Polydopamine-coated silica gel modified by polyethylene polyamine, method for preparing polydopamine-coated silica gel modified by polyethylene polyamine and application of polydopamine-coated silica gel modified by polyethylene polyamine

A polyvinylpolyamine and polydopamine technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., to achieve the effects of firm bonding, large adsorption capacity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

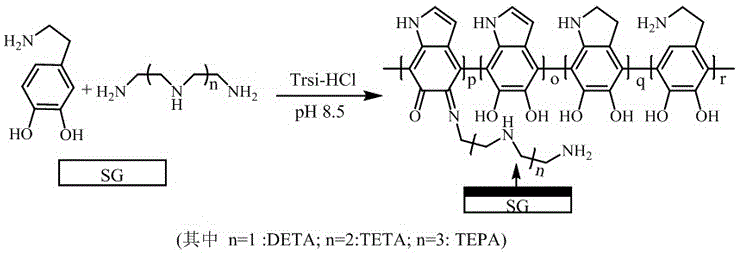

[0018] Example 1 Preparation of polydopamine-coated silica gel SG@DETA / PDA modified by diethylenetriamine

[0019] (1) Activation of silica gel: place the silica gel in a nitric acid solution with a volume concentration of 50% for 12 h, wash it with deionized water until it is neutral, and dry it; After washing with deionized water until neutral, vacuum-dry at 60°C for 12 h, and set aside;

[0020] (2) Synthesis of polyethylene polyamine-modified polydopamine-coated silica gel: disperse 0.2 g of activated silica gel in 200 mL of Tirs-HCl buffer solution with pH=8.5, stir for 5 min, then add 0.4 g of dopamine hydrochloride and 6 mmol Diethylenetriamine (DETA) was slowly stirred at 25 °C for 24 h, and the product was centrifuged and washed with distilled water, then dried in vacuum at 55 °C to obtain SG@DETA / PDA.

Embodiment 2

[0021] Example 2 Preparation of triethylenetetramine-modified polydopamine-coated silica gel SG@TETA / PDA

[0022] The diethylenetriamine added in step (2) of Example 1 was replaced with triethylenetetramine (TETA), and other operations were carried out as in Example 1 to obtain SG@TETA / PDA.

Embodiment 3

[0023] Example 3 Preparation of tetraethylenepentamine-modified polydopamine-coated silica gel SG@TEPA / PDA

[0024] The diethylenetriamine added in step (2) of Example 1 was replaced with tetraethylenepentamine (TEPA), and other operations were carried out according to Example 1 to obtain SG@TEPA / PDA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com