Patents

Literature

37results about How to "Suitable for adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

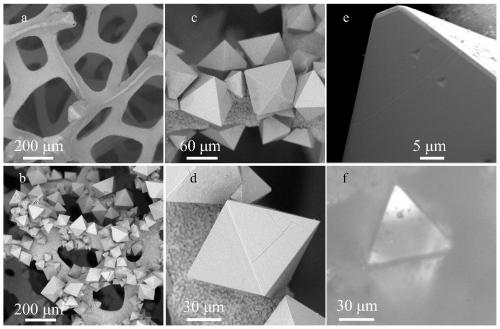

One-dimensional organic semiconductor spiral nano-wires with fluorescence response upon organic amine gases, and preparation method and application thereof

ActiveCN104130257ASuitable for adsorptionSuitable for detectionOrganic chemistryFluorescence/phosphorescenceQuantum yieldSolvent

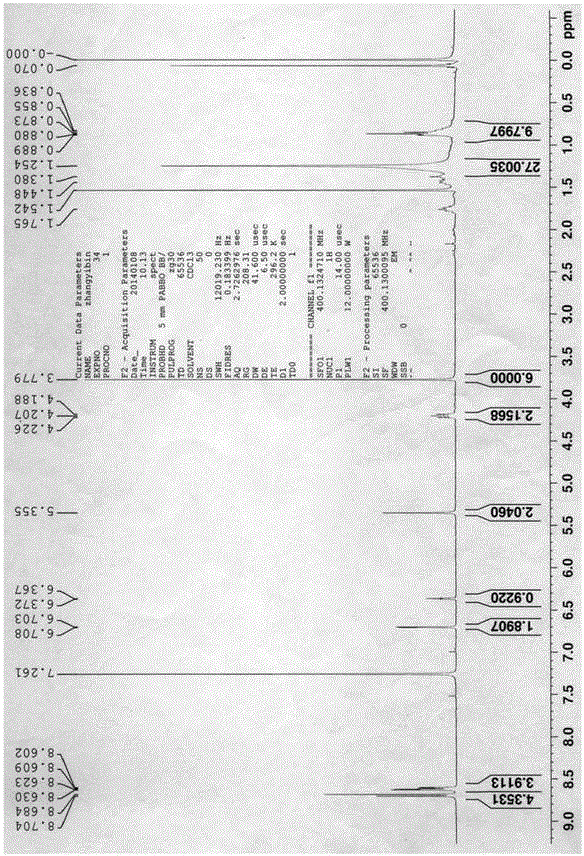

The invention relates to one-dimensional organic semiconductor spiral nano-wires with ultra-sensitive fluorescence response upon organic amine gases, and a preparation method and an application thereof. According to the invention, perylene imide derivatives comprising perylene and with asymmetric amphiphilic substituents on two ends are adopted as construction units; in a mixed liquid of a good solvent and a poor solvent, through pi-pi interactions between perylenes of a plurality of perylene imide derivatives comprising perylene and with asymmetric amphiphilic substituents on two ends, the one-dimensional organic semiconductor spiral nano-wires are obtained through self-assembly. The one-dimensional organic semiconductor spiral nano-wires have two significant advantages of a nano-grade spiral structure and good fluorescence quantum yield (up to 25%), such that the nano-wires are suitable to be used in fluorescence detection of organic amine in air. When a network-structured porous membrane woven by using the one-dimensional organic semiconductor spiral nano-wires contacts trace amine vapour (with a concentration of ppb-ppm level), the fluorescence is quenched.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Ceramsite Produced by Using River/Lake/Sea Sludge and Seashell Powder as Raw Materials and Preparation Method Thereof

ActiveUS20190247824A1Good expansion rateImprove adsorption capacityOther chemical processesSolid waste managementSludgeSlag

A ceramsite produced by using a river / lake / sea sludge and seashell powder as raw materials and a preparation method thereof are provided. The ceramsite is made of the following raw materials in parts by weight: 15-50 parts of shell powder, 5-15 parts of kaolin, 1-5 parts of peat ash, 15-30 parts of siliceous shale, 15-40 parts of furnace slag, 10-20 parts of fly ash, 15-40 parts of zeolite, 10-30 parts of river / lake / sea sludge, and 10-25 parts of peat. The shell powder is pulverized to a particle size of 60-200 mesh in fineness. A content of silica in the siliceous shale is 87.0%-89.5%. The preparation method of the ceramsite includes the following steps: taking raw materials, pulverizing, stirring, granulating, calcining, and naturally cooling, so as to obtain the ceramsite.

Owner:QINGDAO YI ECO ENVIRONMENTAL PROTECTION TECH CO LTD

Synthesis technology of heavy metal adsorbent

InactiveCN106732461AIncrease acidityImprove mechanical stabilityOther chemical processesWater contaminantsSorbentAdsorption effect

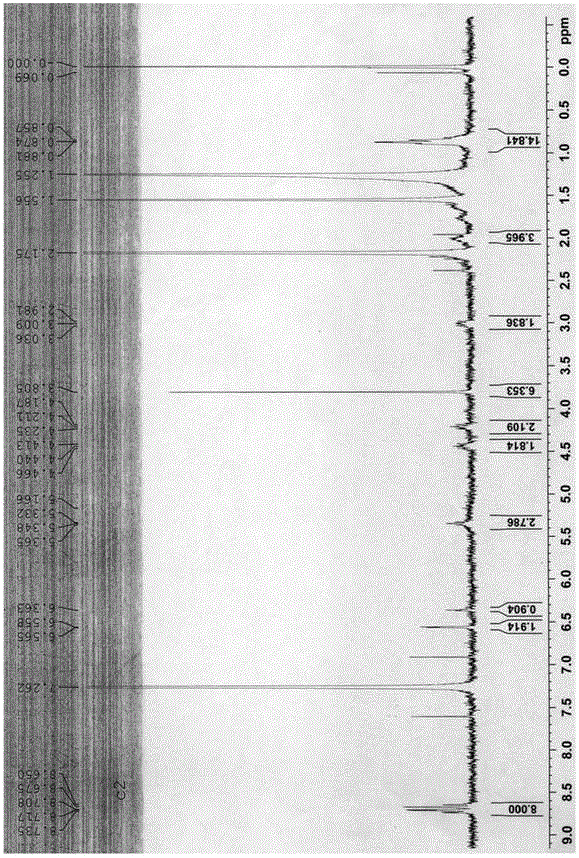

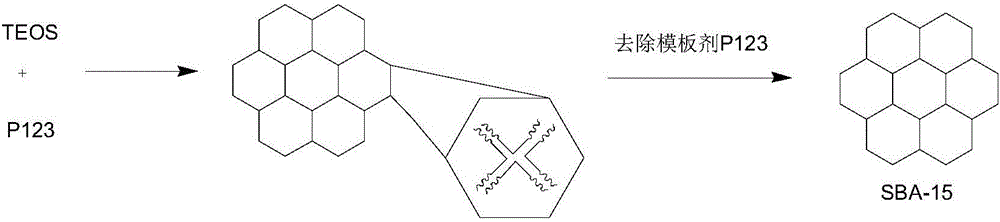

The invention relates to a synthesis technology of a heavy metal adsorbent. The technology comprises the following steps: stirring a triblock copolymer P123 adopted as a template and ethyl orthosilicate as a silicon source in an acidic medium at room temperature, crystallizing the obtained solution, calculating obtained crystals to synthesize an ordered meso-porous material SBA-15; adding a functional group compound to the SBA-15 to carry out primary modification in order to generate an amino group and / or mercapto group modified SBA-15; and adding a compound which can react with the amino group and / or the mercapto group to the primary modified SBA-15 to carry out secondary modification in order to obtain hydroxyl modified SBA-15. Reaction conditions for synthesizing pure silicon SBA-15 are mild, the reaction is carried out at room temperature, the obtained SBA-15 has thick hole walls, the mechanical stability and the hydrothermal stability of a meso-porous molecular sieve skeleton structure are improved, and the hydroxyl, amino and mercapto modified SBA-15 improves the adsorption effect and the selectivity of heavy metal ions.

Owner:上海泰坦科技股份有限公司

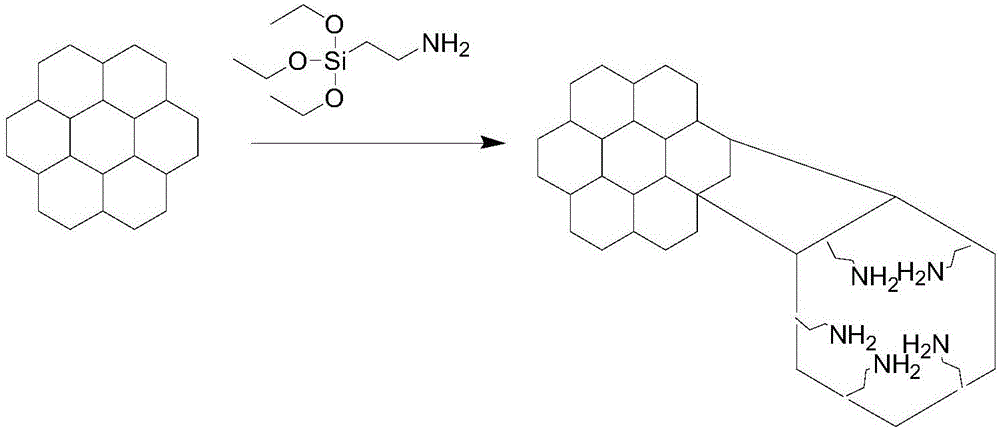

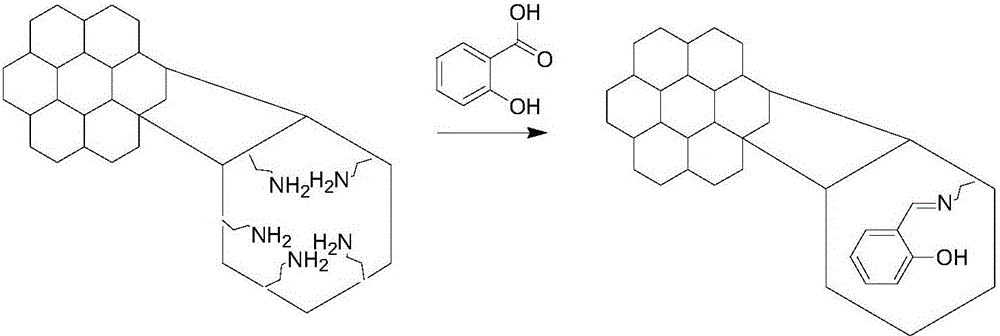

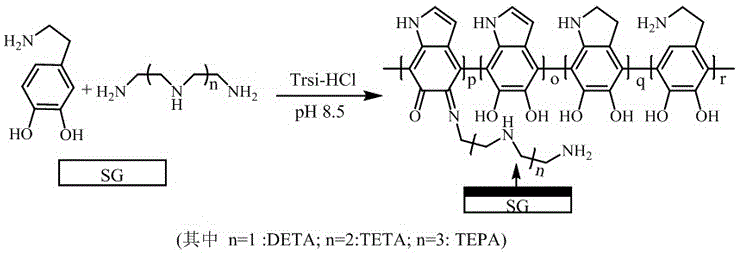

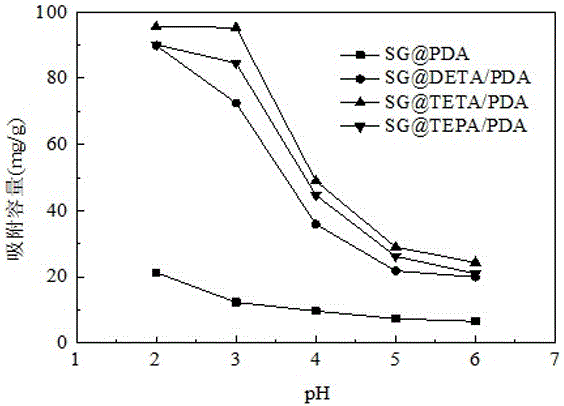

Polydopamine-coated silica gel modified by polyethylene polyamine, method for preparing polydopamine-coated silica gel modified by polyethylene polyamine and application of polydopamine-coated silica gel modified by polyethylene polyamine

InactiveCN107519848AGood stabilityImprove adsorption capacityOther chemical processesWater contaminantsPolyethylene polyamineActive group

The invention discloses polydopamine-coated silica gel modified by polyethylene polyamine, a method for preparing the polydopamine-coated silica gel modified by the polyethylene polyamine and application of the polydopamine-coated silica gel modified by the polyethylene polyamine, and belongs to the field of preparation of adsorption materials. The method particularly includes activating silica gel; coating the silica gel with polydopamine; modifying polydopamine-coated silica gel by the polyethylene polyamine by the aid of the polydopamine which is used as a bridge. The polydopamine-coated silica gel modified by the polyethylene polyamine, the method and the application have the advantages that a large quantity of amine is led into the polydopamine-coated silica gel, accordingly, the content of active groups in the polydopamine-coated silica gel modified by the polyethylene polyamine can be increased, the adsorption performance of the polydopamine-coated silica gel modified by the polyethylene polyamine can be improved, and the polydopamine-coated silica gel modified by the polyethylene polyamine can be used as an adsorbent for dye in environmental water samples and particularly can be used for adsorbing anionic dye.

