Rubber powder aftertreatment equipment

A post-processing and rubber powder technology, which is applied in the field of production equipment for producing rubber granules from waste tire rubber powder, can solve problems such as difficulty in establishing production norms and standards, high energy consumption, and difficult compression of production process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

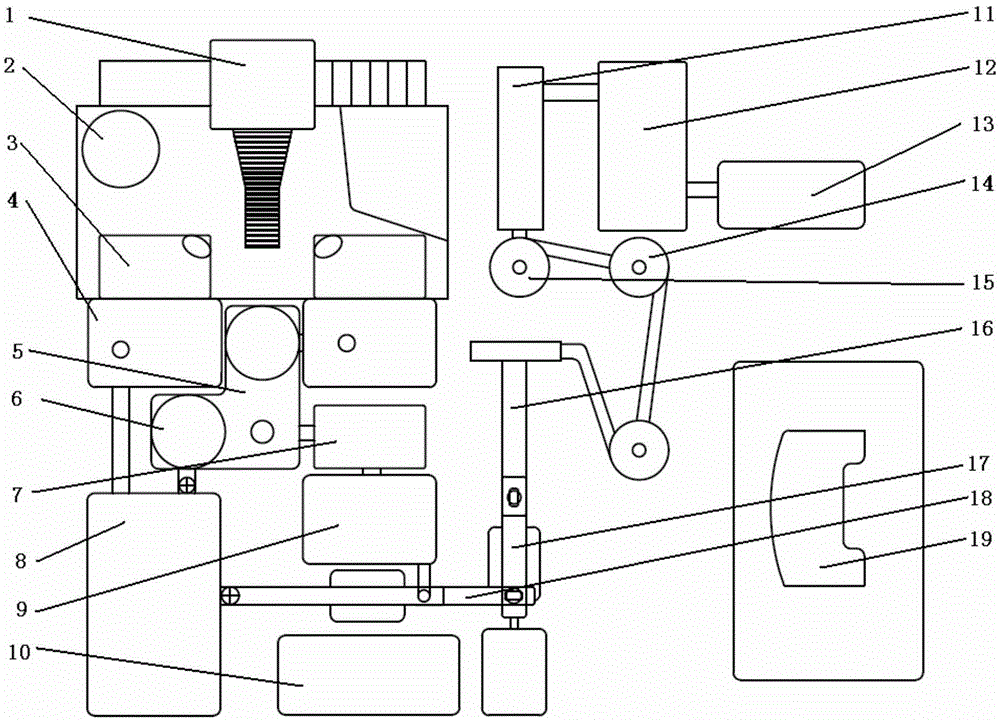

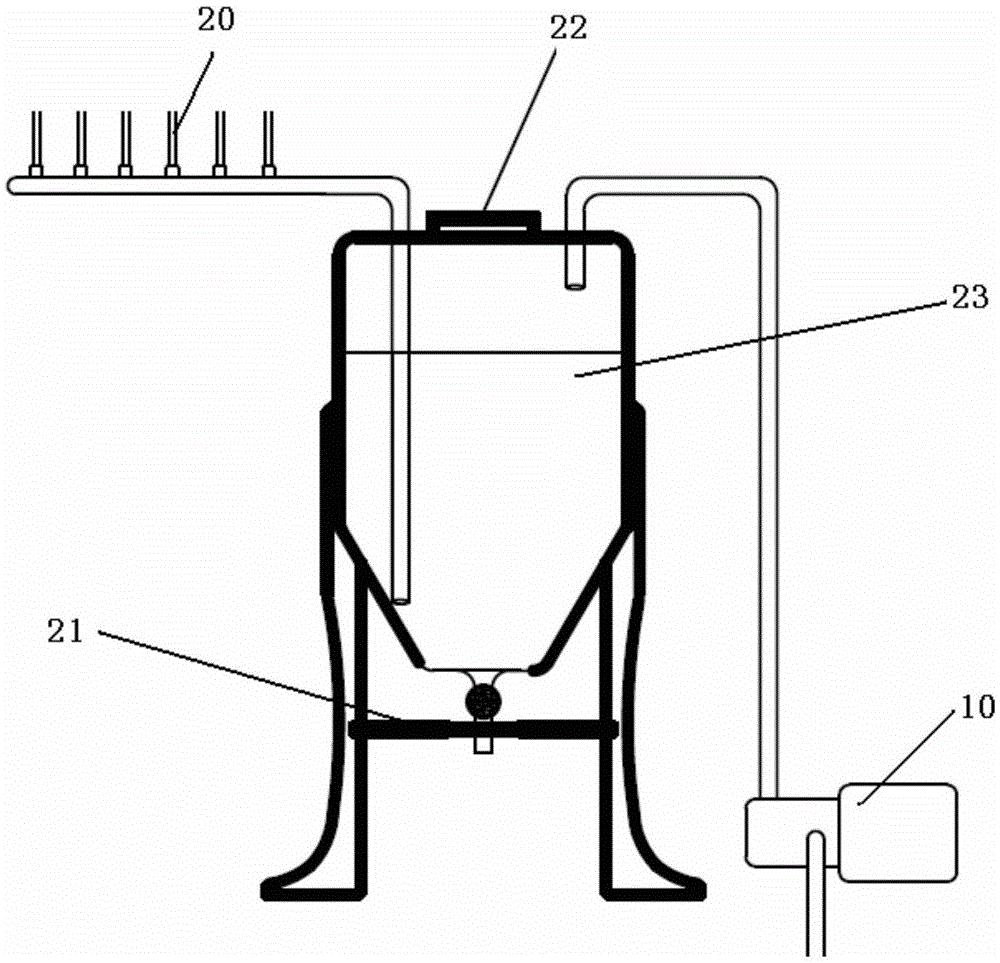

[0015] like figure 1 As shown, a rubber powder post-processing equipment according to the present invention is composed of a plurality of working modules, including: a feeding platform 1, an oil storage tank 2, a mixer I3, a hopper I4, a hopper II5, and a dynamic automatic weighing machine 6 , mixer II7, desulfurizer 8, hopper III9, vacuum pump 10, vibrating screen 11, finished product storage tank 12, automatic metering packaging machine 13, air cylinder I14, air cylinder II15, granulator 16, mixer 17, mixing Machine 18, central control room 19.

[0016] The waste tire powder enters through the feeding platform 1, and the downstream of the feeding platform 1 is provided with an oil storage tank 2 and a functional formula material area, and a mixer I3 is respectively arranged at the downstream of the oil storage tank 2 and the functional formula material area.

[0017] Two hoppers I4 are respectively set at the downstream of the above-mentioned two mixers 3, and a hopper II5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com