Catalyst and aromatic amino compound preparation method

A catalyst and compound technology, applied in the field of preparation of catalysts and aromatic amino compounds, can solve the problems of reduced yield of aniline, cumbersome processing, etc., and achieve the reduction of low boiler content, reduction of by-product content, high catalytic activity and selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

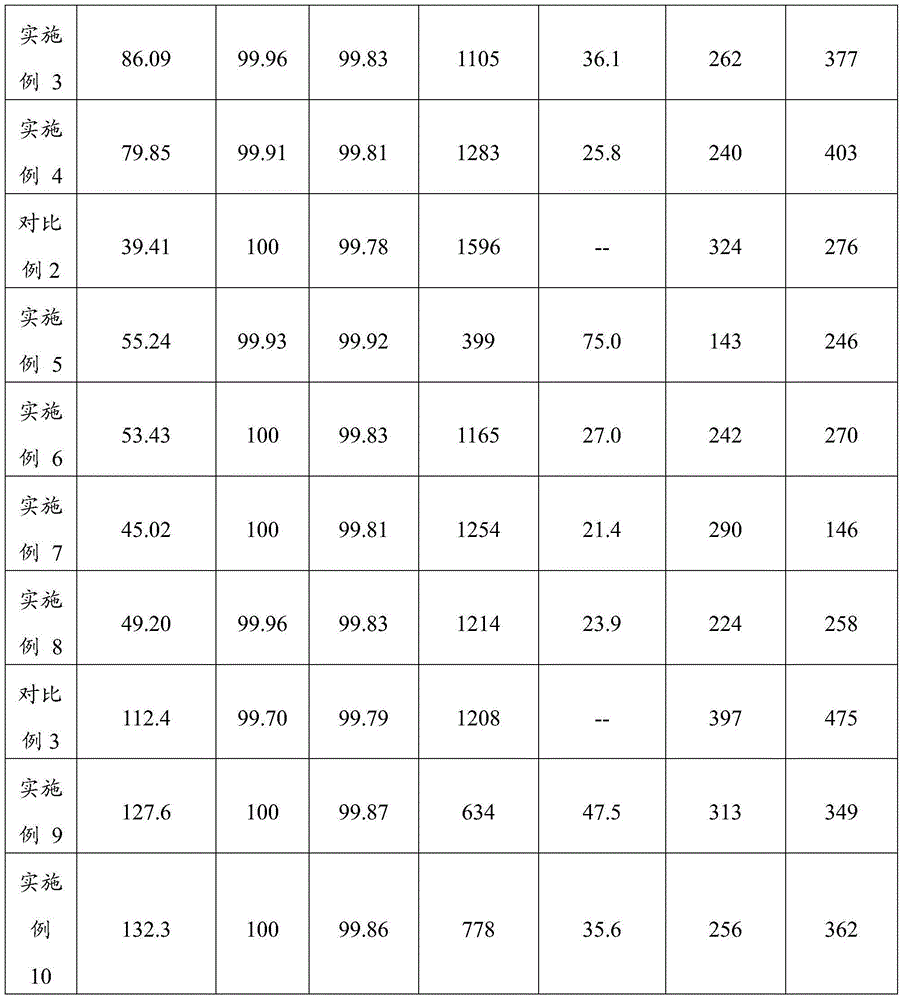

Examples

preparation example Construction

[0025]The present invention does not have special limitation to the preparation method of described catalyst, the method well-known to those skilled in the art gets final product, can be prepared according to the following method:

[0026] The carrier is uniformly dispersed in an alkaline aqueous solution, mixed with a solution of a compound containing a main precious metal element, a compound containing a secondary precious metal element, a compound containing a main non-precious metal element and a compound containing a secondary non-precious metal element, and then reacted with After it is reduced by the reducing agent, the catalyst can be obtained.

[0027] Firstly, the carrier is uniformly dispersed in an alkaline aqueous solution, and the alkaline aqueous solution may be sodium carbonate solution, sodium bicarbonate solution or sodium hydroxide solution; after the carrier is dispersed therein, a carrier suspension is formed. The carrier suspension is mixed with the solut...

Embodiment 1

[0048] Example 1Pd-Pt-Fe-Co / AC

[0049]8.90g activated carbon (AC) is dispersed in the sodium hydroxide aqueous solution of 180mL1mol / L, to wherein adding the hydrochloric acid solution containing 0.79g palladium chloride, 0.14g hexachloroplatinic acid and 2.42g iron chloride and 0.43g cobalt chloride 16.46g of 37% formaldehyde solution was added to the obtained mixed solution, reacted at 90°C for 4 hours, and the obtained product was filtered and dried to obtain a Pd-Pt-Fe-Co / AC catalyst, wherein, The loading amount of Pd was 4.5 wt%, that of Pt was 0.54 wt%, that of Fe was 5 wt%, and that of Co was 1 wt%.

Embodiment 2

[0050] Embodiment 2Pd-Pt-Fe-Ni / AC

[0051] 8.90g activated carbon (AC) is dispersed in the sodium hydroxide aqueous solution of 180mL1mol / L, to wherein adding the hydrochloric acid solution containing 0.79g palladium chloride, 0.14g hexachloroplatinic acid and 2.42g ferric chloride and 0.41g nickel chloride 16.39g of 37% formaldehyde solution was added to the obtained mixed solution, reacted at 90°C for 4 hours, and the obtained product was filtered and dried to obtain a Pd-Pt-Fe-Ni / AC catalyst, wherein, The loading amount of Pd was 4.5 wt%, that of Pt was 0.54 wt%, that of Fe was 5 wt%, and that of Ni was 1 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com