Owner:FUZHOU UNIVERSITY

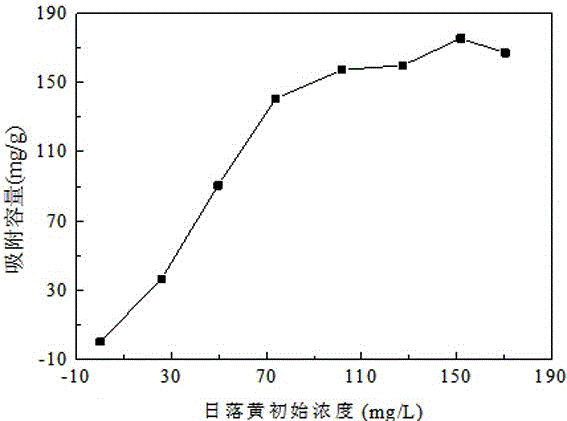

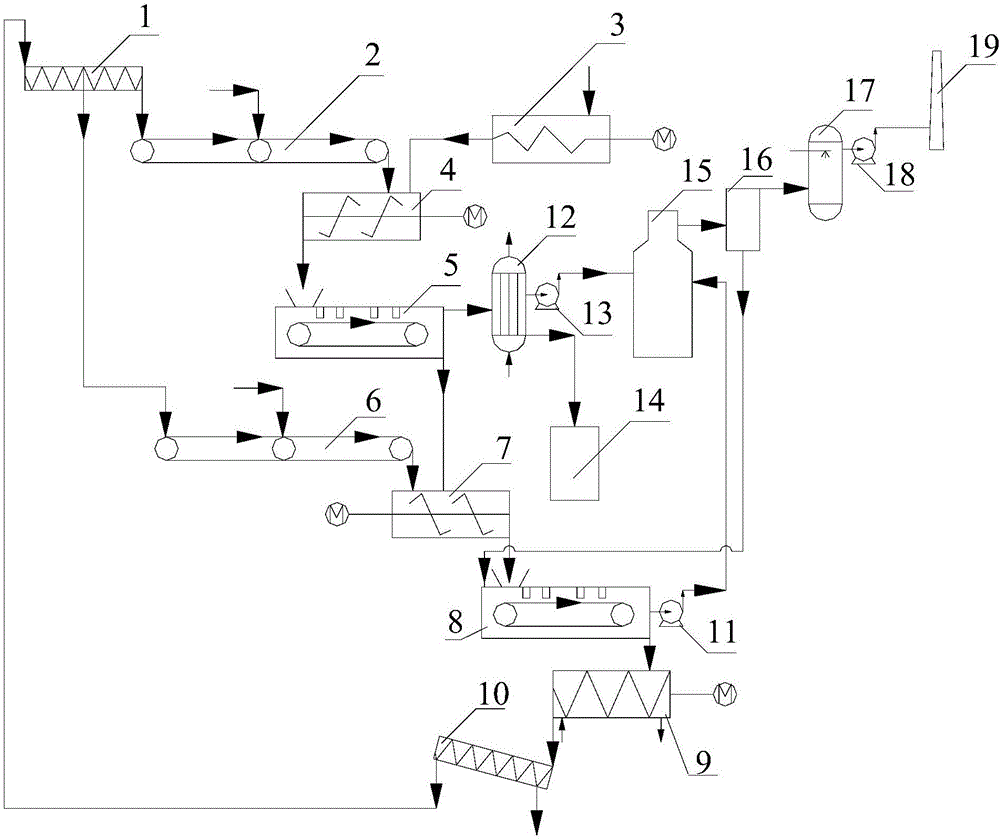

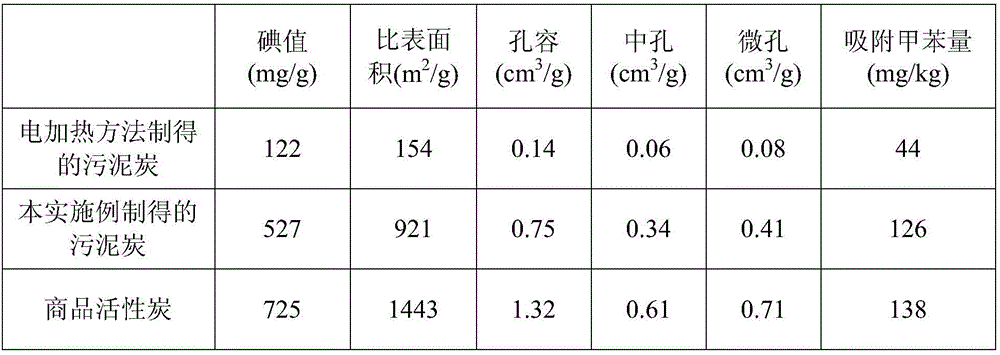

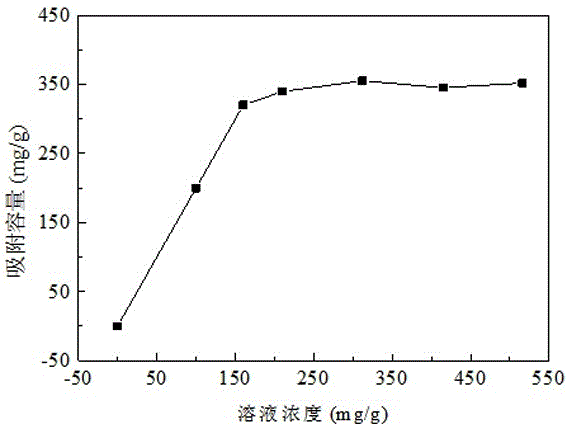

System and method for repairing organic contaminated soil through sludge microwave gasification residues in targeting mode

ActiveCN106694538ARealize capacity reductionUniform pore sizeSludge treatment by pyrolysisByproduct vaporizationSoil treatmentSludge

The invention discloses a system and method for repairing organic contaminated soil through sludge microwave gasification residues in a targeting mode, and belongs to the technical field of contaminated soil repairing. The system comprises a first stirring and mixing device, a gasification reactor, a second stirring and mixing device, a desorption reactor and a screening device. Dewatered sludge is pyrolyzed and carbonized in the gasification reactor to form sludge carbon, through the characteristic of multi-pore adsorption and absorption of microwave assisted heating, the desorption of pollutants in the soil can be effectively promoted in the process of mixing the sludge with the organic contaminated soil, and organic matter in the soil is adsorbed; and in the subsequent microwave heating process of the desorption reactor, the organic matter adsorbed on the sludge carbon is volatilized in a gas form, and the residual sludge carbon returns to the first stirring and mixing device and the second stirring and mixing device to participate in sludge carbonization and organic matter adsorption. Sludge treatment and organic contaminated soil treatment are combined to achieve the purpose of treating waste with waste, the sludge carbon can be recycled after adsorption and desorption, and the cost is lowered.

Owner:浙江博世华环保科技有限公司

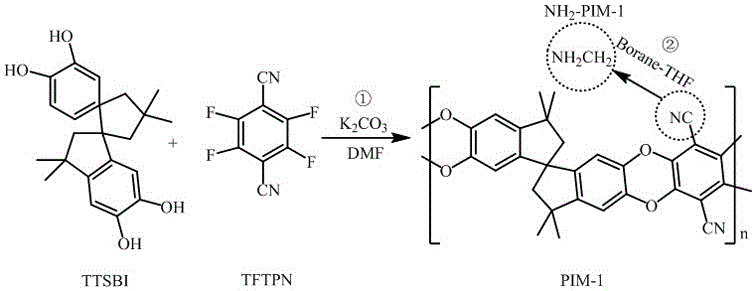

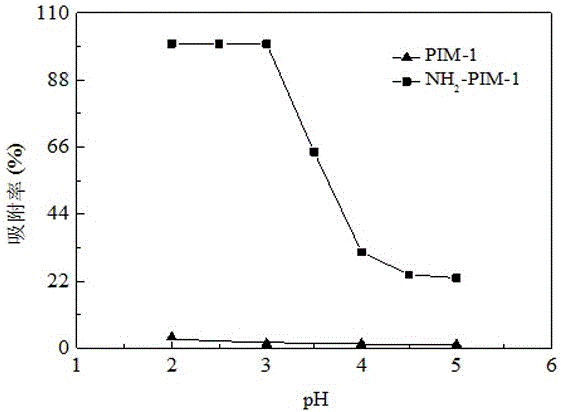

Amination polymer of intrinsic micro-porosity adsorbent and application thereof

InactiveCN107519849AImprove stabilityImprove adsorption capacityOther chemical processesWater contaminantsMaterials preparationMicro porosity

The invention discloses an amination polymer of intrinsic micro-porosity adsorbent and an application thereof, and belongs to the field of adsorbing material preparation. According to the adsorbent, a borane-tetrahydrofuran complex serves as a reducing agent, and cyan on a polymer of intrinsic micro-porosity is reduced into amidogen to obtain the adsorbent. According to the adsorbent, a lot of amidogen is introduced into the polymer of intrinsic micro-porosity, the content of active groups of the polymer of intrinsic micro-porosity is increased, and the adsorption performance of the adsorbent is improved, so that the adsorbent can be used for dyes in environmental water samples and particularly is used for adsorbing anionic dyes.

