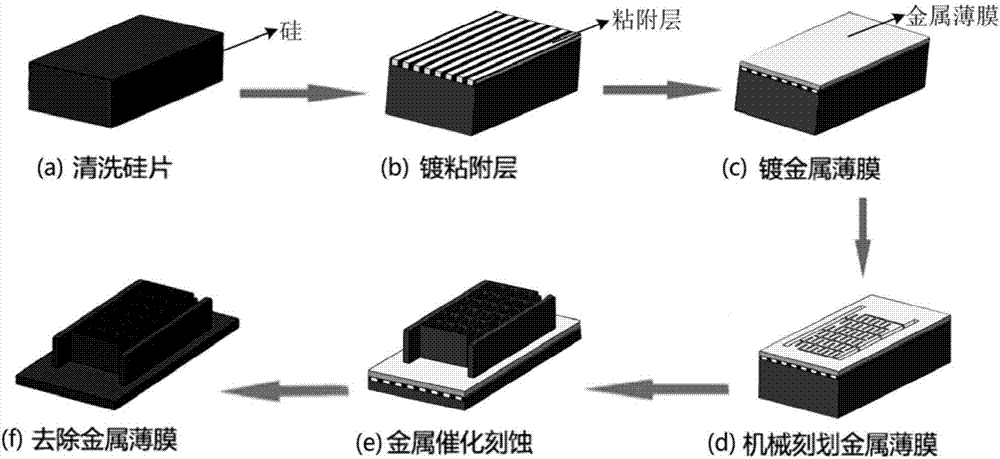

Preparation method for silicon micro/nano structure based on mechanical carving and metal catalysis etching

A technology of mechanical scribing and metal catalysis, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of high cost and difficulty in large-scale integrated manufacturing, and achieve the effect of small applied load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] S1. Pretreatment of silicon wafer: Put the silicon wafer in acetone for ultrasonic cleaning for 5 minutes, then wash it with deionized water, then put the silicon wafer into ethanol solution for ultrasonic cleaning for 10 minutes, then rinse it with deionized water repeatedly and dry it with nitrogen. Get sample A;

[0026] S2. Integration of precious metal nano-film: A resistance thermal evaporation coating instrument (Wuhan Namei Technology Co., Ltd.) is used to integrate a titanium / silver nano-film on the surface of sample A. During the coating process, the thickness of the titanium nano-film is 2nm. When silver nano-film is plated, the vacuum degree of the coating instrument is set to 10 -4 Pa, the current is set to 110A, and a silver nano-film with a thickness of about 50nm is deposited to obtain sample B;

[0027] S3: Mechanical scribing of precious metal nano-films: Using multi-point contact micro-nano processing equipment, using a ball-point pen tip spherical steel b...

Embodiment 2

[0030] This embodiment is compared with the embodiment 1, except that in step S2, a different coating method is used to integrate the silver nano-film, the other steps are the same. In this embodiment, step S2 is specifically:

[0031] S2. Integrated silver nano-film: A magnetron sputtering machine (BEIYI JPGF 700A) is used to deposit a titanium / silver nano-film on the surface of sample A. The thickness of the adhesion layer titanium nano film is 2 nm. During the magnetron sputtering process, the radio frequency mode is adopted, the air pressure is set to 0.2Pa, and the power is set to 100W. After igniting, cover the sample with the baffle for about 3 minutes, and then remove the baffle after the oxide layer on the surface of the target material is removed. The coating time is set to 50s, the thickness of the obtained silver nano-film is about 50nm, and sample B is obtained.

Embodiment 3

[0033] This embodiment is compared with the embodiment 1, except that different types of nano-films are integrated in step S2, the other steps are the same. In this embodiment, step S2 is specifically:

[0034] S2. Integrated gold nano-film: using resistive thermal evaporation coater (Wuhan Namei Technology Co., Ltd.), deposit a titanium / gold nano-film on the surface of sample A, where the thickness of the adhesion layer is 2nm and the thickness of the gold nano-film Is 50 nm, and sample B is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com