Antibacterial carboxymethyl chitosan/nano zinc oxide composite microsphere and preparation method thereof

A technology of carboxymethyl chitosan and nano-zinc oxide, which is applied in the field of biomedical composite materials, can solve the problems of unsolved dispersibility of nZnO in thin films, the influence of nano-zinc oxide composite materials, and the dispersal situation of nZnO is not involved. Good loading and appearance controllability, safe and non-toxic raw materials, and significant bacteriostatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

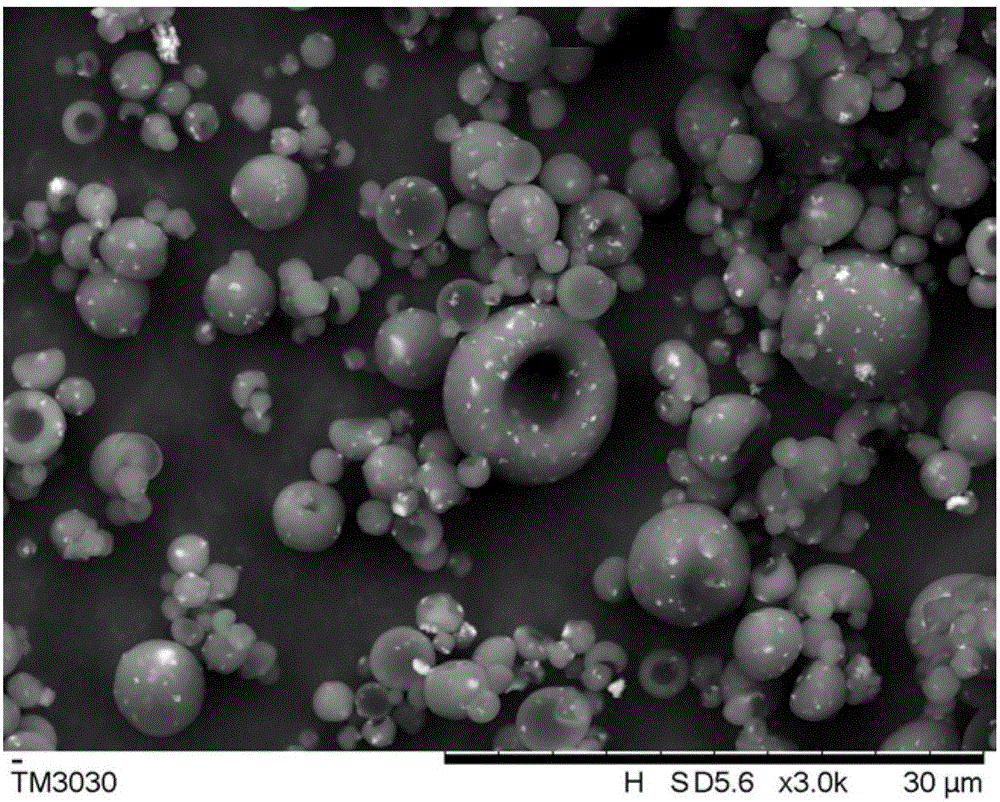

[0037] The steps of using carboxymethyl chitosan and nano-zinc oxide (particle size ~ 10nm) to prepare composite microspheres in a mass ratio of 100:8 are as follows:

[0038] (1) Weigh 5g of carboxymethyl chitosan powder (SIGMA-ALDRICH, viscosity 200-800mpa·s) into 300mL of deionized water, and stir with a stirrer. After the powder is completely dissolved, a solution of 1.67wt% is obtained ;

[0039](2) Preparation of nZnO: zinc acetate and dimethyl sulfone were dissolved in methanol to prepare a solution of 0.015 mol / L, and 0.001 mol / L methanol solution of potassium hydroxide was slowly dropped into it, and a transparent solution was obtained after the reaction for 12 hours. Add deionized water to precipitate the nanoparticle crystals, centrifuge and wash the precipitate with ethanol, and then dry to obtain powdery nZnO;

[0040] (3) Weigh 0.4 g of nZnO powder (about 10 nm in diameter) obtained in step (2), and add it to the carboxymethyl chitosan obtained in step (1) at a ...