Owner:FUZHOU UNIV

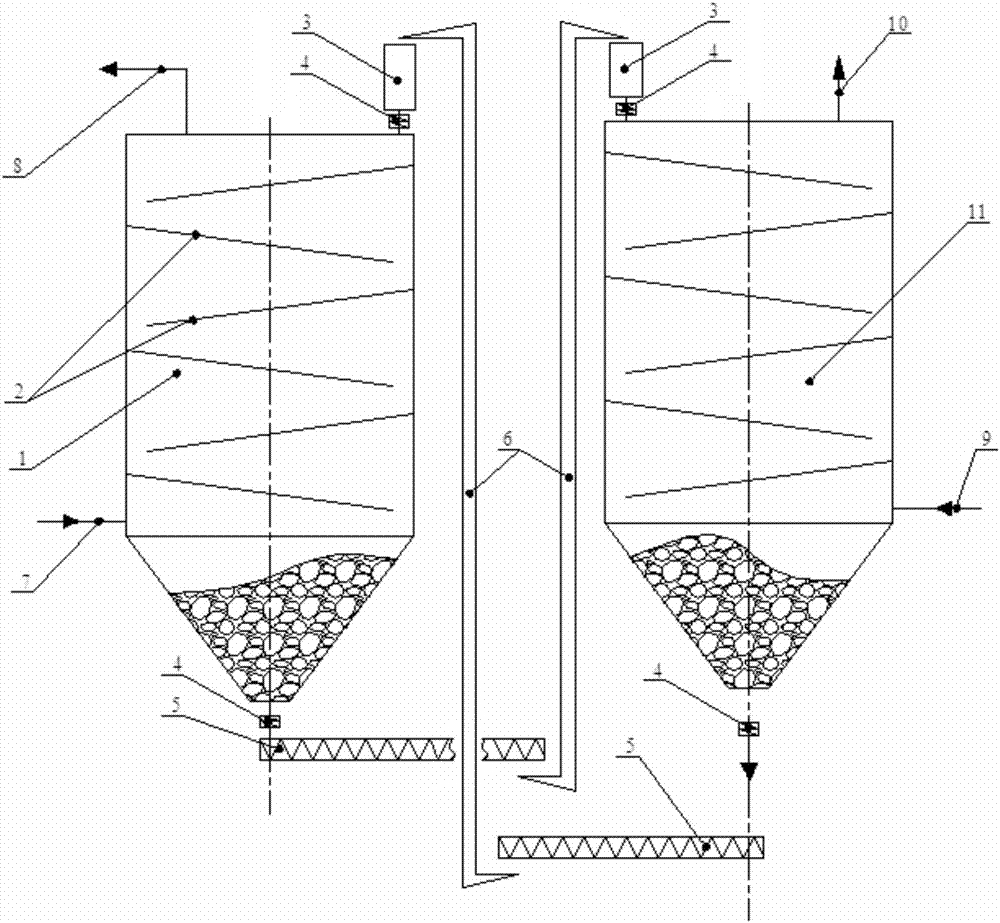

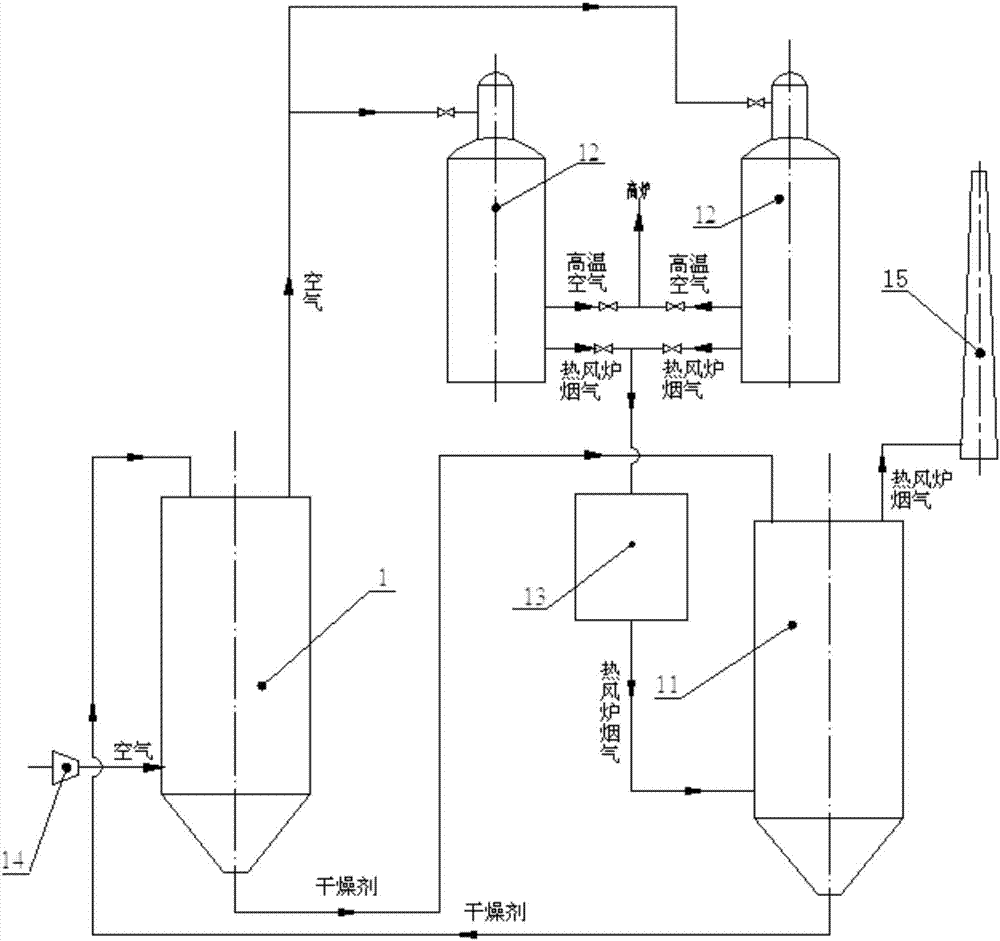

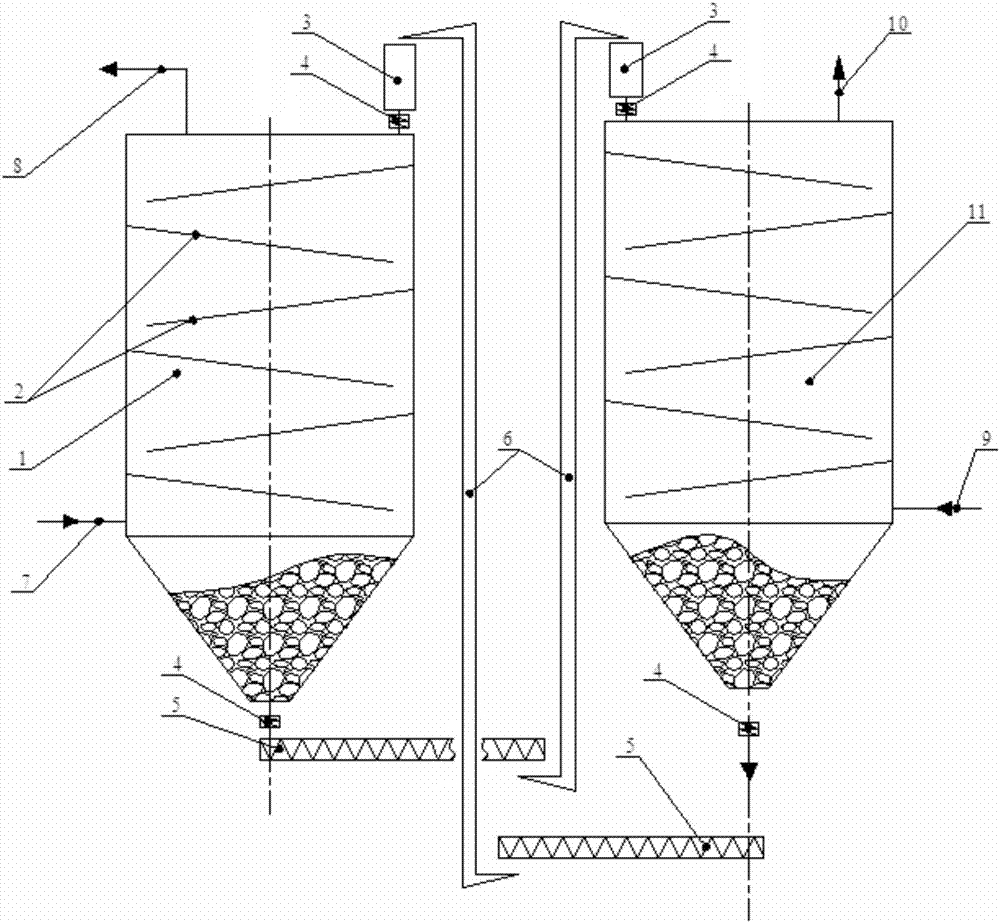

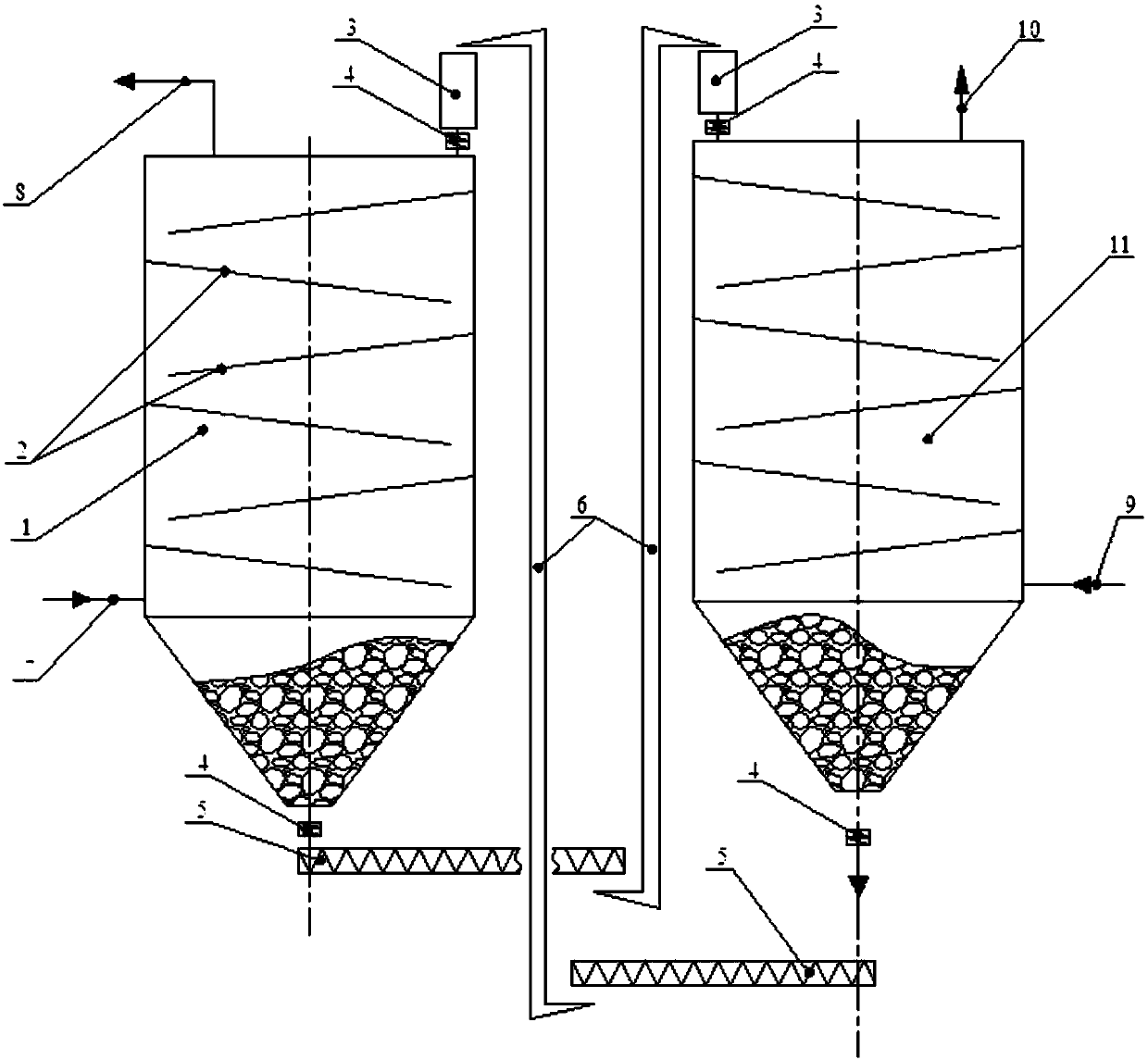

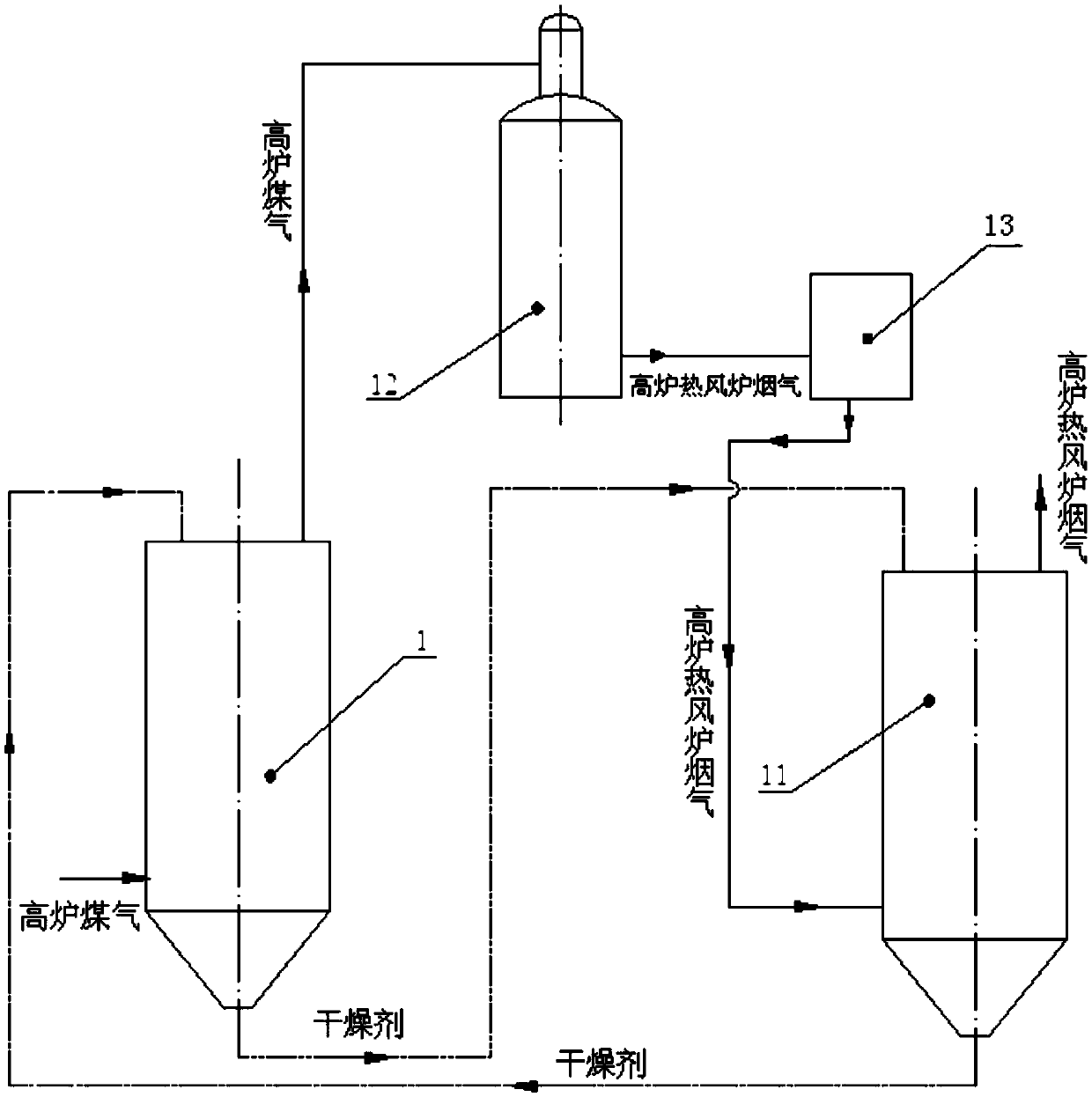

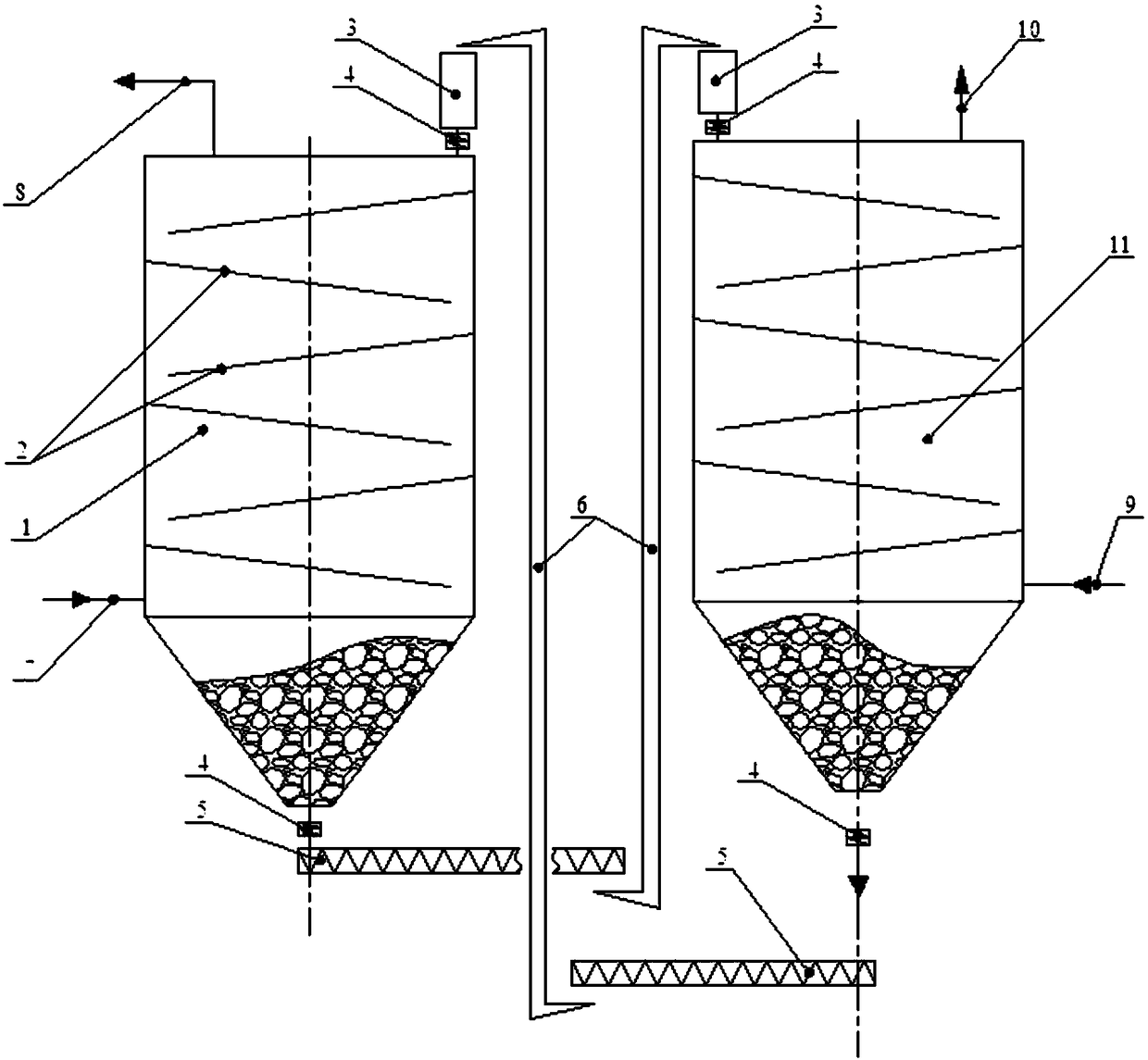

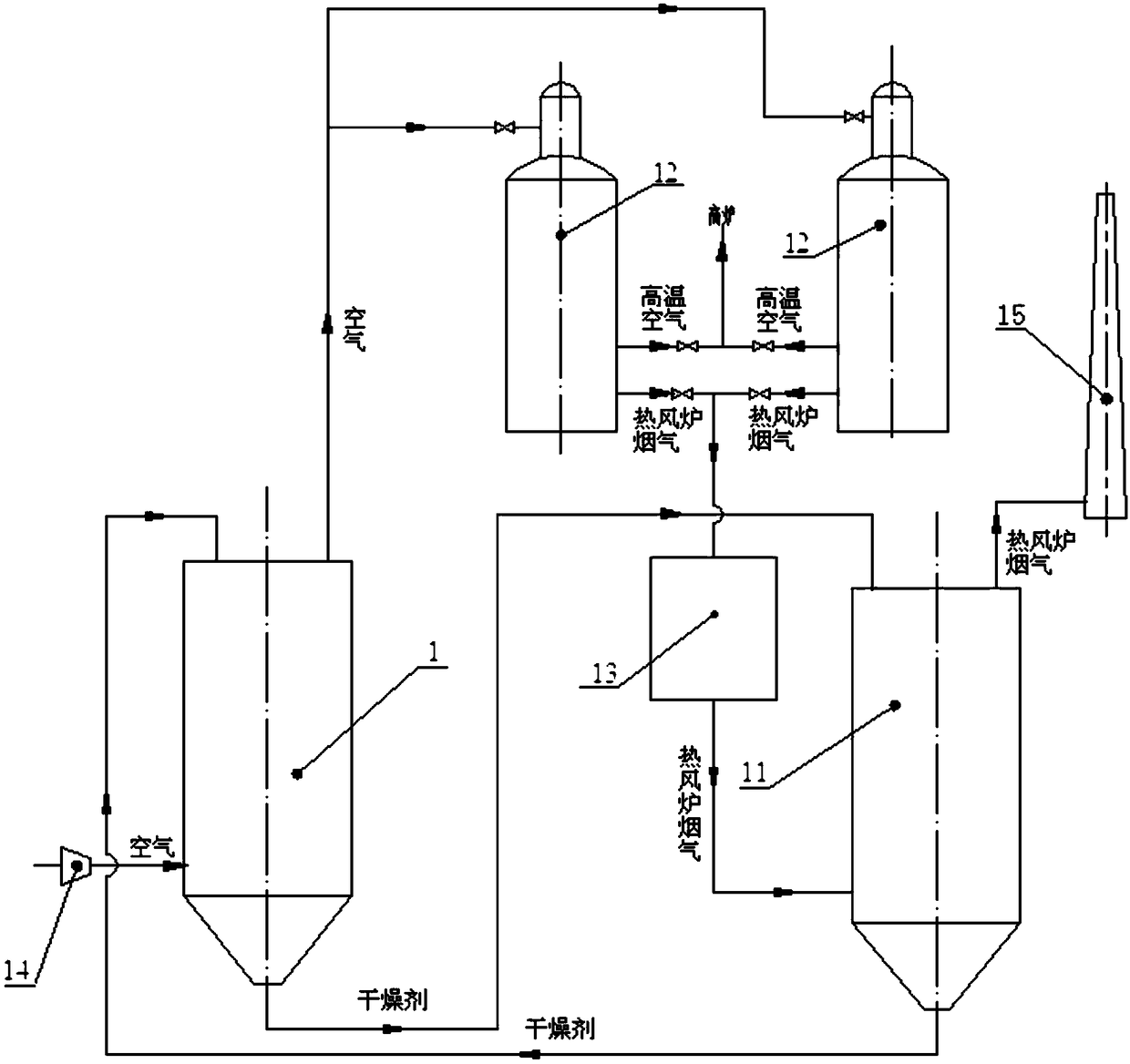

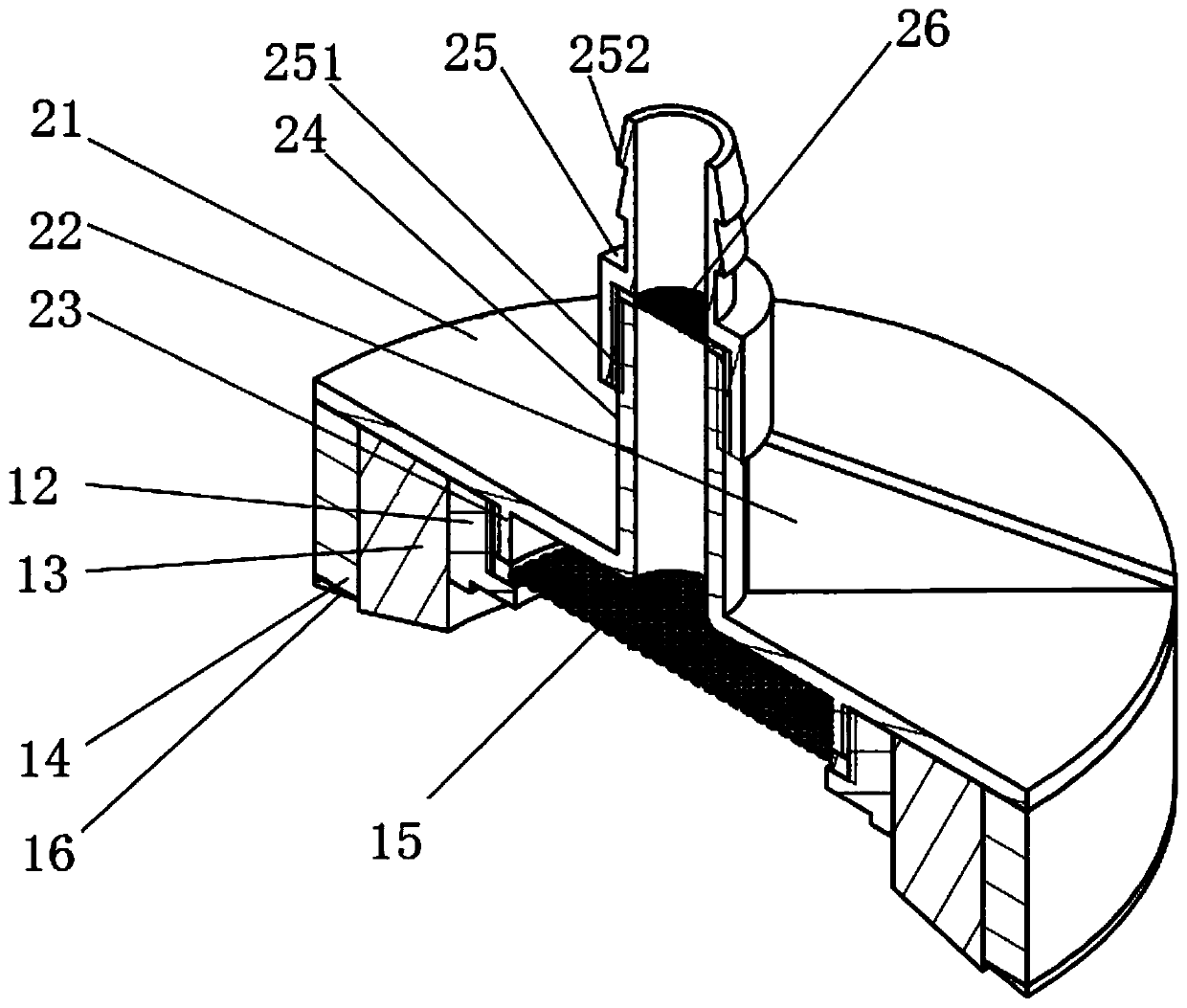

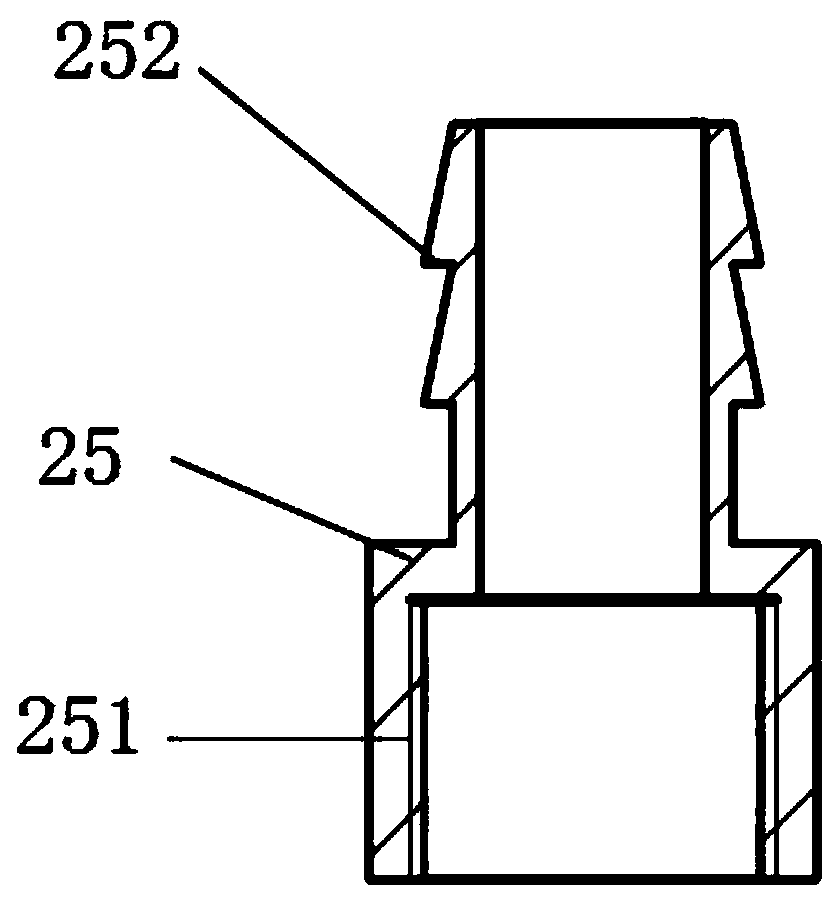

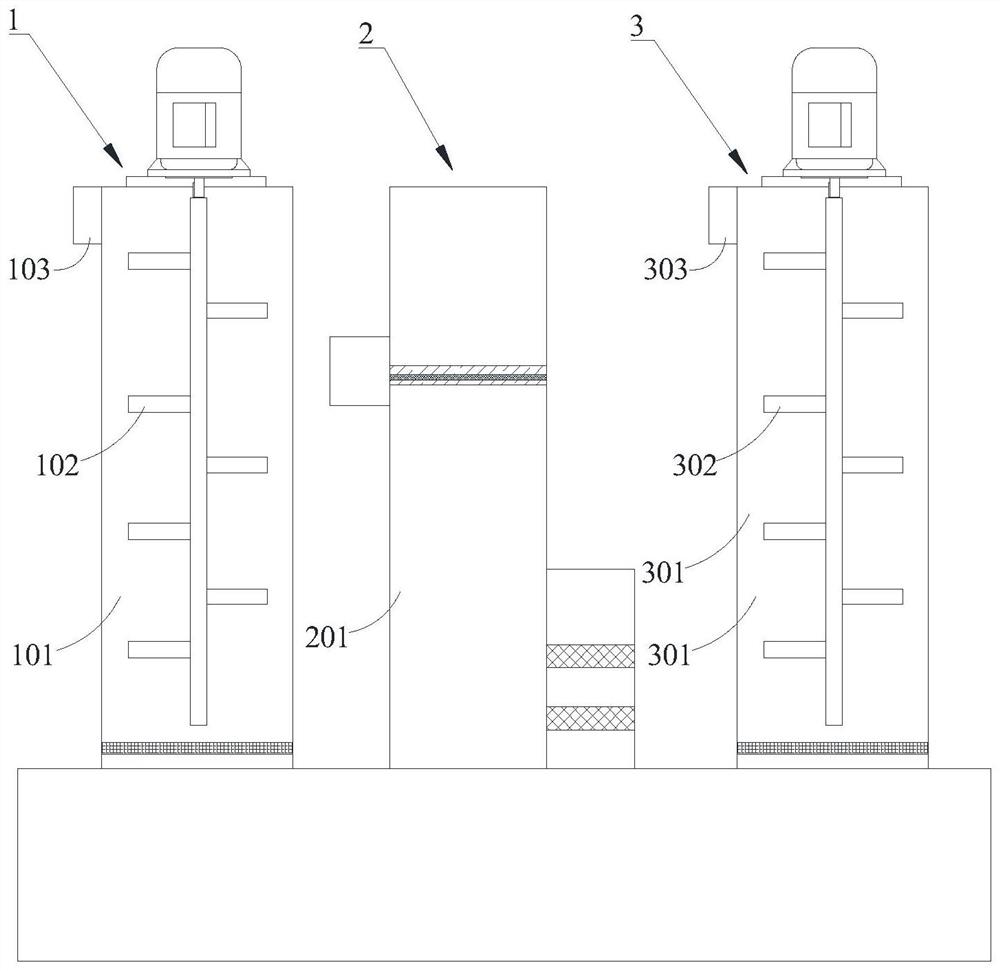

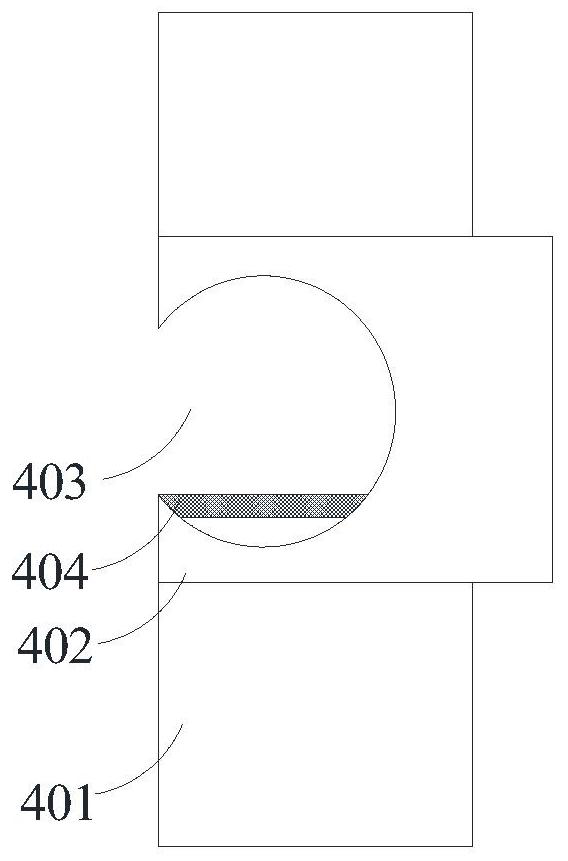

Process system for air-blasting dehumidification through smoke waste heat of hot-blast stove

ActiveCN107083465AIncrease contact timeReduce the overall heightBlast furnace detailsHeating stovesProcess systemsDesiccant

The invention relates to a process system for air-blasting dehumidification through smoke waste heat of a hot-blast stove. The process system comprises a dryer, a regenerator, two sets of conveying and lifting devices and a drying agent. A drying agent discharge opening is formed in the bottom of the dryer, an air inlet is formed in the lower portion of the dryer, a drying channel is formed in the middle portion of the dryer, and a drying agent feed opening and an air outlet are formed in the top of the dryer. A drying agent discharge opening is formed in the bottom of the regenerator, a hot-blast stove smoke inlet is formed in the lower portion of the regenerator, a drying agent regeneration channel is formed in the middle portion of the regenerator, and a drying agent feed opening and a hot-blast stove smoke outlet are formed in the top of the regenerator. The air inlet is connected to an air blower, the air outlet is connected to an inlet of the hot-blast stove, a smoke outlet of the hot-blast stove is connected to the hot-blast stove smoke inlet through a preheater, and the drying agent is circularly conveyed in the dryer and the regenerator through the two sets of conveying and lifting devices. The system indirectly dehumidifies air through the smoke waste heat of the hot-blast stove, a low-temperature environment does not need to be provided, pollution to the air cannot be caused, the energy sources are saved, and the blast furnace coke ratio is reduced.

Owner:WISDRI ENG & RES INC LTD

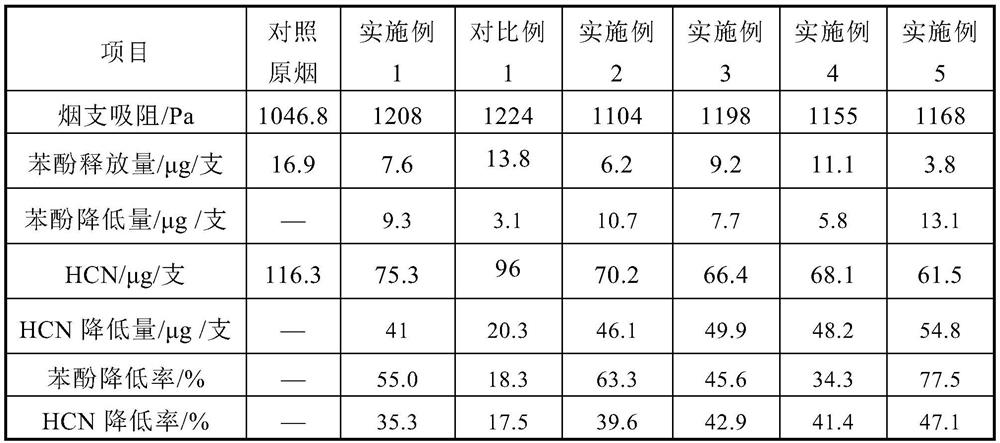

Preparation method and application of stepped-pore tobacco stalk carbon

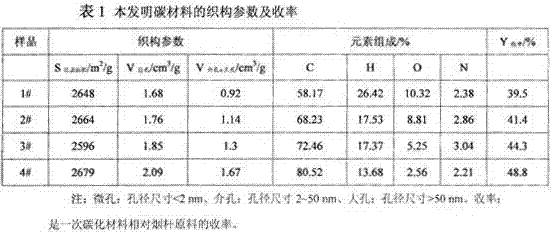

ActiveCN106904591AContribute to carbonizationHigh yieldTobacco smoke filtersCarbon preparation/purificationCelluloseSolid acid

