Patents

Literature

42results about How to "Pollution generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Irradiation crosslinked chitosan/gelatin/polyvinyl alcohol hydrogel dressing as well as preparation method and application thereof

ActiveCN103480034ARapid hemostasisLow toxicityAbsorbent padsBandagesCrosslinked chitosanBiocompatibility Testing

The invention discloses an irradiation crosslinking chitosan / gelatin / polyvinyl alcohol hydrogel dressing as well as a preparation method and an application thereof. The preparation method comprises the steps that a chitosan, gelatin and polyvinyl alcohol solution is prepared by using ultrapure water serving as a solvent; the solution is stirred and mixed uniformly and then irradiated, and original hydrogel is obtained; the original hydrogel is put into the ultrapure water to be soaked; and the chitosan / gelatin / polyvinyl alcohol hydrogel dressing is prepared. The hydrogel dressing is extensive in raw material source, simple in preparation technology and stable in performance, and has the advantages of inflammation diminishing, wound pain relieving, scar reduction, wound healing promotion, wound seepage absorption, and excellent biocompatibility. The hydrogel dressing is easy to degrade after abandoned, and has a smaller influence on an environment. The hydrogel dressing can be applied to the fields of trauma hemostasis, inflammation diminishing, scald, postoperative wound healing and the like.

Owner:江西金思康药业有限公司

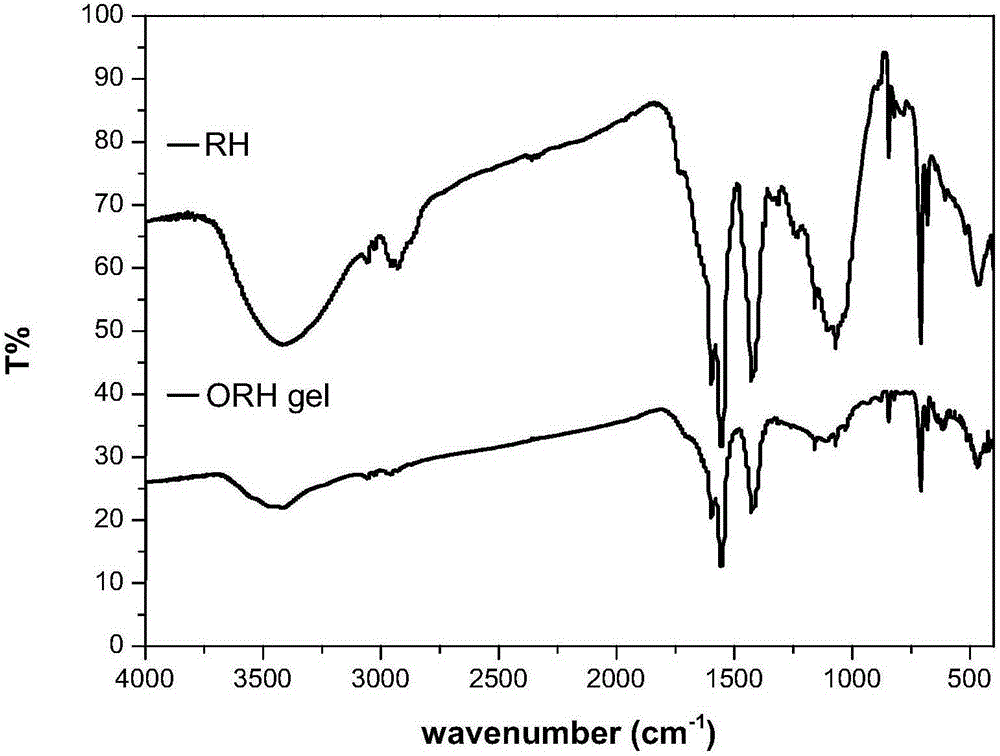

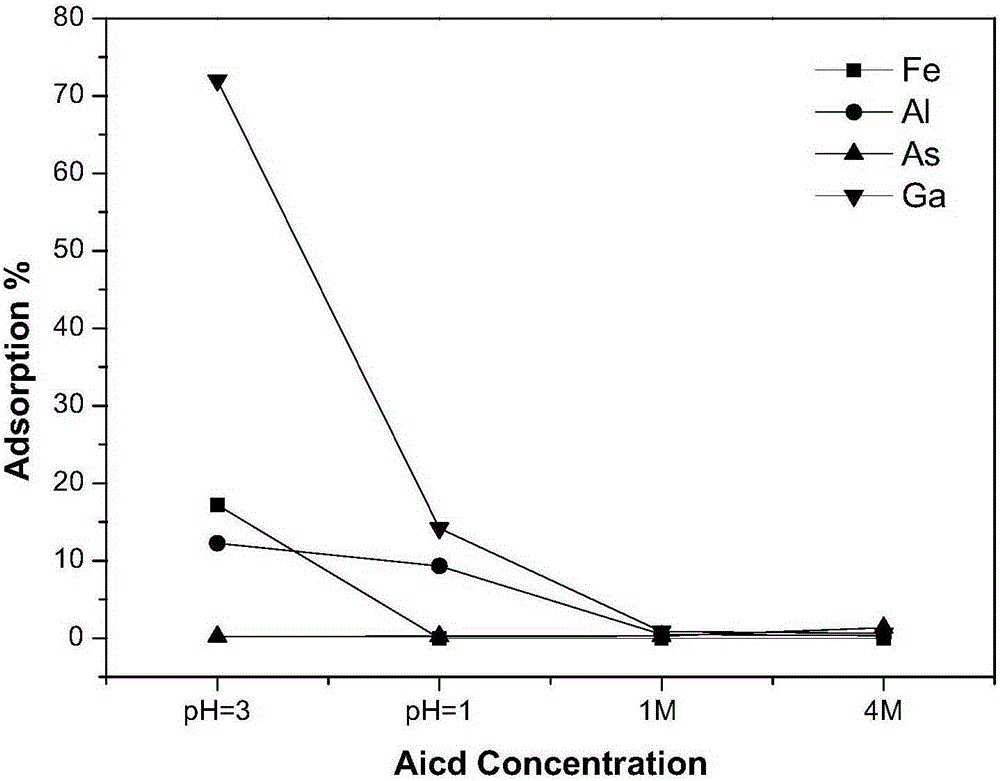

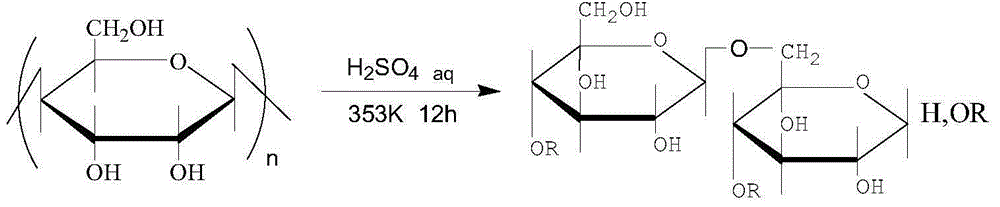

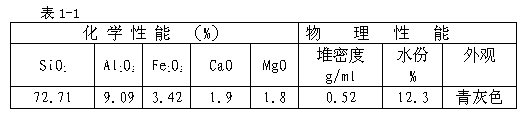

Rice husk cellulose adsorbent, and preparation method and application thereof

ActiveCN105170108AAbundant raw materialsIncrease profitIon-exchange process apparatusOther chemical processesChemistrySodium bicarbonate

The invention discloses a rice husk cellulose adsorbent, and a preparation method and the application of the rice husk cellulose adsorbent. The technical scheme adopted by the preparation method comprises the steps of taking rice husks; putting the rice husks in a constant-temperature drying box after washing the rice husks by deionized water; drying under 40 to 60 DEG C; taking out the rice husks and smashing the rice husks into powder; treating rice husk powder by slowly adding the rice husk powder in concentrated sulfuric acid; carrying out water-bath heating treatment; washing acidized rice husk powder by sodium bicarbonate; washing the powder to be neutral by the deionized water; filtering; carrying out constant-temperature drying under 40 to 70 DEG C; grinding the powder until the grain diameter is 100 to 150 mum. The rice husk cellulose adsorbent, and the preparation method and the application of the rice husk cellulose adsorbent, disclosed by the invention, have the advantages that a functionalized adsorbent is prepared by modifying the rice husks by sulfuric acid, gallium can be adsorbed from gallium-contained solution, low cost is realized, waste is changed into wealth, the adsorption amount is large, and the like.

Owner:LIAONING UNIVERSITY

Oil absorbent prepared from low grade diatomite and preparation method thereof

InactiveCN103252209AGood compatibilityGood dispersionFatty/oily/floating substances removal devicesOther chemical processesVolumetric Mass DensityPollution

The invention relates to a preparation method of an oil absorbent, in particular to a method for preparing the oil absorbent from low grade diatomite. The preparation method comprises the following 9 steps of: low grade diatomite raw material selection, crushing, acidification treatment, washing, drying, adding of the assistant (3%-5%) Na2Cl (industrial salt) and mixing, roasting at 750-850DEG C, breaking winnowing, and adding of the silane coupling agent KH-550 (gamma-aminopropyl triethoxysilane, Nanjing Union silicon Chemical Co., LTD. 5%-7%) to conduct modification treatment, thus obtaining the particle and powder diatomite oil absorbent. The oil absorbent has simple and easy preparation method, wide raw material sources and low cost, solves the current solid waste pollution problem of low grade diatomite, opens up a new way for low grade diatomite application, and realizes recycling of waste materials. The oil absorbent has good selectivity, strong absorptivity up to 500% of its own weight, rapid oil absorption speed, small oil absorbent stacking density, a melting point of 1450DEG C, and a high use temperature, and can float on the water surface before and after oil absorption, thus being convenient for recovery and post-treatment.

