Preparation method and application of self-cleaning glass hydrophobic agent

A hydrophobic agent and self-cleaning technology, which is applied in the field of glass surface treatment, can solve the problems of blurred front and rear view mirrors of automobile windshields, side windshields, and poor light transmission, so as to maintain beautiful appearance, less adhesion, and quantification. Effects with low production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

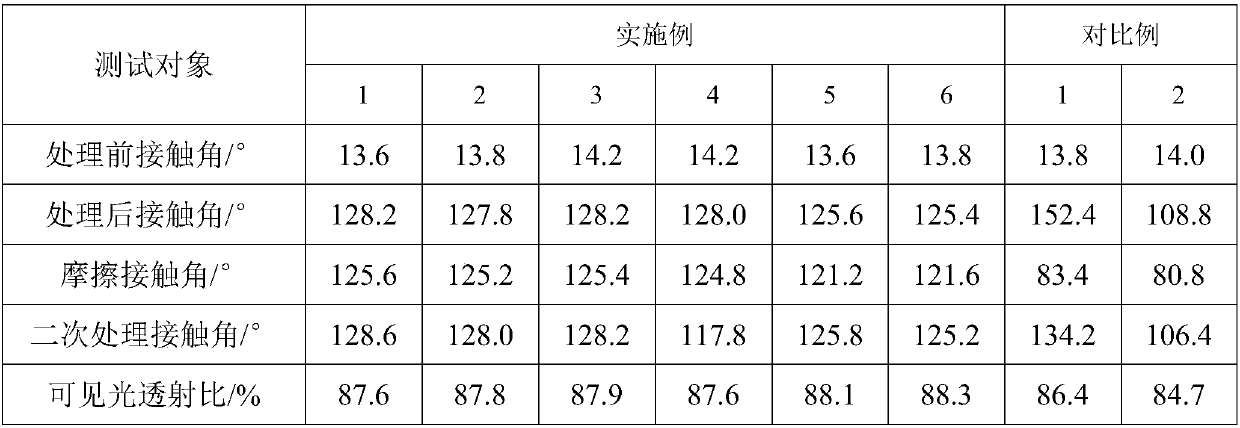

Examples

Embodiment 1

[0026] A self-cleaning glass hydrophobic agent is prepared through the following steps:

[0027] S1, to prepare component A, weigh dimethylcyclosiloxane, phenyl-containing siloxane and silane coupling agent in proportion, mix and stir evenly, and heat to 80°C to obtain hot material; Under the condition that the stirring speed is 30~60rpm, add the basic catalyst to the hot material continuously within 3 hours, and obtain the ternary copolymerized polysiloxane through the polymerization reaction. After cooling to room temperature, add the surfactant, mix well and then add the solvent for Emulsify and filter to obtain component A;

[0028] Each substance and content in each raw material in component A are as shown in Table 1, and the unit of each component content is g;

[0029] Dimethylcyclosiloxane is octamethylcyclotetrasiloxane;

[0030] Phenyl-containing siloxanes include octaphenylcyclotetrasiloxane, tetramethyltetraphenylcyclotetrasiloxane, short-chain dimethyldiphenylsi...

Embodiment 2

[0041] A self-cleaning glass hydrophobic agent is prepared through the following steps:

[0042] S1, to prepare component A, weigh dimethylcyclosiloxane, phenylsiloxane and silane coupling agent in proportion, mix and stir evenly, and heat to 90°C to obtain hot material; Under the condition that the stirring speed is 60rpm, add the basic catalyst to the hot material continuously within 5h, and carry out the polymerization reaction to obtain the terpolymeric polysiloxane. After cooling to room temperature, add the surfactant, mix well and then add the solvent for emulsification , to obtain A component by filtration;

[0043] Each substance and content in each raw material in component A are as shown in Table 1, and the unit of each component content is g;

[0044] Dimethylcyclosiloxane includes octamethylcyclotetrasiloxane and dimethylcyclosiloxane in a weight ratio of 1:1;

[0045] Phenyl-containing siloxanes include octaphenylcyclotetrasiloxane, tetramethyltetraphenylcyclot...

Embodiment 3

[0056] A self-cleaning glass hydrophobic agent is prepared through the following steps:

[0057] S1, to prepare component A, weigh dimethylcyclosiloxane, phenylsiloxane and silane coupling agent in proportion, mix and stir evenly, and heat to 85°C to obtain hot material; Under the condition that the stirring speed is 45rpm, add the basic catalyst to the hot material continuously within 4 hours, and carry out the polymerization reaction to obtain the ternary copolymerized polysiloxane. After cooling to room temperature, add the surfactant, mix well and then add the solvent for emulsification , to obtain A component by filtration.

[0058] Each substance and content in each raw material in component A are as shown in Table 1, and the unit of each component content is g;

[0059] Dimethylcyclosiloxane includes octamethylcyclotetrasiloxane and dimethylcyclosiloxane in a weight ratio of 1:4;

[0060] Phenyl-containing siloxanes include octaphenylcyclotetrasiloxane, tetramethyltet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com