The invention provides a preparation method of stepped-pore tobacco stalk carbon. The method is characterized in that a method is used for preparing a stepped-pore carbon material with tobacco stalks as raw materials and comprises the following steps that the tobacco stalks as the raw materials are subjected to partial hydrolysis in an alcohol-water solution environment in the presence of solid acid and alkene, then the temperature is increased for carbonization, and the stepped-pore tobacco stalk carbon material can be obtained after alkali washing and water washing. According to the stepped-pore carbon material prepared through the method, the pores of the material are distributed in micropore, mesoporous, macropore ranges, so that the stepped-pore carbon material is more suitable for absorbing cigarette tar wide in particle size distribution; when the prepared stepped-pore carbon material is added into a cigarette filter tip, the effect of reducing the tar in main stream smoke is obvious, and the reduction rate is 20% or above. The preparation method and application of the stepped-pore tobacco stalk carbon has the advantages that organic acid generated in the process that the solid acid catalyzes the hydrolysis of cellulose is reacted with alcohol to generate ester so that the problem that a reactor is corroded by the organic acid can be avoided. By the addition of the alkene, the solid acid easily catalyzes the hydrolysis of polysaccharide and the carbonization of a hydrolysis product, so that the yield of a carbon product obtained in the subsequent carbonization stage is increased.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Preparation process of zirconium silicate ball filler

PendingCN112457006AImproves Strength and ToughnessStrong impact toughnessCatalyst carriersOther chemical processesChemical industryStrong acids

The invention discloses a preparation process of a zirconium silicate ball filler. The preparation process comprises the following steps of: step 1, adding zircon sand, alumina powder, a fluxing agentand charcoal powder into an aqueous solution, and mixing the materials to form a mixture; 2, introducing argon into a hearth for atmosphere protection, gradually adding the mixture into the hearth, and heating the mixture to be in a molten state, and forming a molten mixture; and step 3, pouring the mixture in the molten state out of the hearth, blowing the molten mixture flowing out of a launderof the hearth by using compressed air, blowing the molten mixture into balls, performing cooling, solidifying and heat preservation to obtain zirconium silicate ball fillers with different particle sizes. The zirconium silicate ball filler provided by the invention has compressive strength of more than 30MPa, strong acid corrosion resistance and impact toughness, and micron-sized through apparentporosity of 25-40%, and is suitable for chemical industry, water treatment filtration and inorganic salt adsorption.

