A kind of diatomite/allophane composite material with multi-level pore structure and its preparation method

A technology of allophane and pore structure, which is applied in the direction of aluminum silicate, separation methods, silicon compounds, etc., can solve the problems of poor thermal stability, single pore structure, complex preparation process, etc., and achieve low hydrothermal reaction temperature, specific The effect of large surface area and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Add 10 g of diatomaceous earth to 2 L of aluminum chloride solution with a concentration of 0.1 M, and stir at room temperature for 1 h to obtain a suspension.

[0030] 2) Add 1.5 L of 0.1 M sodium orthosilicate solution to the suspension obtained in step 1) at a rate of 10 mL / min, and stir at room temperature for 1 h to obtain a mixture of diatomite and allophane precursor.

[0031] 3) The mixture obtained in step 2) was subjected to solid-liquid separation by centrifugation, and the separated solid was placed in a hydrothermal kettle, and reacted at 100° C. for 48 hours.

[0032] 4) The reaction product obtained in step 3) was centrifuged and washed until the supernatant was neutral, and then freeze-dried to obtain the diatomite / allophane composite material with a multi-level pore structure in this embodiment.

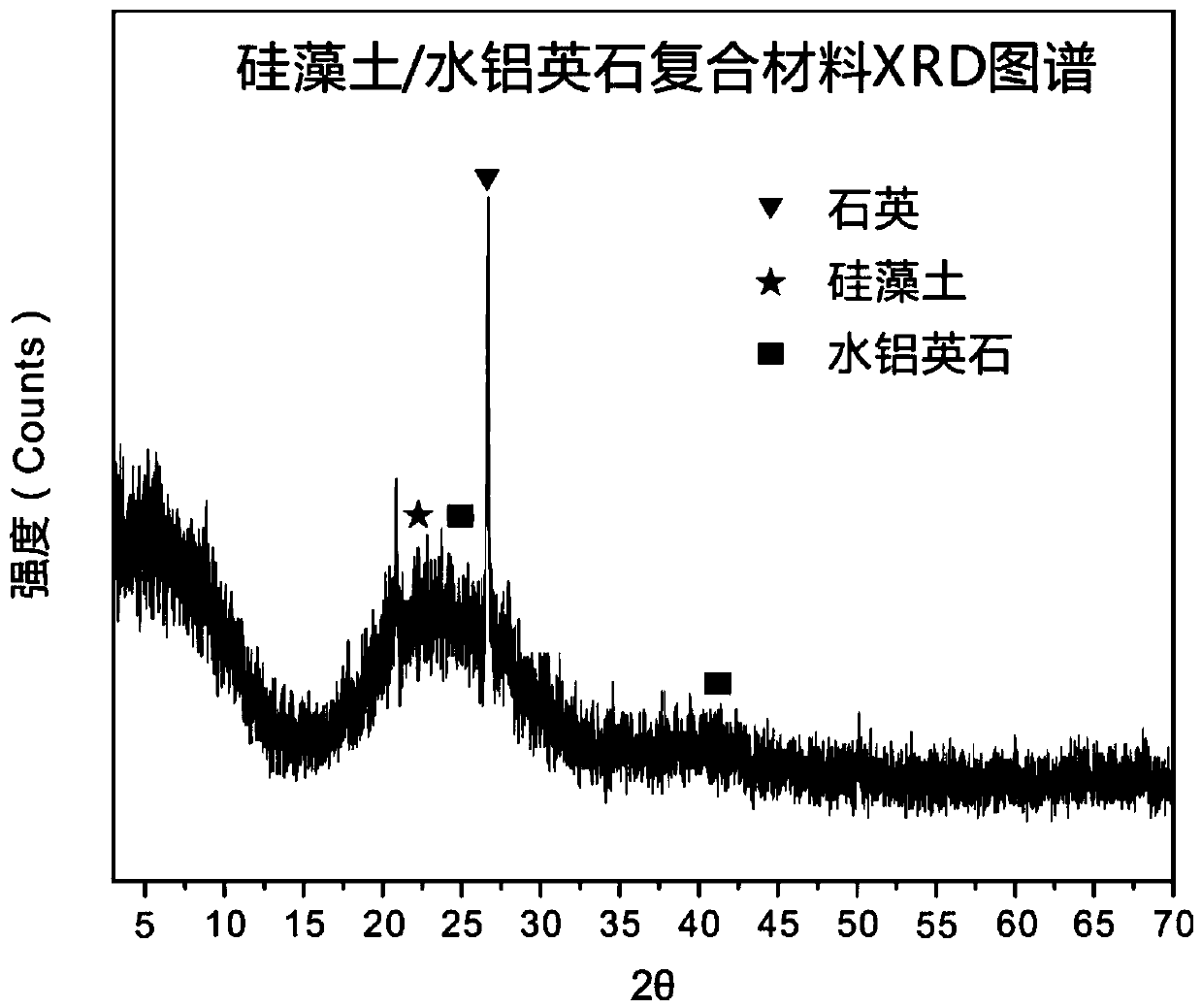

[0033] The crystal structure of the diatomite / allophane composite material with multi-level channel structure prepared in this example was analyzed by X-ra...

