Combined machining method for SLA orthosis formed by three-dimensional printing

A technology of 3D printing and compound processing, which is applied in the fields of medical science and prostheses, can solve the problems of heat resistance, 3D printed orthotics are easy to age, and high material cost, so as to improve loading performance, overcome aging brittleness, digital Prosthetic orthopedic precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

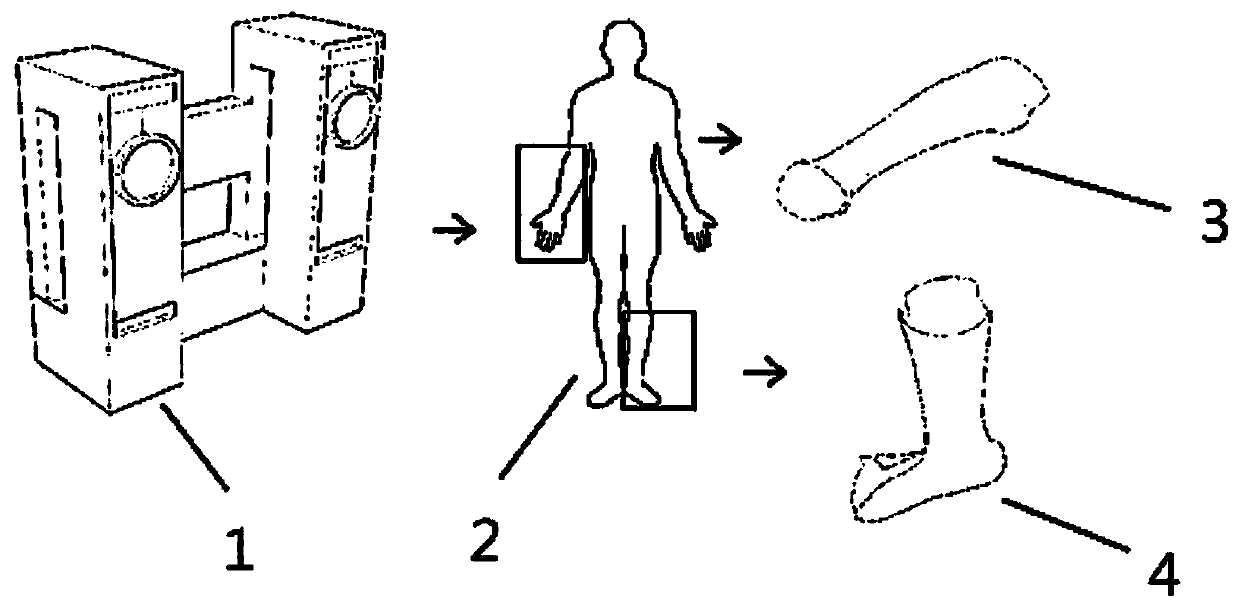

[0036] By operating the Artec Eva handheld body scanner 3D scanner (1) of Artec 3D Company, the patient needs to be corrected, that is, the limb to be scanned (2) is scanned in 3D, and the ankle-foot part (4) of the patient to be corrected is scanned in 3D scan data, such as figure 1 shown.