Owner:CHANGSHA XINGUANG SPECIAL CERAMIC CO LTD

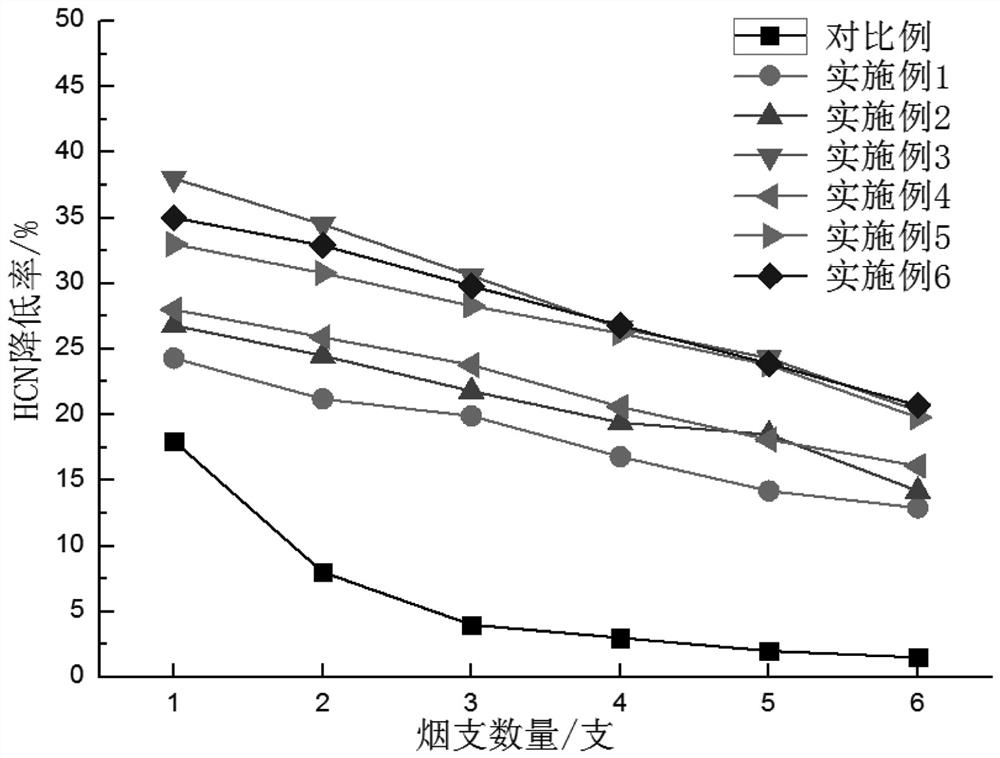

Preparation method and application of high-porosity stepped hole carbon material cigarette filter tip additive

ActiveCN107117594AReduced benzo[a]pyreneReduce tar contentTobacco smoke filtersCarbon preparation/purificationPorosityHydrolysate

The invention relates to a preparation method of a high-porosity stepped hole carbon material cigarette filter tip additive. The preparation method is characterized by comprising the following steps: performing partial hydrolysis on tobacco stems under the action of solid acids, performing solid-liquid separation, loading mixed metal oxide on residues and carbonizing to obtain a metal oxide carbon material; adding the metal oxide carbon material into a filtrate, performing hydrothermal carbonization and then pickling and washing to obtain the high-porosity stepped hole carbon material cigarette filter tip additive. As the material is added into a cigarette filter tip, the effect of reducing the benzo(a)pyrene and tar in cigarette mainstream smoke is significant. The preparation method provided by the invention has the advantage that organic acids generated in the solid acid catalyzed cellulose hydrolysis process react with alcohols to form esters, so that the corrosion problem of the organic acids to a reactor can be solved. Wet-process dipping hydrolysis filter residues are conducive to the dispersion of metal components; metal-supported filter residue carbon can further promote the carbonization of hydrolysates in the filtrate, so that the yield of carbon products is increased.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

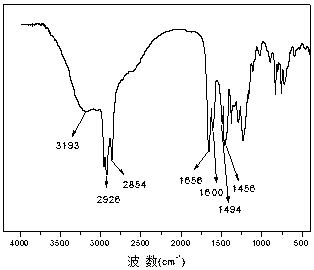

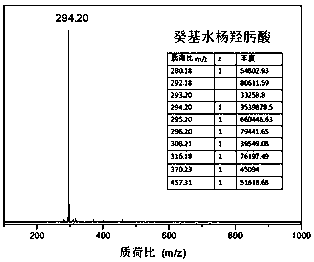

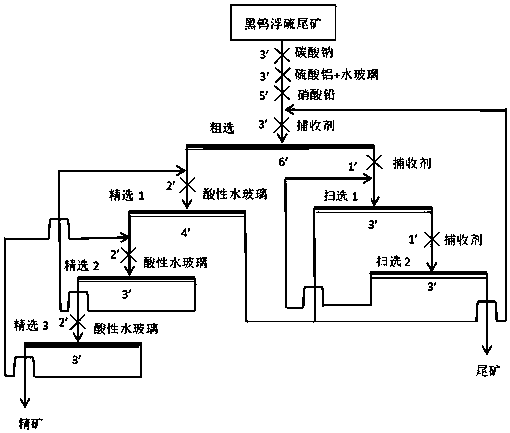

Decyl salicylhydroxamic acid and application thereof

The invention discloses a decyl salicylhydroxamic acid and application thereof. The chemical structure of the decyl salicylhydroxamic acid is shown as 1. The hyperconjugation structure of decyl and benzene rings in the molecular structure of the decyl salicylhydroxamic acid enables the benzene ring structure to have higher electronegativity. The nucleophilic ability of solid affinity groups of hydroxamic acid molecules is higher through the above double factors, so that collecting agent molecules are more liable to adsorb on the surfaces of target minerals. The hydrophilic and hydrophobic properties of the target minerals can be changed by the collecting agent molecules through longer hydrophobic structures more effectively, and the adhesion efficiency of bubbles and minerals is improved;for flotation of refractory oxidized ore, the usage amount of lead nitrate or other metal salt activators can be reduced, and the collecting agents are applicable for flotation of tungsten ore, rare earth ore and tin ore.

Owner:广东省资源综合利用研究所 +1

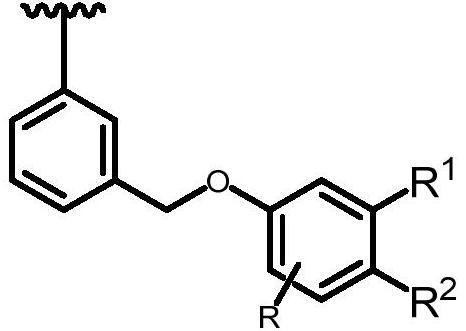

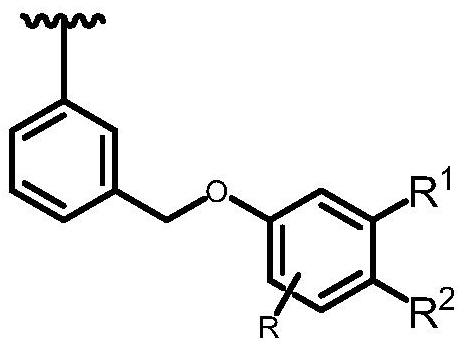

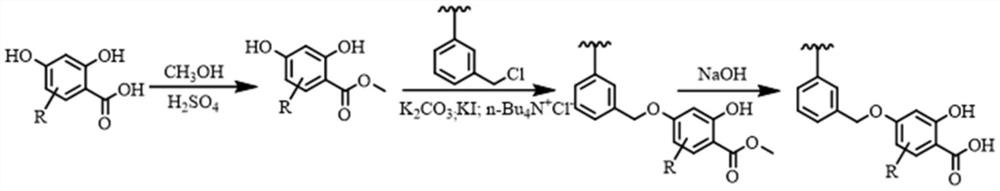

Chelate resin as well as preparation method and application thereof

ActiveCN114044844AHigh adsorption selectivitySuitable for adsorptionOther chemical processesWater/sewage treatment by sorptionAlkoxy groupMetal impurities

The invention relates to a chelate resin and a preparation method and application thereof, wherein the chelate resin has the following structure: in the formula, R is selected from any one or more of H, alkyl or alkoxy containing C1-C10 straight chains or branched chains, chlorine and bromine, R1 is selected from (CH2) nOH, R2 is selected from (CH2) nCOOH, and n is 0-3 and represents a chloro-sphere; Compared with the prior art, the synthesized novel chelate resin product can effectively remove metal impurities such as nickel, cobalt, manganese, calcium, magnesium, iron, zinc and copper in metal wastewater under different acidity, the removal rate reaches up to 99%, and the chelate resin can be used for purifying water or treating wastewater containing metal ions.

Owner:SHANGHAI INST OF TECH

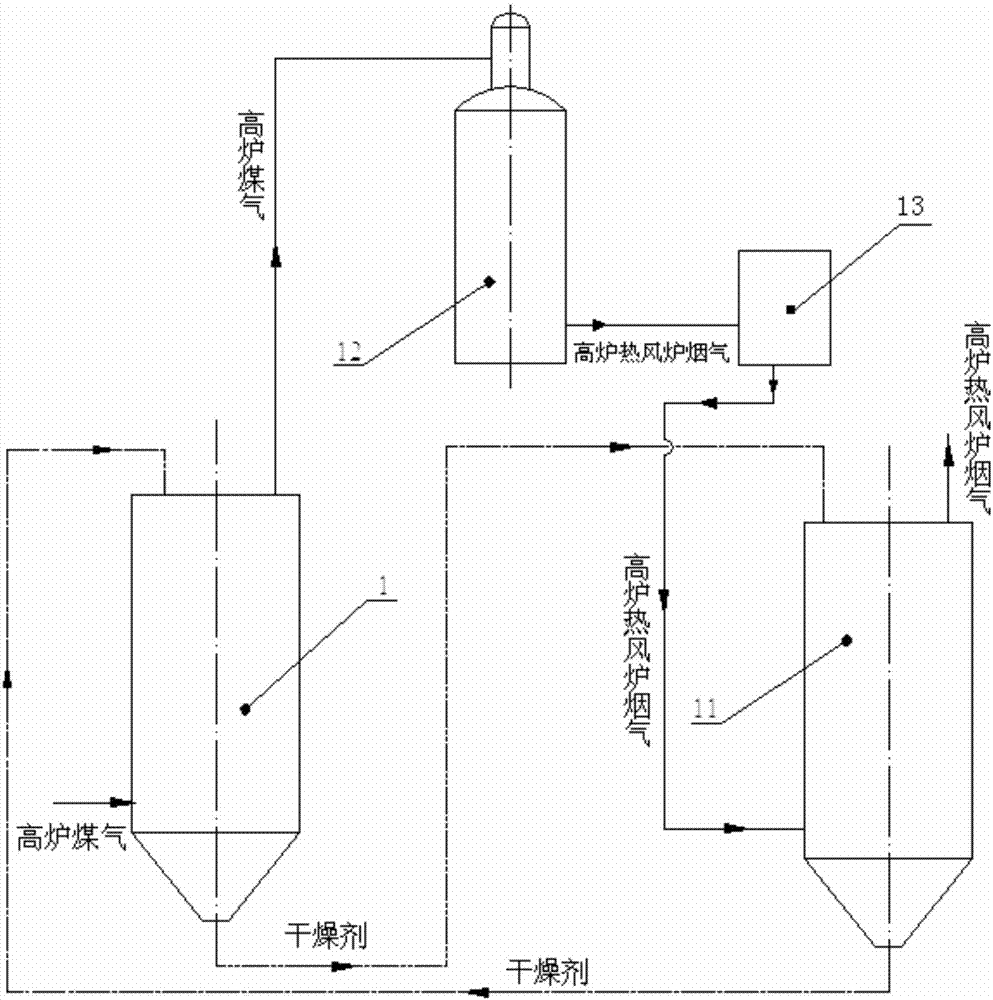

Process system for drying blast furnace gas through smoke waste heat of hot blast stove

ActiveCN107119164AIncrease contact timeReduce the overall heightBlast furnace detailsHeating stovesProcess systemsProcess engineering

The invention relates to a process system for drying blast furnace gas through smoke waste heat of a hot blast stove. The process system comprises a dryer, a regenerator, two sets of conveying and lifting devices and a drying agent. A drying agent discharging port is formed in the bottom of the dryer, a blast furnace gas inlet is formed in the lower portion of the dryer, a drying channel is formed in the middle portion of the dryer, and a drying agent feeding port and a blast furnace gas outlet are formed in the top of the dryer. A drying agent discharging port is formed in the bottom of the regenerator, a hot blast stove smoke inlet is formed in the lower portion of the regenerator, a drying agent regeneration channel is formed in the middle portion of the regenerator, a drying agent feeding port and a hot blast stove smoke outlet are formed in the top of the regenerator. The blast furnace gas outlet is connected to the hot blast stove, the hot blast stove is connected with the hot blast stove smoke inlet through a preheater, the drying agent discharging port of the dryer is connected to the drying agent feeding port of the regenerator through one set of conveying and lifting device, and the drying agent discharging port of the regenerator is connected with the other set of conveying and lifting device. The process system indirectly dries the blast furnace gas through the smoke waste heat of the hot blast stove, no pollution is caused for the blast furnace gas, energy sources are saved, and the calorific value of the blast furnace gas is increased.

Owner:WISDRI ENG & RES INC LTD

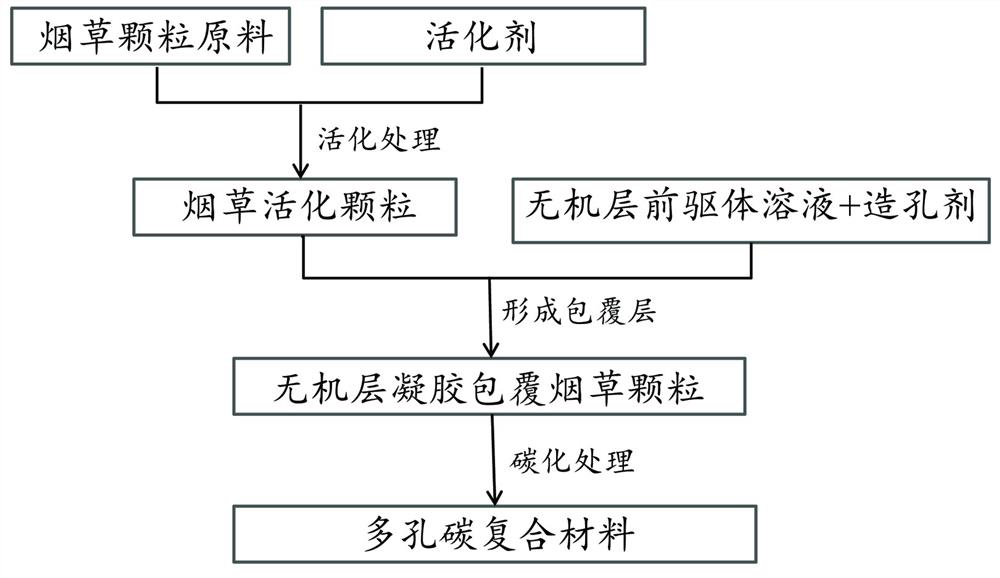

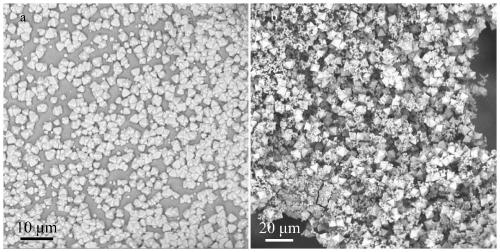

Porous carbon composite material with core-shell structure as well as preparation method and application thereof

ActiveCN112645324ASlow down or avoid churnIncrease contributionCarbon compoundsCarbon compositesPorous carbon

The invention provides a porous carbon composite material with a core-shell structure. The porous carbon composite material comprises porous carbon particles and an inorganic porous layer coating the porous carbon particles. The invention also provides a preparation method of the porous carbon composite material; the preparation method comprises activation treatment, coating layer formation and carbonization treatment, wherein the coating layer formation step comprises the steps: firstly, providing a coating solution which comprises an inorganic layer precursor and a pore-forming agent which are uniformly mixed, and forming an inorganic gel coating layer on the surfaces of tobacco activated particles. In the carbonization treatment process, an inorganic gel layer becomes an inorganic porous layer, nicotine escaping from a tobacco material is bound before the inorganic porous layer is formed, carbonization of nicotine is promoted through the provided microenvironment, and the utilization rate of an endogenous nitrogen element and the yield of a carbon product in the preparation process of the tobacco-based carbon material are effectively increased. The invention also provides an application of the porous carbon composite material in cigarette filters, soil conditioners, water treatment adsorbents or electrodes.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

High activated carbon powder waste gas treatment material and preparation method thereof

InactiveCN109675520AImprove adsorption capacityImprove absorption rateOther chemical processesDispersed particle separationActivated carbonPolyvinyl alcohol

The invention provides a high activated carbon powder waste gas treatment material. The high activated carbon powder waste gas treatment material comprises the following materials in parts by weight:51-55 parts of graphene, 30-32 parts of coconut shell activated carbon powder, 7-10 parts of nano silicon dioxide, 15-20 parts of polyvinylpyrrolidone, 5-10 parts of diatomite, 10-13 parts of polyvinyl alcohol, 20-22 parts of calcined kaolin, 4-7 parts of hydroxymethyl celluloses and 5-9 parts of cordierite. According to the invention, the graphene, the coconut shell activated carbon powder and the calcined kaolin are used as raw materials, and pollutants in waste gas are coordinately absorbed by the materials, so that the absorption rate can be increased, and toxic and harmful substances canbe effectively adsorbed; and a preparation method provided by the invention is simple, the cost is low, the powdery materials are mixed and roasted at high temperature to prepare carbon powder with high activity, and the carbon powder is suitable for adsorbing various waste gases.