Owner:任象玉

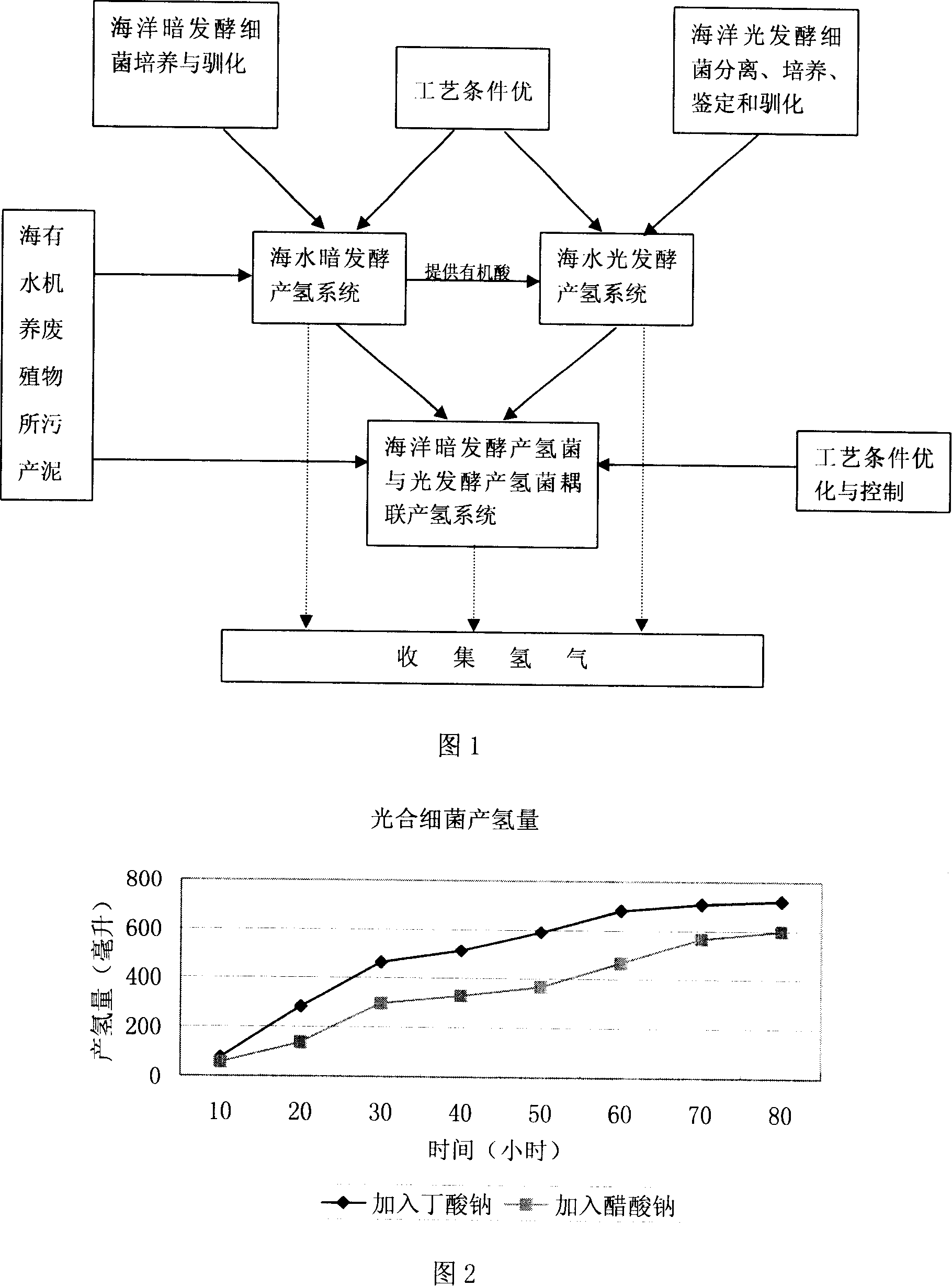

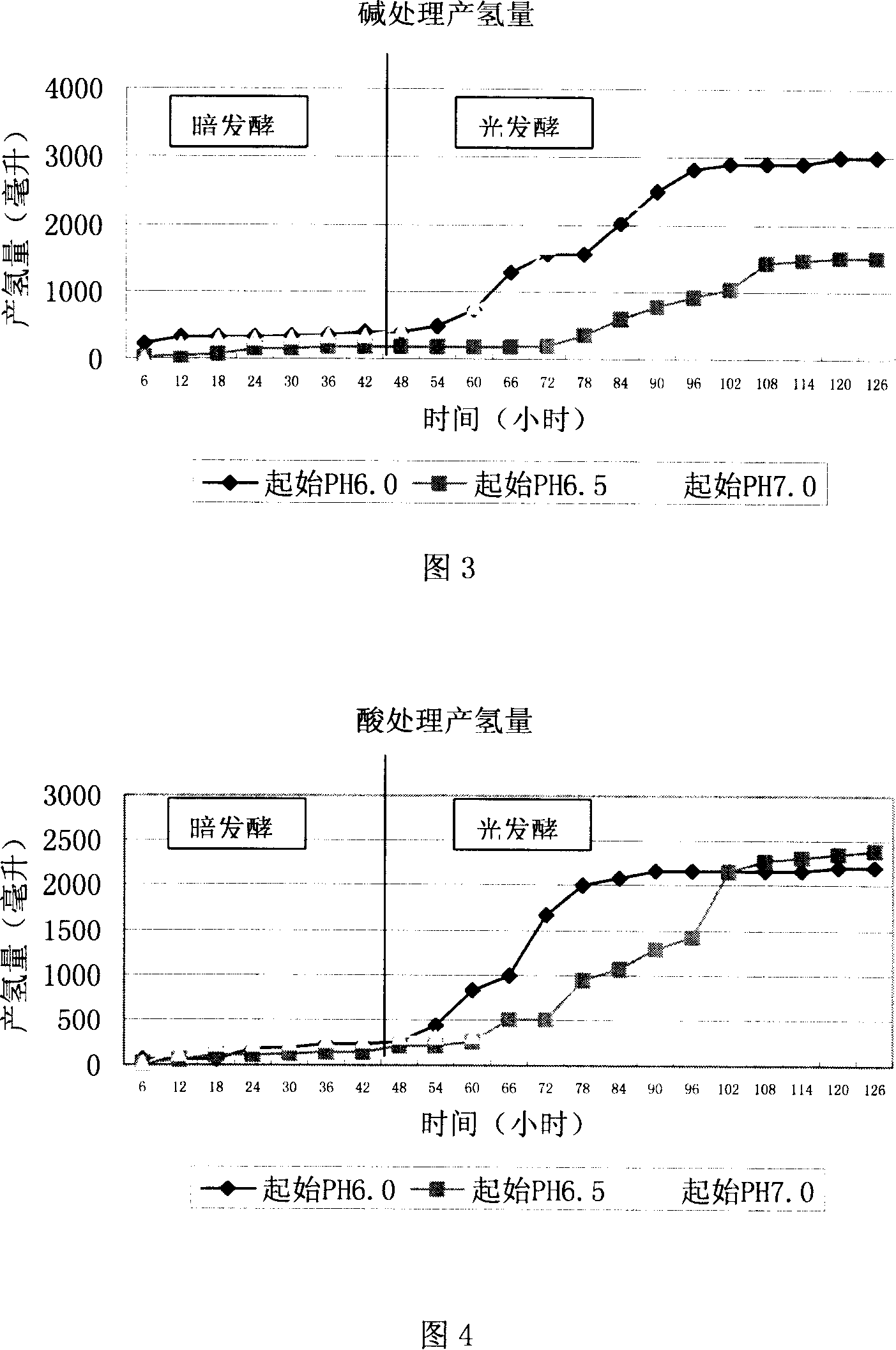

Method for culturing marine photosynthetic bacteria used for light-dark fermentation and coupling hydrogen production

InactiveCN101130786AHigh hydrogen production rateIncrease profitMicroorganism based processesFermentationSludgeSewage

The invention relates to a method for light-blind-fermentation-coupling-producing hydrogen by culturing sea photosynthetic bacterium with sludge and effluent of sea cultivation section, The method comprises the following steps: proceeding with culturing without light in order to produce hydrogen with sludge and effluent of sea cultivation as the culture medium; culturing with light; proceeding with coupling-production hydrogen by adding light fermenting bacteria in the culture medium in order to improve the releasing quantity of hydrogen and recover the production-hydrogen activity of the sea blind fermentation production-hydrogen bacterial. The method not only reduces the pollution of the environment, but also can release the present nervous energy crisis pressure.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Engine coolant

InactiveCN106916574AFormula stableGood corrosion inhibitionHeat-exchange elementsChemistryCarboxylate

The invention belongs to the technical field of chemical composition and particularly relates to an engine coolant. The engine coolant is prepared from the following substances in parts by weight: 45-55 parts of water, 25-35 parts of ethylene glycol, 5-8 parts of carboxylate, 5-12 parts of silicate stabilizer, 1-3 parts of nano oxide, 15-25 parts of propylene glycol, 1-5 parts of cesium formate, 3-5 parts of trimethylglycine, 5-8 parts of citric acid, 5-10 parts of ammonium citrate, 15-25 parts of molybdate, 8-12 parts of fatty acid, 0.5-0.8 part of antifoamer, 15-25 parts of potassium aminopropylsilicate, 5-10 parts of sodium octylsilicate, 5-8 parts of sodium benzoate, 3-5 parts of benzotriazole and 5-8 parts of methylbenzotriazole. The engine coolant provided by the invention is stable in formula, has long-acting bacteriostasis and anti-corrosion capability, is free of high-pollutional substances, cannot cause pollution to environments, has a very good corrosion inhibition action and can be used for effectively protecting engines.

Owner:青岛城轨交通装备科技有限公司

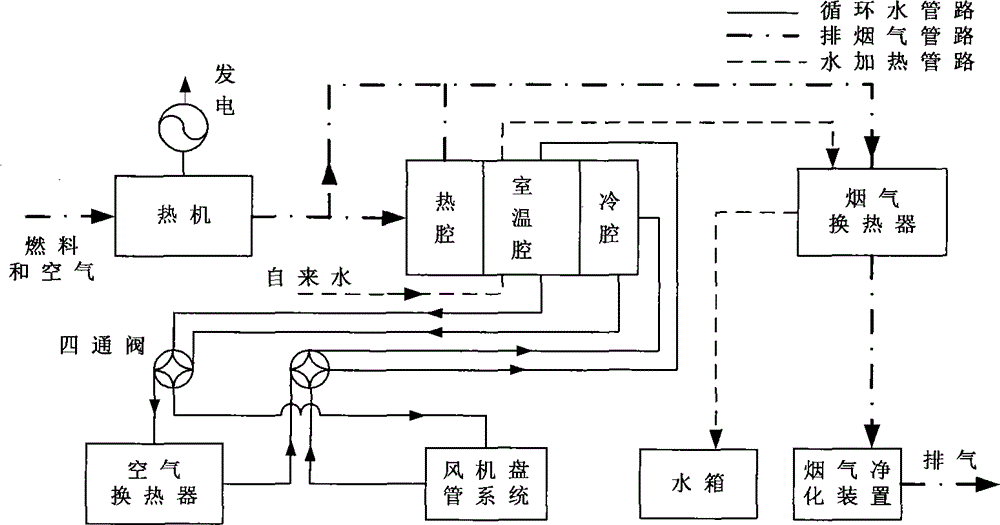

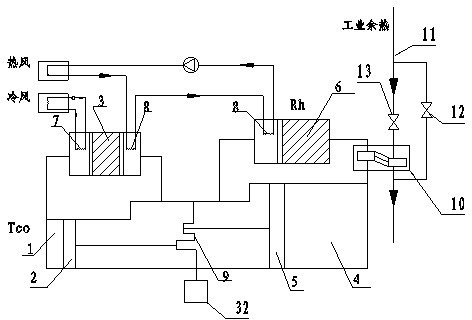

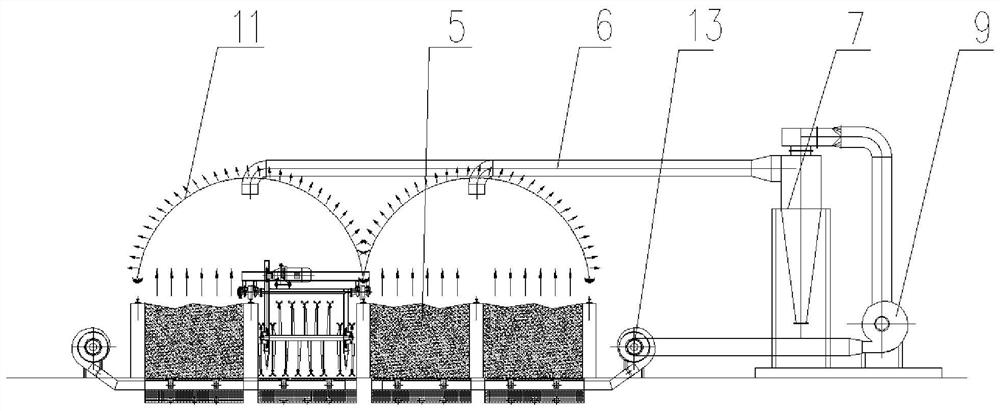

Distributive energy system of heat engine driven VM circulating heat pump

InactiveCN105783330ARealize cascade utilizationSave resourcesInternal combustion piston enginesGas turbine plantsEngineeringElectric power

The invention discloses a distributive energy system of a heat engine driven VM circulating heat pump, and belongs to the field of distributive energy systems. The system comprises such parts as a heat engine, a generator, a VM circulating heat pump, a smoke discharge heat exchanger and a fan coil. The heat engine consumes a fossil fuel to drive the generator to generate electricity; and discharged smoke drives the VM circulating heat pump for heating or cooling. In winter, the fan coil system is connected with a room-temperature cavity of the VM circulating heat pump for heating; and in summer, the fan coil pipe system is connected with a cold cavity of the VM circulating heat pump for cooling. Meanwhile, the system is additionally provided with a hot water supply system. The distributive energy system can supply electric power, cold or heat and living hot water, has such characteristics as energy conservation, environmental protection and flexible operation and adjustment modes, and is specifically suitable for small-volume users.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

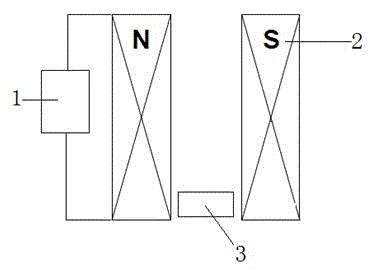

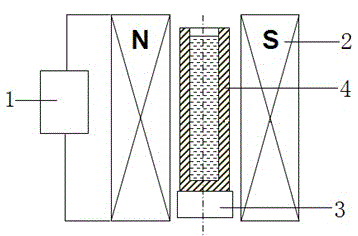

Method for controlling long-periodic structure to strengthen magnesium alloy matrix crystallization texture through direct current magnetic field

The invention relates to a method for controlling a long-periodic structure to strengthen magnesium alloy matrix crystallization texture through a direct current magnetic field, which comprises the following steps of: 1) melting the magnesium alloy; keeping the melted magnesium alloy warm under a certain degree of superheat; and then placing a preheated die in a direct current magnetic field solidification device, wherein the degree of superheat of the alloy is 10-150 DEG C, and the preheating temperature of the die is 100-700 DEG C; and 2) pouring the melted alloy into the die; switching on a direct current control device in the direct current magnetic filed solidification device after the completion of pouring so as to solidify the melted alloy completely under the effect of direct current magnetic field, wherein the strength of the direct current magnetic field is 0.1-1.0T; and placing the die between two magnetic poles of the direct current magnetic field solidification device, pouring the melted alloy into the die, and carrying out action on the melted alloy through the direct current magnetic field generated between two magnetic poles. The method can control the long-periodic structure to strengthen the magnesium alloy matrix crystallization texture effectively, thus having advantages of being free from contamination, simple in technology, convenient in operation, easy to control and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

