrachloride. The preparation method is simple in technology and good in reproducibility; the prepared mesoporous metal organic framework nanomaterial is adjustable in particle size, uniform in dimension and good in dispersity.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Distributed storage method

PendingCN110909077AImproved distributed storage methodIncrease chances of executionDatabase distribution/replicationSpecial data processing applicationsExecution planMetadata management

The invention discloses a distributed storage method. The method is used for realizing storage and query of big data in a cloud storage system. The cloud storage system comprises a main node, a distributed computing node and a data node, a data management engine is operated on the main node, a user query is received, the query is compiled, converted and optimized, a query execution plan is generated and the query is executed, and metadata management and node monitoring are carried out at the same time; a server process is operated on the distributed computing node, and a distributed computingtask is executed; the working process of distributed computing and a single-node database are deployed at a data node, and a data table is stored in the database of the data node; the sub-queries converted from the user query are executed in a database or in a distributed computing framework. A hybrid data warehouse architecture incorporating a database and a distributed computing framework is presented.

Owner:四川中讯易科科技有限公司

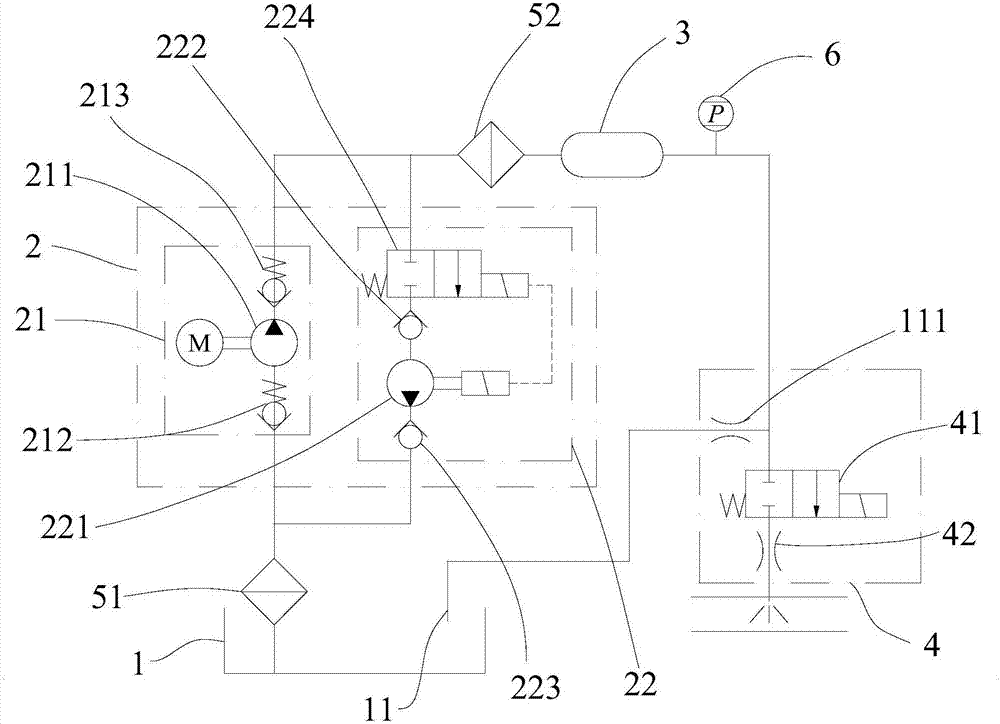

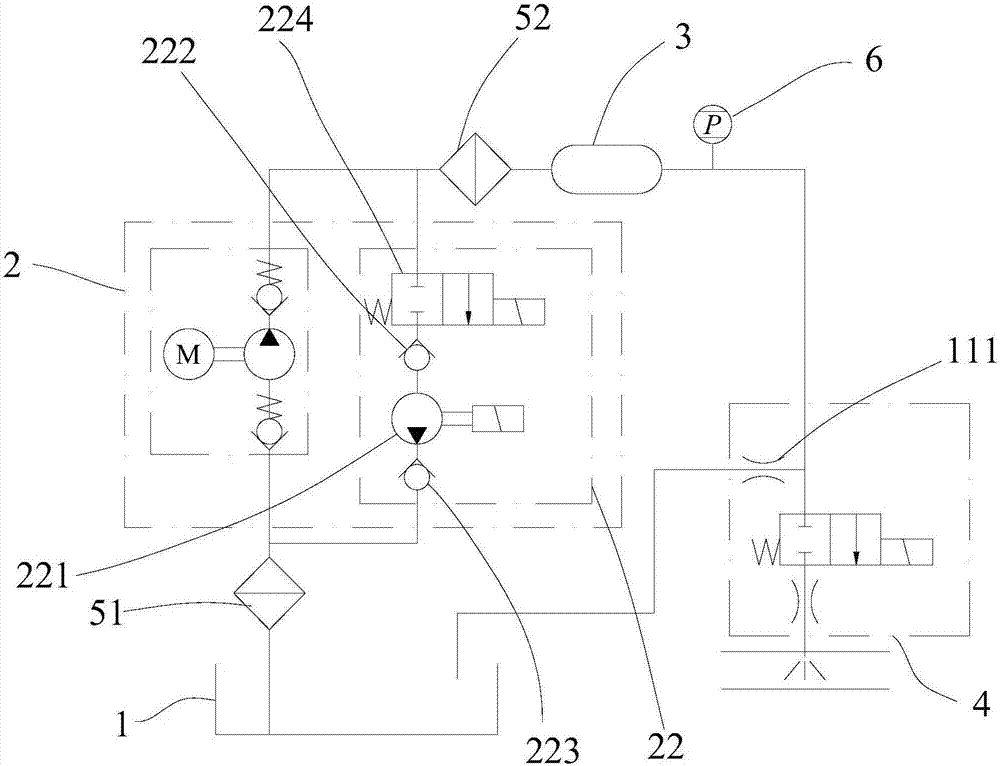

Urea pumping system

PendingCN107246302AResolve residual crystalsSolve the problem of blocked pipesExhaust apparatusSilencing apparatusRefluxElectromagnetic valve

The invention discloses a urea pumping system. The urea pumping system comprises a urea box, a urea pump module, an energy accumulator and a nozzle module which are sequentially connected through a pipeline, wherein the urea pump module comprises a main pump used for pumping a liquid in the urea box to the nozzle module, and an auxiliary pump used for reversely sucking a liquid in the pipeline back into the urea box; the nozzle module comprises a first electromagnetic valve and an atomization nozzle; the first electromagnetic valve is connected with the energy accumulator and the atomization nozzle through the pipeline; a reflux pipeline which communicates with the urea box is arranged on the pipeline between the first electromagnetic valve and the energy accumulator; and a first damping hole is formed in the reflux pipeline. According to the urea pumping system, an airfree auxiliary structure is adopted, double-pump parallel connection is adopted, when a urea solution is injected, the main pump is started, the urea solution is pumped from the urea box to the nozzle module, after injection, the auxiliary pump sucks the urea solution remaining in the system back into the urea box, and the problems of urea crystallization and pipeline blocking are solved.

