Preparation method of porous nitrogen-rich carbon material

A technology of porous composite materials and carbon materials, which is applied in the field of preparation of porous nitrogen-rich carbon materials, can solve the problems of large randomness of nitrogen content and no literature reports, and achieves the improvement of utilization rate, contribution and yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

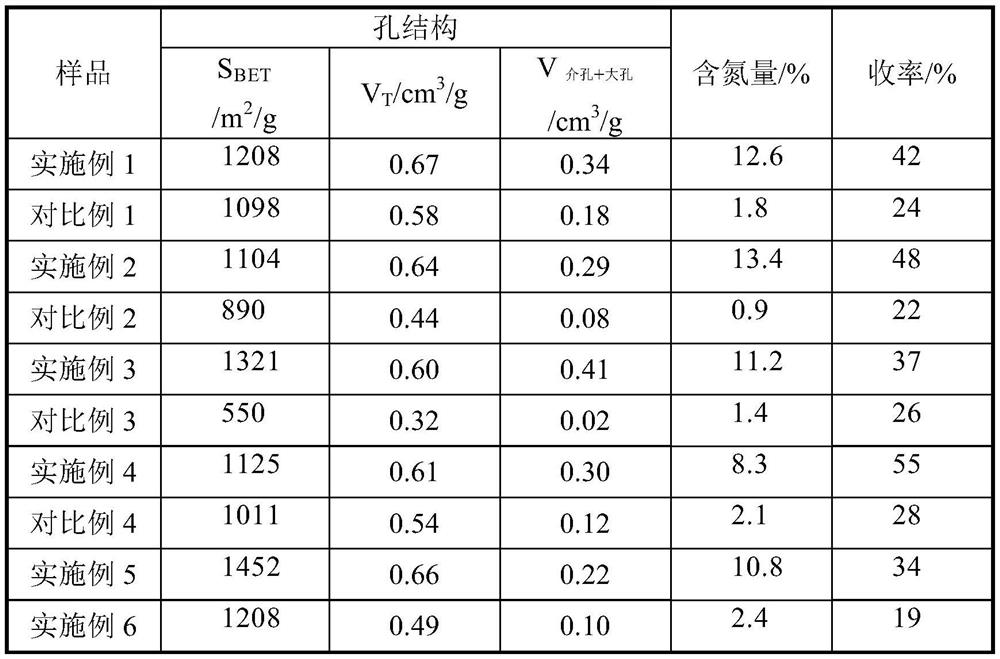

Embodiment 1

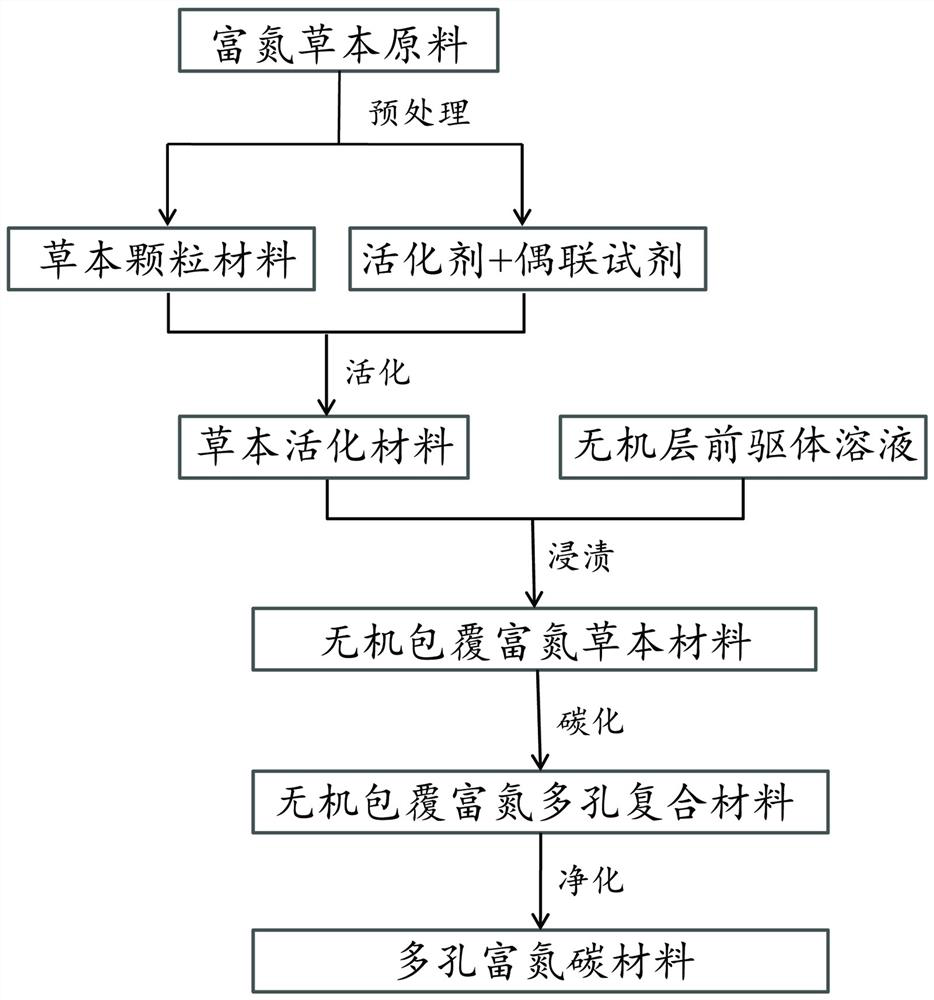

[0035] see figure 1 , the present embodiment provides a method for preparing a porous nitrogen-rich carbon material, comprising:

[0036] In the pretreatment, the tobacco leaves are washed and then dried in an oven at 50° C. to a moisture content of 5%, and pulverized to 20-40 mesh to obtain tobacco leaf particulate material, which is irregular spherical; an activation solution is provided, and the activation solution is composed of 5% ZnCl 2 and 0.5mol / L CuBr;

[0037] Activation: Weigh 10 g of the obtained tobacco leaf particulate material, place it in the activation solution after drying, immerse it in the activation solution, filter it, dry it in an oven at 50 °C, and adjust the ZnCl for several times. 2 and the total loading of CuBr to obtain tobacco leaf activation material, and the ZnCl in it 2 and the total loading of CuBr is 5% of the mass of the tobacco leaf particles;

[0038] Impregnated with 5% SiCl by volume 4 ether solution, the SiCl 4 Dip the tobacco leaf...

Embodiment 2

[0042] This embodiment provides a preparation method of a porous nitrogen-rich carbon material. The preparation method is basically the same as the preparation method provided in Embodiment 1. The main difference is that the raw material used in this embodiment is tobacco sheet, and the coupling reagent is CuOTf, other steps and process parameters are the same.

Embodiment 3

[0044] This embodiment provides a preparation method of a porous nitrogen-rich carbon material. The preparation method is basically the same as the preparation method provided in Embodiment 1. The main difference is that the raw material used in this embodiment is tobacco stalk, and the coupling reagent is FeCl 2 , other steps and process parameters are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com