Preparation method of corn starch

A corn and starch technology, applied in the preparation methods of peptides, chemical instruments and methods, organic chemistry, etc., can solve the problems of insufficient utilization of waste materials, high processing cost and energy consumption, and imperfect process matching, etc. The effect of increasing the output of end products, producing more, and avoiding the waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

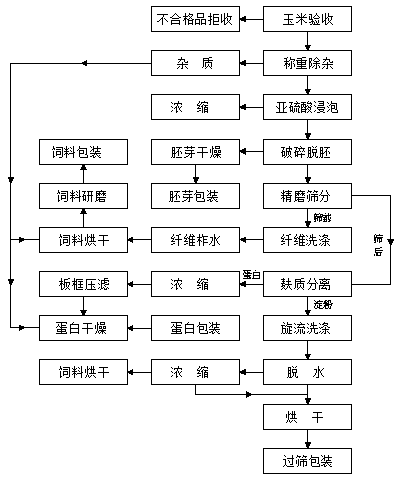

[0019] Such as figure 1 Shown, a kind of preparation method of corn starch, concrete operation method is as follows:

[0020] a. Impurity-removing soaking: After removing impurities from the raw corn kernels, soak them in a sulfurous acid solution with a concentration of 0.18% at 52°C for 42 hours to obtain a slurry and wet corn kernels after removing impurities. This is a liquid soaking reaction process; the slurry is passed through After concentration and drying, zein is made into zein, and the slurry is concentrated by using a waste heat evaporator so that the dry matter is not less than 45% by mass.

[0021] b. Crushing and degerming: The impurity-removed wet corn kernels obtained in step a are subjected to primary crushing, and process water is added during the crushing process. After crushing, 500 ml is 6-8 whole grains, and then the crushed material is extracted with a germ cyclone to extract the germ, and the bottom flow of the germ cyclone is crushed again, and the m...

Embodiment 2

[0028] Such as figure 1 Shown, a kind of preparation method of corn starch, concrete operation method is as follows:

[0029] a. Impurity-removing soaking: After removing impurities from the raw corn kernels, soak them in a sulfurous acid solution with a concentration of 0.22% for 44 hours at 55°C to obtain a slurry and wet corn kernels after removing impurities. This is a liquid soaking reaction process; the slurry is passed through After concentration and drying, zein is made into zein, and the slurry is concentrated by using a waste heat evaporator so that the dry matter is not less than 45% by mass.

[0030] b. Crushing and degerming: The impurity-removed wet corn kernels obtained in step a are subjected to primary crushing, and process water is added during the crushing process. After crushing, 500 ml is 6-8 whole grains, and then the crushed material is extracted with a germ cyclone to extract the germ, and the bottom flow of the germ cyclone is crushed again, and the m...

Embodiment 3

[0037] Such as figure 1 Shown, a kind of preparation method of corn starch, concrete operation method is as follows:

[0038] a. Impurity-removing soaking: After removing impurities from the raw corn kernels, soak them in a sulfurous acid solution with a concentration of 0.20% for 43 hours at 52°C to 55°C to obtain a slurry and impurity-removing wet corn kernels, which is a liquid soaking reaction process; After the thin slurry is concentrated and dried, it is made into zein, and the thin slurry is concentrated by using a waste heat evaporator to reach a dry matter percentage of not less than 45% by mass.

[0039] b. Crushing and degerming: The impurity-removed wet corn kernels obtained in step a are subjected to primary crushing, and process water is added during the crushing process. After crushing, 500 ml is 6-8 whole grains, and then the crushed material is extracted with a germ cyclone to extract the germ, and the bottom flow of the germ cyclone is crushed again, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com