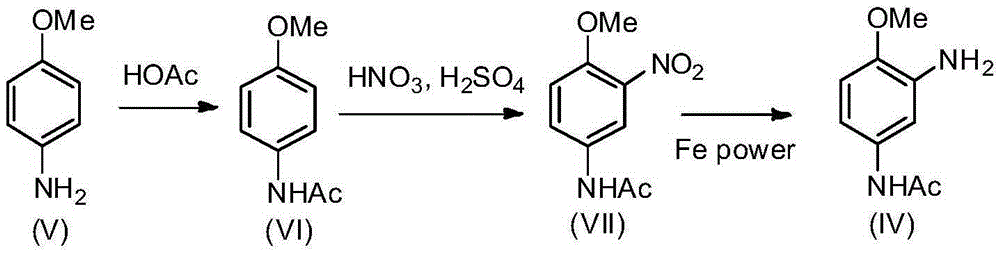

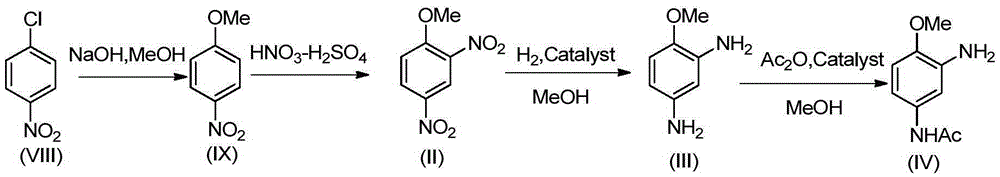

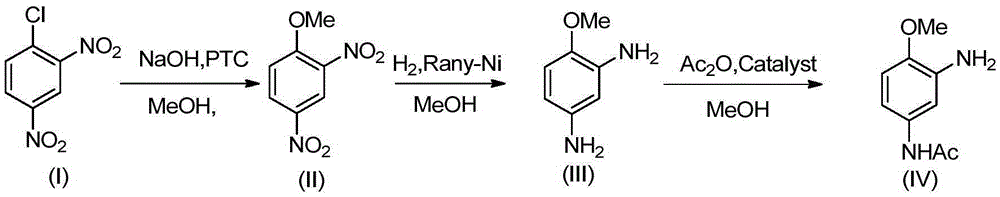

2-amino-4-acetamino anisole synthesis process

A technology of acetamidoanisole and diaminoanisole, which is applied in the field of preparation of organic compounds, can solve the problems of unstable yield and quality of target compounds, unsuitable for industrial production, a large amount of waste solids and waste liquids, etc. The effect of reducing the probability of by-product formation, reducing the dosage, and high industrial safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Weigh 1000g of 2,4-dinitrochlorobenzene (I), 1500g of methanol and 25g of PEG4000 into a four-neck flask, raise the temperature to 60°C, and stir; add 198g of sodium hydroxide and sodium hydroxide in batches within 2.5 to 3.0 hours After adding, keep warm, and the reaction ends. Methanol was recovered by distillation and washed with water to obtain 950.8 g (99%) of 2,4-dinitroanisole (II), with a yield of 96.9%.

[0052] The NMR data of 2,4-dinitroanisole (II) are as follows: 1 HNMR (500MHz, CDCl 3 ): δ8.83(d,1H), 8.4~8.5(dd,1H), 8.72(d,1H), 3.78(s,3H).

Embodiment 2

[0054] Put 950.8g (99%) 2,4-dinitroanisole (II), 3803.2g methanol and 0.95g Raney-Ni catalyst into a four-necked flask, the system pH=8, the temperature rose to 70°C, and the Into 1.0MPa hydrogen, the reaction is complete. The catalyst Raney-Ni was recovered by filtration. The HPLC purity of the active ingredient 2,4-diaminoanisole (III) in the mother liquor was 99.3%, and the conversion rate was 100%. The mother liquor was directly used for the acylation reaction without treatment.

[0055] Add 189.6g of ammonium bicarbonate to the above mother liquor, cool to -5°C, add 489.7g of acetic anhydride, after the addition is complete, raise the temperature to 5°C and keep warm until the reaction is complete. Distill 3042g of methanol, add water to the residue, cool and crystallize, and suction filter to obtain 770.2g (HPLC purity 99.5%) 2-amino-4-acetamidoanisole (IV), 2,4-diacetamidophenyl The amount of methyl ether generated is below 1% (measured by HPLC), and the total yield of...

Embodiment 3

[0058] Weigh 1,000g of 2,4-dinitrochlorobenzene (I), 2,500g of methanol, and 15g of benzyltriethylammonium chloride into a four-neck flask, raise the temperature to 70°C, and stir; within 2.5 to 3.0 hours, batch Add 196g of sodium hydroxide, add sodium hydroxide, keep warm, and the reaction ends. Methanol was recovered by distillation and washed with water to obtain 928.8 g (HPLC purity 99.2%) of 2,4-dinitroanisole (II), with a yield of 94.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com