Preparation method and application of tungsten oxide hydrate single-particle Raman substrate

A tungsten oxide hydrate, Raman substrate technology, applied in tungsten oxide/tungsten hydroxide, Raman scattering, material excitation analysis, etc., can solve the problems of high cost, unfavorable industrial promotion, restrict development, etc., and achieve accurate detection results , Eliminate interference factors, the effect of uniform and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

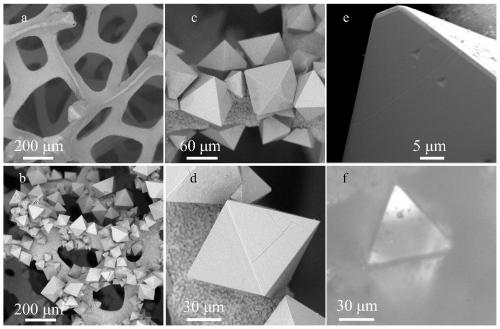

[0031] A method for preparing a tungsten oxide hydrate single particle Raman substrate, the specific steps are as follows:

[0032] (1) Cut the nickel foam into a square of 0.5cm*1cm*1cm, wash the nickel foam square with 1mol / L hydrochloric acid solution for 10-20 minutes, and remove the oil stain on the surface; then wash it repeatedly with ultrapure water and ethanol , Take out the nickel foam and place it on a watch glass, and fully dry it in a vacuum oven at 80°C.

[0033] (2) Add 2mmol of ammonium tungstate pentahydrate, 2mmol of hexamethylenetetramine powder, and 30ml of ultrapure water into the polytetrafluoroethylene liner of a hydrothermal kettle with a volume of 50ml, and stir fully to make the above powder as much as possible Dispersed in ultrapure water without obvious precipitation;

[0034] (3) Throw in a plurality of pieces (4 pieces) of foamed nickel processed through step (1); insert the high-pressure hydrothermal kettle after sealing; place the high-pressure...

Embodiment 2

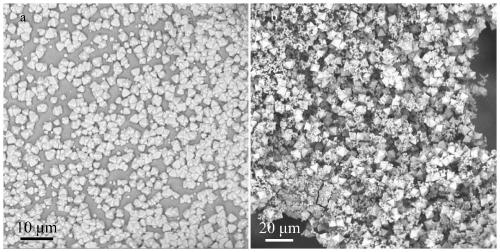

[0047] A method for preparing tungsten oxide hydrate single particles, the specific steps are as follows:

[0048](1) Cut the nickel foam into a square of 0.5cm*1cm*1cm, wash the nickel foam square with 1mol / L hydrochloric acid solution for 10-20 minutes, and remove the oil stain on the surface; then wash it repeatedly with ultrapure water and ethanol , Take out the nickel foam and place it on a watch glass, and fully dry it in a vacuum oven at 80°C.

[0049] (2) Add 2mmol ammonium tungstate pentahydrate, 2mmol hexamethylenetetramine powder, 1mmol urea powder, and 30ml ultrapure water into the polytetrafluoroethylene liner of a hydrothermal kettle with a volume of 50ml, fully stir, Make the above powder dispersed in ultrapure water without obvious precipitation;

[0050] (3) Throw in a plurality of pieces (4 pieces) of foamed nickel processed through step (1); insert the high-pressure hydrothermal kettle after sealing; place the high-pressure hydrothermal kettle as a whole in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com