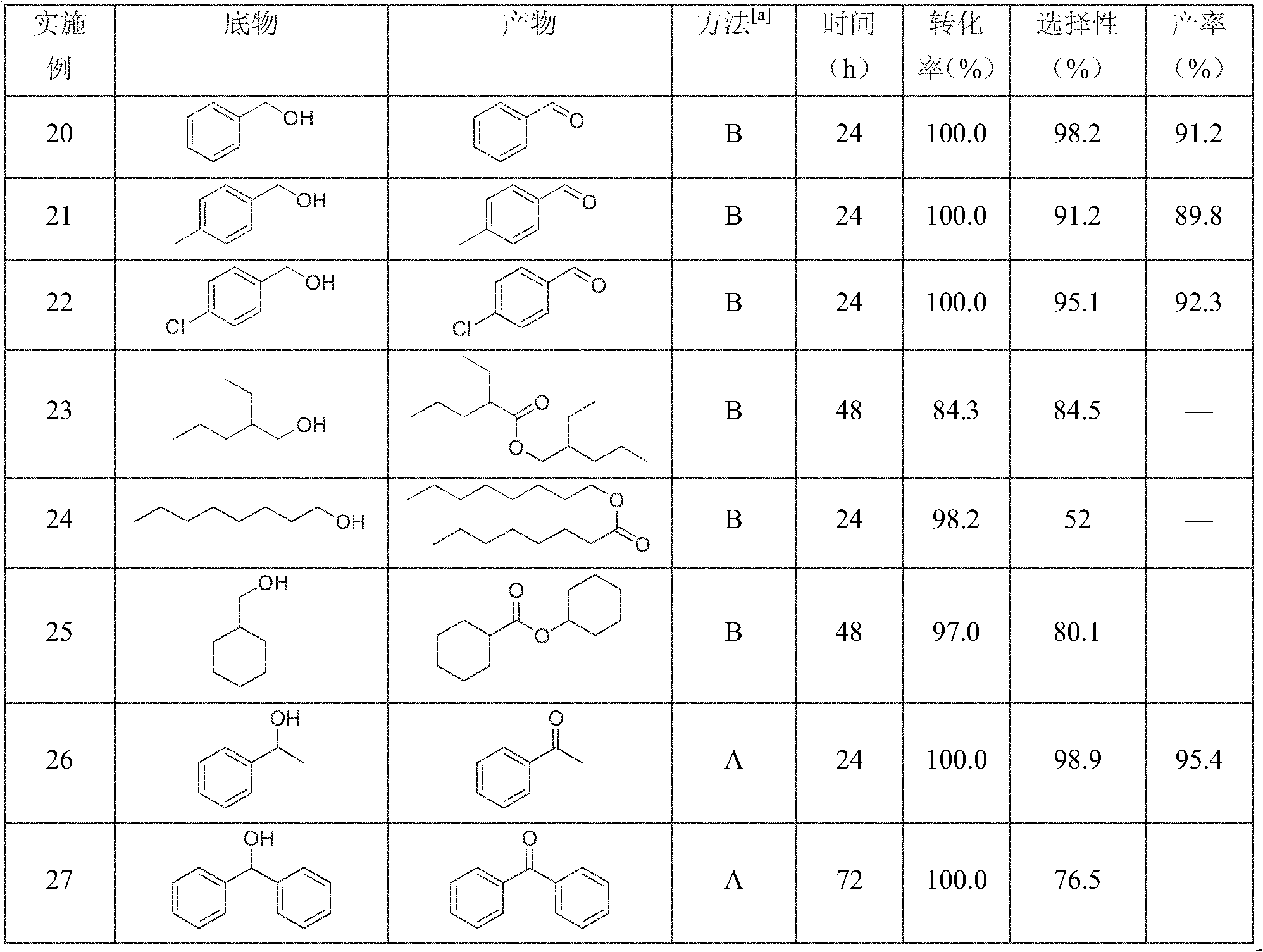

Method for preparing carbonyl compounds by alcohol catalytic oxidation through oxygen without transition metal

InactiveCN102653504AApplicable productionLow costOrganic compound preparationCarboxylic acid esters preparationCatalytic oxidationAlkyl nitrites

The invention relates to a method for preparing carbonyl compounds by alcohol catalytic oxidation through oxygen without transition metal, wherein N-bromosuccinimide (NBS) or other halogen compounds, and nitrite esters are used as catalysts, oxygen at a pressure of 0.1-0.8 MPa is used as an oxidant, the reaction is carried out at 0-100 DEG C for 1-72 hours, and a series of alcohol can be oxidized into carbonyl compounds with high selectivity. The invention has the characteristics of high yield, relatively mild reaction conditions, easy operation control, low cost, safety, environment-friendly process, no pollution, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

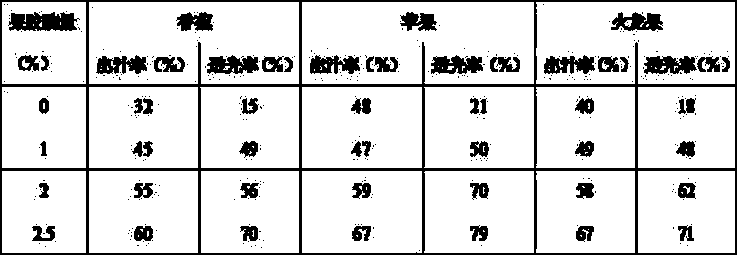

Pectinase and preparation method thereof

InactiveCN107699549AReduce secondary pollutionNo secondary pollutionMicroorganism based processesGlycosylasesAmmonium sulfateChemistry

The invention discloses pectinase and a preparation method thereof and belongs to the technical field of bio-fermentation engineering. The preparation method comprises the following steps: preparing banana peel pomace dry powder, activating strains, preparing seed liquid, carrying out solid fermentation culture, and preparing crude enzyme extracting liquid, wherein the step of activating the strains comprises that aspergillus niger is put into a czapek medium and culture is carried out for 100-120 hours at the temperature of 20-30 DEG C; and the solid fermentation culture comprises the steps of mixing the banana peel dry powder with wheat bran in proportion, adding deionized water, uniformly mixing, then adding ammonium sulfate, dipotassium phosphate and calcium chloride, stirring, charging, carrying out moist heat sterilization for 20-40 minutes at the temperature of 110-125 DEG C, inoculating spore suspension, and culturing for 60-72 hours. The preparation method disclosed by the invention solves the problem of utilization of a main byproduct in a banana deep processing process, preparation technology is simple, cost is low, pectinase activity is high, and juice yield and clarityof common fruit juice can be effectively improved.

Owner:GUANGXI AGRI VOCATIONAL COLLEGE

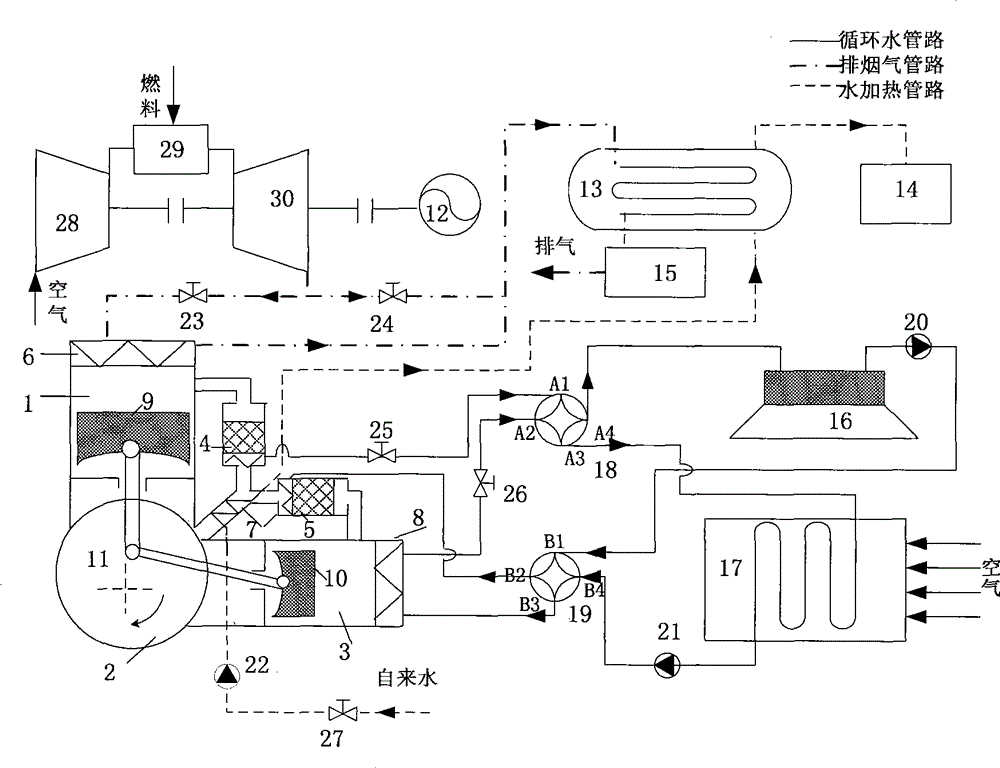

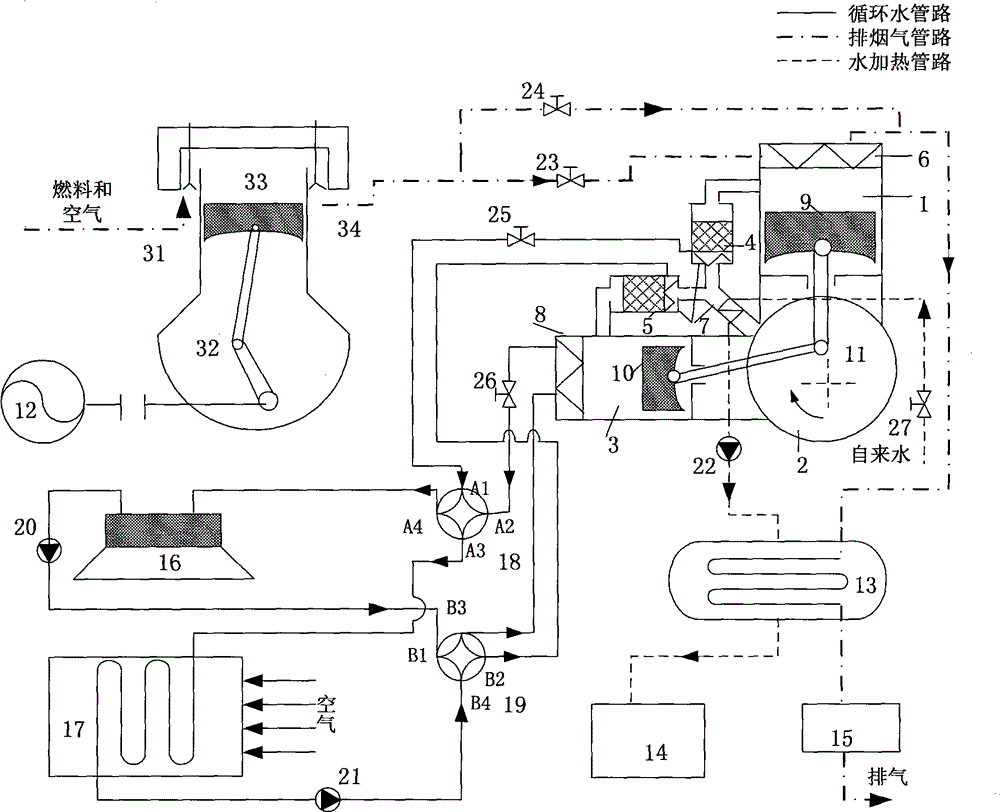

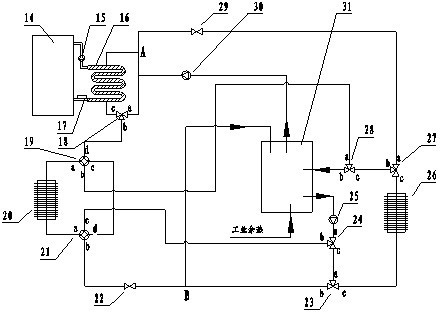

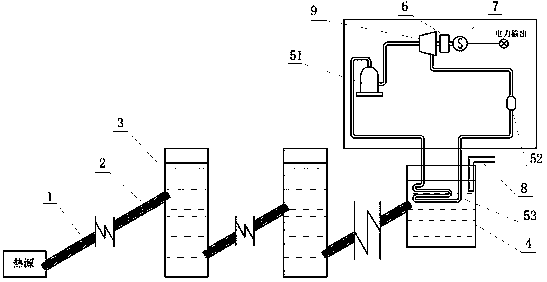

VM (Vuilleumier) cycle heat pump type air-conditioning water heater driven by industrial exhaust heat

