Nickelous chloride assisted synthesis method of fuel cell catalyst carrier ordered mesoporous carbon

A technology of catalyst carrier and fuel cell, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, chemical instrument and method, etc. It can solve the problems that carbon particles cannot be infiltrated, the loading rate is low, and the electrocatalytic performance of Pt nanoparticles is weakened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0011] (1) Add nickel chloride solution on the basis of soft template self-assembly method. That is: 1.0 g of surfactant Pluronic F127 (polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer) was dissolved in 10.0 g of absolute ethanol, and stirred to form a transparent solution. Add 3.0mL, 0.2mol·L -1 Nickel chloride solution was stirred at 40°C for 1 h. Slowly add 2.08g tetraethyl orthosilicate and 2.5g ethanol solution (20%) of phenolic resin dropwise, stir for 2h to make it evenly mixed.

[0012] (2) Transfer the mixture to a flat-bottomed evaporating dish, evaporate the solvent at room temperature (25°C) for 5-8 hours, put it in a vacuum drying oven at 100°C for thermal polymerization for 24 hours, and form a soft film.

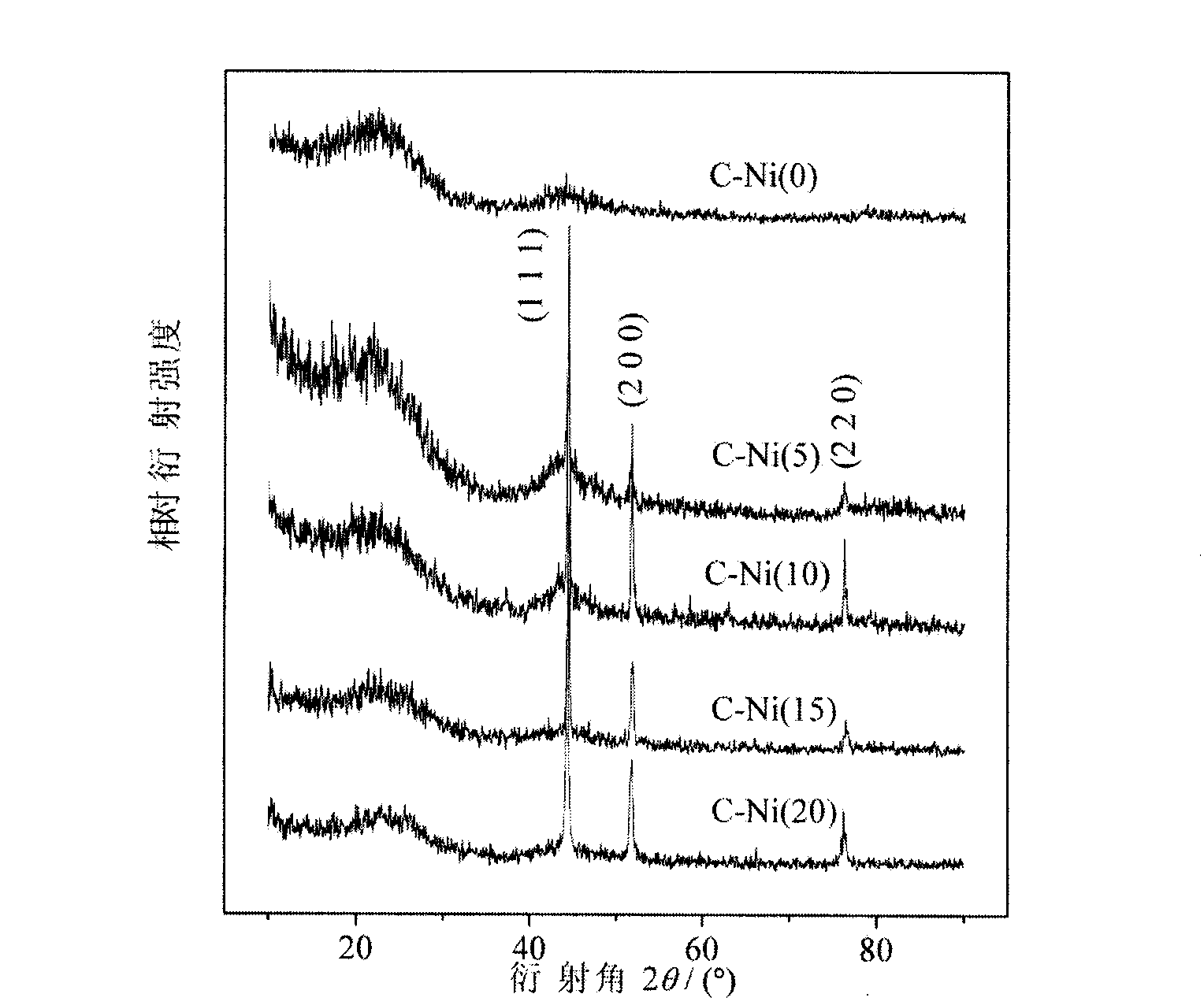

[0013] (3) Carbonization is carried out in an atmosphere tube furnace with nitrogen gas flow. Insulate at 900°C for 2 hours, and the heating rate is strictly controlled at 1°C·min -1 , that is, ordered mesoporous carbon-silicon oxide compos...

specific Embodiment 2

[0018] Specific embodiment two (comparative example):

[0019] (1) Dissolve 1.0 g of surfactant F127 in 10.0 g of absolute ethanol, and stir to form a transparent solution. Without adding nickel chloride solution, stirring was continued at 40°C for 1h. Slowly add 2.08g tetraethyl orthosilicate and 2.5g ethanol solution (20%) of phenolic resin dropwise, stir for 2h to make it evenly mixed.

[0020] (2) Transfer the mixture to a flat-bottomed evaporating dish, evaporate the solvent at room temperature (25°C) for 5-8 hours, put it in a vacuum drying oven at 100°C for thermal polymerization for 24 hours, and form a soft film.

[0021] (3) Carbonization is carried out in an atmosphere tube furnace with nitrogen gas flow. Insulate at 900°C for 2 hours, and the heating rate is strictly controlled at 1°C·min -1 , that is, ordered mesoporous carbon-silicon oxide composites.

[0022] (4) Soak the carbonized and ground sample with a mixed solution of NaOH, ethanol and water (mass rat...

specific Embodiment 3

[0026] (1) Add nickel chloride solution on the basis of soft template self-assembly method. Namely: Dissolve 1.0 g of template agent F127 in 10.0 g of absolute ethanol and stir to form a transparent solution. Add 4.0mL, 0.2mol·L -1 Nickel chloride solution was stirred at 40°C for 1 h. Slowly add 2.08g tetraethyl orthosilicate and 2.5g ethanol solution (20%) of phenolic resin dropwise, stir for 2h to make it evenly mixed.

[0027] (2) Transfer the mixture to a flat-bottomed evaporating dish, evaporate the solvent at room temperature (25°C) for 5-8 hours, put it in a vacuum drying oven at 100°C for thermal polymerization for 24 hours, and form a soft film.

[0028] (3) Carbonization is carried out in an atmosphere tube furnace with nitrogen gas flow. Insulate at 900°C for 2 hours, and the heating rate is strictly controlled at 1°C·min -1 , that is, ordered mesoporous carbon-silicon oxide composites.

[0029] (4) Soak the carbonized and ground sample with a mixed solution of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com