Preparation method and application of high-porosity stepped hole carbon material cigarette filter tip additive

A technology of carbon materials and stepped pores, which is applied in the preparation/purification, application, and e-liquid filter elements of carbon, which can solve the problems of equipment corrosion and low yield, and achieve the effect of promoting carbonization, reducing tar content, and remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

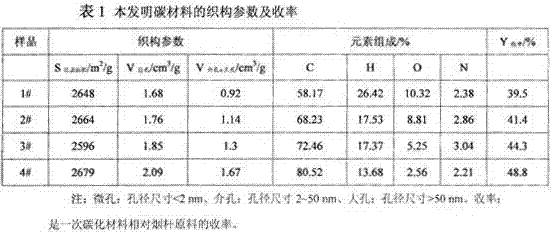

Examples

Embodiment 1

[0025] Put the tobacco rod raw material in an oven at 60°C and dry until the moisture content is below 5%, crush it to 20-40 mesh, weigh 10 g of the sample, and mix it with methanol aqueous solution (methanol concentration 5%wt) according to the solid-liquid volume ratio of 1:15 ) were mixed and transferred to a ball mill jar, 1.0 g of HY molecular sieve (10% of the weight of the tobacco rod) was added and mixed at room temperature for 5 h at a ball mill speed of 300 rpm to obtain a uniform feed liquid. The feed liquid and the agate beads were separated and transferred to a high-pressure reactor, and reacted at 100 °C and 5 MPa for 24 h under a nitrogen atmosphere. After the reaction liquid was cooled to room temperature, it was filtered, and the solid and liquid were separated to obtain the filter residue and filtrate, which were set aside. 1) After the filter residue was washed and dried with water, 50 mg of mixed metal salts (25 mg of cobalt nitrate and 25 mg of lanthanum n...

Embodiment 2

[0027] Put the tobacco rod raw material in an oven at 80°C and dry until the moisture content is below 5%, crush it to 60-90 mesh, weigh 10 g of the sample, and mix it with ethanol aqueous solution (ethanol concentration 8%wt) according to the solid-liquid volume ratio of 1:10 Mix and transfer to a ball mill jar, add 2.0 g of HZSM-5 molecular sieve (20% of the weight of the tobacco rod) and mix at room temperature for 4 h at a ball mill speed of 400 rpm to obtain a uniform feed liquid. The feed liquid and the agate beads were separated and transferred to a high-pressure reactor, and reacted at 120 °C and 10 MPa for 12 h under a nitrogen atmosphere. After the reaction liquid was cooled to room temperature, it was filtered, and the solid and liquid were separated to obtain the filtrate and filter residue, which were set aside. 1) After the filter residue was washed and dried, 0.5 g of mixed metal salts (cobalt nitrate and cerium sulfate, 0.48 g and 0.02 g, respectively) were loa...

Embodiment 3

[0029]Place the raw material of the tobacco stem in an oven at 100°C and dry until the moisture content is below 5%, crush it to 100-120 mesh, weigh 10 g of the sample, and mix it with propanol aqueous solution (propanol concentration 10% according to the solid-liquid volume ratio 1:5) wt) were mixed and transferred to a ball mill, adding SO 3 0.5 g of H-MCM-41 mesoporous material (5% of the weight of the tobacco rod) was mixed at room temperature for 2 h at a ball milling speed of 200 rpm to obtain a uniform material liquid. The feed liquid was separated from the agate beads, and then transferred to a high-pressure reactor, and reacted at 150° C. and 15 MPa for 8 hours under a nitrogen atmosphere. After the reaction liquid was cooled to room temperature, it was filtered, and the solid and liquid were separated to obtain the filtrate and filter residue, which were set aside. 1) After the filter residue was washed and dried, 0.1 g of mixed metal salts (cobalt nitrate and niobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com