InactiveCN102353177AIncrease profitNo shortageEnergy industryFluid circulation arrangementFour-way valveWater storage tank

The invention relates to a VM (Vuilleumier) cycle heat pump type air-conditioning water heater driven by industrial exhaust heat, which is used for solving the problems of refrigerating and heating by sufficiently utilizing industrial exhaust heat. The technical scheme of the invention is that: the VM cycle heat pump type air-conditioning water heater comprises a VM cycle heat pump device, an industrial exhaust heat utilization device, an indoor heat exchanger, an outdoor heat exchanger, a refrigerant-water double-pipe heat exchanger, a water storage tank and a cutoff valve, a three-way valve, a fourth-way valve and a connecting pipeline; a heat pipe type interchanger of the industrial exhaust utilization device is arranged between a hot cylinder and a heat regenerator of the VM cycle heat pump device; and the VM cycle heat pump device, the indoor heat exchanger, the outdoor heat exchanger, the refrigerant-water double-pipe heat exchanger, the water storage tank and the cutoff valve, the three-way valve, the four-way valve and the connecting pipeline constitute refrigerating and heating loops in different modes. According to the invention, an industrial exhaust heat recovery technology and a VM cycle heat pump technology are combined, and the purposes of refrigerating and heating by using the industrial exhaust heat as an energy to drive a VM cycle heat pump to work are achieved; and the VM cycle heat pump type air-conditioning water heater can widely make use of various industrial exhaust heat, thereby improving the energy source utilization rate.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A method of producing dimethyl succinate

InactiveCN106800510AAchieve recyclingExtend the life cycleOrganic compound preparationCarboxylic acid esters preparationDistillationFiltration

A method of producing dimethyl succinate is disclosed. The method includes steps of adding a catalyst, succinic acid and methanol into an esterification kettle provided with an internal reflux condenser, performing a reflux esterification reaction under a pressure ranging from atmospheric pressure to 0.20 MPa until the temperature in the kettle is stable to obtain a crude ester, allowing the crude ester to stand, cooling the crude ester, subjecting the crude ester to suction filtration, transferring a suction filtration product to a rectification column, recovering a methanol-water solution under atmospheric pressure by adopting a rectification process, removing water through distillation in vacuum, and performing vacuum rectification to obtain the dimethyl succinate. The catalyst is potassium bisulfate monohydrate. The method effectively achieves reuse of the catalyst and raw materials. The total yield of a finished product is not less than 97%. Energy consumption and material consumption are low. The service cycle of the catalyst is prolonged.

Owner:上海唯稳实业有限公司 +5

Pollution-free leather manufacturing technology

ActiveCN104962666APollution generationWill not polluteTanning treatmentPre-tanning chemical treatmentTime rangeWater volume

The invention discloses a pollution-free leather manufacturing technology. The pollution-free leather manufacturing technology includes the steps of leather finishing, leather soaking, preliminary tanning, secondary tanning, repeated secondary tanning, tanning finishing, dye-fixing agent adding, semi-finished product manufacturing, softening and finished product manufacturing. In the leather soaking step, the water volume for soaking naked leather accounts for 30% to 50% of the mass of the naked leather, and soaking time ranges from 20 min to 30 min. In addition, the ratios of solutions added to a drum are adjusted in proportion in the steps, and the rotation time of the drum is controlled. Thus, by the adoption of the pollution-free leather manufacturing technology, the use ratio of water to auxiliary materials is strictly controlled, all liquid is completely absorbed by leather, no sewage is drained, and no pollution is generated to the environment.

Owner:林善溪

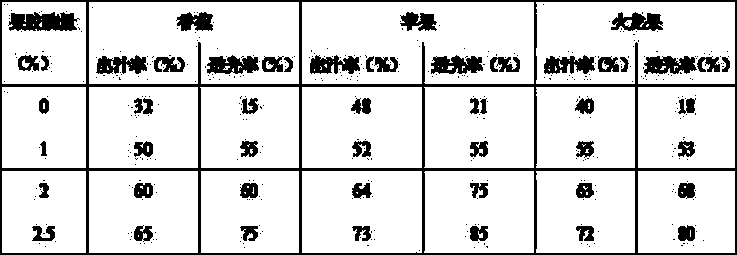

Sterilization method for fresh-cut vegetables and fruits in electromagnetic field

InactiveCN103798353AControl quantityControl temperature riseFruits/vegetable preservation by heatingWork periodWork cycle

The invention discloses a sterilization method for fresh-cut vegetables and fruits in an electromagnetic field. The sterilization method is characterized by comprising the following steps: 1), placing fresh-cut vegetables and fruits into a container, and placing the container in the electromagnetic field; 2) starting the electromagnetic field, heating the fresh-cut vegetables and fruits to 50 to 55 DEG C by adopting continuous microwaves firstly and then processing the fresh-cut vegetables and fruits by adopting pulse microwaves, wherein the power of the continuous microwaves is 700 to 1,000W, the processing times performed by the pulse microwaves are 10 to 90 times, the pulse microwaves are obtained by periodically cutting the continuous microwaves, the working period of the pulse microwaves is 2 to 5 seconds, the duration time of the microwaves in a period is 0.5 to 1.5 seconds, and the fresh-cut vegetables and fruits are the vegetables and fruits which are not sensitive to heat. By adopting the sterilization method, the number of bacteria in the fresh-cut vegetables and fruits and the temperature rise of the fresh-cut vegetables and fruits can be controlled effectively, and the sterilization method has the advantages of being free from pollution, simple, convenient to operate, easy to control and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

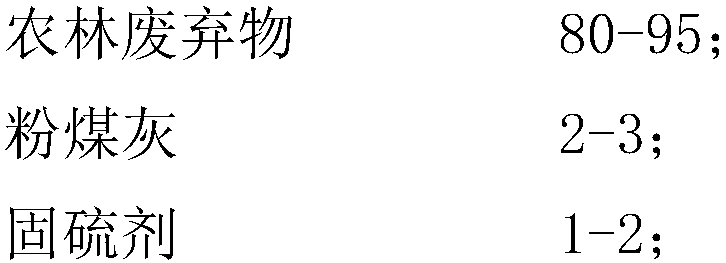

High-heat environment-friendly biomass and preparation method therefor

The invention discloses high-heat environment-friendly biomass and a preparation method therefor. The method comprises the steps: 1) carrying out primary crushing on wastes of agriculture and forestry; 2) feeding the primary-crushed wastes of agriculture and forestry to a finishing crusher through a conveying belt, wherein the diameter of the finishing-crushed wastes of agriculture and forestry isnot greater than 8mm; 3) feeding the finishing-crushed material to a material regulating and mixing bunker through a pumping machine, meanwhile, adding fly ash, a sulfur fixation agent, a combustionimprover, a surfactant and a metal catalyst into a mixer, and carrying out mixing, so as to obtain a mixture; 4) uniformly mixing the obtained mixture and crushed materials in the material regulatingand mixing bunker through a conveying device, so as to obtain a raw material for granulation, wherein the raw material for granulation has the wettability of 12% to 18%; and 5) feeding the raw material for granulation obtained in the step 4) to a press-granulating production machine through a pumping machine, and carrying out granulating, thereby obtaining the high-heat environment-friendly biomass. According to the high-heat environment-friendly biomass and the preparation method therefor, resources are saved, the energy consumption is lowered, and the production value is increased.

Owner:潍坊市绿中新能源科技有限公司

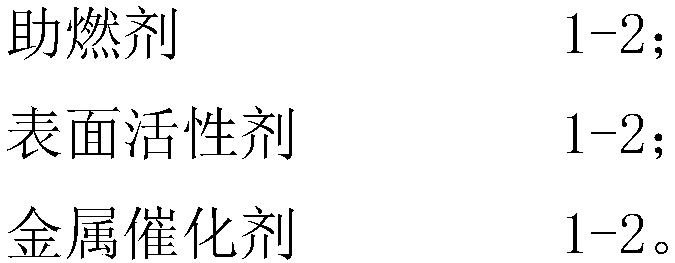

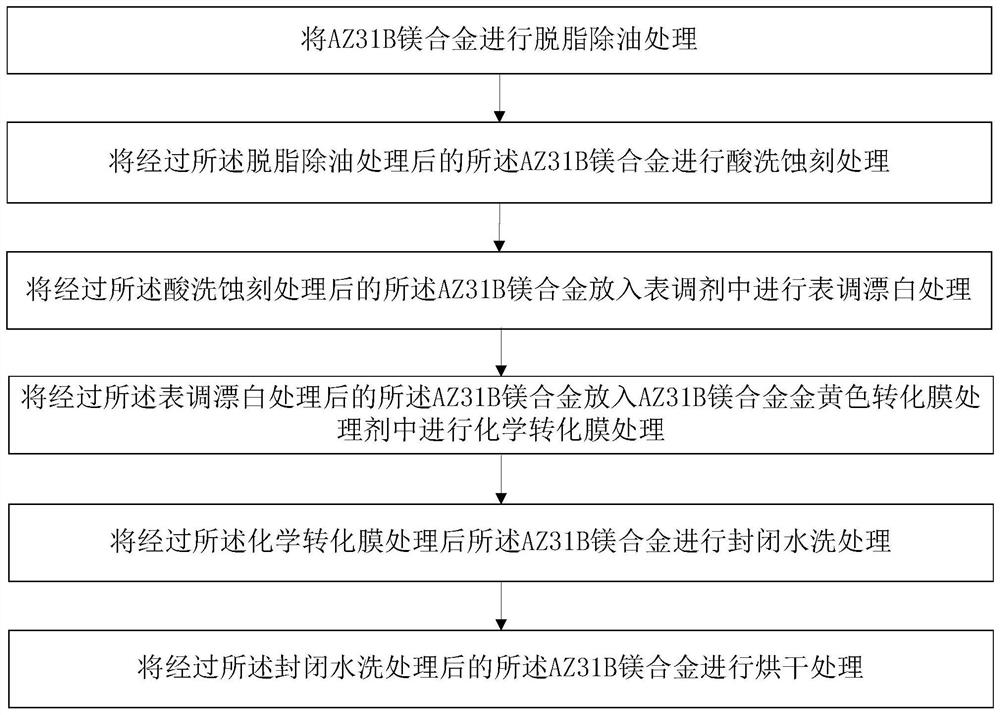

AZ31B magnesium alloy golden conversion film treatment agent and AZ31B magnesium alloy surface treatment method

