Production process of special wire harness for new energy automobile

A new energy vehicle and production process technology, which is applied in the manufacture of wire harnesses, electrical components, circuits, etc., can solve the problems of short life of wire harnesses, immature wire harness production technology, and low production pass rate, so as to improve utilization rate and avoid production technology. The effect of immaturity and complete process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

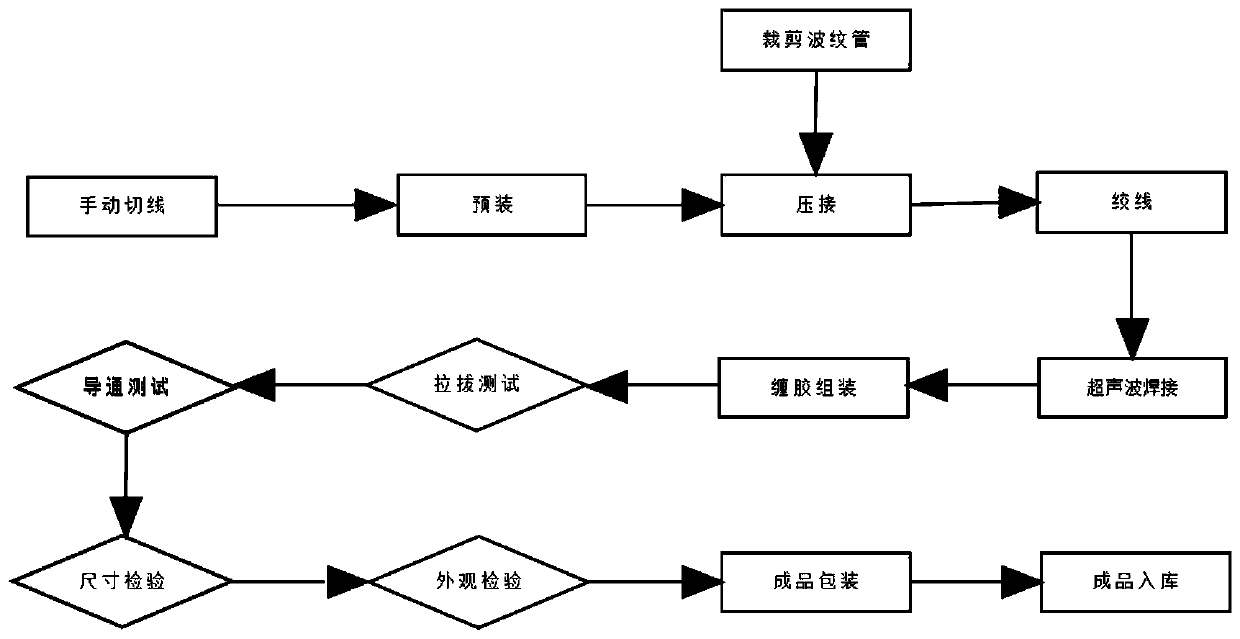

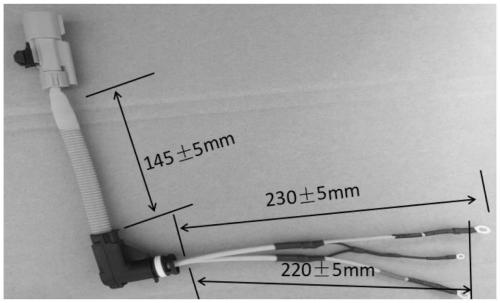

[0035] The production process of a kind of new energy vehicle special wire harness that the present invention proposes, comprises the following steps:

[0036] S1. Preparatory work: prepare the materials required for wire harness production;

[0037] S2. Tangent: Check whether the size of the main conductor meets the design requirements. If it meets the requirements, locate the main conductor to be cut according to the design requirements. The ratio of the stripping length of the insulation skin at the tangent position to the stripping length required by the design is 2:3, perpendicular to the axis of the main conductor Cut the wire in the direction, and carry out visual inspection. The qualified standard is that there are no broken core wires, uneven core wires, damaged core wires, bent core wires, residual wire sheath, and unpeeled rubber;

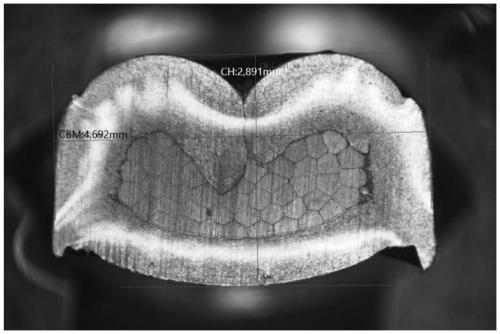

[0038] S3. Pre-installation, crimping, stranding, ultrasonic welding: pre-thread the two main wires after tangent in step S2 into diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com