Owner:HUST WUXI RES INST +1

Air gun bullet wheel

InactiveCN105403101ARealize the function of reloading and shooting multiple times at one timeTo facilitate the need for multiple shotsCompressed gas gunsEngineeringTorsion spring

Owner:ZHEJIANG XINHUA SPORTS EQUIP MFG

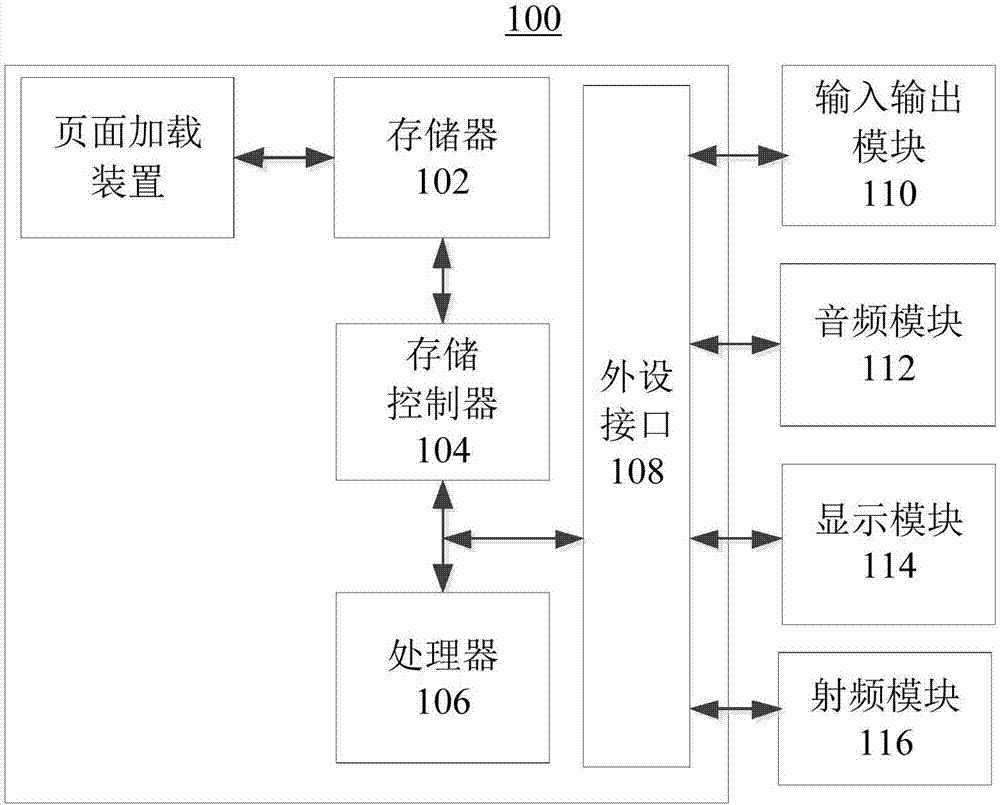

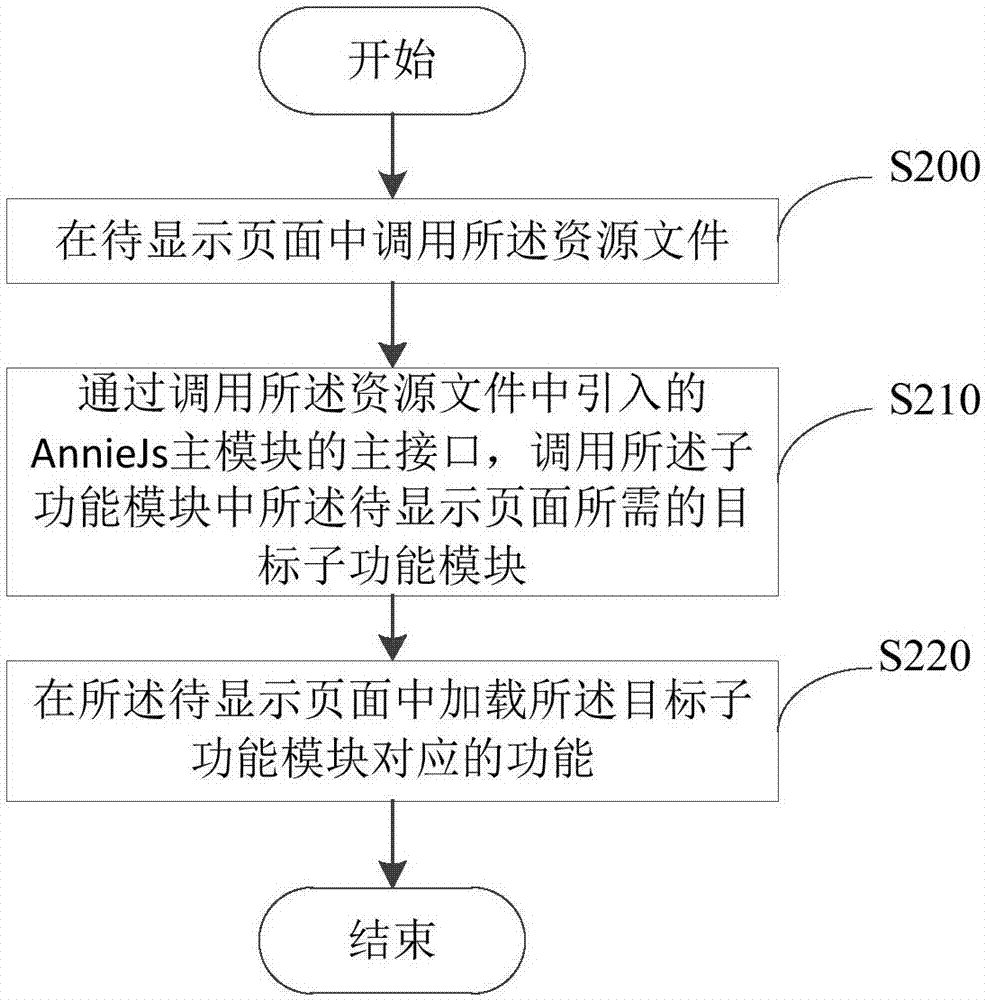

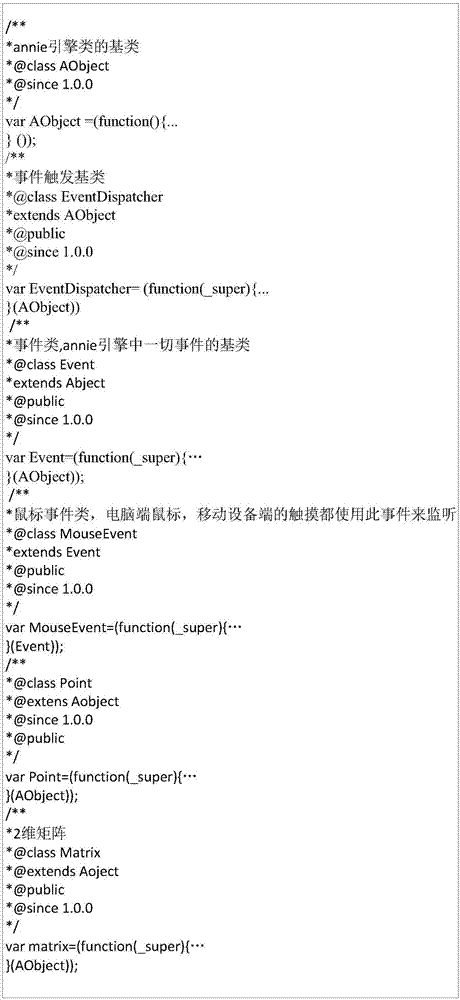

Page loading method and device, electronic equipment and storage medium

InactiveCN107506483AImprove loading effectAvoid resource requestsWebsite content managementProgram loading/initiatingThe InternetComputer module

An embodiment of the invention provides a page loading method and device, electronic equipment and a storage medium, and relates to the technical field of internet. The page loading method and device are applied to resources obtained by a packaging tool, the resources comprise self-defined resource files, a preset AnnieJs main module is introduced into the resource files and comprises a plurality of secondary function modules, the AnnieJs main module is provided with a main interface, and each secondary function module is correspondingly provided with a respective calling interface. The method comprises the following steps: calling the resource files from a page to be displayed; calling the required target secondary function module for the page to be displayed in the secondary function modules by calling the main interface of the AnnieJs main module introduced into the resource files; and loading functions corresponding to the target secondary function module in the page to be displayed so as to reduce resource requests and optimize page loading performance by introducing the AnnieJs main module to the resource files called by the page to be displayed.