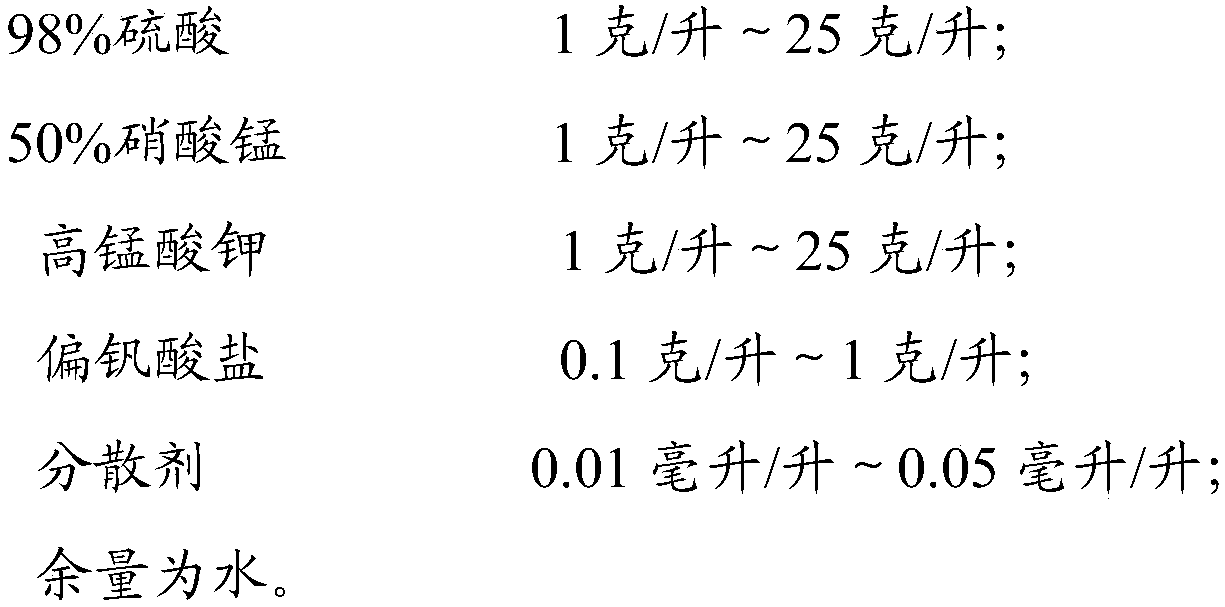

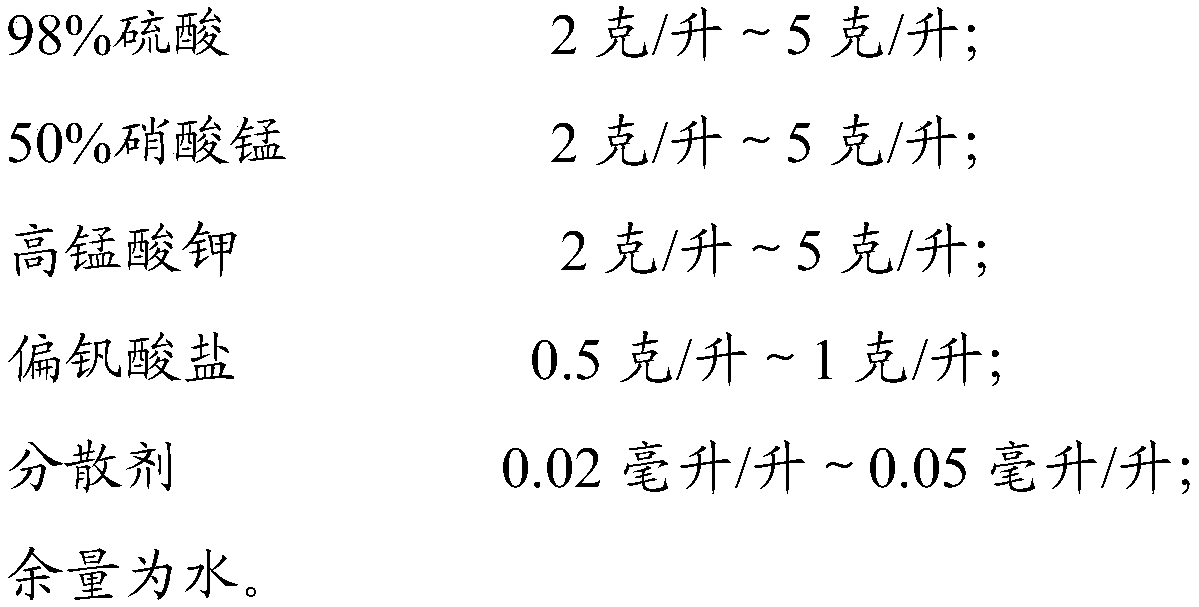

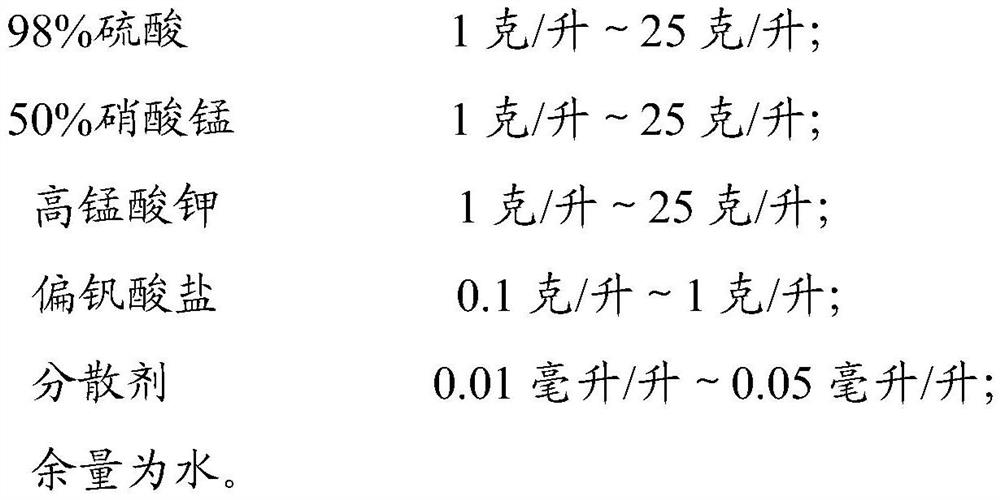

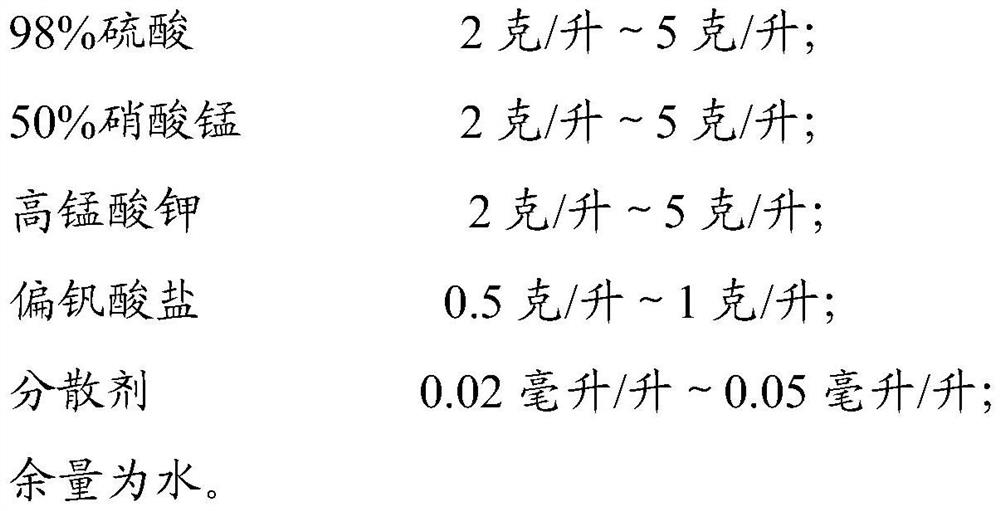

ActiveCN109536941AImprove corrosion resistanceImprove adhesionMetallic material coating processesNitrateManganese

The invention discloses an AZ31B magnesium alloy golden conversion film treatment agent and an AZ31B magnesium alloy surface treatment method. The AZ31B magnesium alloy golden conversion film treatment agent comprises components with the following concentrations: 1-25 g / l of 98% of sulfuric acid, 1-25 g / l of 50% of manganese nitrate, 1-25 g / l of potassium permanganate, 0.1-1 g / l of metavanadate, 0.01-0.05 ml / l of dispersing agent, and the balance of water. After the AZ31B magnesium alloy golden conversion film treatment agent is applied to the surface treatment of AZ31B magnesium alloys, golden conversion films can be formed on the surfaces of the AZ31B magnesium alloys, so that the corrosion resistance of the AZ31B magnesium alloys can be improved. The formed golden conversion films havethe advantages of good adhesion, good salt mist performance and good film forming uniformity. In addition, the AZ31B magnesium alloy golden conversion film treatment agent contains no phosphorus and chromium, so that the problem of environmental pollution caused by common use of phosphorus and chromium in traditional alloy treatment agents is prevented, no environmental pollution is generated, andthe environmental protection is better.

Owner:广东东明新材科技有限公司

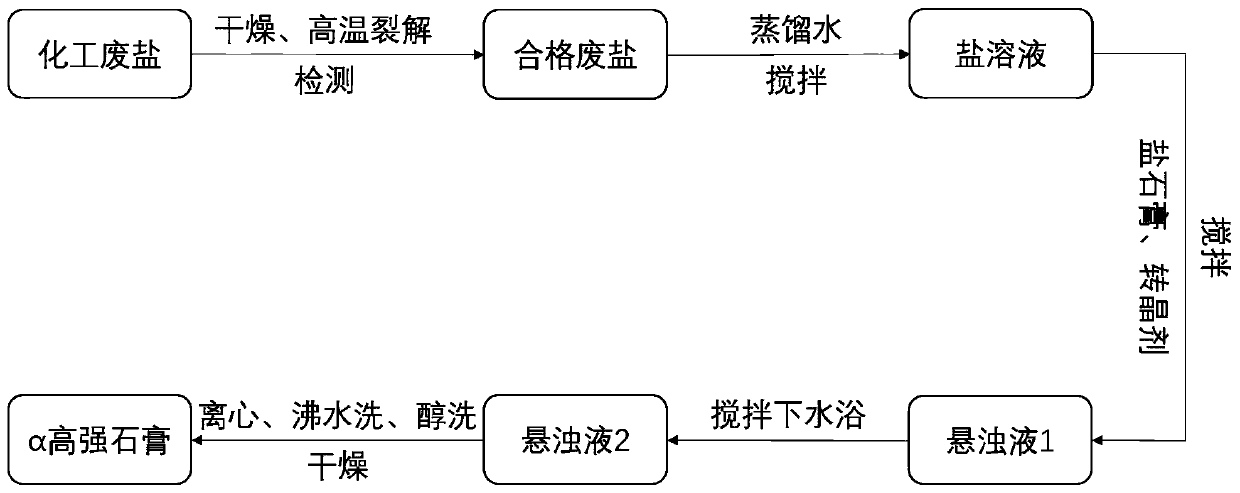

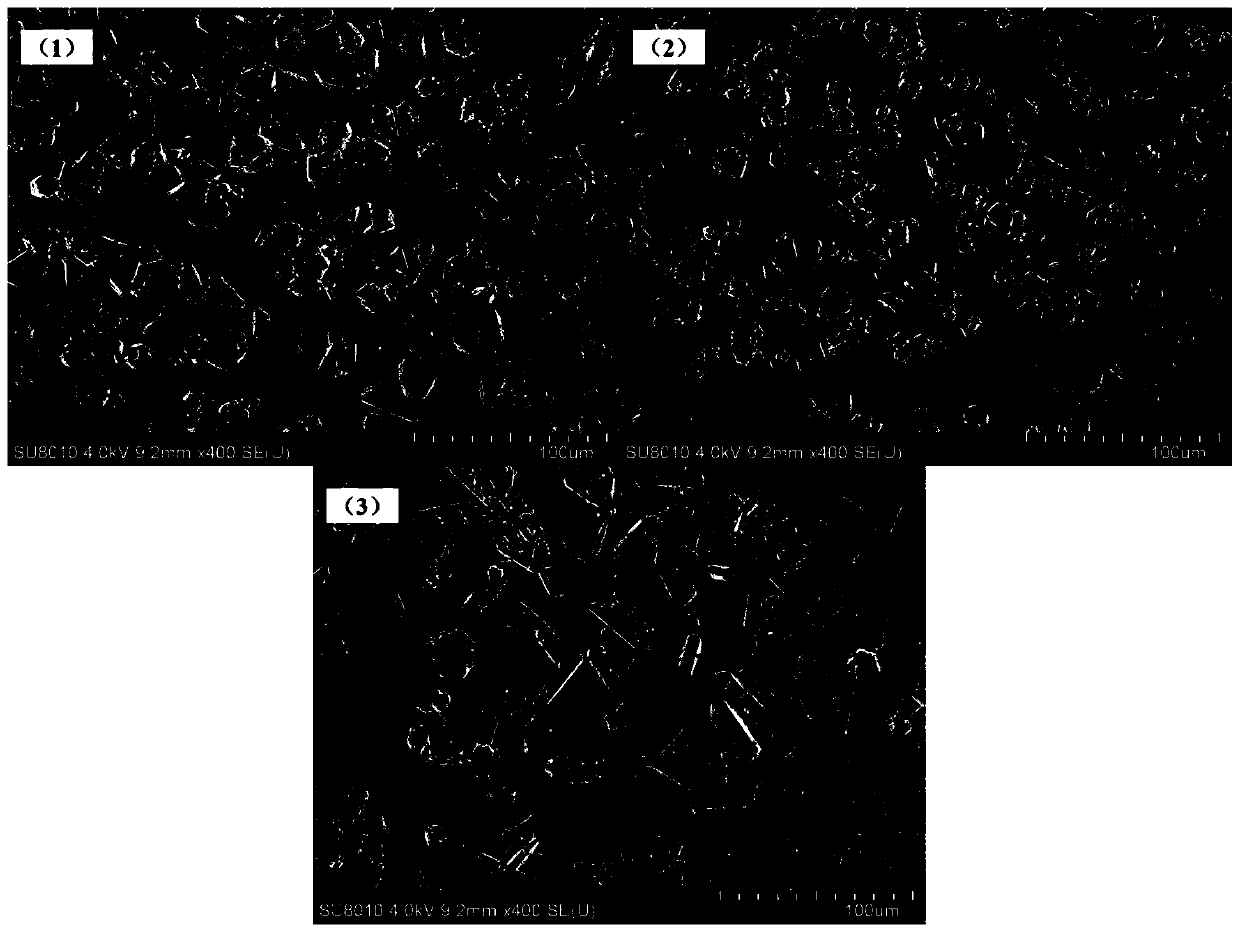

Method for preparing alpha high-strength gypsum through atmospheric pressure salt solution method by using chlor-alkali by-product salt gypsum and chemical waste salt

InactiveCN110589869ALarge choiceReduce riskCalcium/strontium/barium sulfatesEnvironmental chemistryWater of crystallization

The invention discloses a method for preparing alpha high-strength gypsum through an atmospheric pressure salt solution method by using a chlor-alkali by-product salt gypsum and a chemical waste salt.First, the chemical waste salt is dried to remove free water and part of crystallization water, and then sent to a high-temperature incineration apparatus for incineration or high-temperature cracking to remove organic harmful substances, and then the incinerated or high-temperature cracked chemical waste salt is mixed with distilled water in a conical flask to prepare a salt solution; then the chlor-alkali by-product salt gypsum powder and a crystal conversion agent is added into the salt solution, and a water bath reaction is carried out after stirring; and after the water bath reaction iscompleted, solid-liquid separation is performed quickly by a centrifuge and washing is performed with boiling water for several times, then absolute ethanol is added for washing to stop the reaction,then drying is performed in an oven at 60-100 DEG C for 1-5 h, and a final powder, namely the alpha high-strength gypsum powder, is obtained. The product preparation process is simple in operation, low in cost, and suitable for industrial mass production, and has obvious economic and environmental benefits.

