Coupling process for advanced treatment of landfill leachate

A technology for landfill leachate and advanced treatment, which is applied in special treatment targets, water/sewage treatment, adsorbed water/sewage treatment, etc. It can solve the problems of difficult treatment of concentrated liquid, large initial investment, and high process operating costs, so as to alleviate the problem of membrane fouling phenomenon, increase stability, and improve the effect of membrane separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

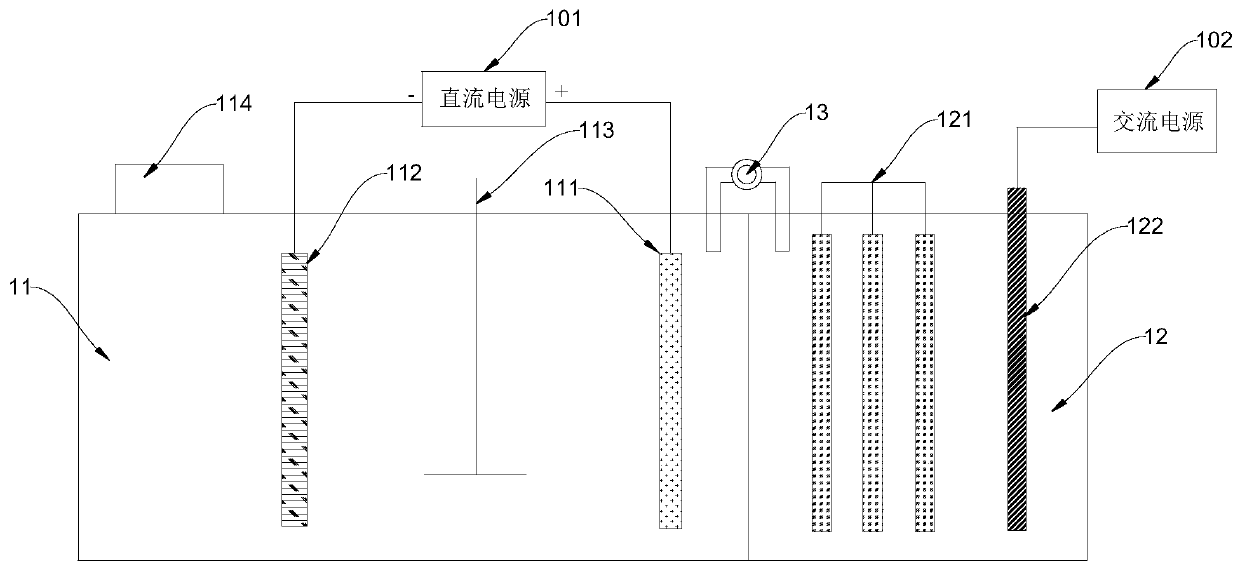

[0026] see figure 1 , this embodiment provides an electrocoagulation coupling system for advanced treatment of landfill leachate, including: an electrocoagulation coupling filter device, the electrocoagulation coupling filter device is configured with an electrolytic flocculation pool 11 at the front end and a photocatalytic ceramic membrane filter at the rear end pool 12; the electrolytic flocculation pool 11 is provided with an anode electrolysis plate 111, a cathode electrolysis plate 112, an agitator 113 and a pH adjustment device 114; the photocatalytic ceramic membrane filter pool 12 is provided with a photocatalytic ceramic mold assembly 121 and a photocatalyst Catalytic light source 122; the electrolytic flocculation tank 11 pumps the landfill leachate after electrolytic flocculation into the photocatalytic ceramic membrane filter tank 12 through the lift pump 13; the current density of the electrolytic flocculation tank 11 is 10-1000mA / cm2, The distance between the an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com