Method for preparing cerium dioxide nanometer powder

A technology of nano-powder and ceria, which is applied in the field of preparation of ceria nano-powder, can solve the problems of long time consumption, low yield, unfavorable mass production, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Step 1: Analytical pure Ce(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to obtain Ce(NO 3 ) 3 solution;

[0017] Ethylenediamine, PVP, KBrO 3 with Ce(NO 3 ) 3 ·6H 2 O mixes ethylenediamine, PVP, KBrO in a molar ratio of 2:4:3:1 3 Add Ce(NO 3 ) 3 The solution was continuously stirred at 60°C for 2 hours to obtain a mixed solution;

[0018] Step 2: Transfer the mixed solution into a reaction kettle, place it in a microwave hydrothermal instrument at 180°C for 0.5h, centrifuge and wash after reaction, and dry at 80°C to obtain CeO 2 Nano powder.

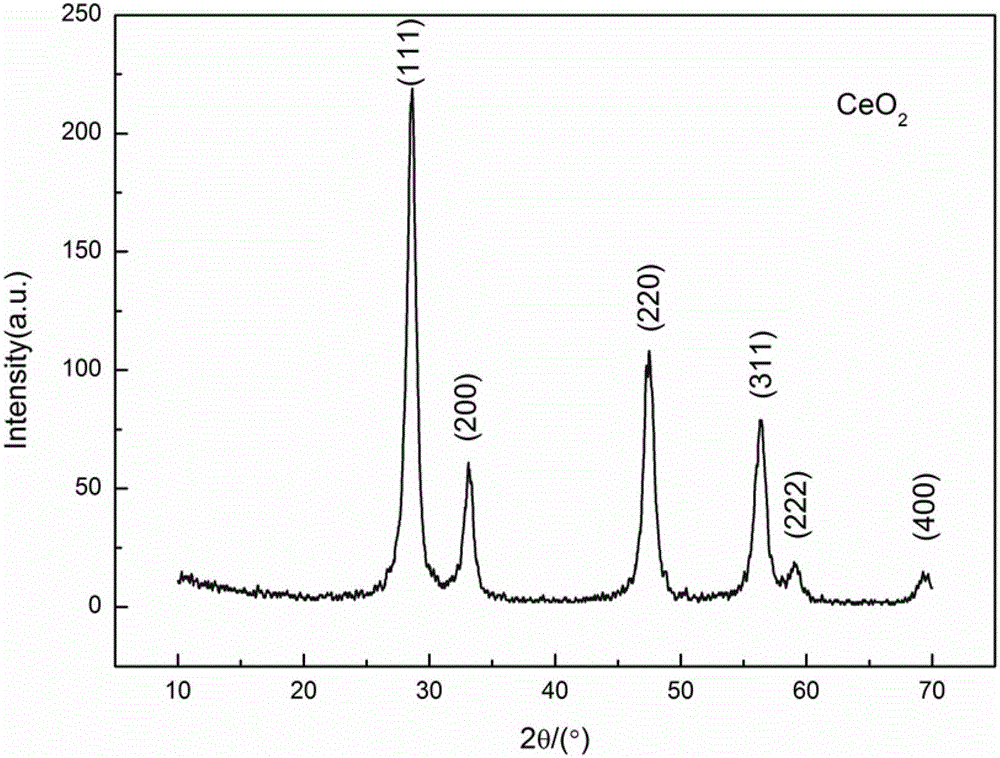

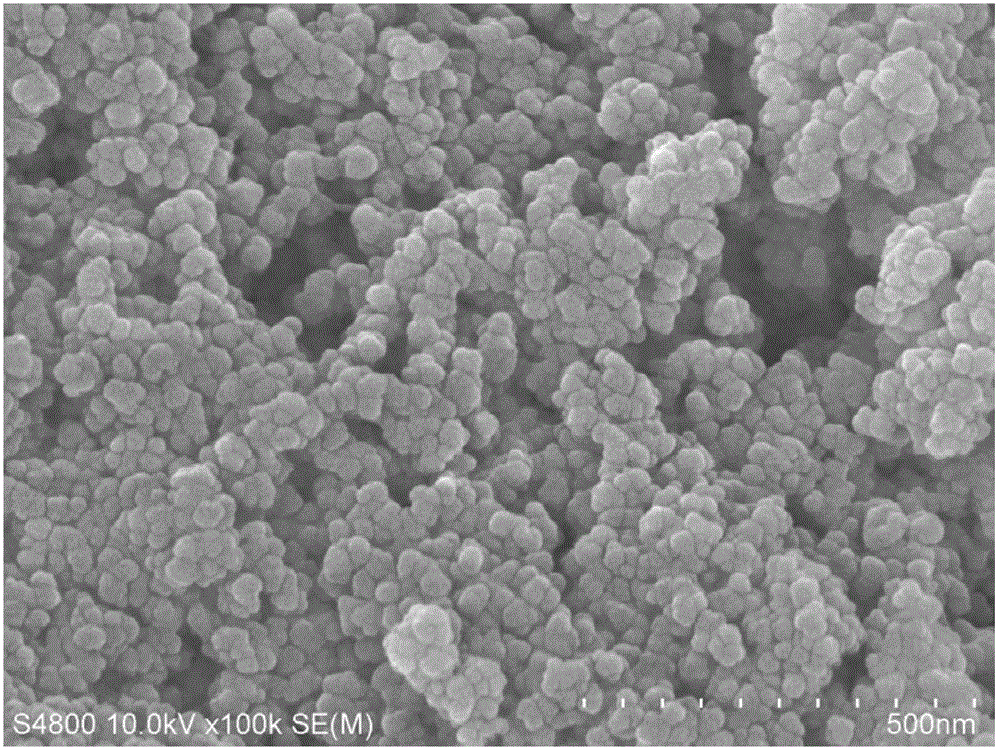

[0019] The resulting CeO 2 The nano-powder is measured with a D / Max-2200pc type X-ray diffractometer produced by Japan Rigaku Company, and the results are as follows: figure 1 As shown, the pure phase CeO with better crystallinity was obtained 2 Nano powder, the JCPDS card number of the product is found to be 33-0394, which belongs to the cubic crystal system. The microscopic morphology of the sample was obse...

Embodiment 2

[0021] Step 1: Analytical pure Ce(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to obtain Ce(NO 3 ) 3 solution;

[0022] Ethylenediamine, PVP, KBrO 3 with Ce(NO 3 ) 3 ·6H 2 O mixes ethylenediamine, PVP, KBrO in a molar ratio of 4:3:5:1 3 Add Ce(NO 3 ) 3 The solution was continuously stirred at 60°C for 2 hours to obtain a mixed solution;

[0023] Step 2: Transfer the mixed solution into a reaction kettle, place it in a microwave hydrothermal instrument and react at 160°C for 1.5h, centrifuge and wash after reaction, and dry at 80°C to obtain CeO 2 Nano powder.

Embodiment 3

[0025] Step 1: Analytical pure Ce(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to obtain Ce(NO 3 ) 3 solution;

[0026] Ethylenediamine, PVP, KBrO 3 with Ce(NO 3 ) 3 ·6H 2 O mixes ethylenediamine, PVP, KBrO at a molar ratio of 1:6:4:1 3 Add Ce(NO 3 ) 3 The solution was continuously stirred at 60°C for 2 hours to obtain a mixed solution;

[0027] Step 2: Transfer the mixed solution into a reaction kettle, place it in a microwave hydrothermal instrument at 190°C for 1 hour, centrifuge and wash after reaction, and dry at 80°C to obtain CeO 2 Nano powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com