Owner:HUBEI UNIV OF TECH

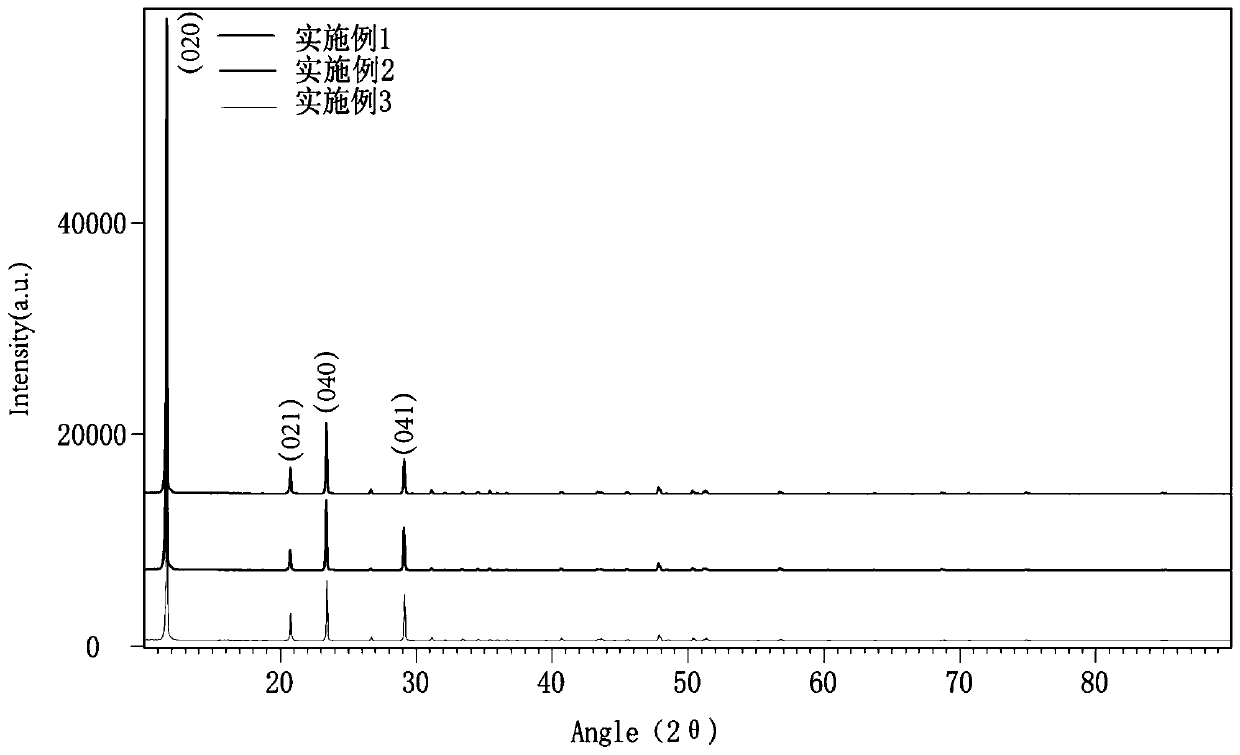

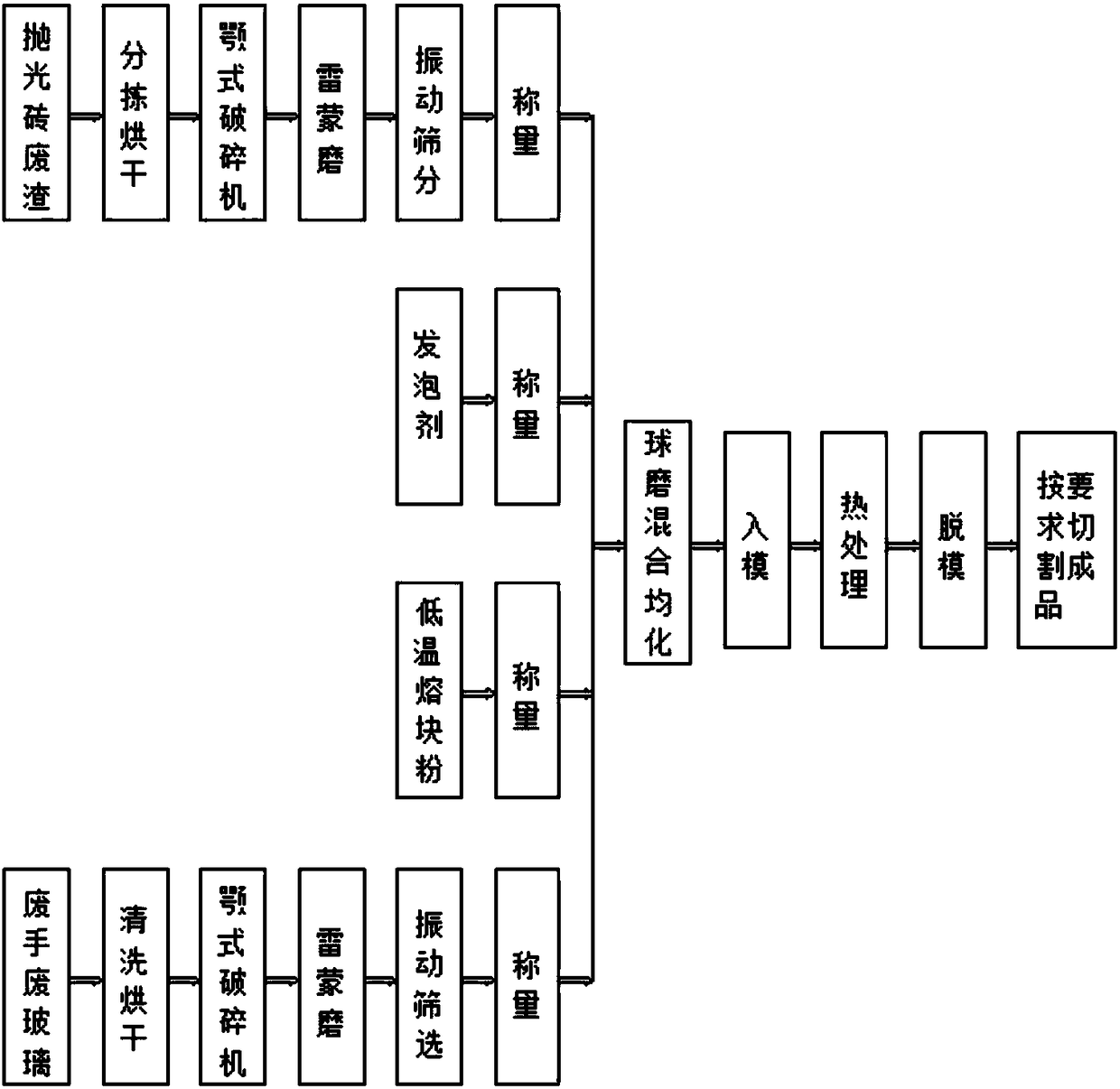

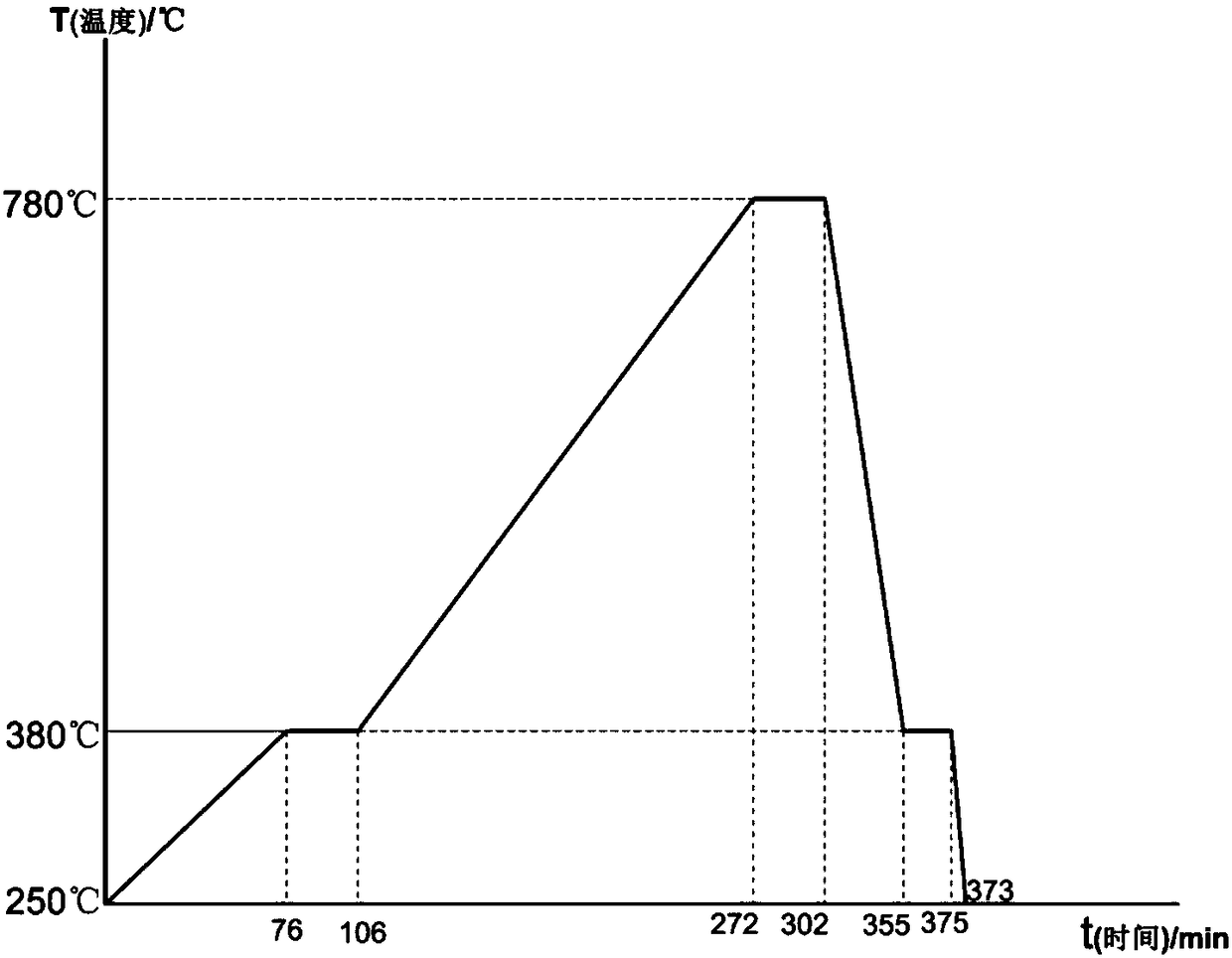

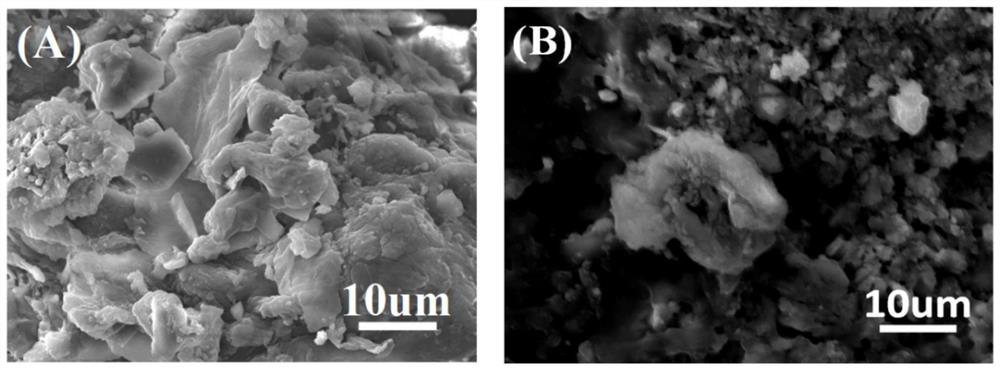

Low-melting-point porous foam stone and preparation method thereof

InactiveCN108546147ANo pollution in the processAvoid pollutionWater/sewage treatmentOrganic fertilisersPorosityBrick