Embodiment 2

[0037] 1) Add 15 g of diatomaceous earth into 1.5 L of aluminum sulfate solution with a concentration of 0.05 M, and stir at room temperature for 2 h to obtain a suspension.

[0038] 2) Add 1.5 L of 0.05 M sodium orthosilicate solution to the suspension obtained in step 1) at a rate of 50 mL / min, and stir at room temperature for 2 h to obtain a mixture of diatomite and allophane precursor.

[0039] 3) The mixture obtained in step 2) was subjected to solid-liquid separation by centrifugation, and the separated solid was placed in a hydrothermal kettle, and reacted at 50° C. for 72 hours.

[0040] 4) The reaction product obtained in step 3) was centrifuged and washed until the supernatant was neutral, and then freeze-dried to obtain the diatomite / allophane composite material with a multi-level pore structure in this embodiment.

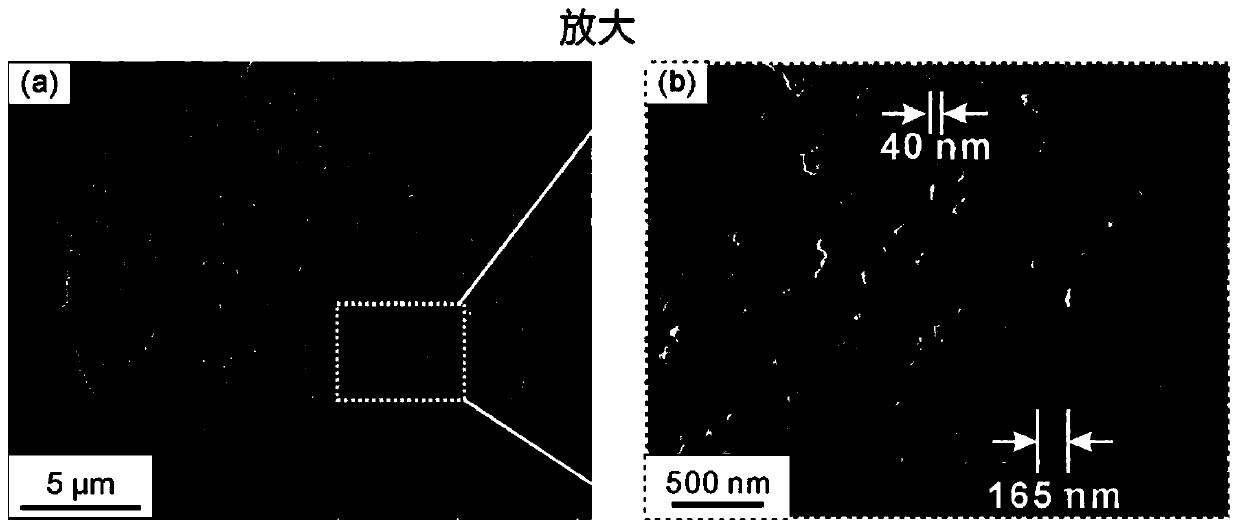

[0041] The morphology and structure of the diatomite / allophane composite material with a hierarchical pore structure prepared in this example were anal...

Embodiment 3

[0045] 1) Add 20 g of diatomaceous earth into 2 L of aluminum nitrate solution with a concentration of 0.03 M, and stir at room temperature for 3 h to obtain a suspension.

[0046] 2) 1 L of tetraethyl orthosilicate solution with a concentration of 0.03M was added to the suspension obtained in step 1) at a rate of 5 mL / min, and stirred at room temperature for 3 h to obtain a mixture of diatomite and allophane precursor.