Owner:GUANGZHOU UC NETWORK TECH CO LTD

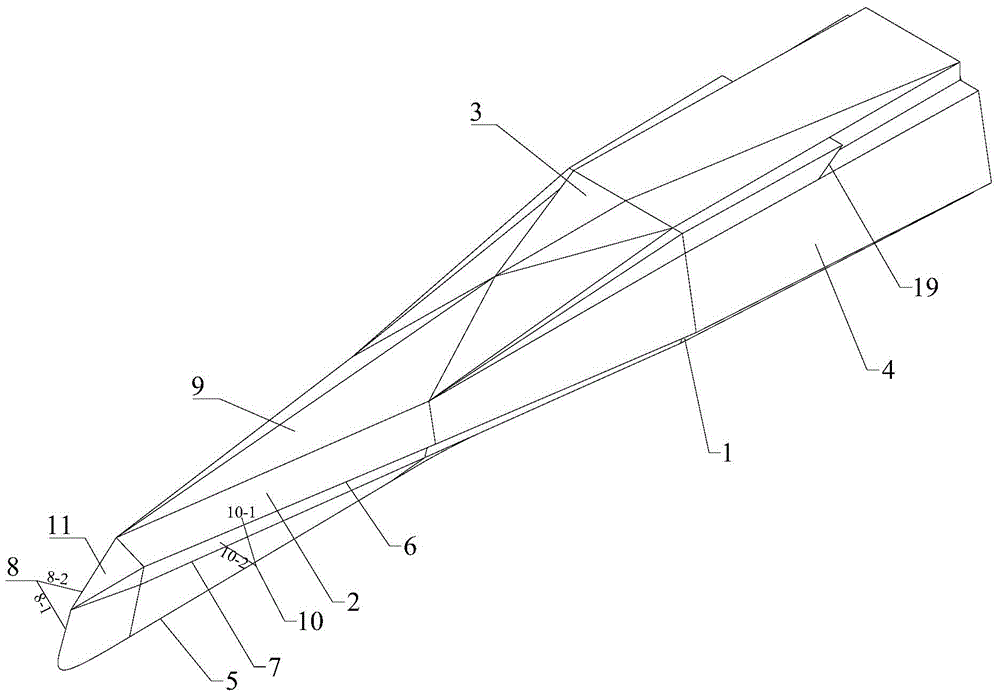

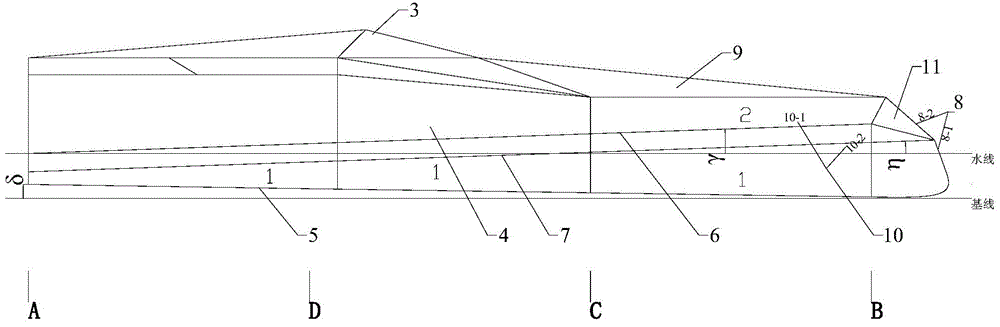

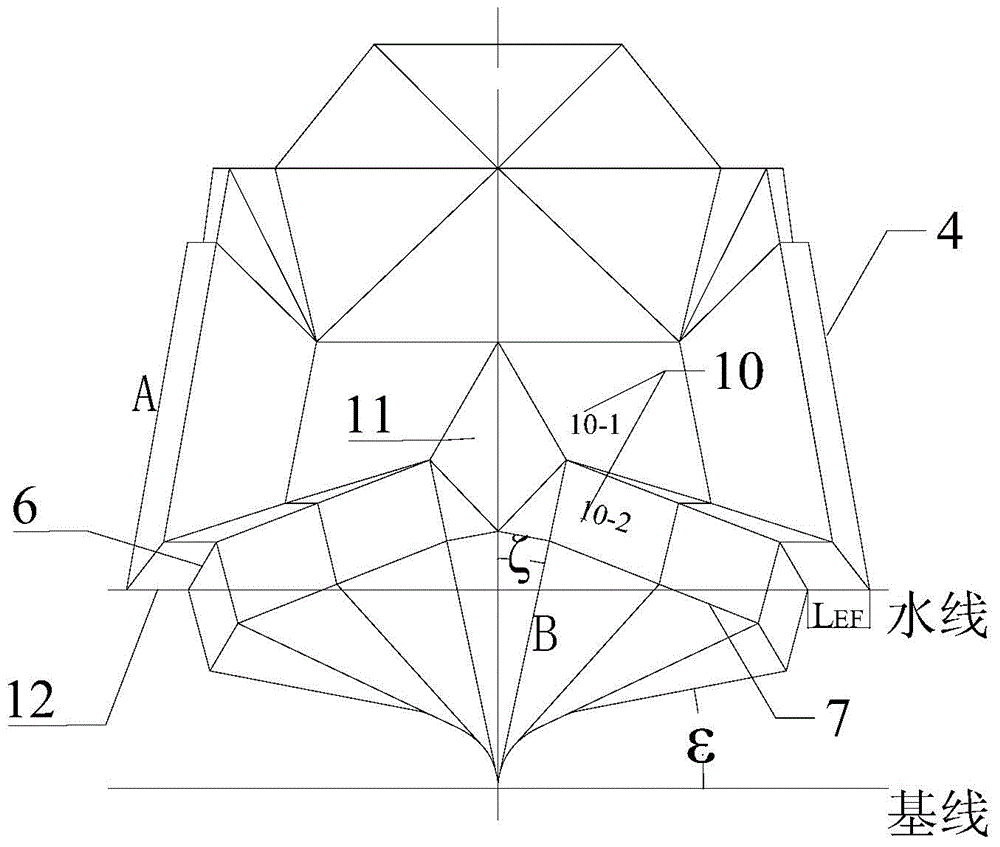

Single-body semiplaning wave-piercing ship

The invention discloses a single-body semiplaning wave-piercing ship and belongs to the field of small speed boats. The single-body semiplaning wave-piercing ship comprises an improved mixing type inward-tilting wave-piercing bow, a semiplaning underwater main ship body, an inward-tilting wave-pressing freeboard and a totally-enclosed upper building, wherein the improved mixing type inward-tilting wave-piercing bow comprises a bow column, a totally-enclosed bow deck and a tow freeboard, the tow freeboard comprises an inward-tilting part and an outward-tilting part, the inward-tilting part and the outward-tilting part are connected to form a freeboard knuckle line, and the included angle gamma between the projection, on the longitudinal section in center plane, of the freeboard knuckle line and the waterline ranges from 1 degree to 3 degrees. According to the single-body semiplaning wave-piercing ship, the wave-piercing capacity, the hiding capacity, the rapidness, the wave making capacity, the stability and the loading capacity of the ship body are improved; compared with the prior art, flooding and wetting of the freeboard are further controlled, lifting force is provided by the freeboard to lift the ship body, and resistance is reduced.