The invention relates to a low-melting-point porous foam stone and a preparation method thereof. The low-melting-point porous foam stone is prepared by utilizing two solid wastes--waste glass and waste polished brick slags in cement, glass and ceramic industries as main raw materials and adding a small amount of a low-temperature frit and foaming agent through a proper heat treatment system. According to the invention, 90% of raw materials are derived from industrial waste residues, so waste is turned into treasure; meanwhile, no pollution to the environment is generated in the processes of production and application, so the unity of environmental protection and energy conservation is realized; and an effective method for resourceful reutilization of industrial solid wastes and solving ofenvironmental pollution of the industrial solid wastes is obtained. The foam stone produced by using the preparation method provided by the invention has the advantages of lightweight, porousness, high porosity, fine and uniform pores, good adsorption and water retention, good air permeability, and fireproof and heat-resistant performances. The preparation process for the foam stone provided by the invention has the advantages of simple operation process, low cost, applicability to large-scale industrial production, and significant economic benefit and environmental protection benefit.

Owner:HUBEI UNIV OF TECH

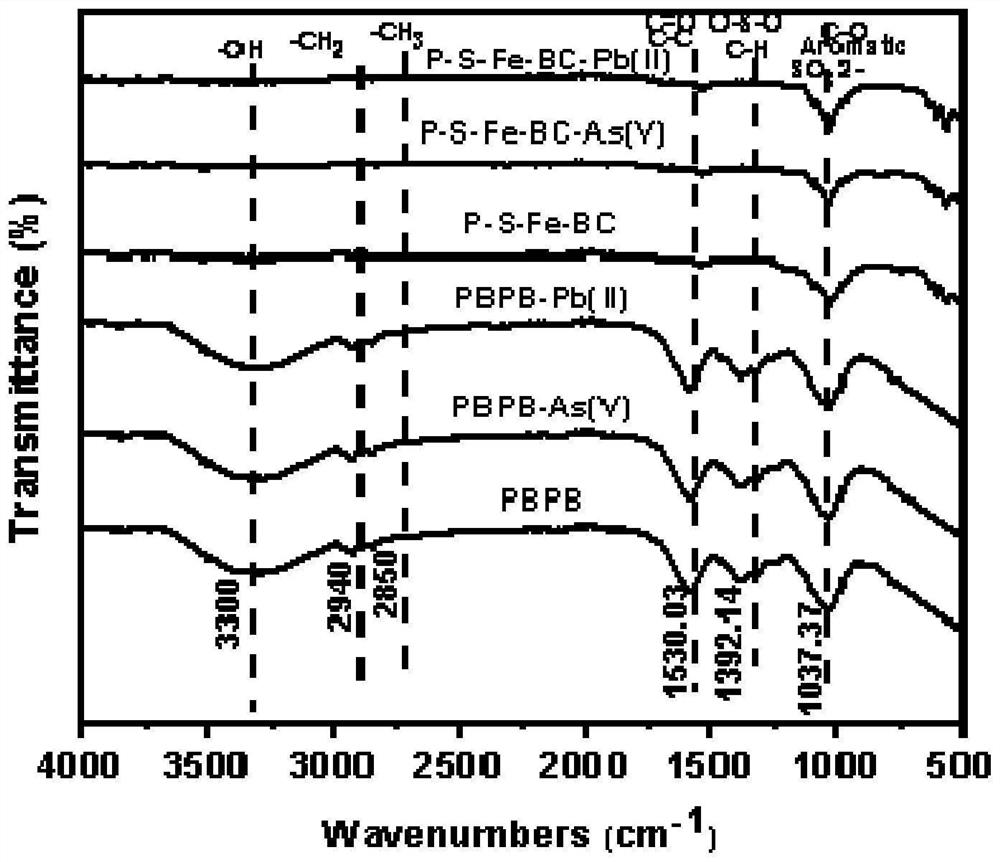

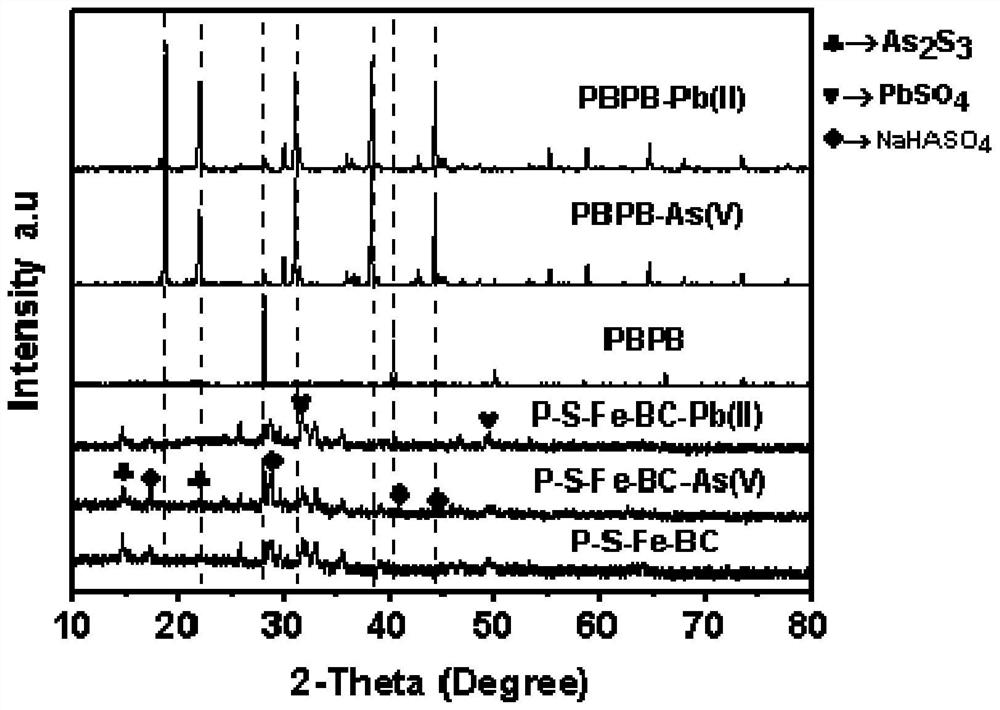

Composite modified banana peel biochar as well as preparation method and application thereof

PendingCN114749148AEnhance physical adsorption capacityHigh adsorption capacityOther chemical processesWater contaminantsEnvironmentally friendlyPhosphate

The invention provides a preparation method of composite modified banana peel biochar, which comprises the following steps: obtaining first pretreated biochar and second pretreated biochar, and then mixing the first pretreated biochar and the second pretreated biochar to obtain the composite modified banana peel biochar, wherein the first pretreated biochar is banana peel biochar subjected to hydrothermal synthesis treatment of calcium salt and phosphate, and the second pretreated biochar is banana peel biochar subjected to high-temperature carbonization treatment of sulfuric acid and ferric salt. Compared with existing materials, after the composite modified banana peel biochar is applied to thallium, arsenic and lead combined polluted water, the composite modified banana peel biochar has the advantages of being high in adsorption performance, stable in adsorption combination, low in price, environmentally friendly and high in applicability.

Owner:CENT SOUTH UNIV

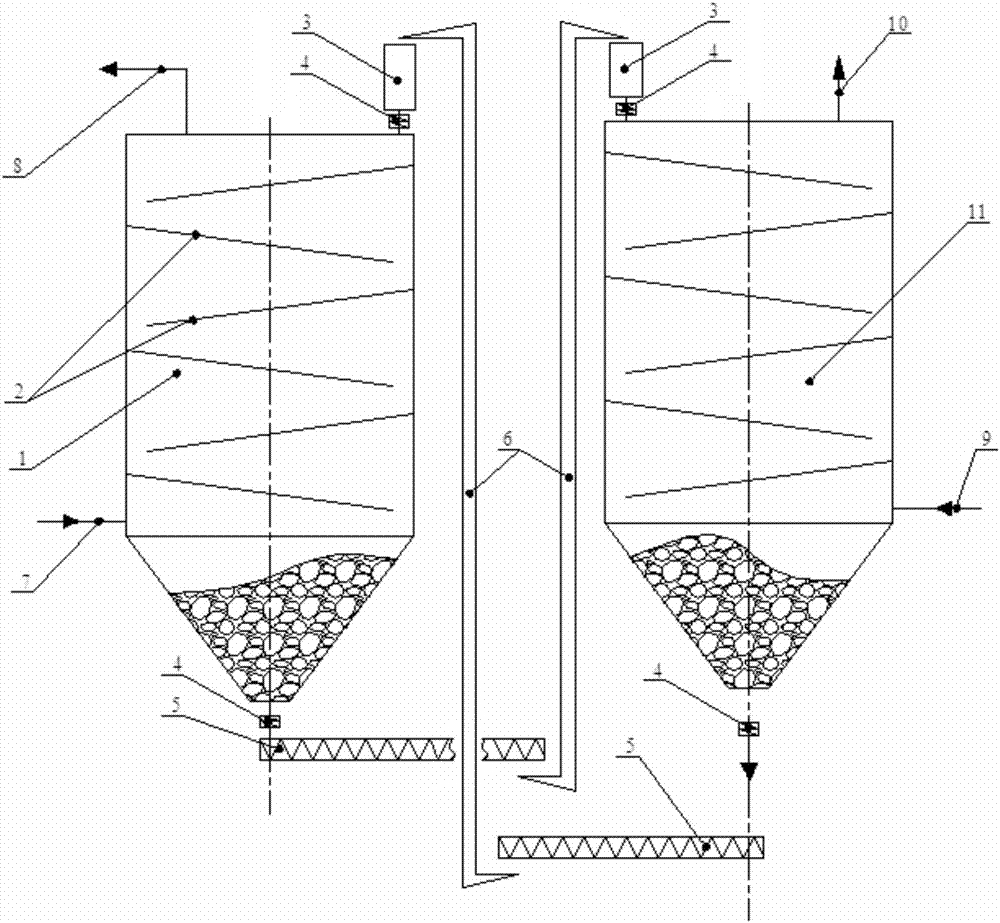

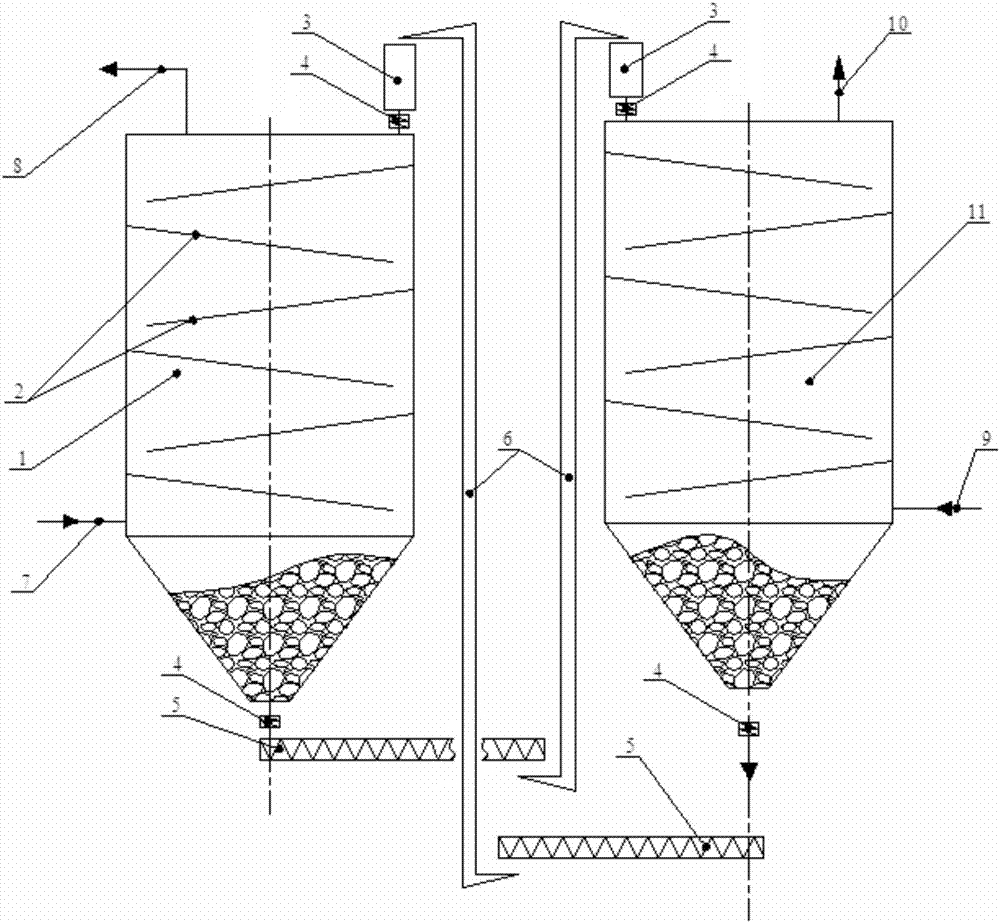

Process system for air-blasting dehumidification through smoke waste heat of hot-blast stove