[0047] 3) The mixture obtained in step 2) was subjected to solid-liquid separation by centrifugation, and the separated solid was placed in a hydrothermal kettle, and reacted at 150° C. for 24 hours.

[0048] 4) The reaction product obtained in step 3) was centrifuged and washed until the supernatant was neutral, and then freeze-dried to obtain the diatomite / allophane composite material with a multi-level pore structure in this embodiment.

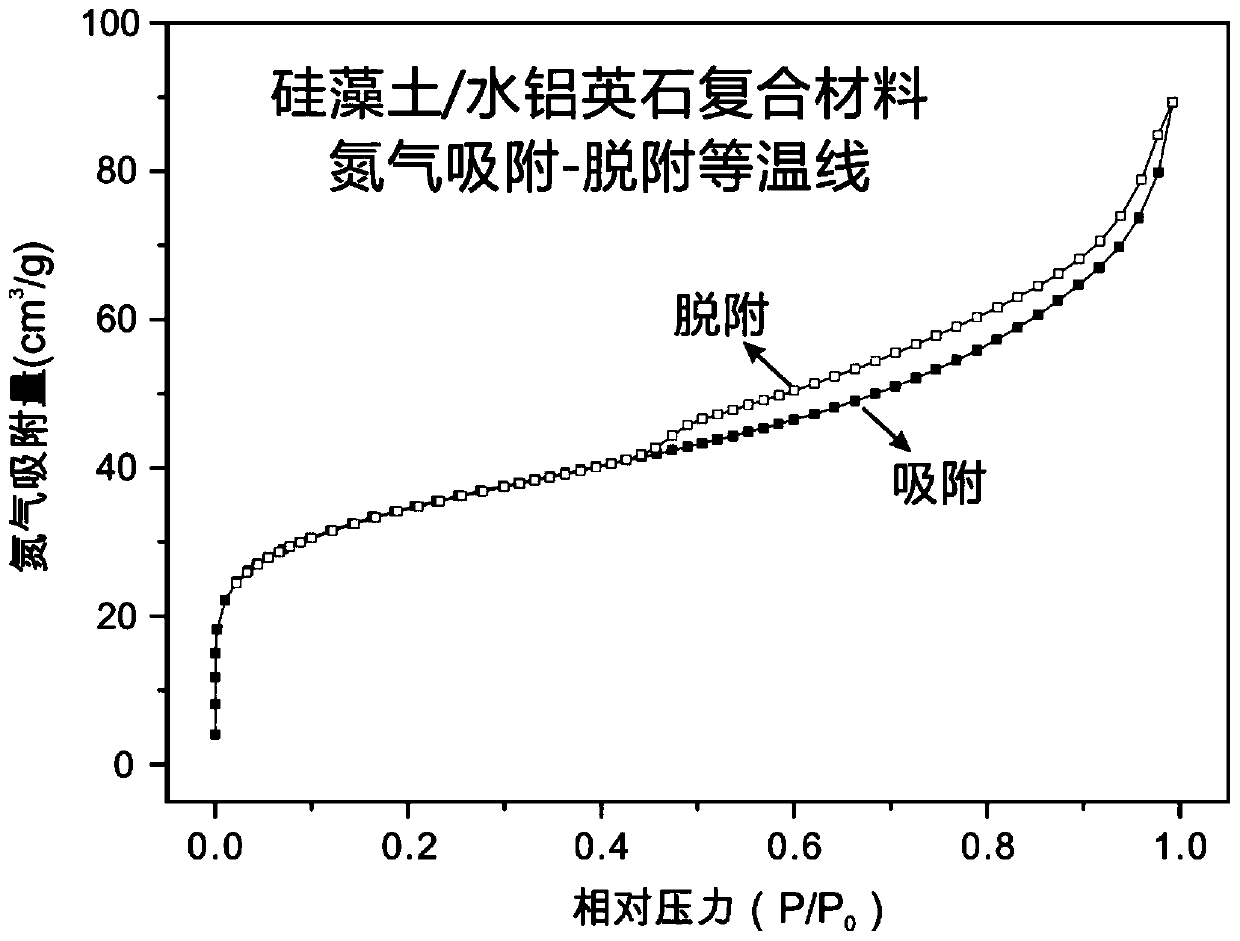

[0049] image 3 is the nitrogen adsorption-desorption isotherm of the diatomite / allophane composite material with mult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com