Owner:SHANGHAI JIAO TONG UNIV

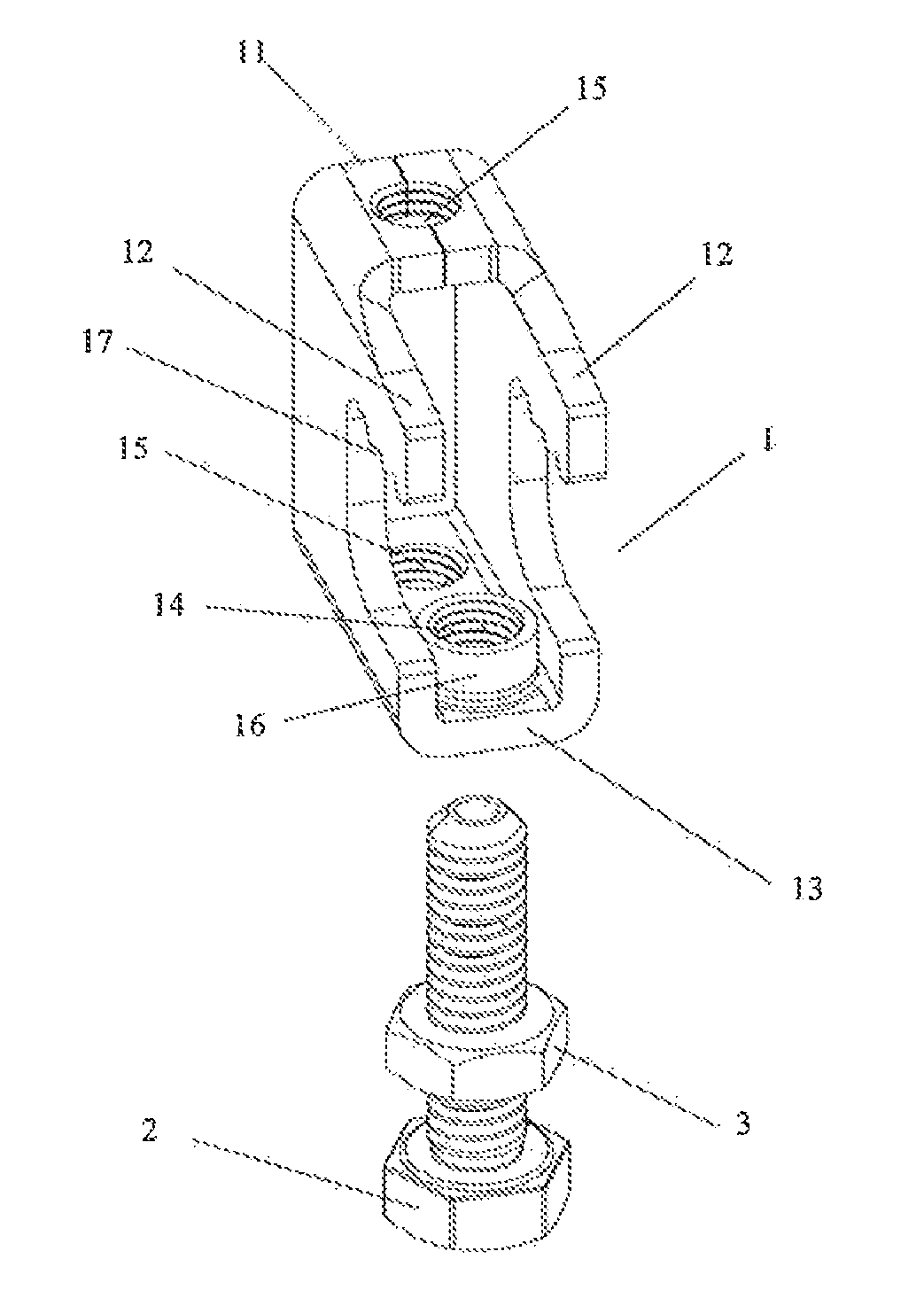

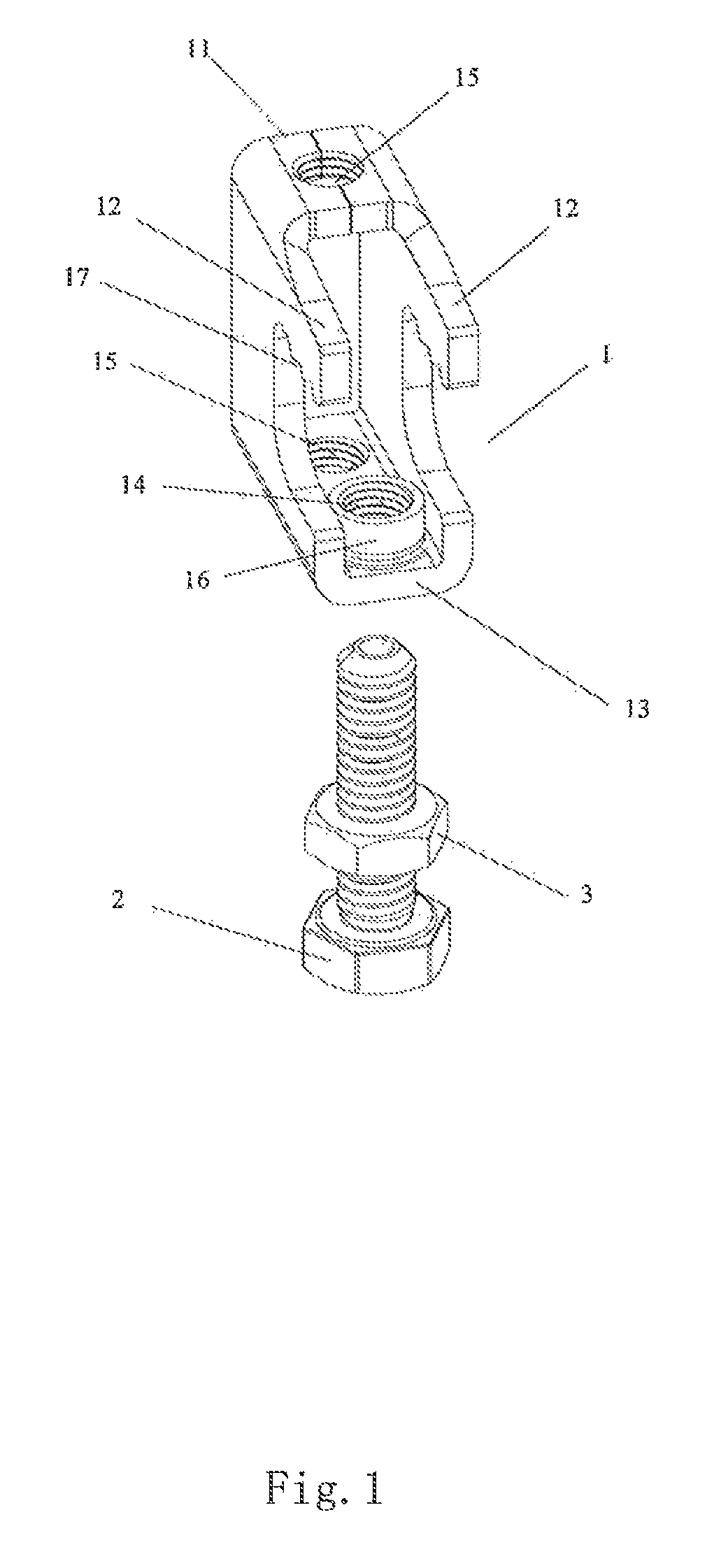

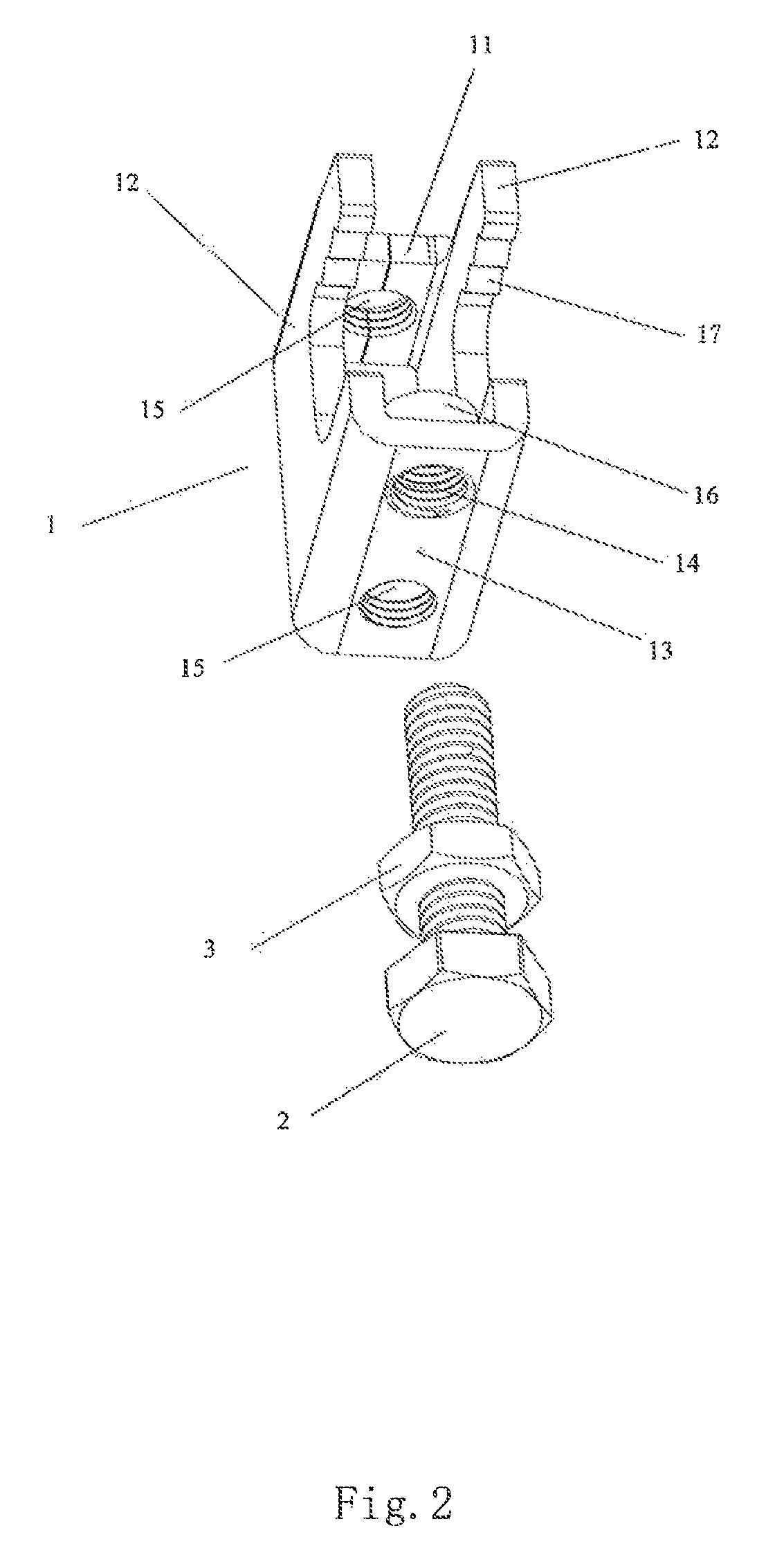

Beam clamp

ActiveUS9746011B2Accurately laser boredImprove efficiencyPipe supportsFriction grip releasable fasteningsButt jointEngineering

A beam clamp, including a clamp body having a rectangular shape symmetrically bent and butt-jointed by a plate material is described. On one side of the body housing a butt seam is a butt-joint face, and clamping jaws are protruded on the two sides of the body at the two sides of the butt-joint face. A clamping plate face is convexly disposed on one side of the body opposite the butt-joint face, and a screw hole corresponding to the clamping jaw is bored on the plate face. The screw hole is tapped and a bolt is disposed therein. The bolt and jaws form three-point clamping, providing high fastening performance. Corresponding threaded rod holes are bored on the plate face and butt-joint face and tapped. The resulting clamp has high processing precision, efficiency, and adaptability; the structure strength is high; load performance is good; and the size is small.