Owner:ANHUI LANDING ENVIRONMENTAL PROTECTION ENERGY TECH

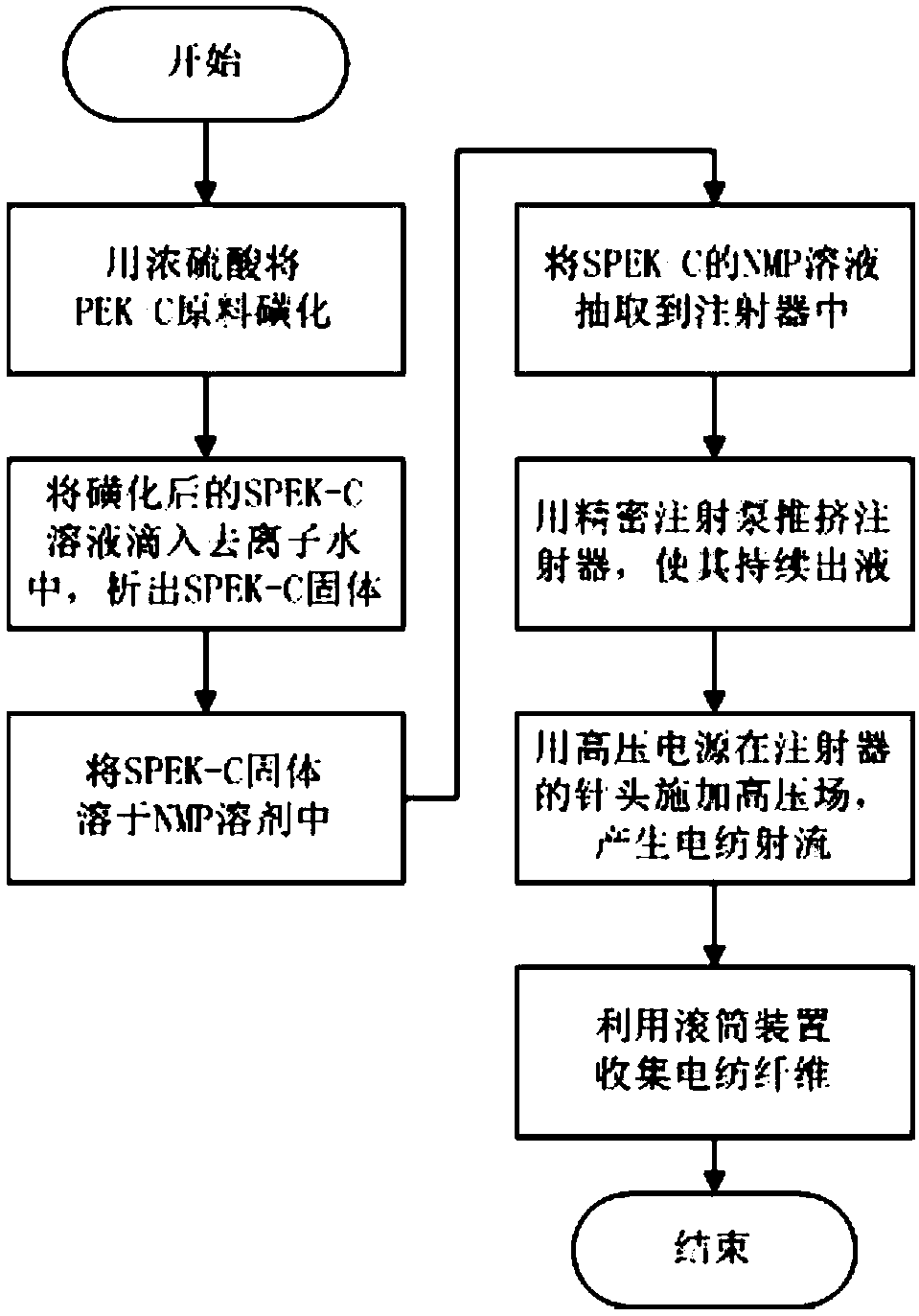

Sulfonated polyaryletherketone positive-electric particle adsorption membrane and electrospinning preparation method thereof

InactiveCN109385752ASolve Adsorption Removal ProblemsSolve just-needed problemsOther chemical processesWater contaminantsFiberSolvent

The invention relates to an electrospun fiber membrane and a preparation method thereof, in particular to a positive-electric particle adsorption membrane prepared by using a sulfonated polyaryletherketone (SPEK-C) material and an electrospinning preparation method thereof. The method comprises the basic steps that concentrated sulfuric acid is used for sulfonating a polyaryletherketone (PEK-C) material, deionized water is used for separating the sulfonated polyaryletherketone (SPEK-C) material, N-methylpyrrolidone (NMP) is taken as a solvent to dissolve the SPEK-C to prepare an electrospinning liquid, and finally the SPEK-C fiber membrane for adsorption is prepared by an electrospinning device with a roller. The degree of sulfonation of SPEK-C is deepened with the sulfonation time, and the adsorption capacity is also increased, that is to say that an adsorption active site can be controlled by adjusting a sulfonation parameter; the SPEK-C fiber membrane can be desorbed and regeneratedthrough a desorbent, and the electrospun fiber membrane can be recycled and used many times, is environmentally friendly, and greatly reduces the adsorption cost.

Owner:XIAMEN UNIV

Preparation method and application of a filter tip additive

ActiveCN107055506BSolving Corrosion ProblemsSuitable for adsorptionOther chemical processesDispersed particle separationCelluloseCarbonization

The invention discloses a preparation method of a filter tip additive. The preparation method is characterized by being a method using tobacco stems as a raw material to prepare a cascade pore carbon material and specifically including: using the tobacco stems as a raw material, partly hydrolyzing in an alcohol-water solution environment under action of solid acid, heating for carbonization, and performing alkali washing and water washing to obtain the cascade pore carbon material. The cascade pore carbon material prepared by the method has certain distribution within ranges of micropores (small than 2nm), mesopores (2-50nm) and macropores (greater than 50nm and is more suitable for adsorption of cigarette tar wide in particle size distribution; by adding the cascade pore carbon material prepared by the method into a cigarette filter tip, effect of lowering mainstream smoke tar is remarkable, and lowering rate is higher than 20%. The preparation method has the advantages that organic acid generated in the process of catalyzing cellulose for hydrolysis by the solid acid reacts with alcohol to generate ester, and corrosion of the organic acid to a reactor can be avoided.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Drying agent for precision optical instrument and preparation method of drying agent

PendingCN114632500AImprove hydrophilicityImprove water absorption and retention capacityOther chemical processesDispersed particle separationCompression moldingSilicic acid

The invention discloses a drying agent for a precise optical instrument. The invention discloses a preparation method of the drying agent for the precise optical instrument, which comprises the following steps: cross-linking ammonium acrylate and macroporous silica gel, so that the inner and outer surfaces of the through holes of the macroporous silica gel are coated with polyacrylamide to obtain a silica gel compound; the preparation method comprises the following steps: mixing and dissolving calcium nitrate and glycine, adding tetraethoxysilane, heating and reacting under an acidic condition, drying and roasting to obtain calcium oxide with high specific surface area, and the mass ratio of calcium nitrate to a glycine aqueous solution to tetraethoxysilane is (2-8): (5-10): (1-2); a silica gel compound, high-specific-surface-area calcium oxide, bentonite, attapulgite and aluminum oxide are evenly mixed, compression molding is conducted, vacuum drying is conducted till the weight is constant, cooling is conducted, and the drying agent for the precision optical instrument is obtained. The mass ratio of the silica gel compound to the high-specific-surface-area calcium oxide to the bentonite to the attapulgite to the aluminum oxide is (8-16): (6-12): (1-5): (1-5): (1-2).

Owner:HANGZHOU GANJIANG IND

Preparation method of ZnCl2-microwave activated corncob activated carbon for treating basic dye wastewater

InactiveCN112403434AStrong absorption capacityIncreased porous structureOther chemical processesWater contaminantsActivated carbonDyeing wastewater

The invention relates to a preparation method of ZnCl2-microwave activated corncob activated carbon for treating basic dye wastewater. The preparation method comprises the following steps: step 1, pretreating raw materials; step 2, weighing the raw materials; step 3, performing heating reflux; step 4, performing microwave activation; step 5, washing and filtering; step 6, drying; and step 7, cooling and storing. The prepared activated carbon has a large number of micropore structures, the pore size distribution is uniform, the surface contains rich oxygen-containing functional groups, dye molecules can be attached and deposited on the activated carbon adsorbent easily, and the activated carbon is more suitable for adsorption. The removal rate of methylene blue dye can reach 99.9% at most,the maximum adsorption capacity can reach 440.5 mg / g, the product can be used for treating wastewater containing basic dye, and the adsorbent is simple in preparation process, low in cost, environmentally friendly and easy to popularize.

Owner:TIANJIN UNIV OF SCI & TECH

Preparation method and application of tungsten oxide hydrate single-particle Raman substrate

ActiveCN111204810AUniform surfaceSuitable for adsorptionTungsten oxides/hydroxidesRaman scatteringHexamethylenetetramineTungstate

The invention discloses a preparation method of a tungsten oxide hydrate single-particle Raman substrate. The preparation method specifically comprises the following steps: (1) cleaning foamed nickeland then drying for later use; (2) mixing ammonium tungstate pentahydrate, hexamethylenetetramine powder and ultrapure water according to a part ratio of 1:1:830 to obtain a mixed solution for later use; (3) pouring the mixed solution in the step (2) into a polytetrafluoroethylene liner; (4) putting the foamed nickel treated in the step (1) into the polytetrafluoroethylene liner; inserting a sealing cover into a high-pressure hydrothermal kettle; putting the high-pressure hydrothermal kettle into a blast drying oven, heating to 105 DEG C at a speed of 5 DEG C / min, and keeping the temperature for at least 12 hours at the temperature of 105 DEG C to enable submillimeter tungsten oxide hydrate to grow on the surface of the foamed nickel; and cleaning foamed nickel to remove impurities; and (5) separating the tungsten oxide hydrate single particles in the step (4) from the foamed nickel by using ultrasonic waves; and drying to obtain tungsten oxide hydrate single particles. The particles are mainly used for ratio detection of molecules such as cytochrome C.