Embodiment 2

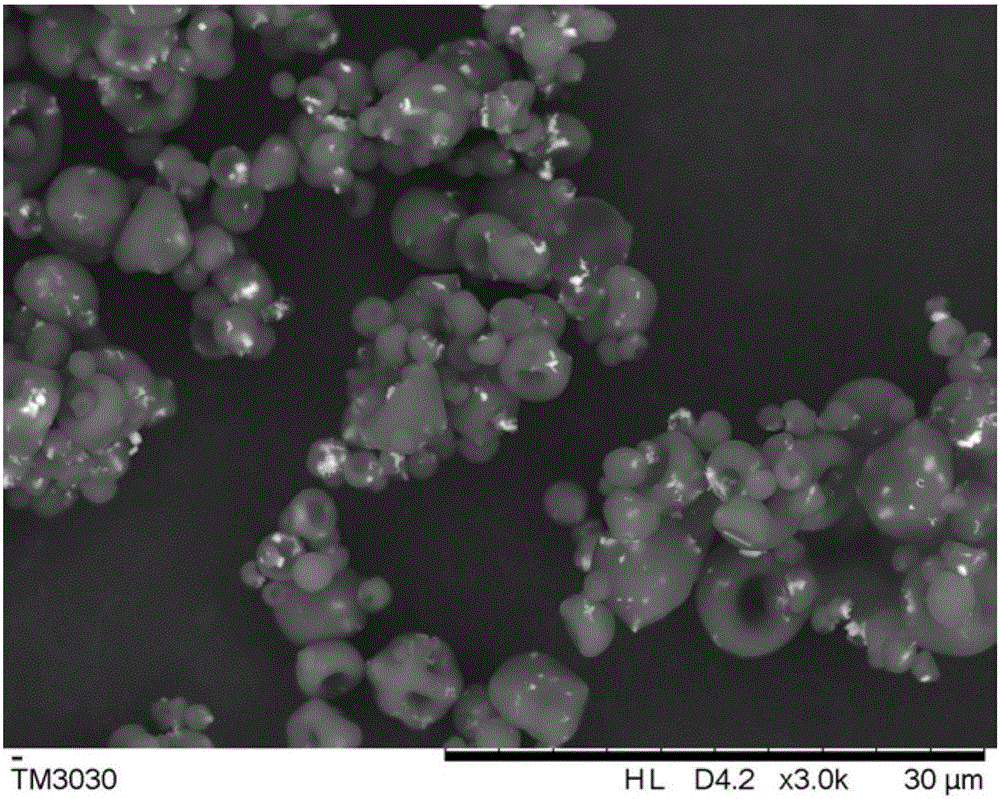

[0044] The steps of using carboxymethyl chitosan and nano-zinc oxide (particle size ~ 30nm) to prepare composite microspheres in a mass ratio of 100:8 are as follows:

[0045] (1) Weigh 5g of carboxymethyl chitosan powder (SIGMA-ALDRICH, viscosity 200-800mpa·s) into 300mL of deionized water, and stir with a stirrer. After the powder is completely dissolved, a solution of 1.67wt% is obtained ;

[0046] (2) Weigh 0.4 g of nano-zinc oxide powder (ALADDIN, diameter 30±10 nm), and add it to the carboxymethyl chitosan solution obtained in step (1) at the ratio of nano-zinc oxide / carboxymethyl chitosan=8wt% And use the ultrasonic oscillator for 20min to disperse, and let it stand for later use after the dispersion is uniform;

[0047] (3) the mixed suspension obtained in step (2) is spray-dried with a spray dryer, the inlet temperature is 220 ° C, the air intake is 90%, the feeding rate is 7.5 mL / min, and the obtained composite microsphere powder is stored Reserve in a moisture-pro...

