Preparation method of cross-linked anion exchange membrane with low water content

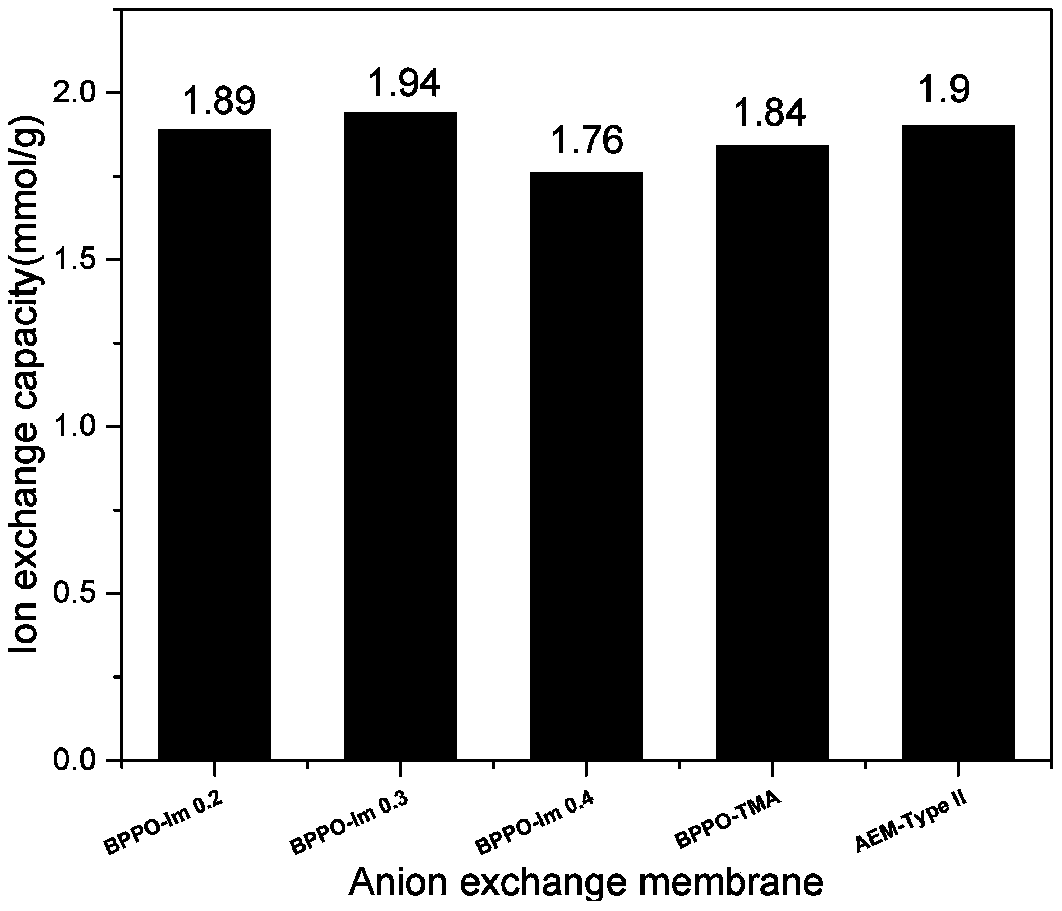

An ion-exchange membrane and cross-linking technology, which is applied in the field of preparation of cross-linked anion-exchange membranes, can solve problems such as high hydrophilicity, swelling, and enhanced membrane surface potential, and achieve high ion exchange capacity and conductivity. The process is simple and the effect of ensuring anti-swelling property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