Owner:CHINA JILIANG UNIV

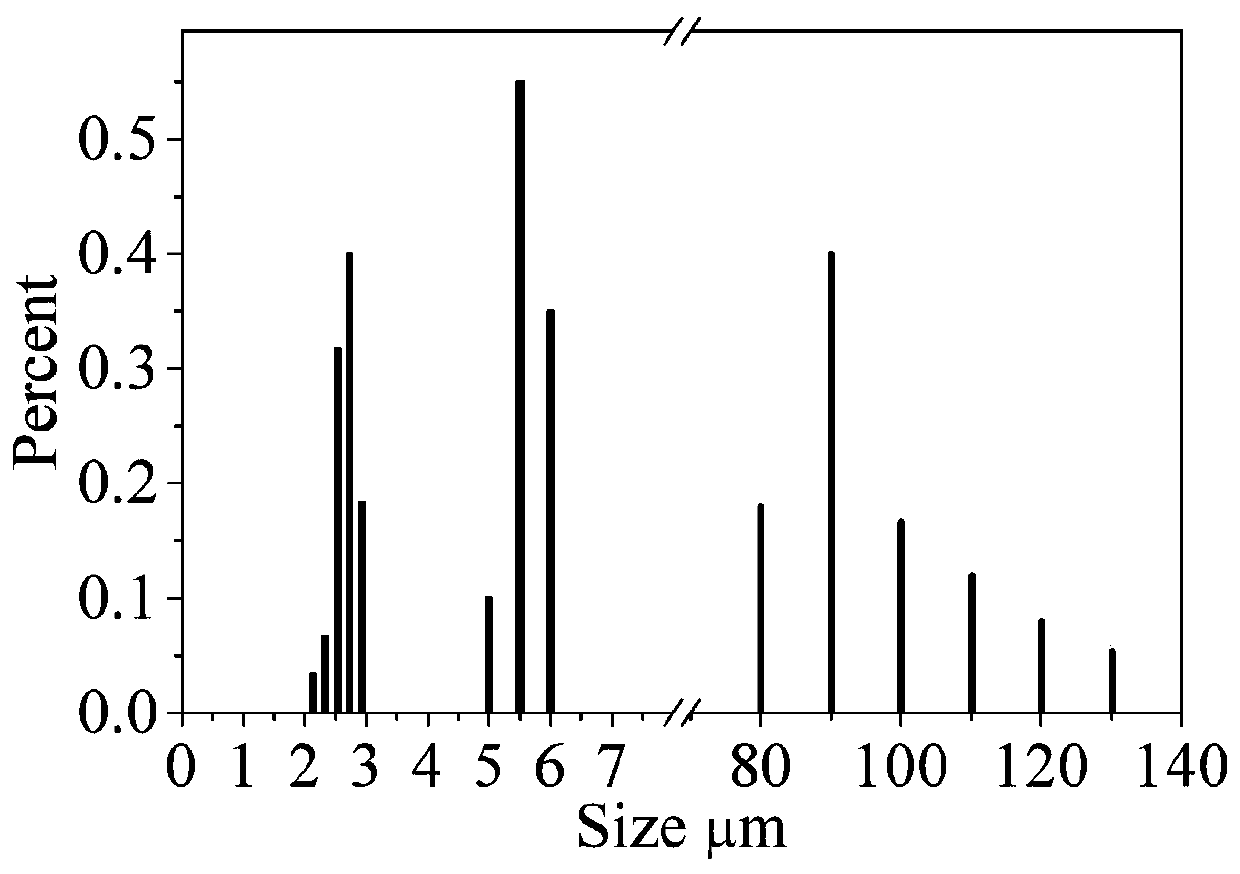

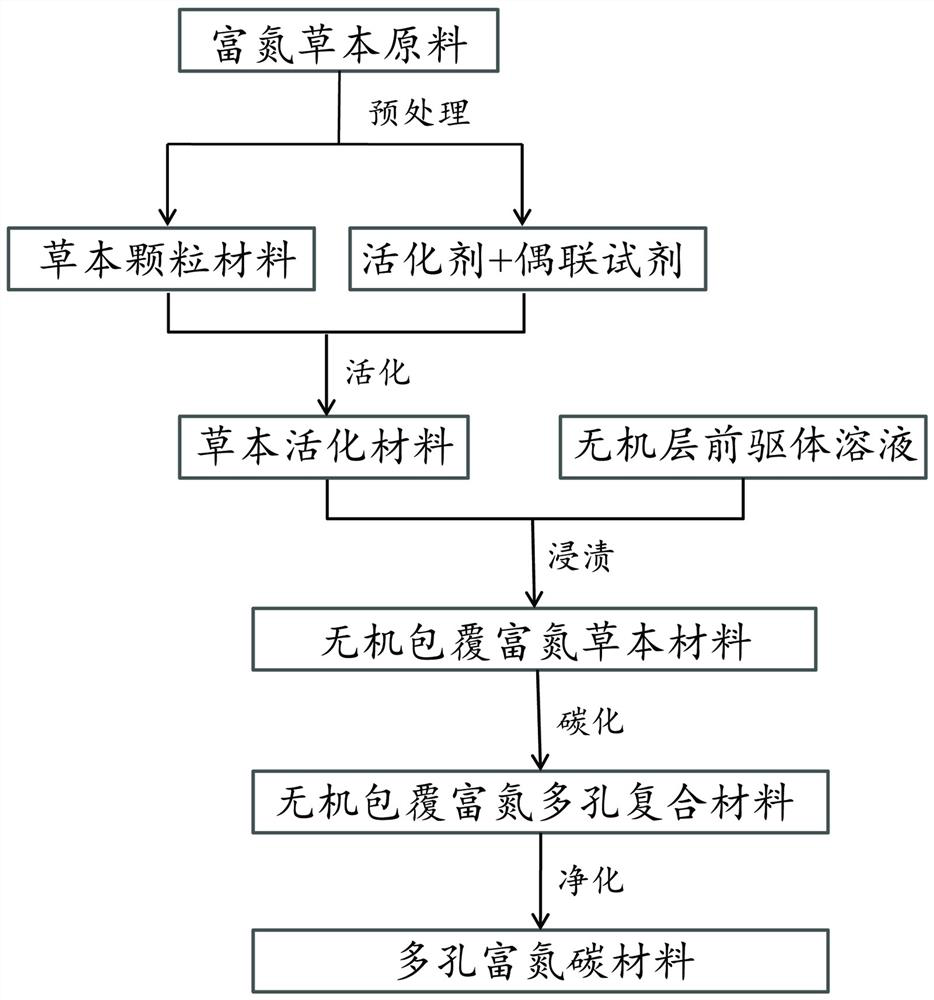

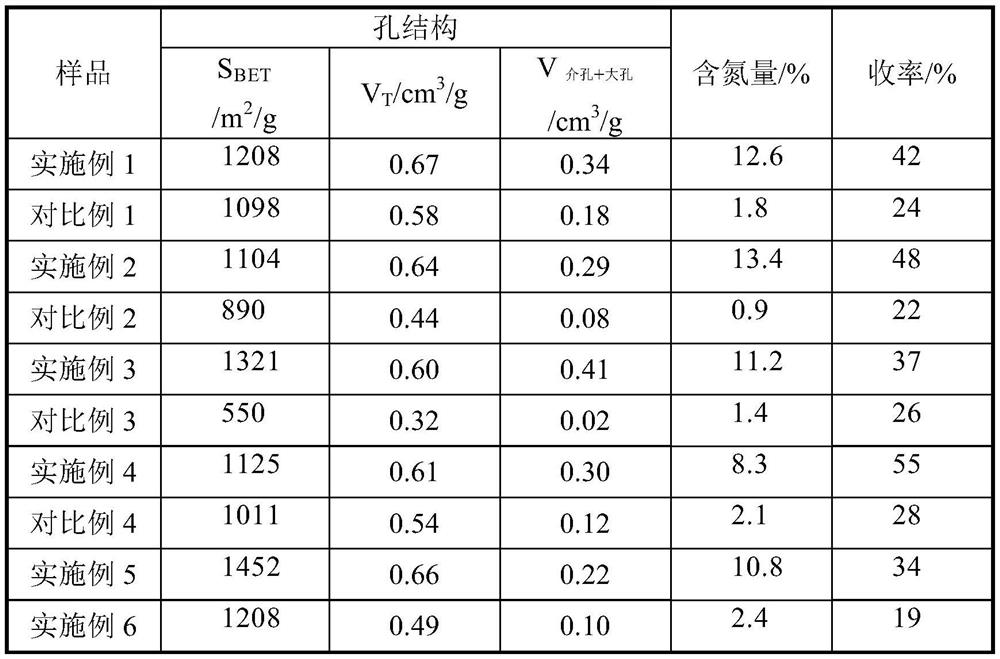

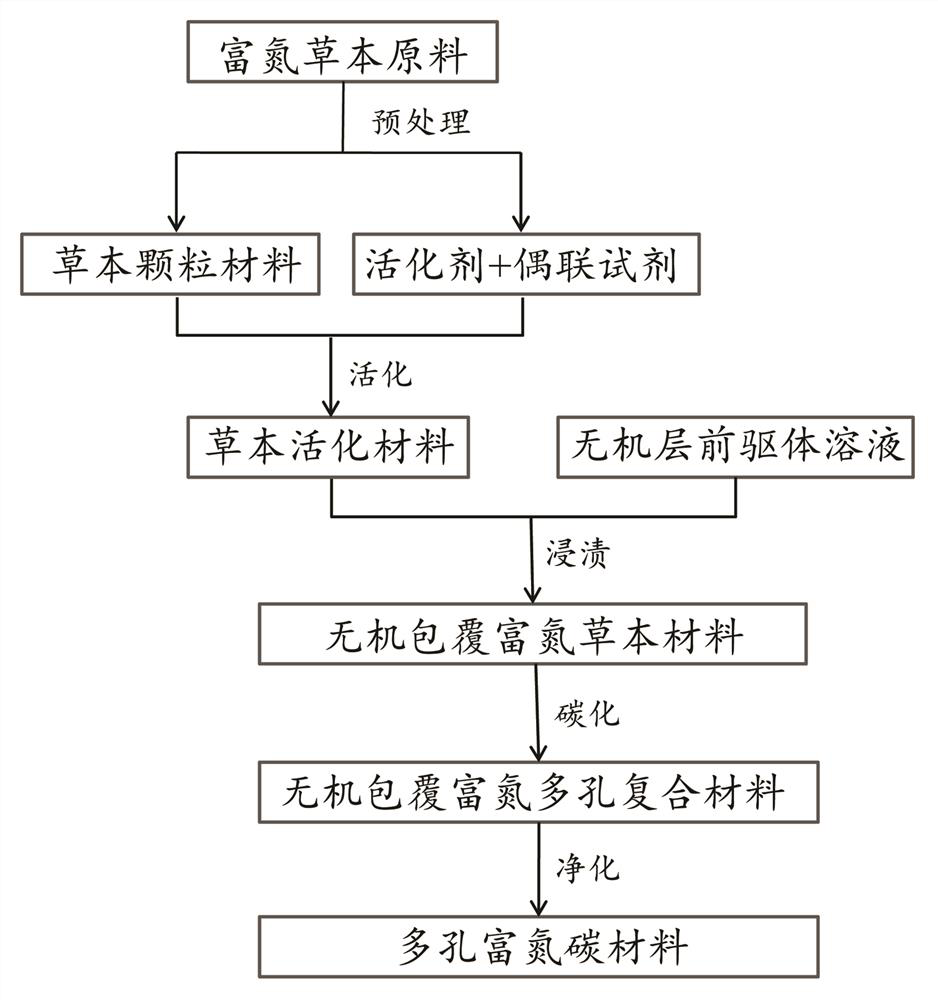

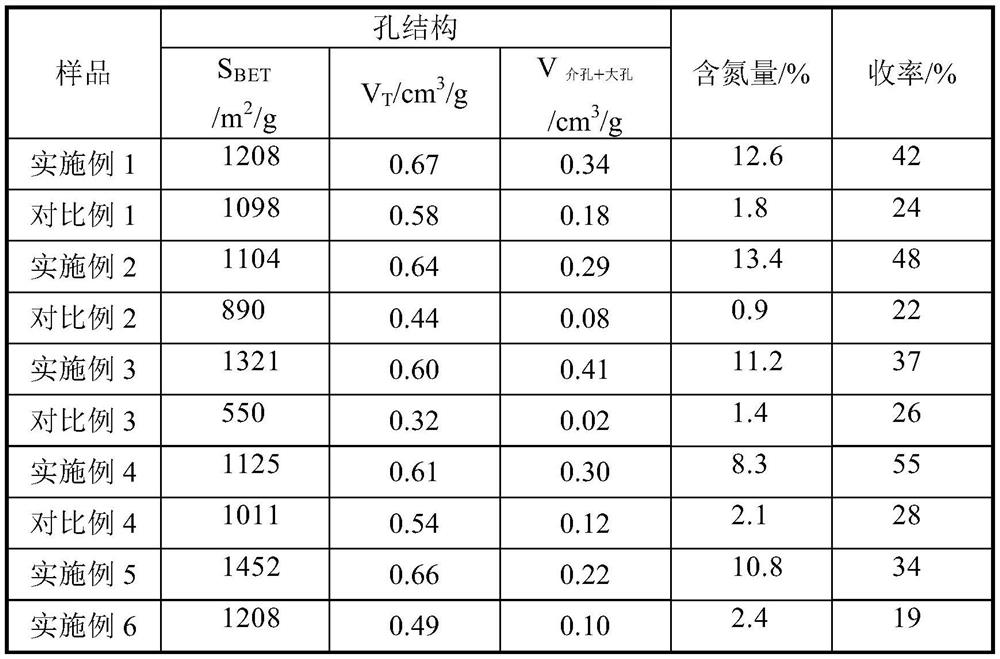

Preparation method of porous nitrogen-rich carbon material

ActiveCN112624106BReduce or avoid churnIncrease contributionCarbon compoundsSimple Organic CompoundsCarbonization

The present invention provides a method for preparing a porous nitrogen-rich carbon material, which comprises: pre-processing, activating, impregnating, carbonizing and purifying a nitrogen-rich herbal material to obtain a porous nitrogen-rich carbon material, wherein the pretreated The step also includes providing an activation solution, the activation solution comprising an activator with a mass fraction of 1% to 20% and a coupling reagent of 0.1 to 2 mol / L; the main purpose of the impregnation step is to form inorganic activating agents on the surface of the herbal activating material. Floor. During the carbonization process, the nitrogen-containing organic compounds in the nitrogen-rich herbal material are grafted into the carbon skeleton under the action of the coupling reagent, and the volatile nitrogen-containing compounds are bound by the coating layer during the heating process to change the carbonization. Therefore, the above preparation method provided by the present invention can effectively improve the utilization rate of endogenous nitrogen elements in the preparation process of herb-based carbon materials, and at the same time increase the yield of carbon products.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

A system for drying blast furnace gas with residual heat from flue gas from hot blast stove

ActiveCN107119164BPollution generationHigh calorific valueBlast furnace detailsHeating stovesProcess systemsEngineering

The invention relates to a process system for drying blast furnace gas through smoke waste heat of a hot blast stove. The process system comprises a dryer, a regenerator, two sets of conveying and lifting devices and a drying agent. A drying agent discharging port is formed in the bottom of the dryer, a blast furnace gas inlet is formed in the lower portion of the dryer, a drying channel is formed in the middle portion of the dryer, and a drying agent feeding port and a blast furnace gas outlet are formed in the top of the dryer. A drying agent discharging port is formed in the bottom of the regenerator, a hot blast stove smoke inlet is formed in the lower portion of the regenerator, a drying agent regeneration channel is formed in the middle portion of the regenerator, a drying agent feeding port and a hot blast stove smoke outlet are formed in the top of the regenerator. The blast furnace gas outlet is connected to the hot blast stove, the hot blast stove is connected with the hot blast stove smoke inlet through a preheater, the drying agent discharging port of the dryer is connected to the drying agent feeding port of the regenerator through one set of conveying and lifting device, and the drying agent discharging port of the regenerator is connected with the other set of conveying and lifting device. The process system indirectly dries the blast furnace gas through the smoke waste heat of the hot blast stove, no pollution is caused for the blast furnace gas, energy sources are saved, and the calorific value of the blast furnace gas is increased.

Owner:WISDRI ENG & RES INC LTD

Preparation method of KOH-microwave activated corncob activated carbon for treating cationic dye-containing wastewater

PendingCN112403435AShort preparation timeImprove adsorption performanceOther chemical processesWater contaminantsMethylene radicalActivated carbon

The invention relates to a preparation method of KOH-microwave activated corncob activated carbon for treating cationic dye-containing wastewater. The preparation method comprises the following steps:step 1, pretreating raw materials; step 2, weighing the raw materials; step 3, performing heating reflux; step 4, performing microwave activation; step 5, washing and filtering; step 6, drying; and step 7, cooling and storing. The activated carbon prepared by the method has a large number of microporous structures, is uniform in pore size distribution, contains rich oxygen-containing functional groups on the surface, is beneficial to attachment and deposition of dye molecules on the surface, and is more suitable for adsorption. The removal rate of methylene blue dye can reach 99.9% at most, the maximum adsorption capacity can reach 636.9 mg / g, the product can be used for treating cationic dye-containing wastewater, and the product is simple in preparation process, low in cost, green, environmentally friendly and easy to popularize.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of activated carbon and its preparation method and application

ActiveCN112079354BIncrease the areaHigh pore volumeHydrogenCarbon compoundsActivated carbonTube furnace

The invention relates to the technical field of hydrogen storage materials, in particular to an activated carbon and its preparation method and application. It is obtained by soaking the debris of biomass raw material in LiOH solution, drying and grinding after ultrasonic treatment, putting it into a special puffing kettle, and heating it up. precursor; then the precursor and anhydrous ZnCl 2 Mixed, put into tube furnace for three-stage heating and calcining, and pass N 2 gas, and finally a modified super activated carbon hydrogen storage material is obtained. The activated carbon material is analyzed and tested, and the specific surface area is ≥3000m 2 / g, the micropore volume reaches 2cm 3 About / g, the micropore volume ratio reaches more than 80%, and the average pore diameter is between 0.5 and 1.2nm. Under the operating conditions of room temperature and 40bar, the hydrogen storage capacity can reach more than 2.5wt%, and the adsorption rate is very fast. This method utilizes the principle of biomass flash explosion wall breaking to modify high-performance hydrogen storage materials, which has low cost and simple manufacturing process, and can achieve high hydrogen storage performance at room temperature, medium and high pressure. An effective way is provided.

Owner:SHANDONG UNIV

Preparation method of porous nitrogen-rich carbon material

The invention provides a preparation method of a porous nitrogen-rich carbon material, which comprises the following steps: carrying out pretreatment, activation, impregnation, carbonization, purification and the like on a nitrogen-rich herbal material to obtain the porous nitrogen-rich carbon material, and the pretreatment further comprises the following steps: providing an activation solution which comprises 1-20 wt% of an activator and 0.1-2 mol / L of a coupling reagent; and the main purpose of the dipping step is to form an inorganic layer on the surface of the herbal activated material. In the carbonization treatment process, nitrogen-containing organic matters in the nitrogen-rich herbal material are grafted into a carbon skeleton under the action of a coupling reagent, and a volatile nitrogen-containing compound is bound by a coating layer in the heating process, so that the carbonization microenvironment is changed; therefore, the preparation method provided by the invention can effectively improve the utilization rate of the endogenous nitrogen element in the preparation process of the herbal-based carbon material, and meanwhile, the yield of the carbon product is increased.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

The process system of using the waste heat of hot blast stove flue gas for blast dehumidification

ActiveCN107083465BPollution generationSave energyBlast furnace detailsHeating stovesProcess systemsDesiccant

The invention relates to a process system for air-blasting dehumidification through smoke waste heat of a hot-blast stove. The process system comprises a dryer, a regenerator, two sets of conveying and lifting devices and a drying agent. A drying agent discharge opening is formed in the bottom of the dryer, an air inlet is formed in the lower portion of the dryer, a drying channel is formed in the middle portion of the dryer, and a drying agent feed opening and an air outlet are formed in the top of the dryer. A drying agent discharge opening is formed in the bottom of the regenerator, a hot-blast stove smoke inlet is formed in the lower portion of the regenerator, a drying agent regeneration channel is formed in the middle portion of the regenerator, and a drying agent feed opening and a hot-blast stove smoke outlet are formed in the top of the regenerator. The air inlet is connected to an air blower, the air outlet is connected to an inlet of the hot-blast stove, a smoke outlet of the hot-blast stove is connected to the hot-blast stove smoke inlet through a preheater, and the drying agent is circularly conveyed in the dryer and the regenerator through the two sets of conveying and lifting devices. The system indirectly dehumidifies air through the smoke waste heat of the hot-blast stove, a low-temperature environment does not need to be provided, pollution to the air cannot be caused, the energy sources are saved, and the blast furnace coke ratio is reduced.

Owner:WISDRI ENG & RES INC LTD

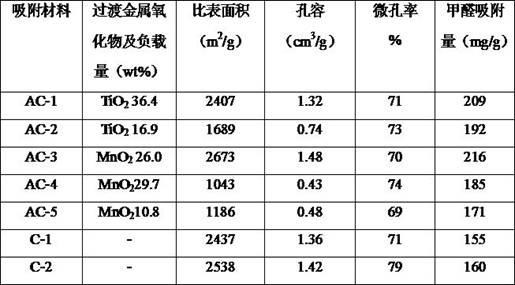

Modified carbon material and preparation method thereof

ActiveCN114471456AImprove adsorption capacityImprove the adsorption and removal rateCarbon compoundsOther chemical processesModified carbonPetroleum coke

The invention discloses a modified carbon material and a preparation method thereof. The modified carbon material comprises a carbon material matrix and transition metal oxides distributed on the matrix, the preparation method comprises the following steps: uniformly mixing petroleum coke, an activating agent and a transition metal compound, activating, reacting to obtain a carbon material, contacting the carbon material with CO2 gas to react, finally performing anodic oxidation reaction on a reaction product, and further washing and drying to obtain the modified carbon material. The modified carbon material with high specific surface area and reasonable pore size distribution is prepared by regulating and optimizing a process route and reaction conditions, and the obtained modified carbon material can effectively adsorb and decompose formaldehyde and realize efficient adsorption and removal of formaldehyde.

