Pressing die for meter-scale buffer material circular building block and building block preparation method

A technology for cushioning materials and pressing molds, which is applied in the direction of manufacturing tools, mold fixtures, mold auxiliary parts, etc., and can solve problems such as no longer applicable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The press mold of a circular block of meter-scale cushioning material provided by the present invention and the preparation method of the block will be further described in detail below in conjunction with the accompanying drawings and specific examples.

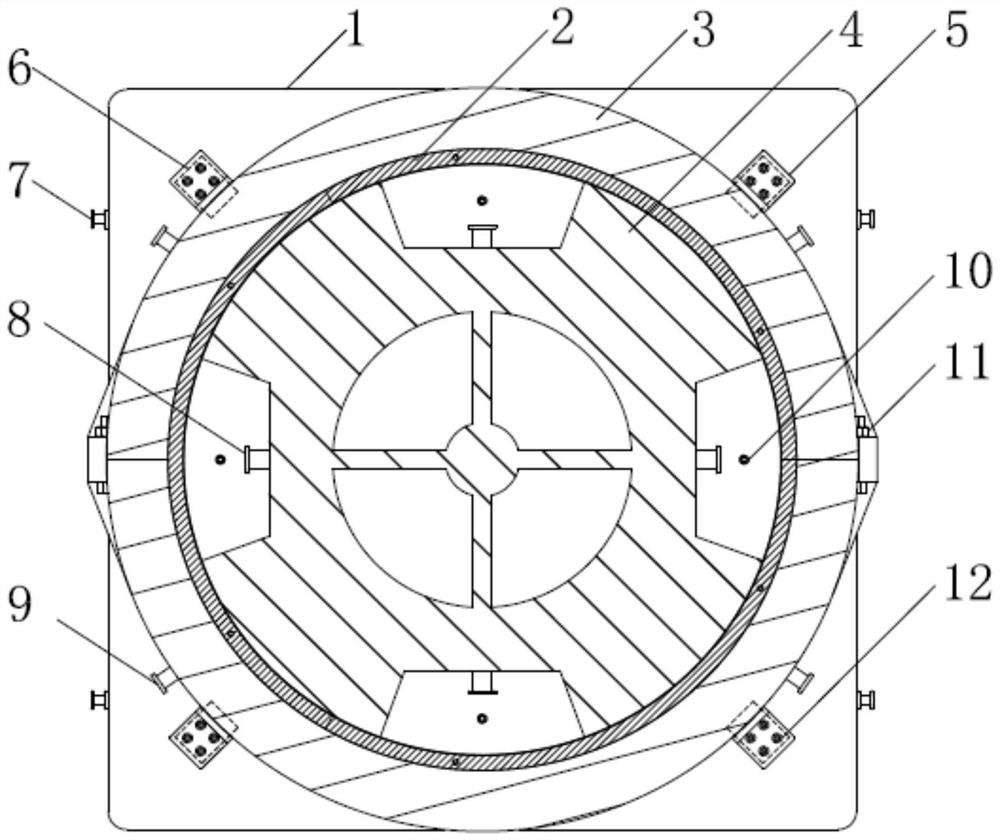

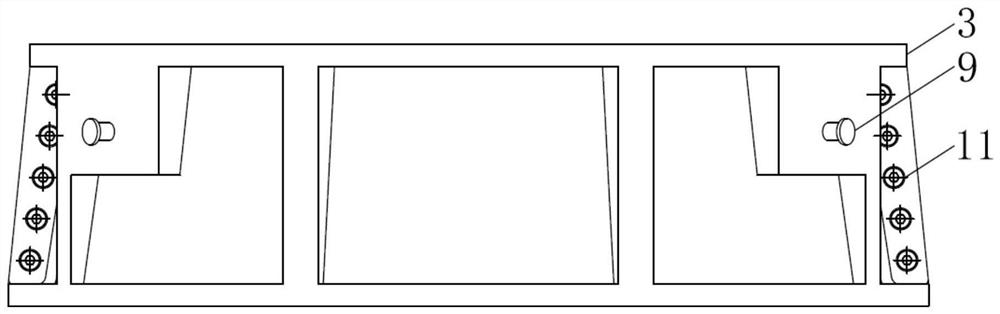

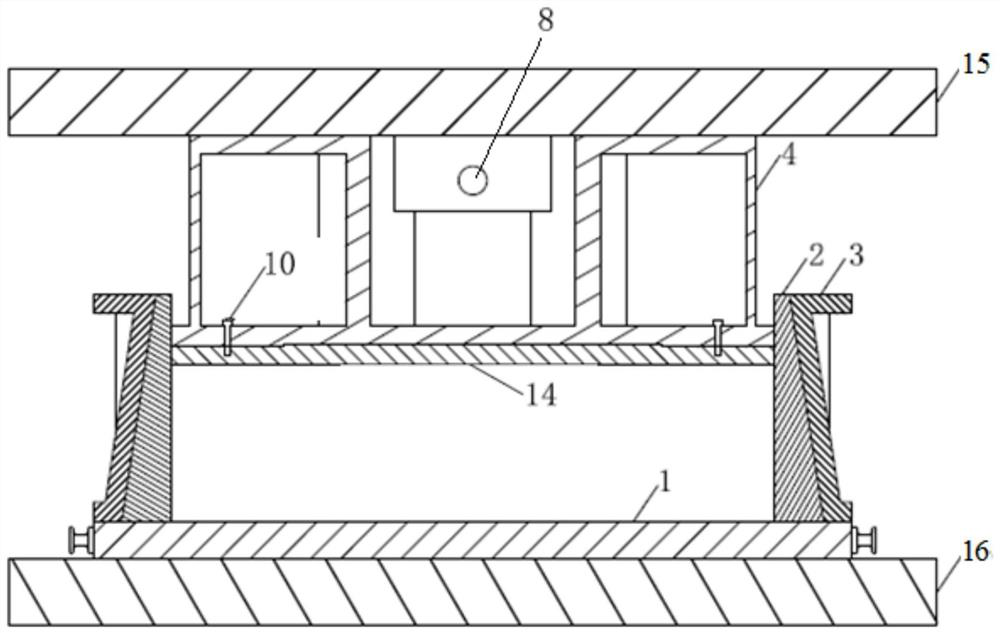

[0045] Such as Figure 1-3 As shown, the present invention provides a meter-scale cushioning material circular block pressing mold, which can be used to prepare a cushioning material circular block with a diameter of 1.6 m and an adjustable height after assembly. It mainly includes a bottom plate 1, two die holders 3, three die inner linings 2, a punch holder 4, a punch liner 14, four positioning stops 5 and four pressure plates 6.

[0046] The die base 3 is semicircular, and two die bases 3 form a circular die through bolts 11; the die lining is a sector of 120°, and three die linings 2 form a circular inner lining and are arranged on On the inner wall of the die seat 3; the diameter of the circle formed by the comb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com