Spiral bevel gear tooth surface loading performance multi-objective optimization method

A multi-objective optimization, spiral bevel gear technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of multiple calculations that are not suitable for multi-objective optimization, unable to accurately calculate the bending stress of the tooth root, and not considering the tooth Root bending stress and other problems, to avoid broken teeth, ensure accuracy, and solve the effect of large amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

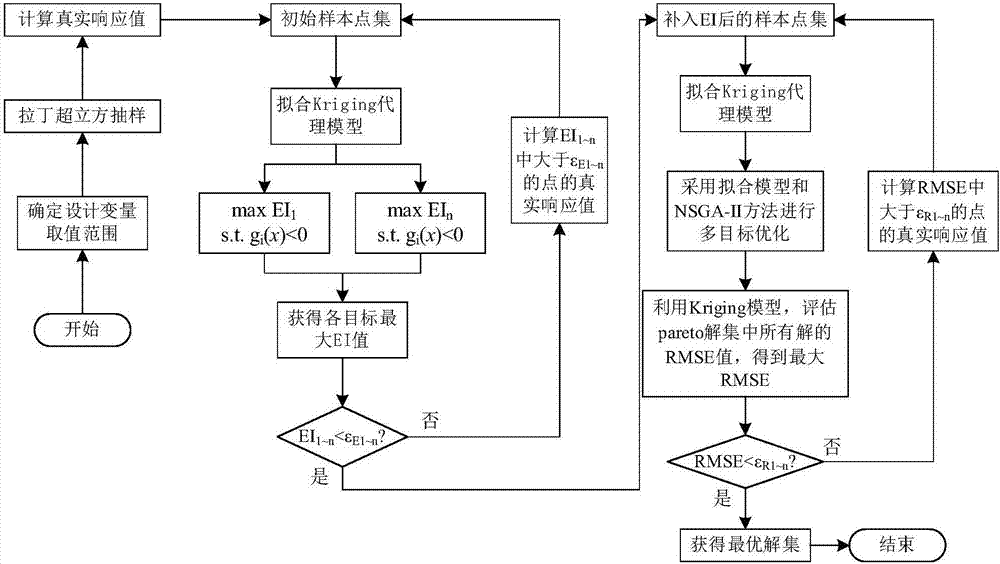

[0047] like figure 1 As shown, a kind of spiral bevel gear tooth surface loading performance multi-objective optimization method provided by the present invention comprises the following steps:

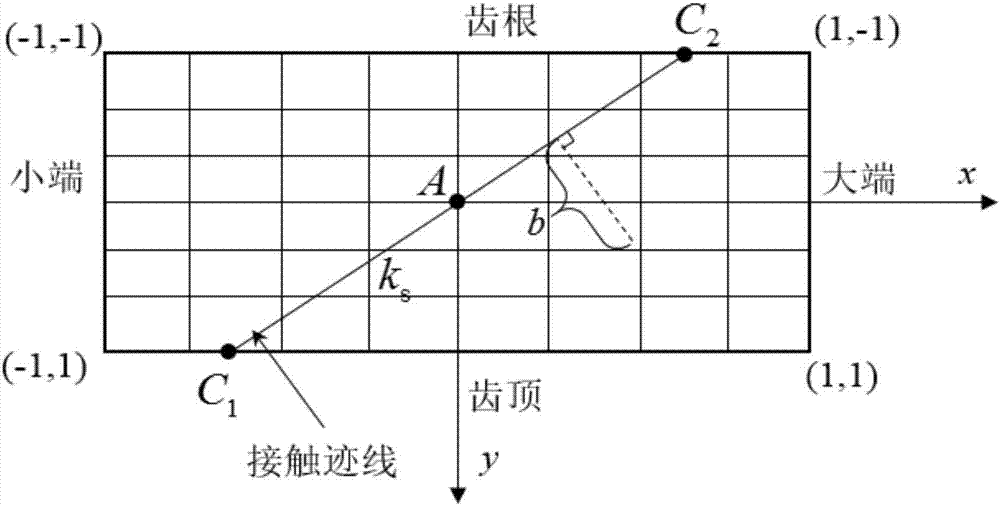

[0048] 1) Establish the mathematical model of the multi-objective optimization problem of the loading performance of the spiral bevel gear tooth surface, and obtain the sample points of the experimental design;

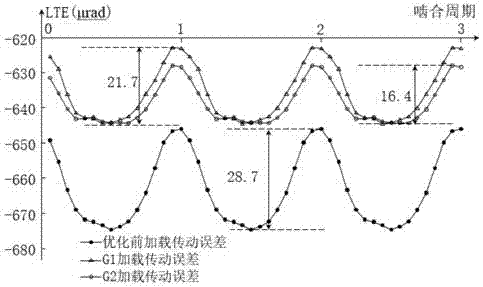

[0049] 2) Establish a tooth surface loading contact analysis method considering the tooth root bending stress, carry out tooth surface loading contact (LTCA) analysis on each test design sample point, and obtain the corresponding response value of each test design sample point, so as to obtain the The initial sample point set of points and their corresponding response values;

[0050] 3) Fit the Kriging proxy model based on the initial sample point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com