Production of nano-catalyst

A nano-catalyst and mesoporous material technology, applied in the field of nano-catalyst preparation, can solve the problems of high cost, easy to raise dust, difficult to process, hazards, etc., to overcome easy to raise dust, difficult to process, large specific surface, and easy to be inhaled to human body damage Healthy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

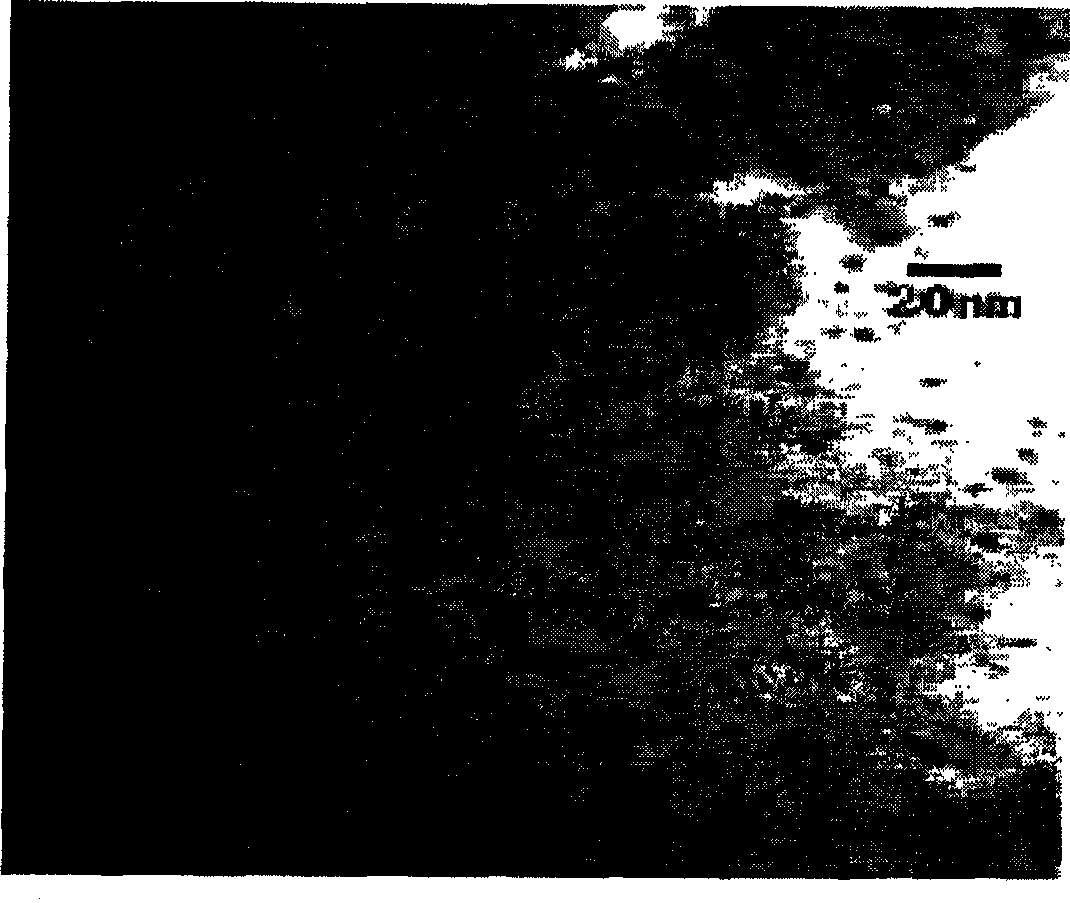

