Method for preparing chemithermomechanical pulp from corn straw by potash process and extracting pulping waste liquid to prepare fertilizer

A technology of corn stalks and pulping waste liquid, which is applied in the direction of alkaline orthophosphate fertilizer, fertilizer mixture, ammonium orthophosphate fertilizer, etc., can solve problems such as difficult to implement, not specific enough, pulping process is not clearly stated, and achieve The effect of complete process, reduced operating costs, and increased farmers' income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

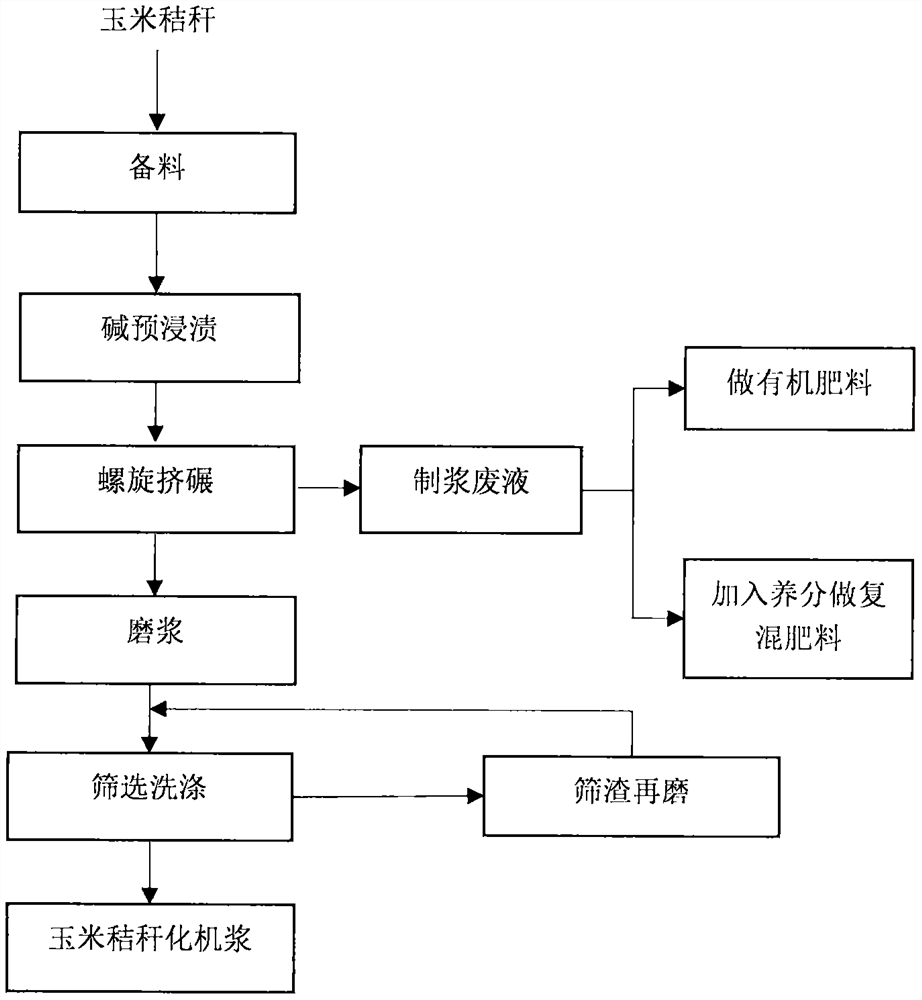

Method used

Image

Examples

Embodiment 1

[0023] The corn stalks of this embodiment were taken from a papermaking enterprise in Liaoning, and were not separated from the skins and stalks, and were whole corn stalks. The preparation of corn stalk chemical pulp by KOH pre-impregnation and refining, and preparation of fertilizer from the pulping waste liquid include the following steps:

[0024] (1) The process parameters of the pre-impregnation are 5.6% of the pre-impregnated potassium hydroxide, the liquid ratio is 1:5, the maximum temperature is 130°C, and the heat preservation time is 30 minutes. The process parameters of the refining are as follows: the concentration of the refining slurry is 20%, the refining gap is 0.5mm, 0.3mm, 0.1mm, 0.1mm, four stages of refining, after screening, the corn stalk chemical mechanical pulp is prepared;

[0025] (2) The screw extruder extracts the pulping waste liquid, which can be concentrated and granulated to produce organic fertilizer. Add 310kg ammonium phosphate to each ton of was...

Embodiment 2

[0028] The corn stalks of this embodiment were taken from a papermaking enterprise in Liaoning, and were not separated from the skins and stalks, and were whole corn stalks. The preparation of corn stalk chemical pulp by KOH pre-impregnation and refining, and preparation of fertilizer from the pulping waste liquid include the following steps:

[0029] (1) The process parameters of pre-impregnation are 6.0% potassium hydroxide, the liquid ratio is 1:4, the maximum temperature is 130°C, and the heat preservation time is 30 minutes. The process parameters of the refining are as follows: the concentration of the refining slurry is 20%, the refining gap is 0.5mm, 0.3mm, 0.1mm, three stages of refining, after screening, the corn stalk chemical pulp is prepared;

[0030] (2) The screw extruder extracts the pulping waste liquid and concentrates it to 35% solid content to produce organic liquid fertilizer. Add 50kg of ammonium bicarbonate and 300kg of diammonium hydrogen phosphate to each t...

Embodiment 3

[0033] The corn stalks in this embodiment were taken from a farm in Beijing, and were not separated from the hides and stalks, and were whole corn stalks. The preparation of corn stalk chemical pulp by KOH pre-impregnation and refining, and preparation of fertilizer from the pulping waste liquid include the following steps:

[0034] (1) The process parameters of the pre-impregnation are 6.0% of the pre-impregnated potassium hydroxide, the liquid ratio is 1:5, the maximum temperature is 110°C, and the heat preservation time is 30 minutes. The process parameters of the refining are as follows: the concentration of the refining slurry is 25%, the refining gap is 0.5mm, 0.3mm, 0.1mm, three stages of refining, after screening, the corn stalk chemical pulp is prepared;

[0035] (2) The screw extruder extracts the pulping waste liquid, which can be concentrated and granulated to obtain organic fertilizer. Adding 260kg of diammonium hydrogen phosphate to each ton of waste liquid solids can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com