Sulfonated polyaryletherketone positive-electric particle adsorption membrane and electrospinning preparation method thereof

A technology of sulfonated polyarylether ketone and adsorption membrane, which is applied in chemical instruments and methods, electrospinning, adsorption water/sewage treatment, etc. It can solve the problems of small diffusion coefficient of pollutants, reduction of adsorption cost, and small adsorption capacity. , to achieve the effect of simple platform construction, reduced adsorption cost, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

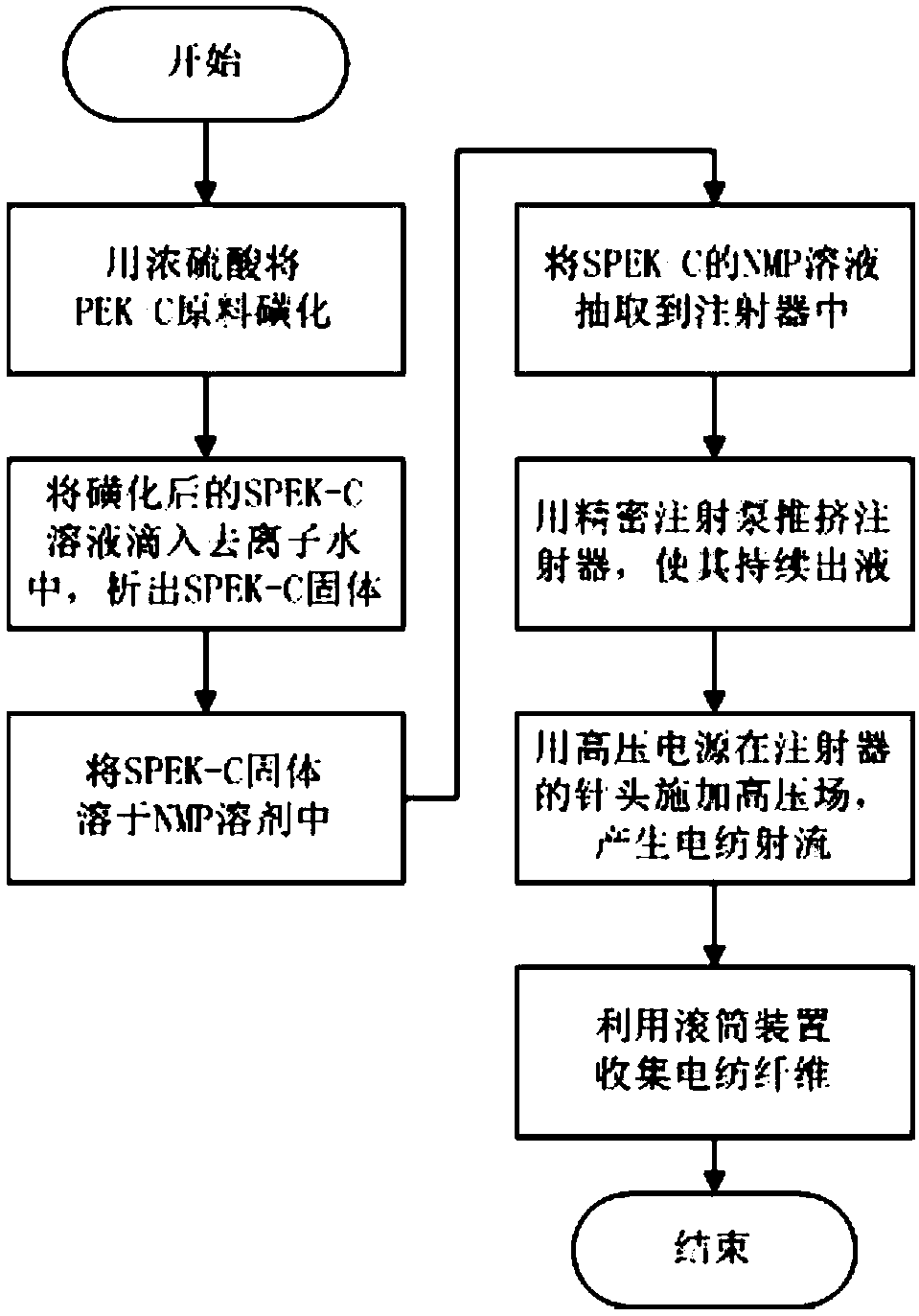

[0032] see figure 1 , this example specifically illustrates the preparation process and performance verification of the electrospinning-based SPEK-C positively charged particle adsorption membrane proposed by the present invention in combination with experiments.

[0033] 1. Material selection

[0034] The materials selected in this experiment are: polyaryletherketone (PEK-C), deionized water, 98% concentrated sulfuric acid as sulfonating agent, N-methylpyrrolidone (NMP) as dispersant; the adsorption test material can be methylene blue (MB), Cr 3+ Wait. The desorption material can be ethanol, hydrochloric acid, acetone, etc.

[0035] 2. Preparation of SPEK-C solid and preparation of electrospinning solution

[0036] Add 6.67g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com