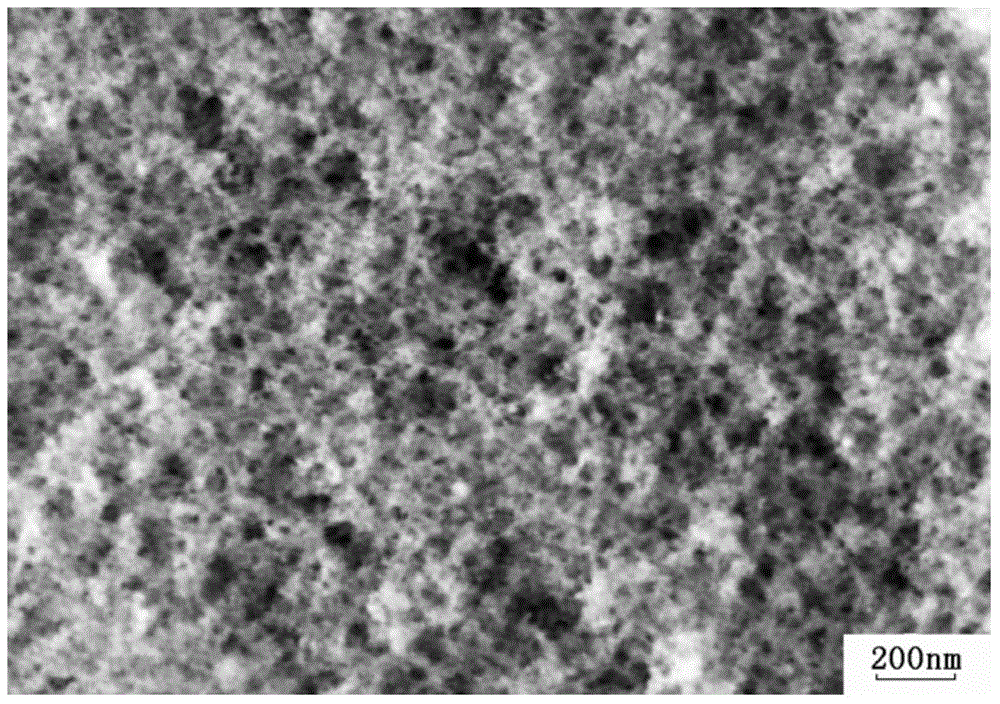

TiO2 nanotube/SiO2 aerogel composite photocatalytic material and preparing method thereof

