Oil cup inner wall grinding and brushing assembly line device

An assembly line and oil cup technology, applied in the direction of grinding machine, grinding head, grinding feed movement, etc., can solve the problems of hidden safety hazards, low processing efficiency, poor processing environment, etc., and achieve time saving, complete process and continuous work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

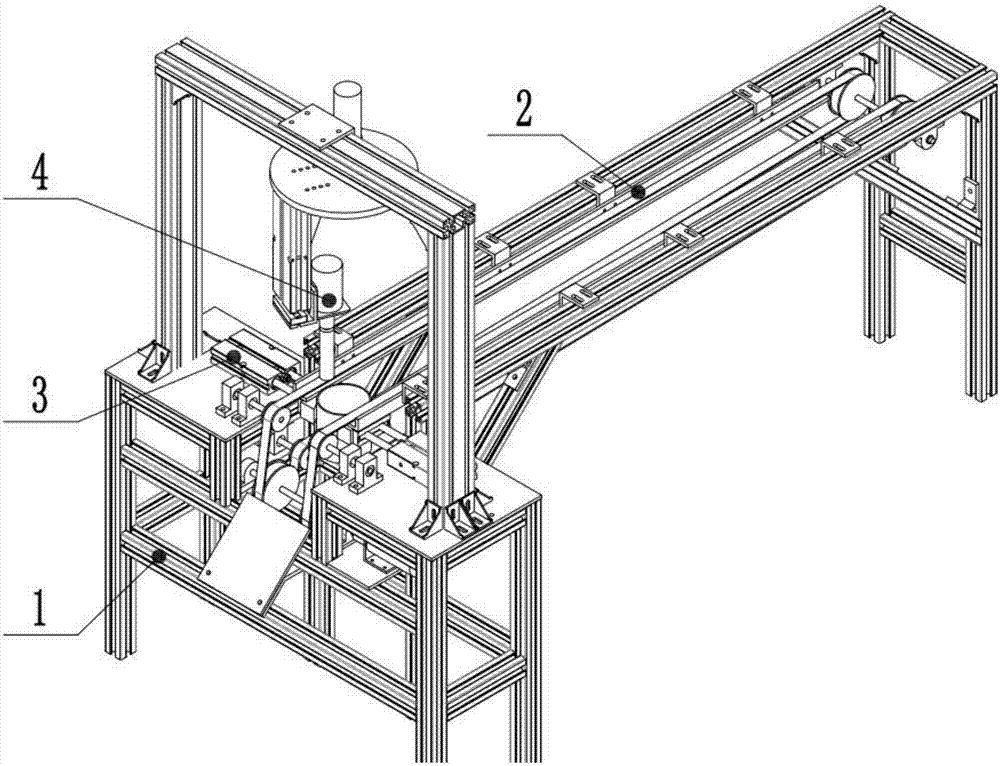

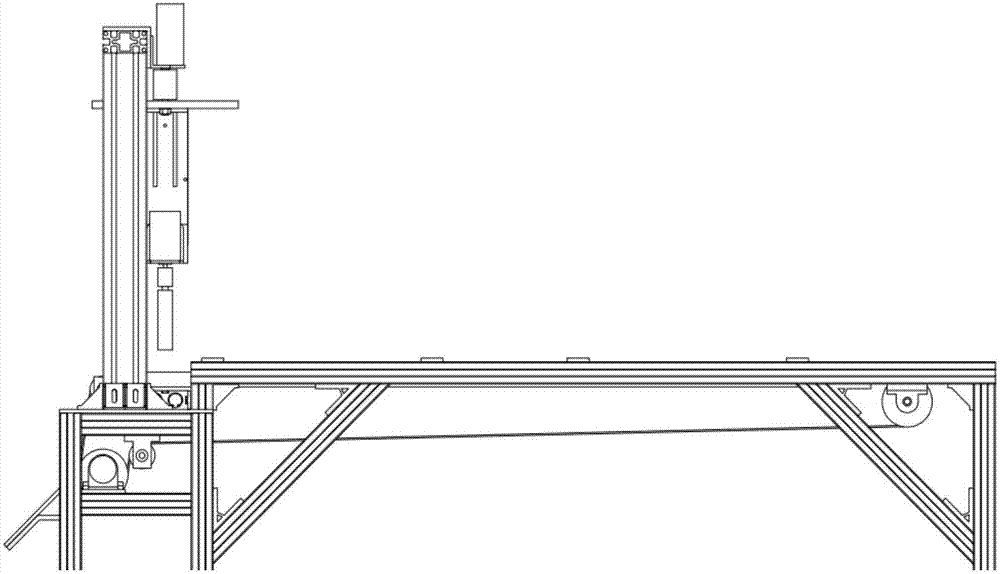

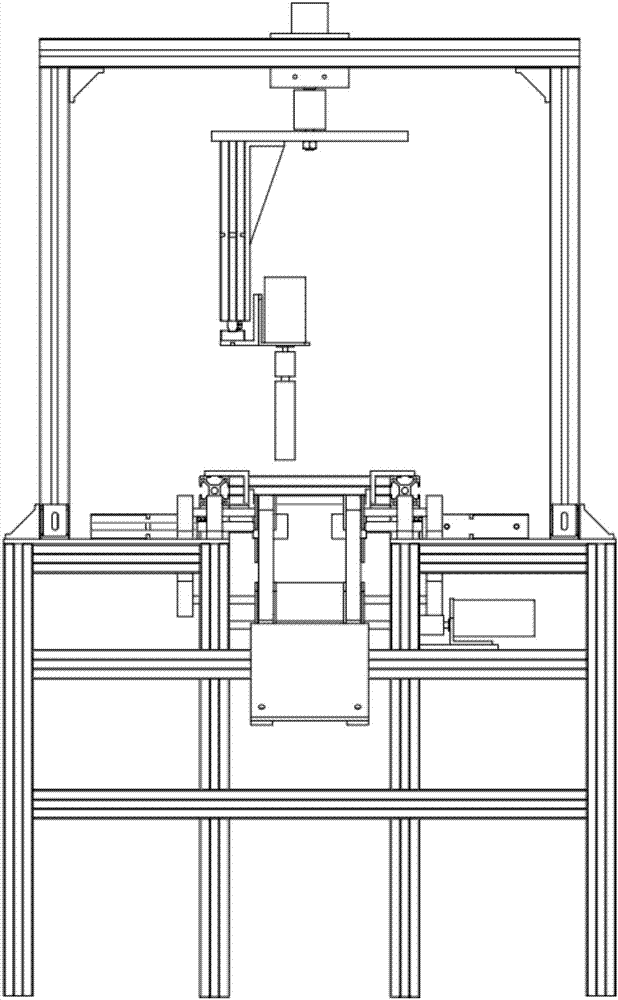

[0022] refer to Figure 1 to Figure 7 , an assembly line device for grinding and brushing the inner wall of an oil cup, including an external frame 1, an adjustable feeding mechanism 2, a clamping and centering mechanism 3, and a grinding and brushing mechanism 4. The layers are arranged in an orderly manner.

[0023] In the adjustable feeding mechanism: as Figure 4 , the conveyor belt 401 is fixed on the frame through a synchronous pulley 402 and a bearing seat 403, and is driven by a DC geared motor 404. The guide groove 405 is fixed on the frame by a guide groove fixing member 406 . A batch of automobile oil cups of the same specification can be placed on the conveyor belt 401, and then can be adjusted when changing another batch of another specification. By adjusting the distance between the two groups of synchronous pulleys 402 and adjusting the position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com