Owner:CHINA PETROLEUM & CHEM CORP +1

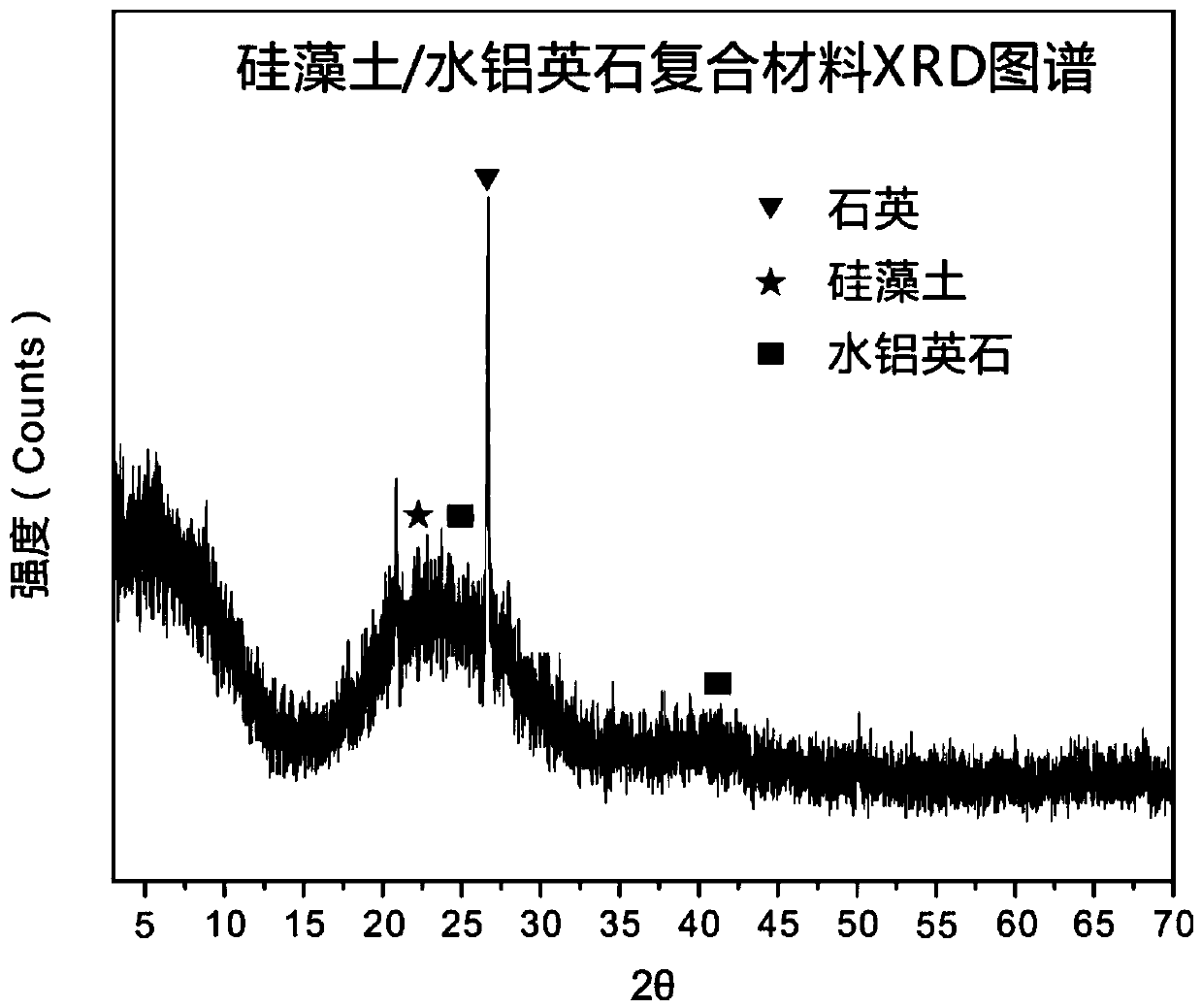

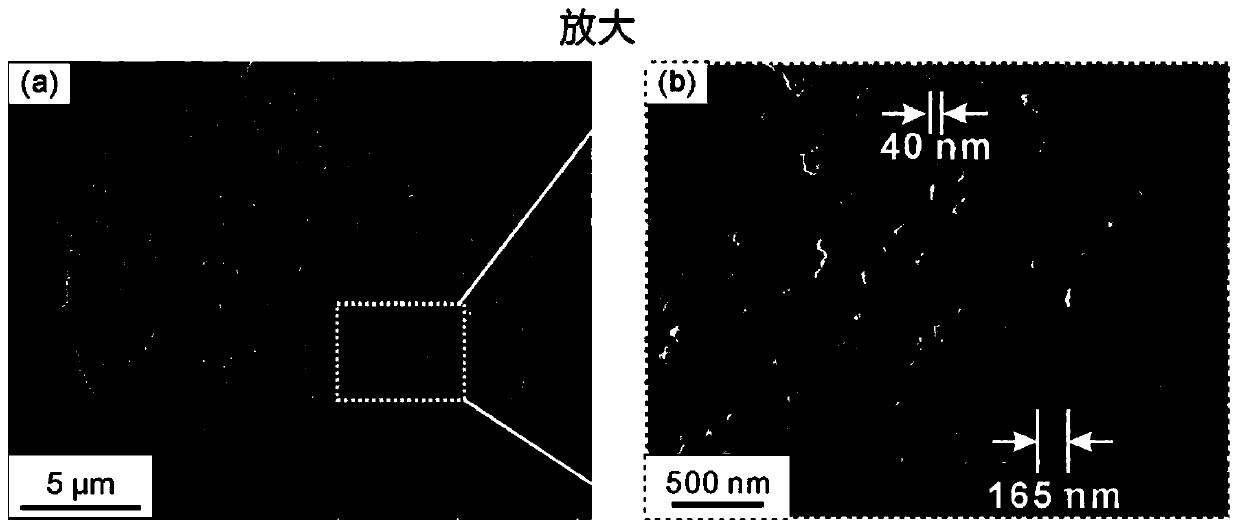

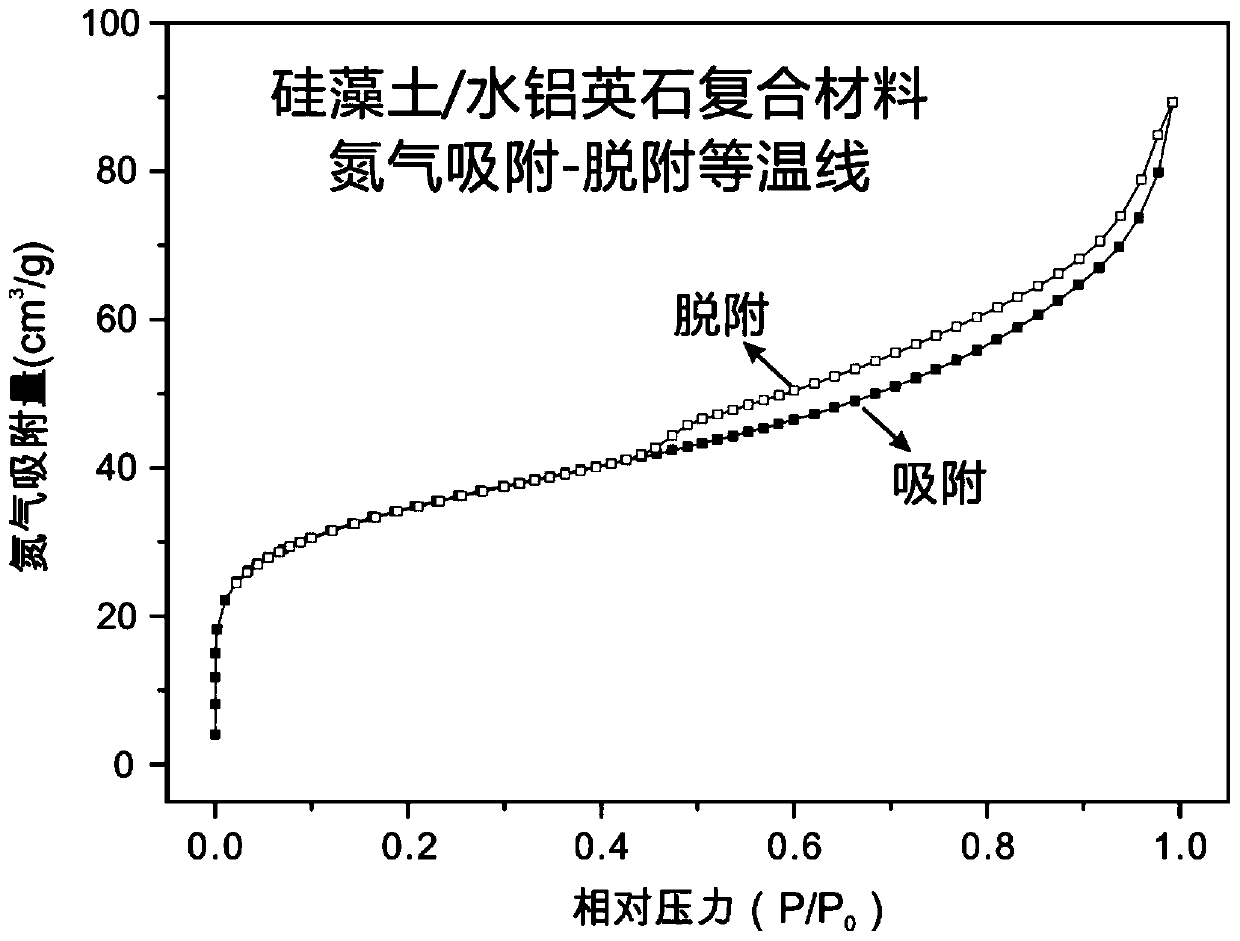

A kind of diatomite/allophane composite material with multi-level pore structure and its preparation method

ActiveCN109248652BRich in microporesLarge specific surface areaGas treatmentOther chemical processesAllophaneNanoparticle

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

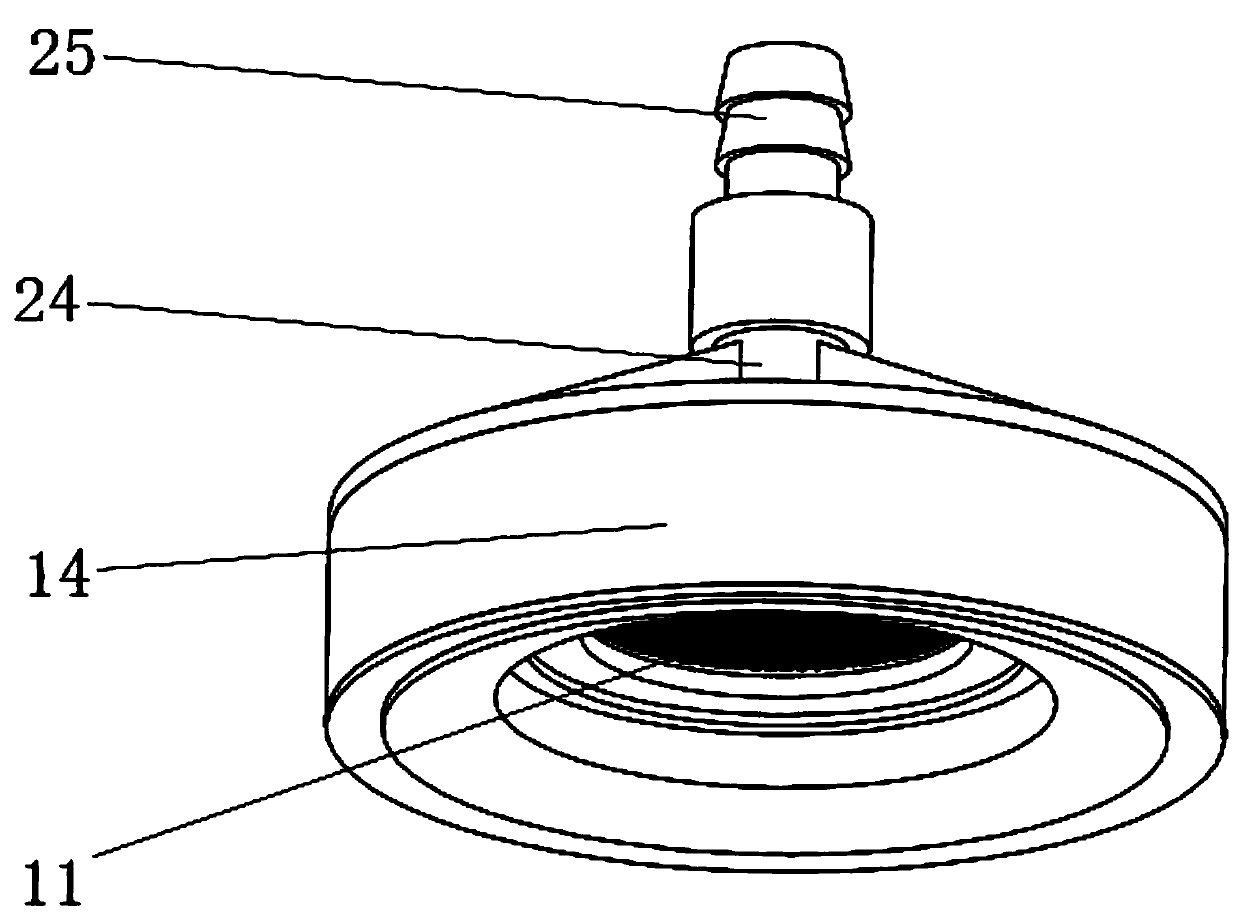

Double-layer sponge vacuum suction cup

The invention discloses a double-layer sponge vacuum suction cup. A raised annular step is arranged at the bottom of the inner wall of an inner layer, a first filter screen is installed on the annularstep, and a rubber pad is arranged at the bottom of an outer layer. A suction cup body is covered with a cover plate. A connecting pipe is connected at the bottom of the cover plate, extends into theinner layer to be connected with the inner layer and presses the first filter screen on the annular step. One end of a vertical air exhaust pipe is installed at the top of the cover plate and communicates with the connecting pipe, a rib plate is connected between the side face of the vertical air exhaust pipe and the top surface of the cover plate, an air exhaust adapter is installed at the otherend of the vertical air exhaust pipe, and a second filter screen is installed between the air exhaust adapter and the vertical air exhaust pipe. The double-layer sponge vacuum suction cup can stablyadsorb products with rough surfaces and the possibility of shedding debris, meanwhile it is ensured that the suction cup works stably for a long time, and the problems such as unstable adsorption, airleakage, failures of suction on rough surfaces and easy blockage of suction holes by debris of existing common vacuum suction cups are solved.

Owner:JILIN UNIV

Alumina powder and boehmite mixed amphiphilic agent and mixing equipment

PendingCN112499655AReduce moisture contentImprove the isolation effectMaterial nanotechnologyTransportation and packagingAmphiphilic AgentsNicotinamide

The invention belongs to the technical field of aluminum oxide, and particularly relates to an aluminum oxide powder and boehmite mixed amphoteric agent and mixing equipment, and the aluminum oxide powder and boehmite mixed amphoteric agent and mixing equipment comprise mixed powder of aluminum oxide powder and boehmite powder; wherein the particle size of the aluminum oxide powder is 80-90 nanometers; wherein the particle size of the boehmite powder is 50-60 nanometers; wherein the content of the aluminum oxide powder is 70-82 wt%; wherein the content of the boehmite powder is 8-20wt%. The composition further comprises nicotinamide adenine dinucleotide phosphate. The weight ratio of the nicotinamide adenine dinucleotide phosphate to the mixed powder is 1:9 to 1:10. The alumina powder andboehmite mixed amphoteric agent and the mixing equipment have the effect of improving the isolation performance of the alumina powder.

Owner:芯科众联新材料(常州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com