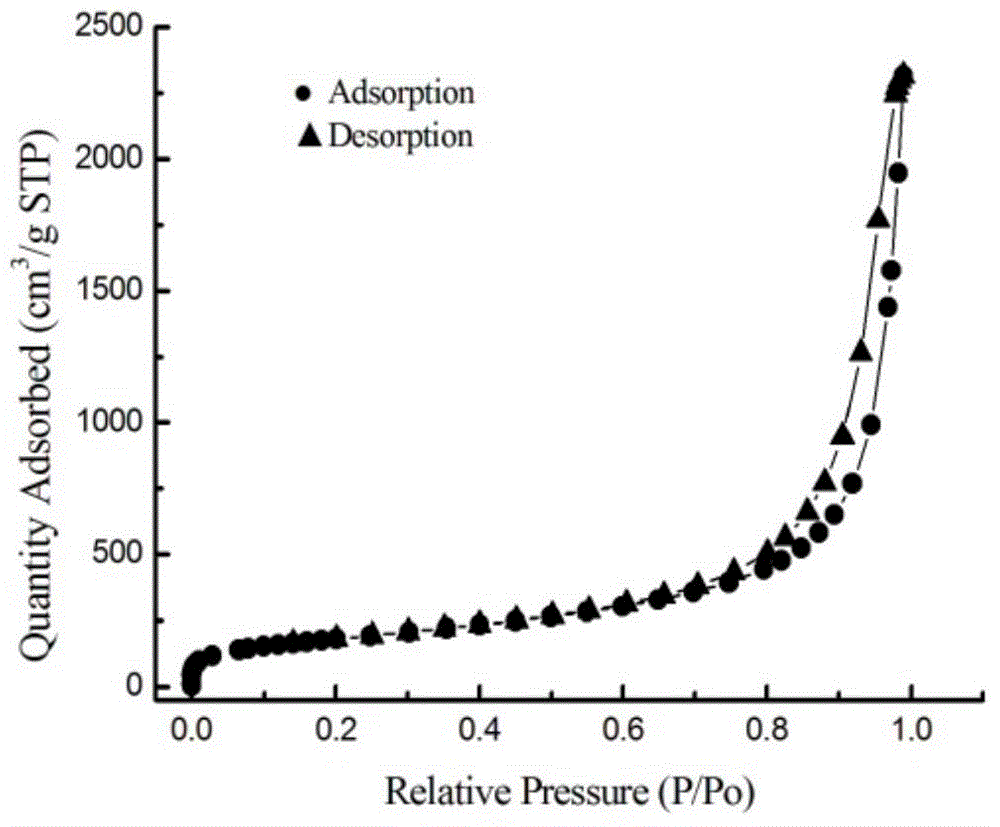

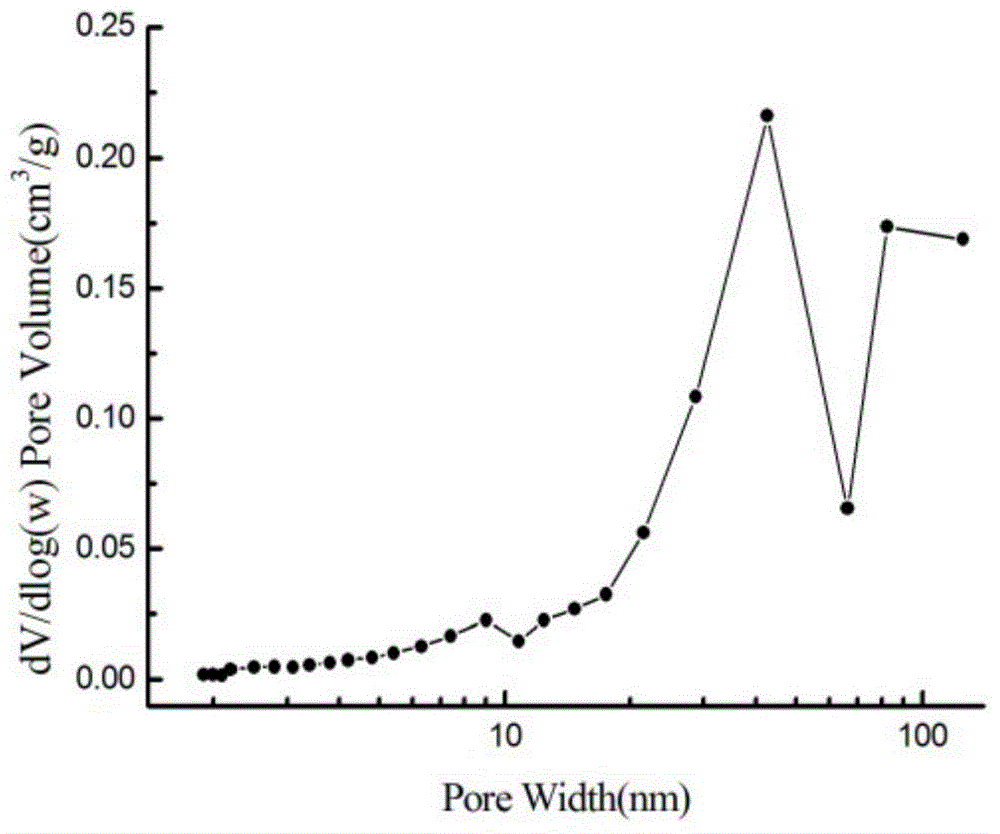

A technology of photocatalytic materials and nanotubes, applied in chemical instruments and methods, physical/chemical process catalysts, colloid chemistry, etc., can solve the problems of high carrier loading rate of semiconductors, small volume of titanium nanotubes, and low catalytic efficiency , to achieve the effect of photocatalytic activity and photocatalytic utilization rate improvement, excellent adsorption performance and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1. Mix titanium dioxide (P25) and 10mol / L NaOH aqueous solution, then add it into an autoclave with a polytetrafluoroethylene liner and stir it evenly, then seal the autoclave and place it in an oven. The temperature was raised from room temperature to 120° C. at a rate of 2° C. / min and kept for 2 days. After the reaction was completed, the autoclave was naturally cooled to room temperature in an oven to obtain a reaction liquid. Wherein, the mass ratio of titanium dioxide to NaOH in NaOH solution is 1:12.

[0035] Step 2: Separating the reaction liquid to obtain a white precipitate, adding 0.2 mol / L hydrochloric acid to the white precipitate to acidify, and magnetically stirring for 2 hours, when the pH value is 6, washing with secondary deionized water until neutral, and then centrifuged to obtain a precipitate, which was dried at 80°C to obtain a solid powder;

[0036] Step 3: Calcining the solid powder at 400°C for 2 hours in an argon atmosphere, and then grin...

Embodiment 2

[0043] Step 1. Mix titanium dioxide (P25) and 10mol / L NaOH aqueous solution, then add it into an autoclave with a polytetrafluoroethylene liner and stir it evenly, then seal the autoclave and place it in an oven. The temperature was raised from room temperature to 120° C. at a rate of 2° C. / min and kept for 2 days. After the reaction was completed, the autoclave was naturally cooled to room temperature in an oven to obtain a reaction liquid. Wherein, the mass ratio of titanium dioxide to NaOH in NaOH solution is 1:12.

[0044] Step 2: Separating the reaction liquid to obtain a white precipitate, adding 0.2 mol / L hydrochloric acid to the white precipitate to acidify, and magnetically stirring for 2 hours, when the pH value is 6, washing with secondary deionized water until neutral, and then centrifuged to obtain a precipitate, which was dried at 80°C to obtain a solid powder;

[0045] Step 3: Calcining the solid powder at 550°C for 2 hours in an argon atmosphere, and then grin...

Embodiment 3

[0057] Step 1. Mix titanium dioxide and 10mol / L NaOH aqueous solution, then add it into an autoclave with a polytetrafluoroethylene liner and stir it evenly, then seal the autoclave and place it in an oven, from room temperature to The temperature was raised to 160° C. at a rate of 2° C. / min and kept for 2 days. After the reaction was completed, the autoclave was naturally cooled to room temperature in an oven to obtain a reaction liquid. Wherein, the mass ratio of titanium dioxide to NaOH in NaOH solution is 1:8.

[0058] Step 2: Separating the reaction liquid to obtain a white precipitate, adding 0.2 mol / L hydrochloric acid to the white precipitate to acidify, and magnetic stirring for 3 hours, when the pH value is 4, wash with deionized water twice to neutrality, and then centrifuged to obtain a precipitate, and dried the precipitate at 60°C to obtain a solid powder;

[0059] Step 3: Calcining the solid powder at 600°C for 2 hours in a nitrogen atmosphere, and then grindin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com