Embodiment 3

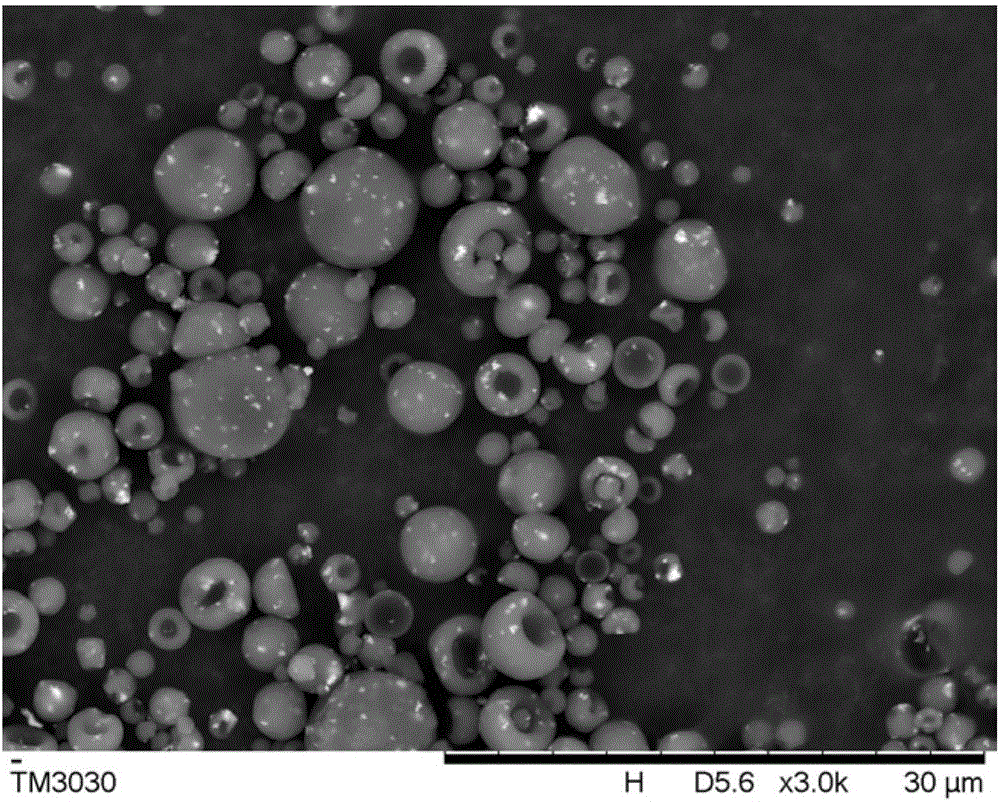

[0050] The steps of using carboxymethyl chitosan and nano-zinc oxide (particle size ~ 30nm) to prepare composite microspheres in a mass ratio of 100:6 are as follows:

[0051] A preparation method of carboxymethyl chitosan / nano zinc oxide composite microspheres, comprising the following steps:

[0052] (1) Weigh 5g of carboxymethyl chitosan powder (SIGMA-ALDRICH, viscosity 200-800mpa·s) into 300mL of deionized water, and stir with a stirrer. After the powder is completely dissolved, a solution of 1.67wt% is obtained ;

[0053] (2) Weigh 0.3 g of nano-zinc oxide powder (ALADDIN, diameter 30±10 nm), add it into the carboxymethyl chitosan solution at the ratio of nano-zinc oxide / carboxymethyl chitosan=6wt%, and shake with ultrasonic The instrument is shaken for 20min to disperse, and after the dispersion is uniform, let it stand for standby;

[0054] (3) the mixed suspension obtained in step (2) is spray-dried with a spray dryer, the inlet temperature is 220 ° C, the air intake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com