Owner:JIANGMEN EUROFIX METAL & RUBBER PROD

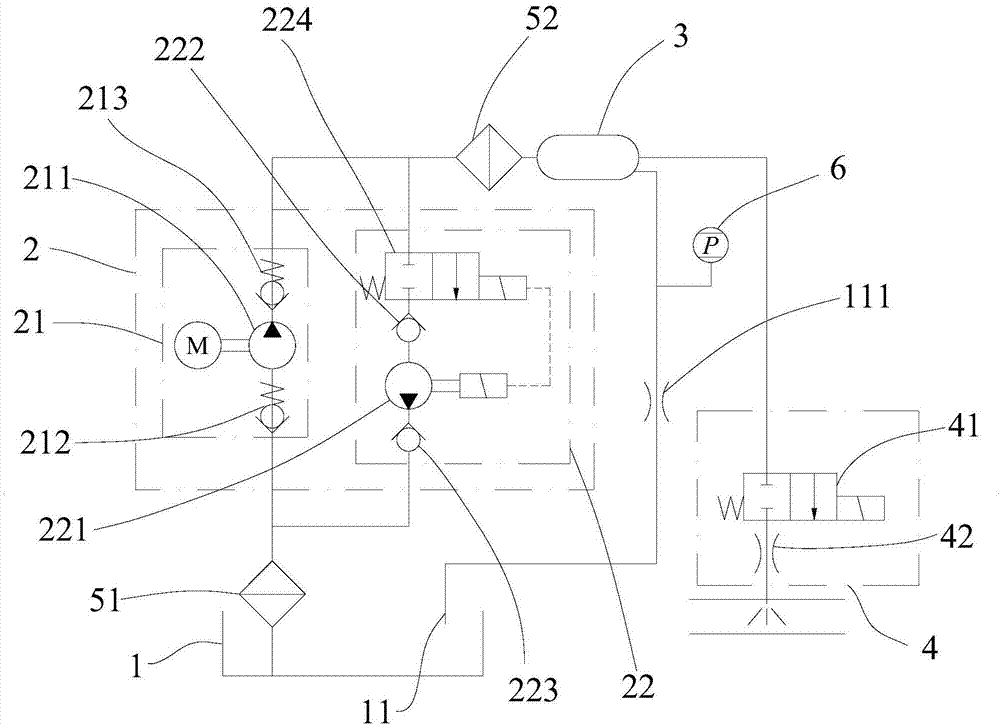

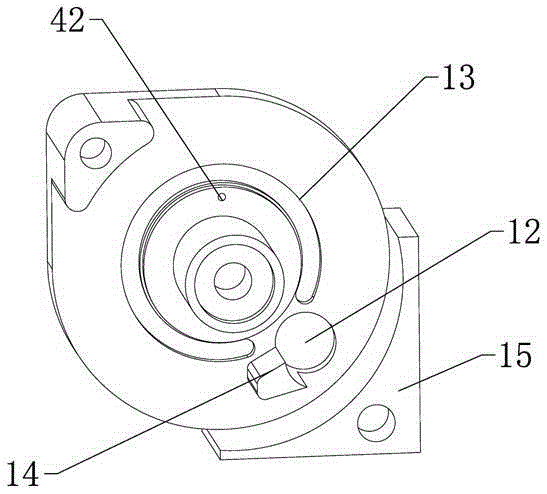

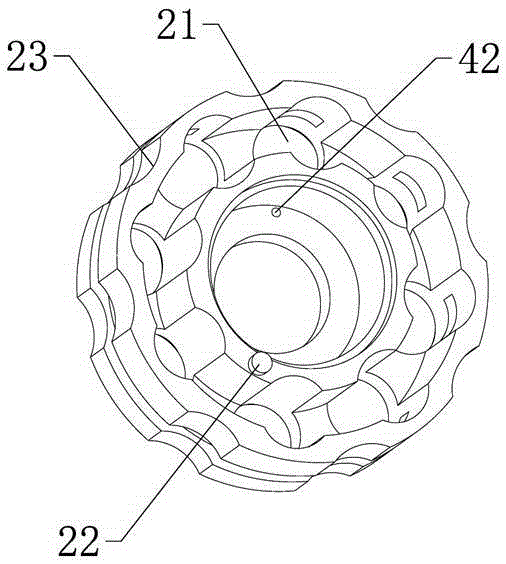

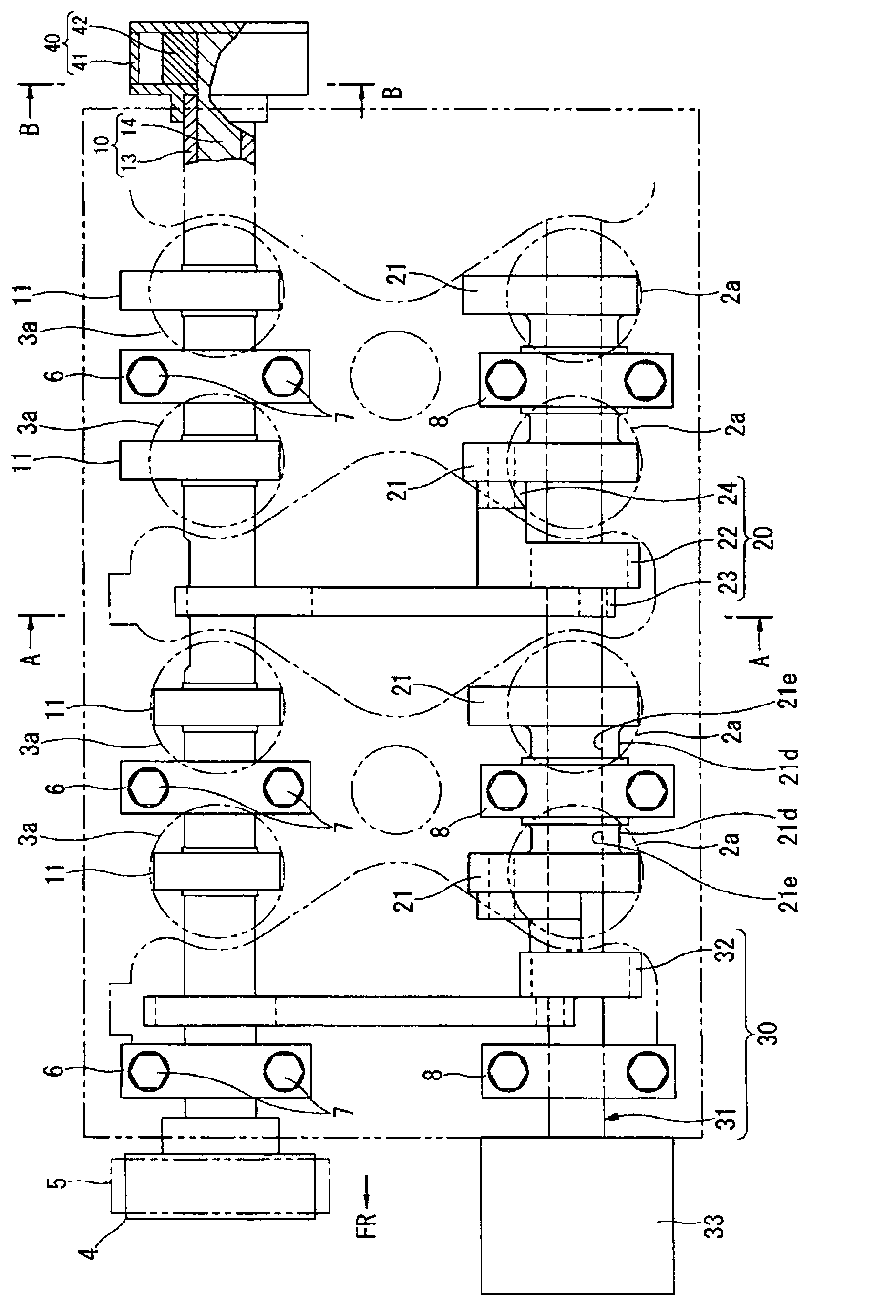

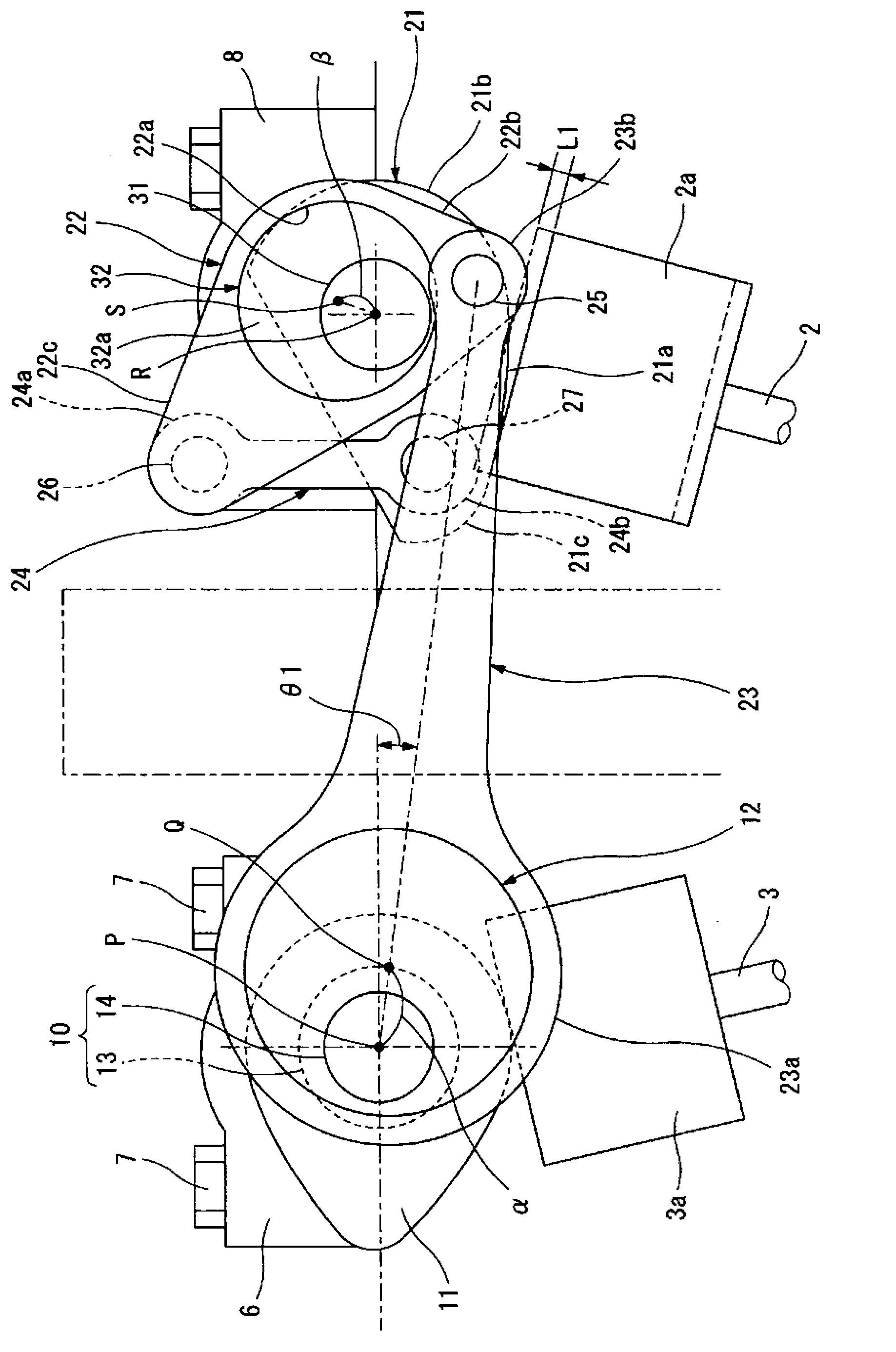

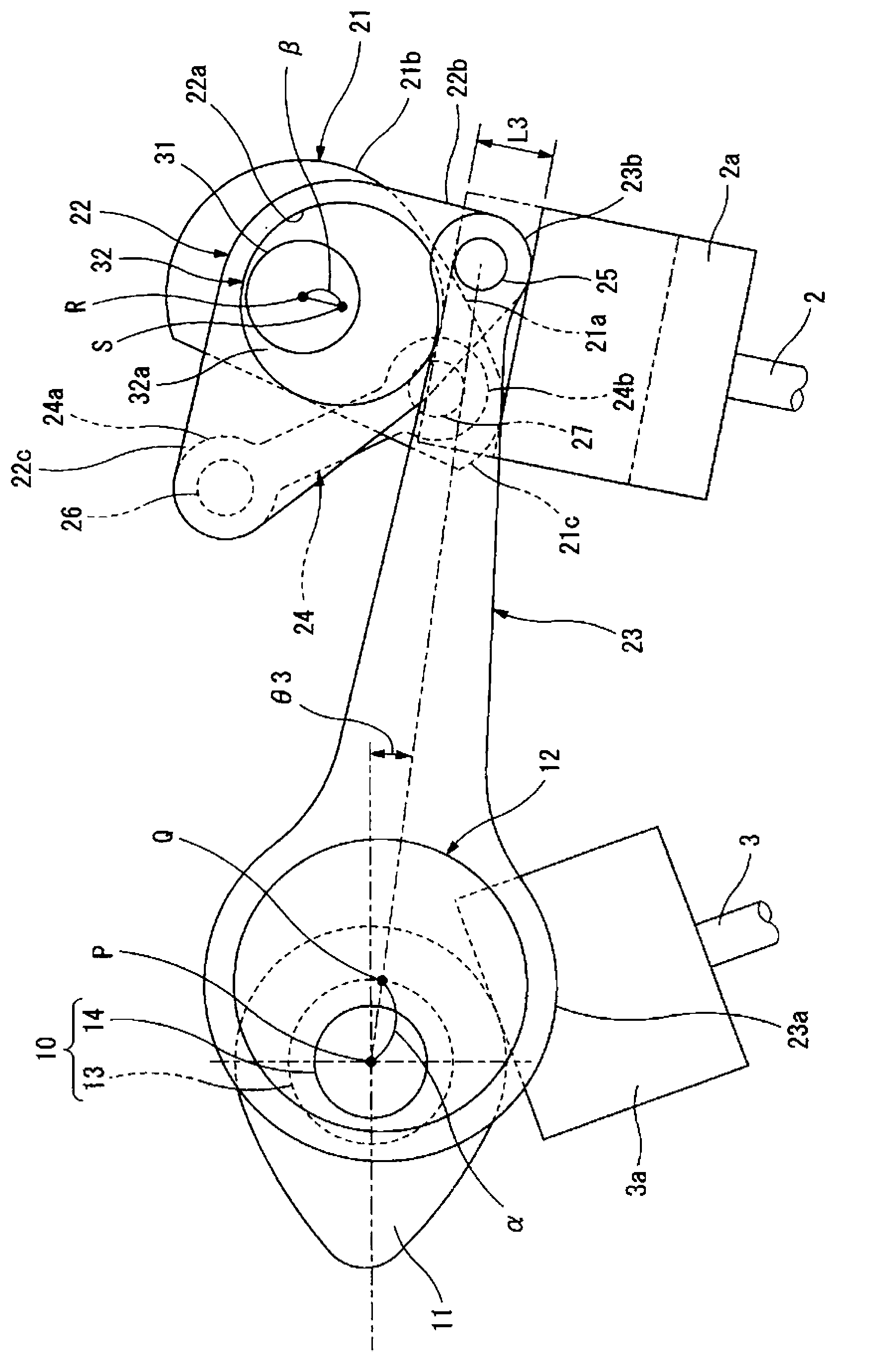

Variable valve apparatus for internal combustion engine

InactiveCN103256088AImprove loading effectPrevent bad situationValve arrangementsMachines/enginesRelative phaseExternal combustion engine

The invention provides a variable valve apparatus for an internal combustion engine. The variable valve apparatus maintains good loading property and makes opening and closing periods of a valve of the internal combustion engine good. In the variable valve apparatus for the internal combustion engine, one of an intake valve and an exhaustvalve is driven by a rocker cam (21) of an operating angle variable mechanism, and the other one is driven by a rotary cam (11), wherein a camshaft (10) which is used to drive one of the valves of the internal combustion engine is made into a dual structure formed by an outer shaft (13) and an inner shaft (14). The two shafts (13,14) are structured to be able to control relative phase by using a phase control mechanism (40). The phase control mechanism (40) is formed by a cylindric housing (41) which is fixed on the outer shaft (13) and a blade rotor (42) which is fixed on the inner shaft (14).

Owner:HITACHI AUTOMOTIVE SYST LTD

Method for directly preparing functional biochar through straw pyrolysis

InactiveCN107500265ATo achieve an organic combinationRealize high value utilizationCarbon preparation/purificationPorosityChemical reaction

The invention discloses a method for directly preparing functional biochar through straw pyrolysis. According to the method, straw pyrolysis based preparation of biochar and functional modification treatment of the biochar are integrated, straw is firstly smashed into powder in the pyrolysis process, a binding agent and a functional aid are added, all materials are mixed, and then a mixture is subjected to compressive granulation by a compression device and pyrolytic carbonization treatment is performed, wherein the binding agent not only has the auxiliary molding effect, but also increases porosity of the biochar and improves structural strength of the biochar; the functional aid is subjected to multiple chemical reactions with raw materials such as a biomass matrix, the binding agent and the like in the carbonization process, organic combination of functional components and the biochar is realized, a good immobilization effect is achieved, and a finally prepared functional biochar material has broad application prospect in the fields of wastewater treatment, soil remediation, anti-bacteria, catalysis and the like; the preparation method is simple and efficient, and high-value utilization of the straw is realized.