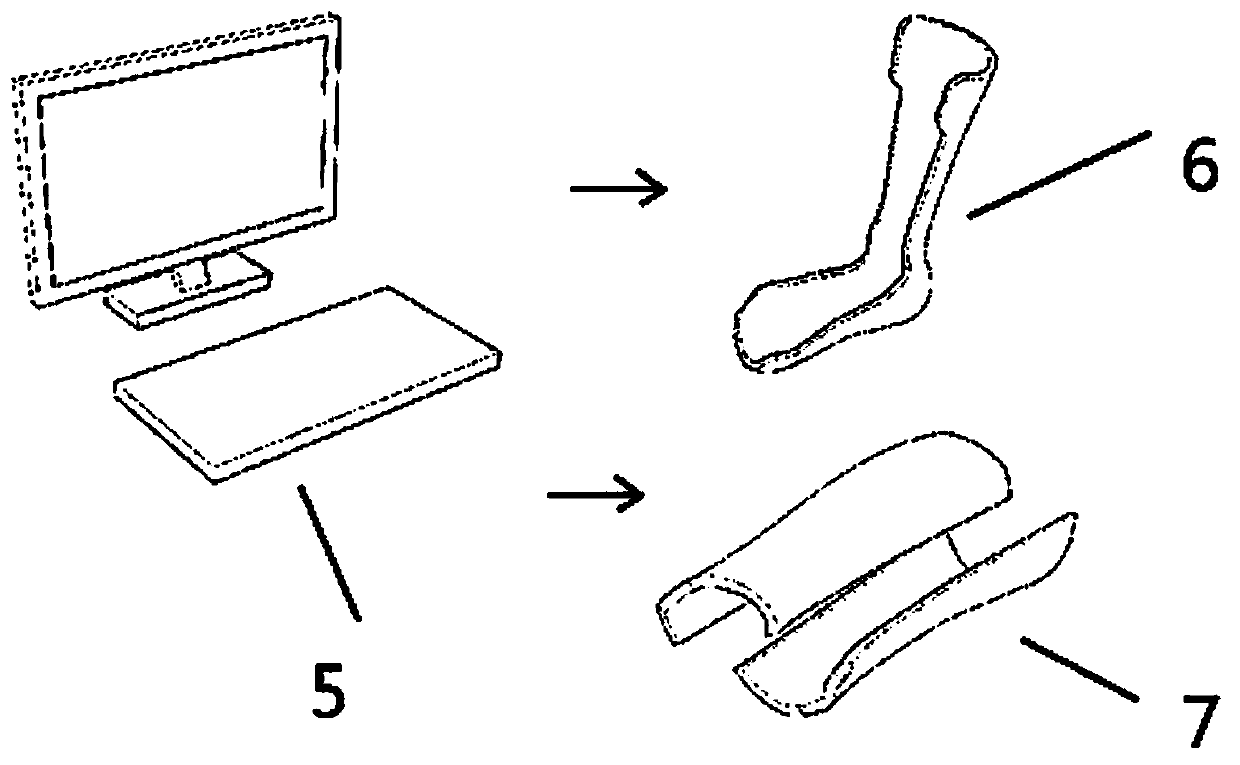

[0037] By using the Magics software of Materialize company to process (5) the limb data obtained by scanning, such as figure 2 As shown in Fig. 1, perform operations such as shape repair and shape correction on the limbs to be orthopedic, and perform shell extraction to obtain a 3D model of the ankle-foot orthosis with a wall thickness of 1 mm and meeting ergonomic requirements (6).

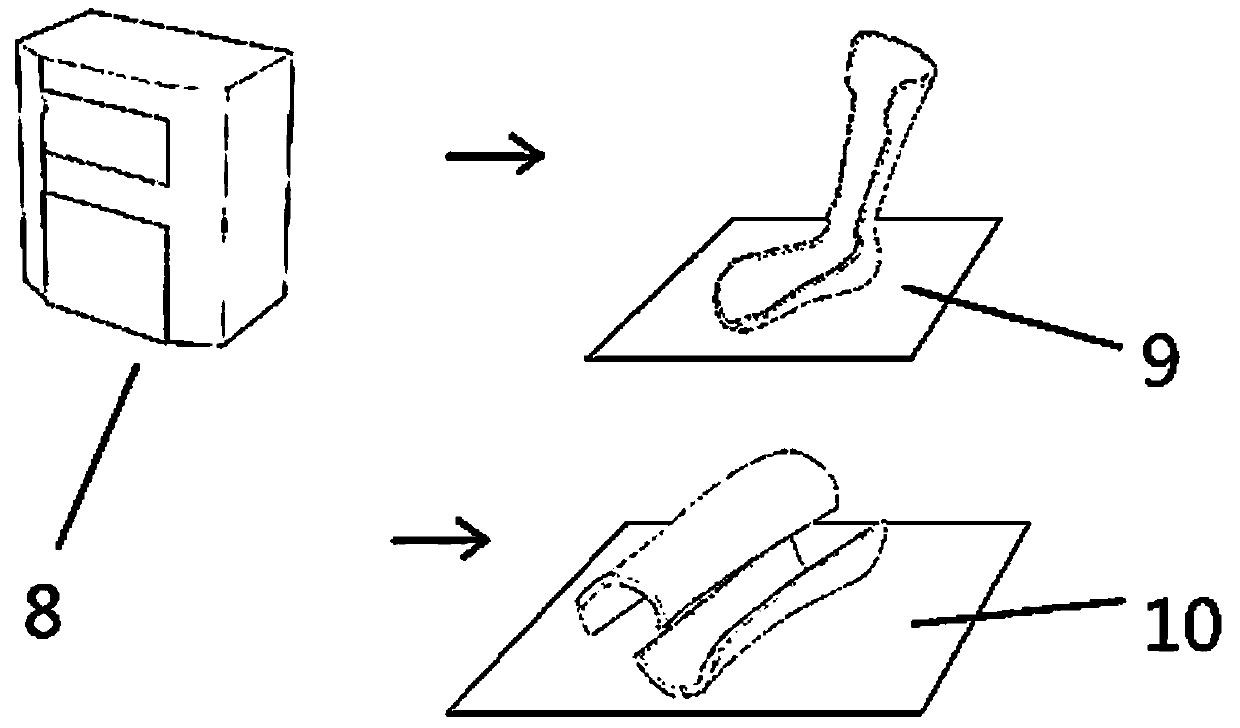

[0038] The 3D model of the ankle-foot-orthosis is input into the iSLA-650 light-curing rapid prototyping printer of SHINING 3D Company, and Somos GP Plus material is used for 3-D printing production through stereolithography rapid prototyping technology (8), and the SLA shell of the ankle-foot-orthosis is ...

Embodiment 2

[0043] By operating the Sense handheld body scanner 3D scanner (1) of 3D Systems, the patient needs to be corrected, that is, the limb to be scanned (2) is scanned in 3D, and the 3D scan data of the patient's arm to be corrected (3) is obtained by scanning ,Such as figure 1 shown.

[0044] By using the Magics software of Materialize company to process (5) the limb data obtained by scanning, such as figure 2 As shown in Fig. 1, perform operations such as shape repair and shape correction on the limbs to be orthopedic, and perform shell extraction to obtain a 3D model of the arm orthosis with a wall thickness of 0.7 mm and meeting ergonomic requirements (7).

[0045] The 3D model of the arm orthosis was input into the iSLA-650 photo-curing rapid prototyping printer of SHINING 3D Company, and the Somos GP Plus material was used to produce 3-D printing through stereolithography rapid prototyping technology (8), and the SLA shell of the arm orthosis (10 ),Such as image 3 shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com