Skid-mounted combined oil removal-impurity removal-iron removal device for oilfield confecting polymer water

A water degreasing, combined technology, applied in water pollutants, water/sewage treatment, mining wastewater treatment, etc., can solve the problem of inability to independently complete the whole process of dispersing water treatment, high dependence on pretreatment and subsequent treatment equipment, Can not meet the requirements of processing equipment and other problems, to achieve the effect of convenient management, low operating costs, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

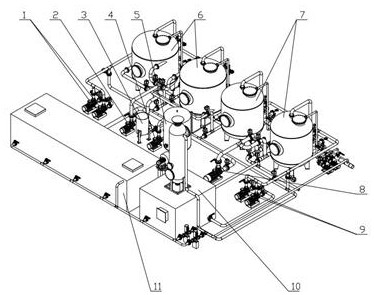

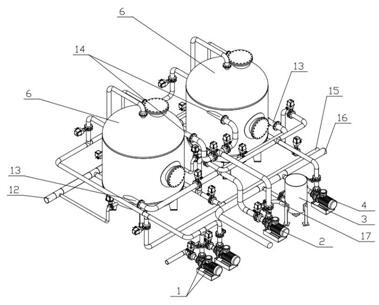

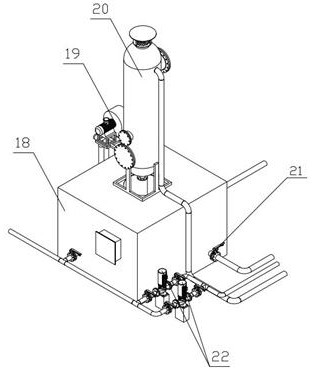

[0026]A skid-mounted combined oilfield mixing water degreasing, impurity and iron removal device, including a primary lift pump (1), a filter (6), an iron remover (7), a secondary lift pump (9), and an aeration device ( 10) and the filtered water tank (11), characterized in that the primary lift pump (1) is connected to the inlet of the filter (6) through a pipeline; the outlet of the filter (6) is connected to the aeration device (10) through a pipeline Inlet connection, the outlet of the aeration device (10) is connected to the liquid inlet pipe of the secondary lift pump (9) through the pipeline, and the liquid outlet pipe of the secondary lift pump (9) is connected to the liquid inlet pipe of the iron remover (7) ;The liquid outlet pipe of the iron remover (7) is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com