Owner:FUNAN NATURE ARTS & CRAFTS

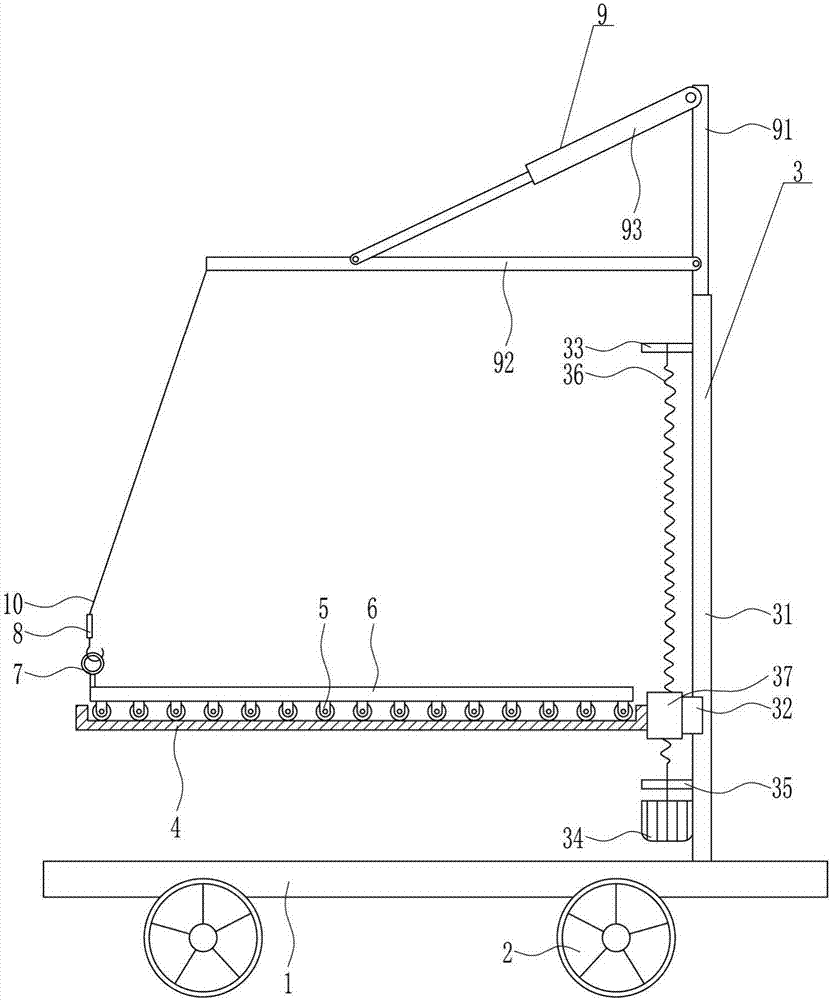

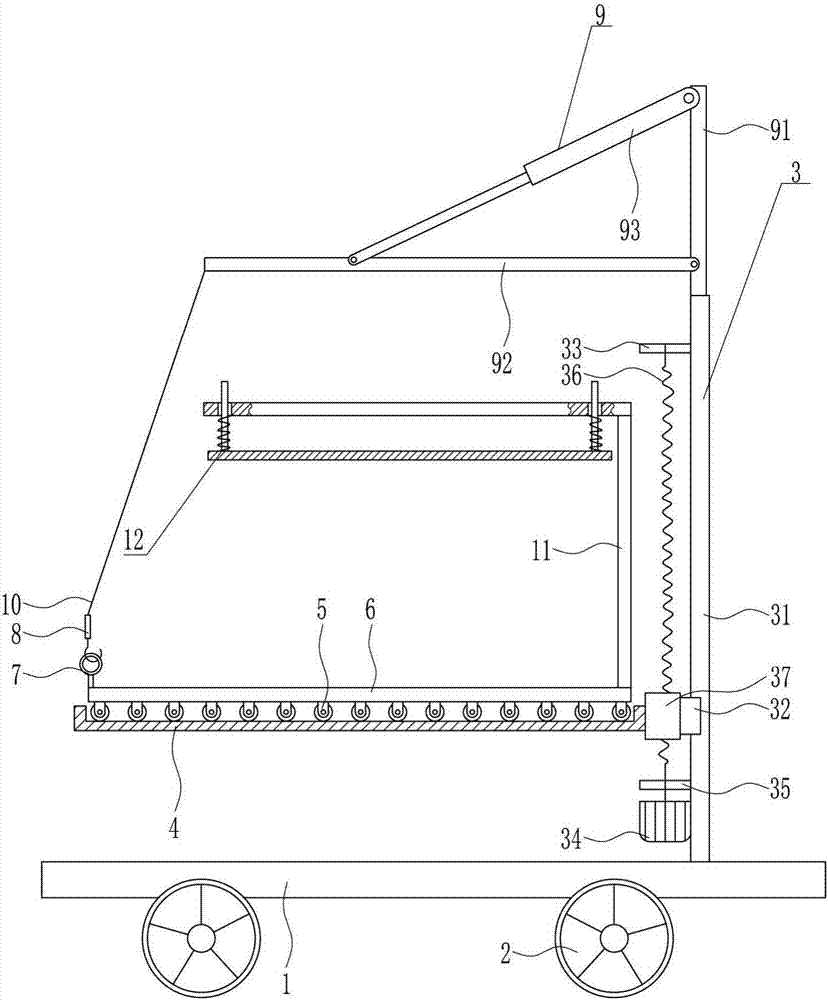

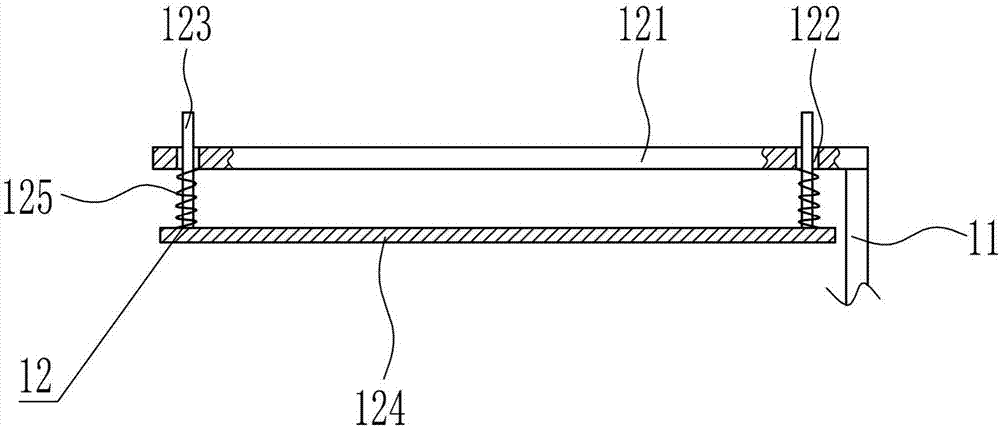

Cultural media book special truck-loading equipment

InactiveCN107128706APrevent fallingImprove work efficiencyLoading/unloadingHand carts with multiple axesEngineeringBilateral symmetry

The invention belongs to the technical field of cultural media and particularly relates to cultural medial book special truck-loading equipment so as to achieve the technical effects that manpower and time can be saved, books are not likely to be damaged, and economic losses can be reduced. In order to achieve the technical effects, the cultural medial book special truck-loading equipment provided by the invention comprises a bottom plate, vehicle wheels, a lifting mechanism, U-shaped plates, wheels, a carrying plate, a hanging ring and the like. The vehicle wheels are rotatably mounted at the bottom of the bottom plate in bilateral symmetry. The lifting mechanism is arranged on the right side of the top of the bottom plate. The U-shaped plates are connected to a lifting component of the lifting mechanism. The U-shaped plates are arranged horizontally. The carrying plate is horizontally arranged over the U-shaped plates. The wheels are rotatably mounted at the bottom of the carrying plate at equal intervals. The cultural medial book special truck-loading equipment can prevent books from falling in the truck-loading process of the books so as to protect the books against damage, and truck-loading is convenient.

Owner:浙江思远电子商务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com