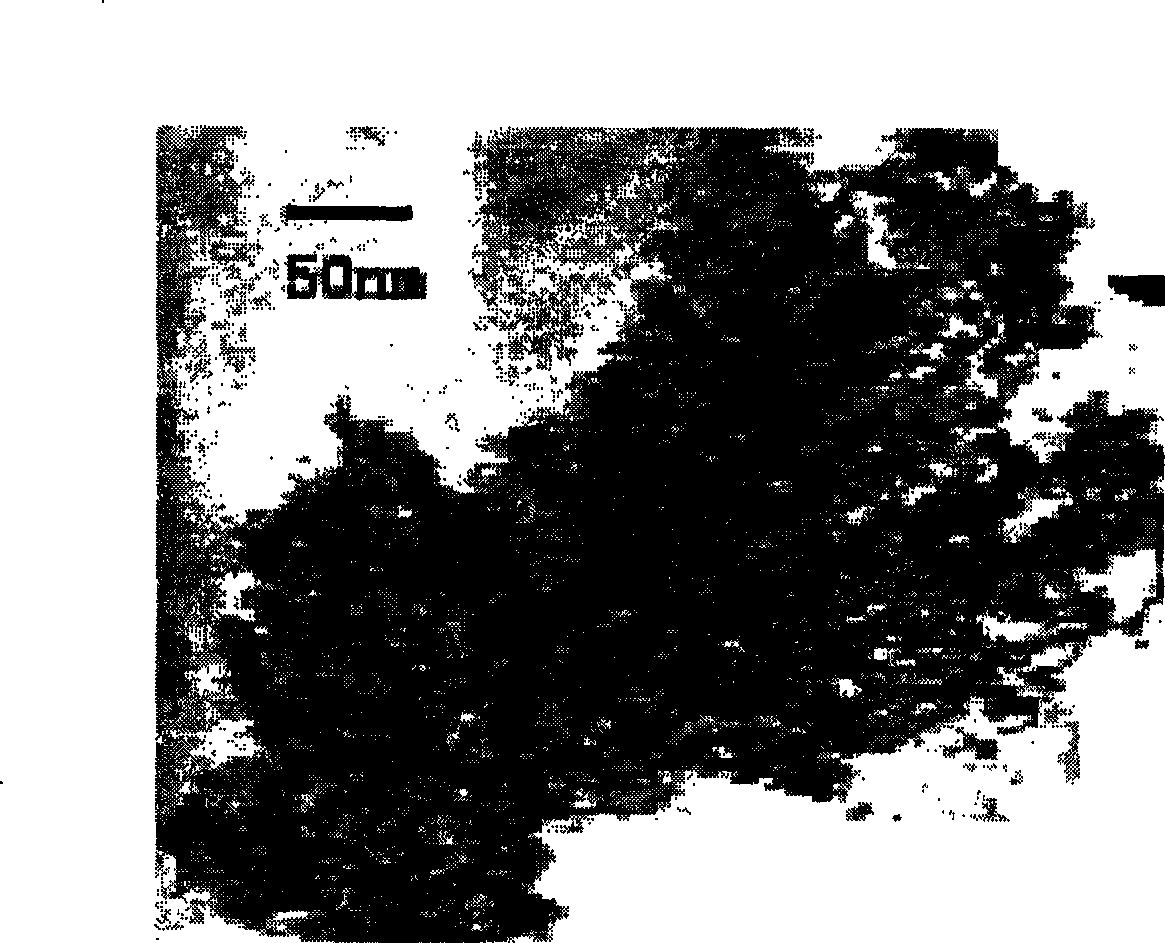

Image

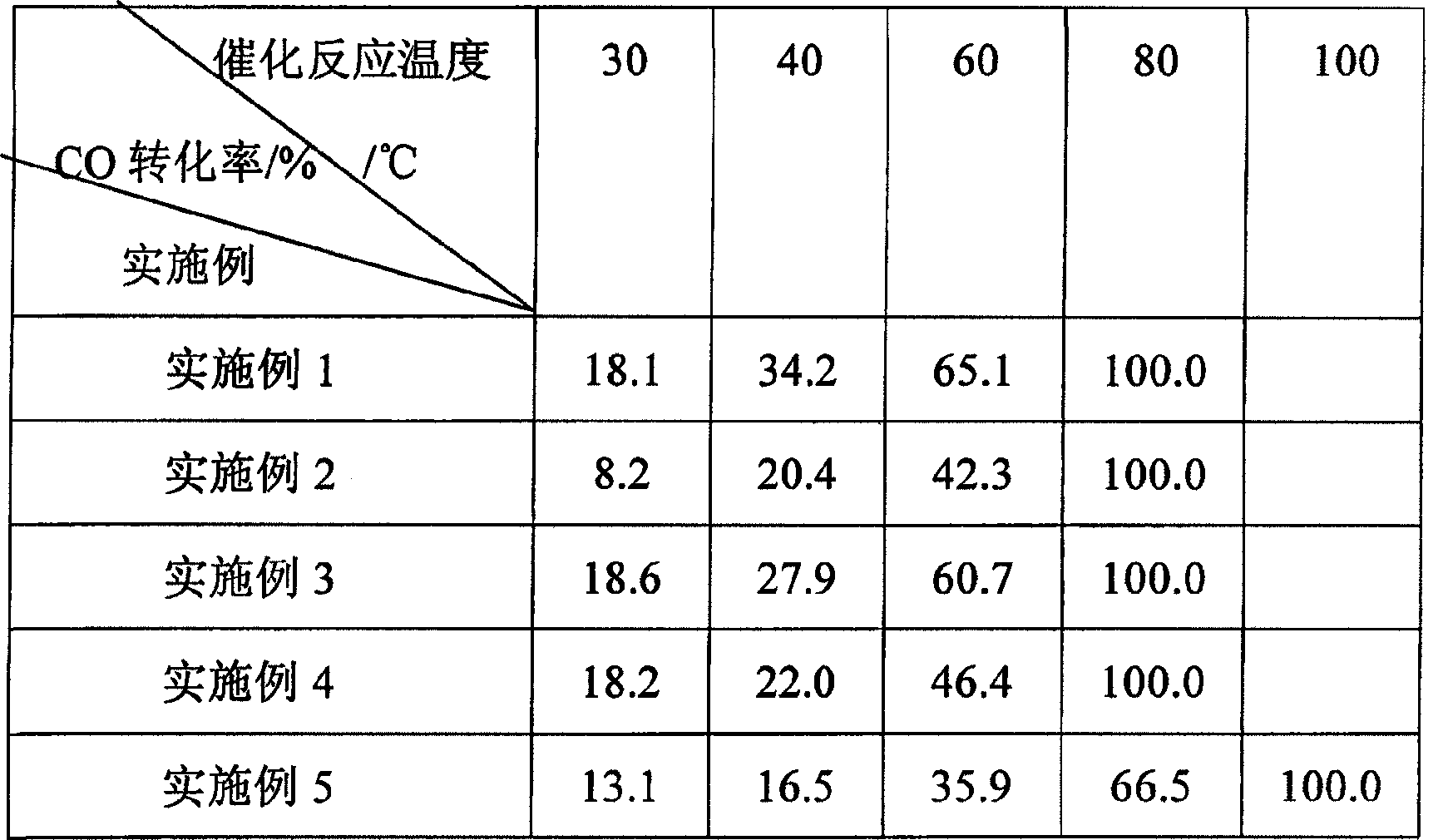

Examples

Embodiment 1

[0021] Embodiment 1: in reaction tank, add CuSO 4 .H 2 O 80mol, MnSO 4 .H 2 O 160mol and 500 kg of deionized water, heated while stirring, heated to 80°C, added 42 kg of 40-80 mesh activated carbon, kept stirring for 1 hour, slowly added 90L NaOH solution (w / w, 25%) dropwise, and continued to stir 10min, filter while hot, wash with hot deionized water until neutral, dry the resulting solid at 110°C to constant weight, then calcinate the solid at 200°C for 3h, sieve after cooling to get 40-80 mesh particles, then .

Embodiment 2

[0022] Embodiment 2: except adding CuSO 4 .H 2 O 80mol, MnSO 4 .H 2 Except O 80mol, all the other are identical with embodiment 1.

Embodiment 3

[0023] Embodiment 3: except adding CuSO 4 .H 2 O 80mol, MnSO 4 .H 2 Except O 240mol, all the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com