Formaldehyde removal liquid added with biological enzyme aid, and preparation method thereof

A bio-enzyme additive and formaldehyde solution technology, which is applied in the field of air purification, can solve the problems of smaller specific surface area of nano-titanium dioxide, poor dispersion, and affecting the efficiency and effect of photocatalyst on formaldehyde purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

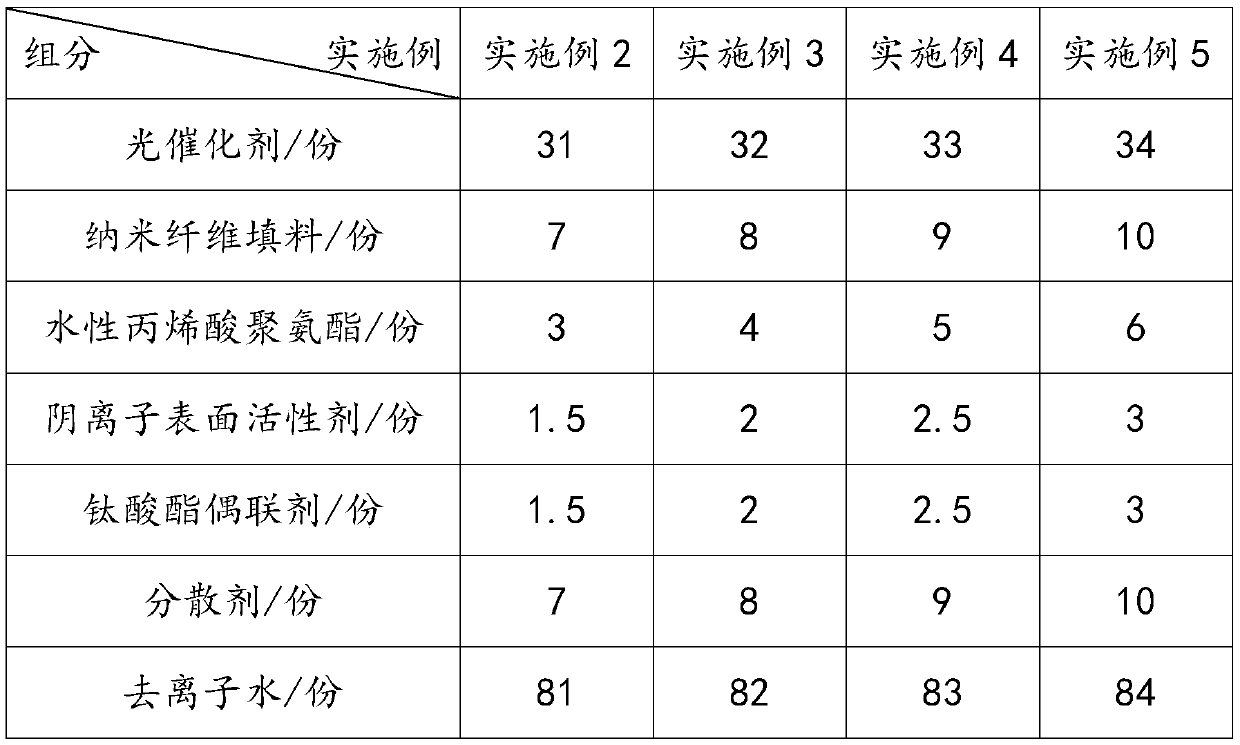

Examples

Embodiment 1

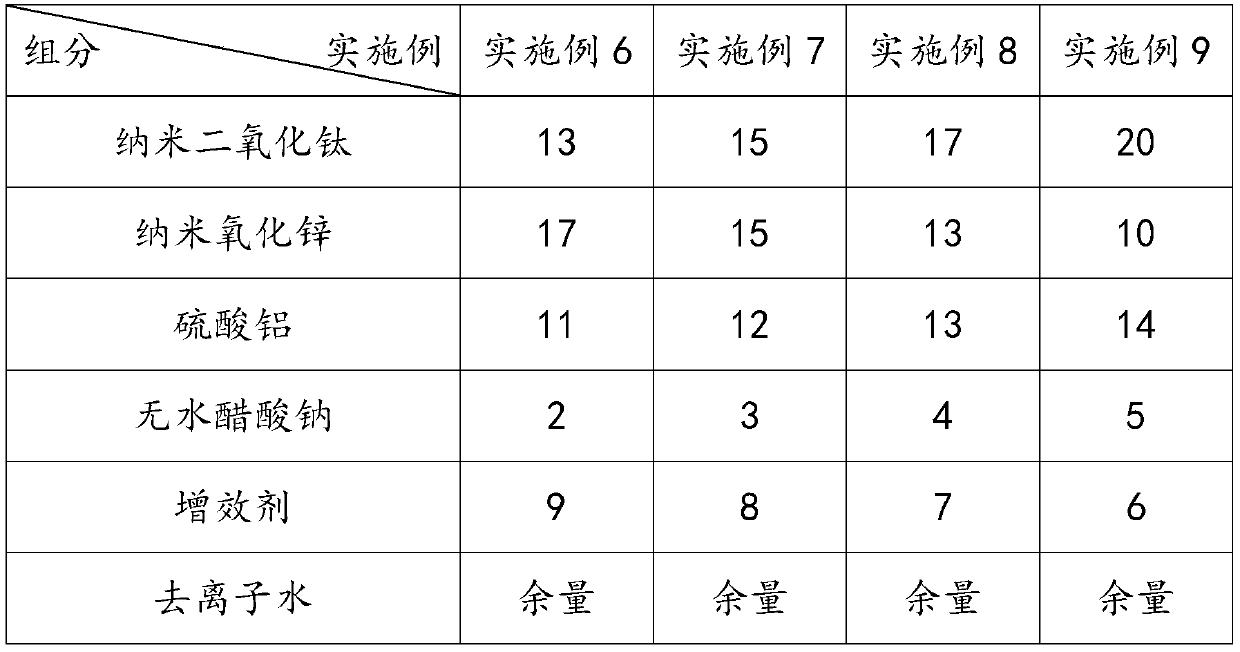

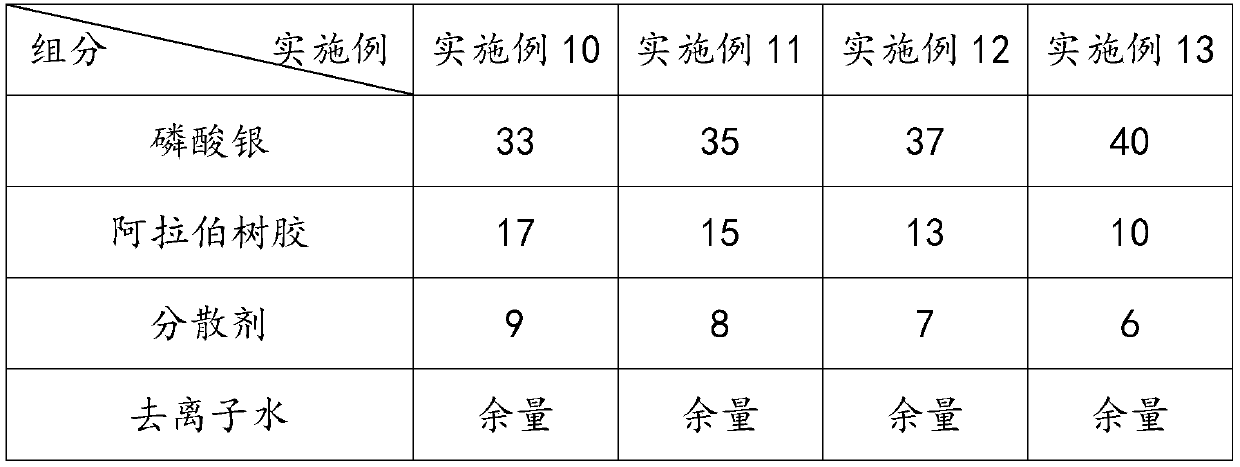

[0084]The difference between embodiments 10-13 and embodiment 1 is that the synergist comprises the following raw materials in weight percent:

[0085]

[0086] The difference between Examples 14-17 and Example 1 is that the nanofibrous filler includes the following raw materials in weight percent:

[0087]

[0088] The difference between Embodiment 18-21 and Embodiment 1 is that the biological deodorant comprises the following raw materials in parts by weight:

[0089]

[0090] The difference between Examples 22-25 and Example 1 is that the biological enzyme auxiliary agent includes the following raw materials in weight percentage:

[0091]

[0092] The difference between embodiments 16-29 and embodiment 1 is that the particle size of the photocatalyst is as shown in the table below:

[0093] Example Example 26 Example 27 Example 28 Example 29 Particle size / nm 85 90 95 100

[0094] The formaldehyde-removing solution prepared in Exam...

Embodiment 1-3 and comparative example 1-8

[0105] Carry out following detection method to embodiment 1-3 and comparative example 1-8:

[0106] 1) Adopt 11 airtight boxes with the specifications of 1m×1m×1m, and place a tabletop board with a size of 500mm×500mm*3mm in each of them. The 11 tabletop boards are of the same type, and each one is coated with the same amount of paint. The amount of paint coating is 100ml, and the paint is water-based furniture paint produced by Qingdao Xingguo paint source manufacturer. The 11 airtight boxes were placed in the same light-proof room with constant temperature and humidity, the temperature was 25° C., and the humidity was 58%. Turn on incandescent lights in the room to ensure that each enclosure is surrounded by sufficient light. 11 desktop boards are statically placed in 11 airtight boxes for 2h, the light is turned off, and the formaldehyde content is detected by a formaldehyde content detector (Mot500), as a reference value; on 11 desktop boards, press the using method of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com