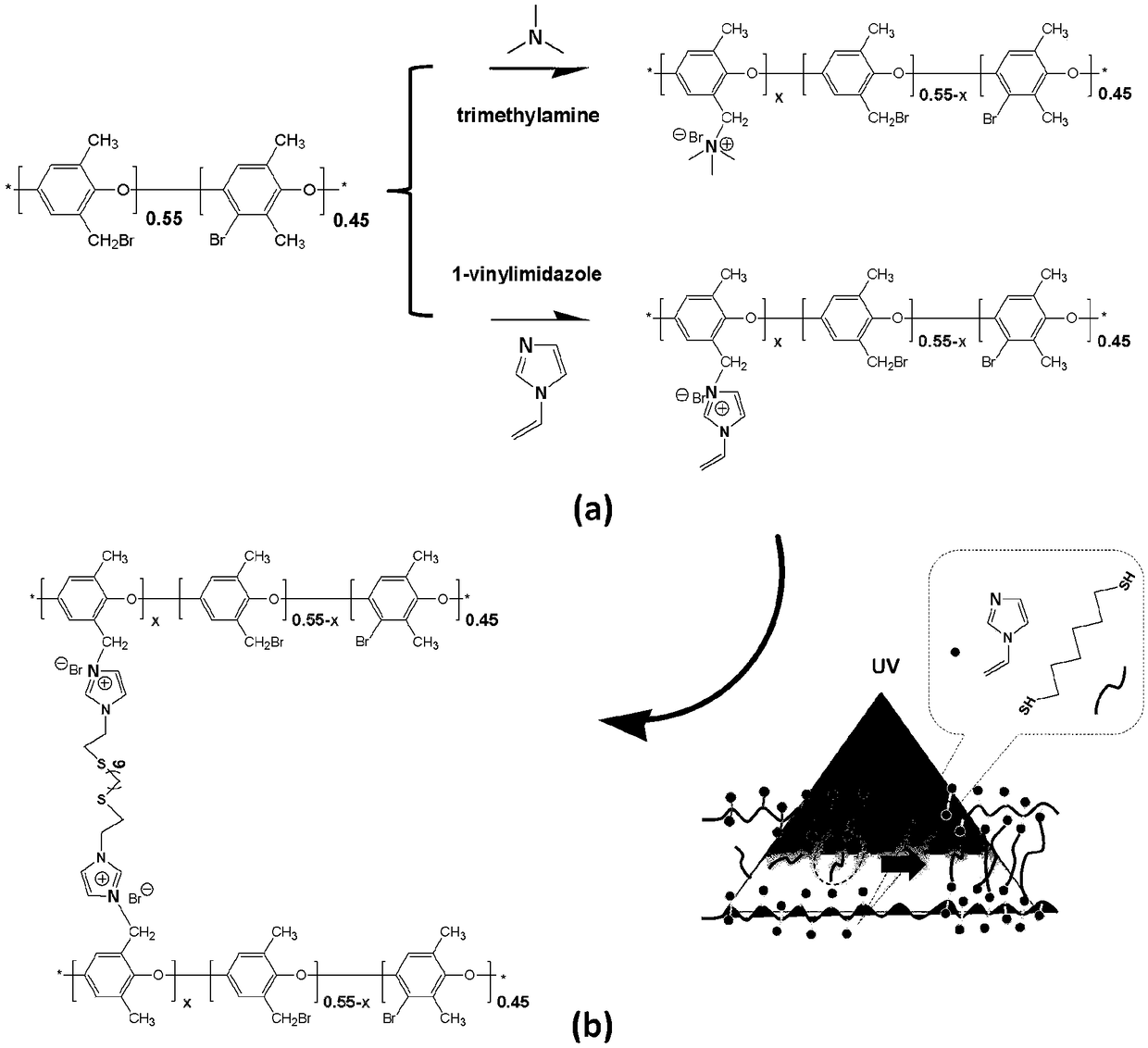

[0031] (1) 2 g of BPPO (manufactured by Shandong Tianwei Company, bromomethylation degree is 55%) was dissolved in 10 mL of 1-methyl-2-pyrrolidone, and magnetically stirred until the BPPO was completely dissolved to obtain a brown transparent solution to obtain a BPPO solution.

[0032] (2) Add 0.4 mL of 1-vinylimidazole (manufactured by Shanghai McLean, 97%) dropwise into the BPPO solution, and react with magnetic stirring for 24 hours at 45°C to obtain a quaternized BPPO solution of 1-vinylimidazole .

[0033] (3) In the BPPO solution of quaternization, add 0.204mL of 1,6-hexanedithiol (produced by Shanghai Aladdin Company, 95%) and 0.05g of photoinitiator 2-benzyl-2-dimethyl Amino-1-(4-morpholinephenyl) butanone (manufactured by Shanghai Aladdin Co.), and magnetically stirred until the solution was evenly mixed. Pour the homogeneous solution on a glass plate, use a 600 μm spatula to scrape the glass plate into a film shape, and place it under the ultraviolet light of 345nm...

Embodiment 2

[0037] Change the amount of the cross-linking agent 16-hexanedithiol in the above example 1 to 0.136 mL, and keep the other steps unchanged to obtain the cross-linked anion exchange membrane BPPO-Im0.3.

Embodiment 3

[0039] Change the amount of the cross-linking agent 1,6-hexanedithiol in the above example 1 to 0.272 mL, and keep the other steps unchanged, to obtain the cross-linked anion exchange membrane BPPO-Im0.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com