ActiveCN107083465AIncrease contact timeReduce the overall heightBlast furnace detailsHeating stovesProcess systemsDesiccant

The invention relates to a process system for air-blasting dehumidification through smoke waste heat of a hot-blast stove. The process system comprises a dryer, a regenerator, two sets of conveying and lifting devices and a drying agent. A drying agent discharge opening is formed in the bottom of the dryer, an air inlet is formed in the lower portion of the dryer, a drying channel is formed in the middle portion of the dryer, and a drying agent feed opening and an air outlet are formed in the top of the dryer. A drying agent discharge opening is formed in the bottom of the regenerator, a hot-blast stove smoke inlet is formed in the lower portion of the regenerator, a drying agent regeneration channel is formed in the middle portion of the regenerator, and a drying agent feed opening and a hot-blast stove smoke outlet are formed in the top of the regenerator. The air inlet is connected to an air blower, the air outlet is connected to an inlet of the hot-blast stove, a smoke outlet of the hot-blast stove is connected to the hot-blast stove smoke inlet through a preheater, and the drying agent is circularly conveyed in the dryer and the regenerator through the two sets of conveying and lifting devices. The system indirectly dehumidifies air through the smoke waste heat of the hot-blast stove, a low-temperature environment does not need to be provided, pollution to the air cannot be caused, the energy sources are saved, and the blast furnace coke ratio is reduced.

Owner:WISDRI ENG & RES INC LTD

Indoor water-based fireproof coating for ultrathin steel structure

InactiveCN109337464ANo pollution in the processNo releaseFireproof paintsAnti-corrosive paintsWater basedCarbon layer

The invention relates to the field of fireproof coatings, in particular to an indoor water-based fireproof coating for an ultrathin steel structure. The indoor water-based fireproof coating is prepared from following raw materials in parts by weight: 10-25 parts of water, 20-35 parts of synthetic emulsion, 0.2-0.6 parts of a dispersing agent, 0.2-0.6 parts of a wetting agent, 0.1-0.5 parts of a defoaming agent, 0.1-0.3 parts of an anticorrosive agent, 0.8-2 parts of a coalescing agent, 5-10 parts of titanium dioxide, 5-10 parts of aluminum hydroxide, 15-25 parts of ammonium polyphosphate, 7-15parts of melamine, 5-10 parts of pentaerythritol, 2-5 parts of expanded graphite, 2-5 parts of a reinforcing agent and 0.4-1 part of a thickening agent. The product is low in processing cost, high inspray coating efficiency, environmentally friendly and easy to transport, compactness and strength of a foaming carbon layer are high, and fireproof performance is high.

Owner:南京展拓消防设备有限公司

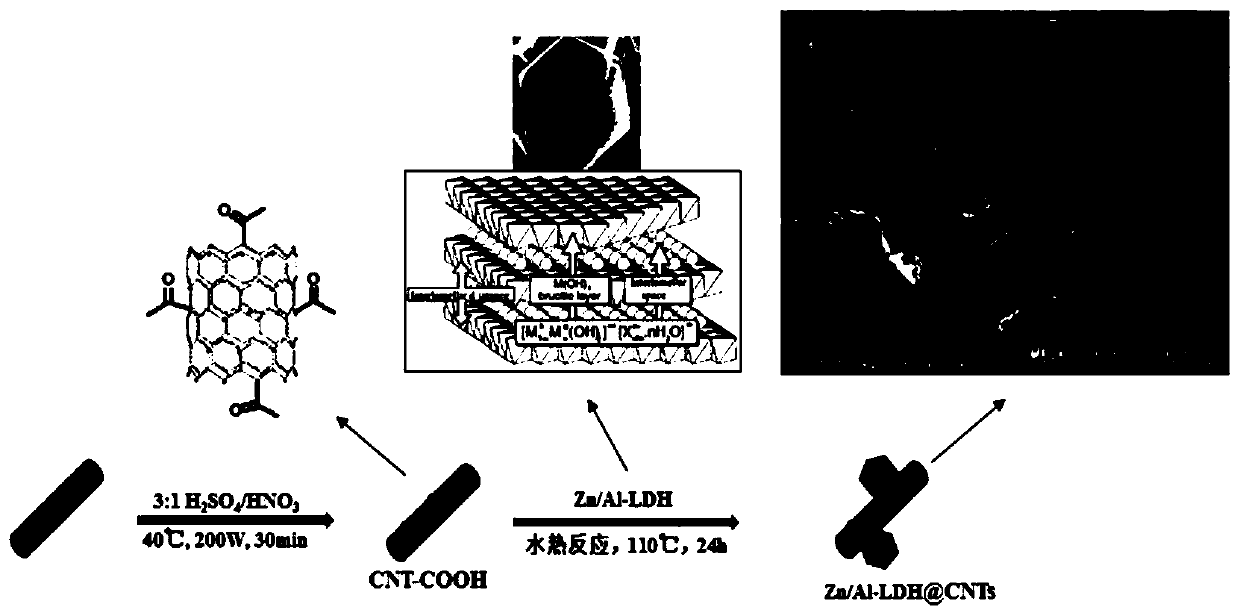

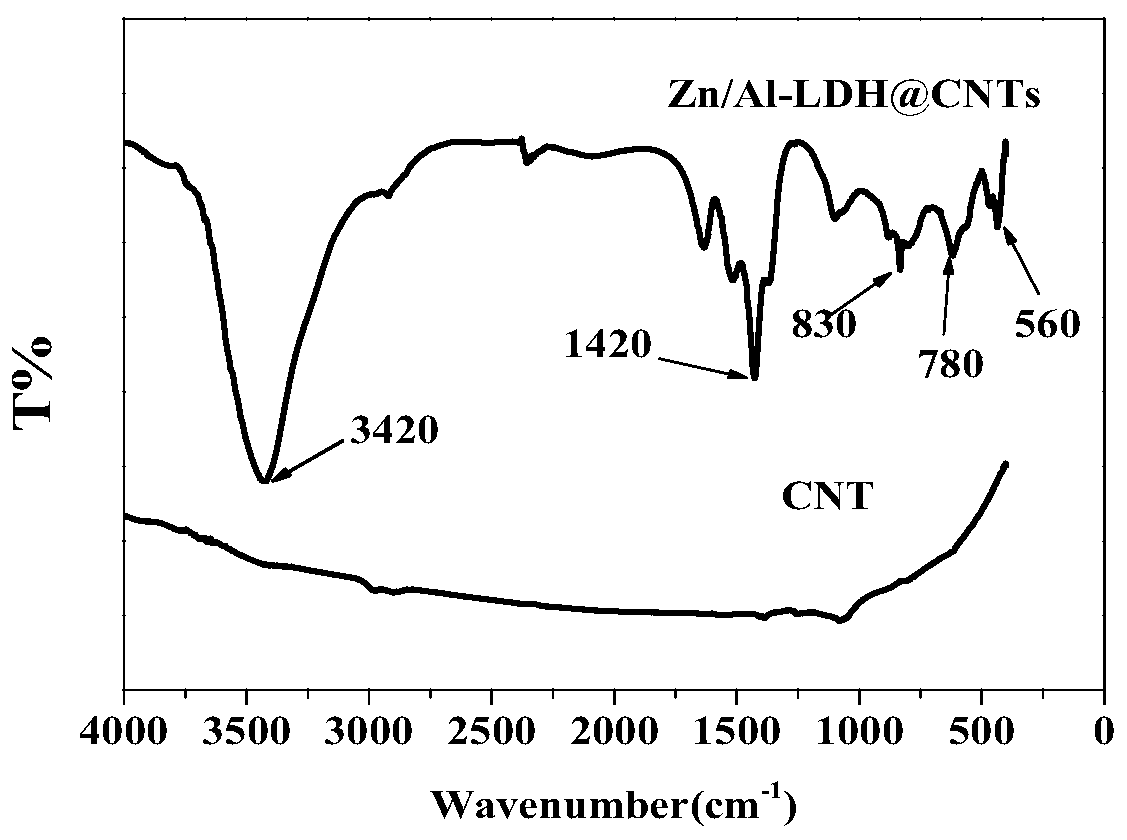

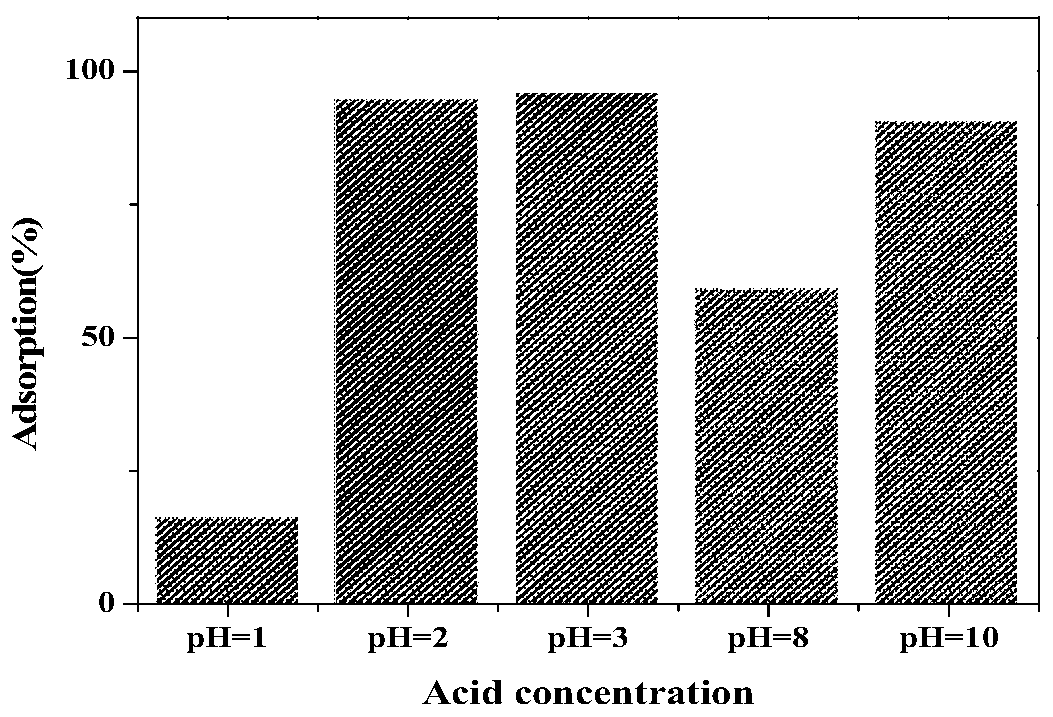

Zinc-aluminum hydrotalcite/carbon nanotube composite adsorption material, preparation method thereof and application in gallium recovery

ActiveCN110404507AImprove adsorption efficiencyImprove adsorption capacityOther chemical processesWater contaminantsWater bathsSynthesis methods

The invention belongs to the technical field of composite materials, and particularly relates to a zinc-aluminum hydrotalcite carbon nanotube composite adsorption material and a preparation method andapplication thereof. The preparation method comprises the following steps: adding carbon nanotubes into a three-neck round bottom flask filled with concentrated nitric acid and concentrated sulfuricacid, stirring and reacting in an ultrasonic water bath for 1.5h, cooling to room temperature, filtering by suction and washing, and drying to obtain an intermediate product named CNT-COOH; weighing zinc chloride and aluminum chloride hexahydrate in a beaker, adding deionized water, stirring to dissolve, adding the intermediate product obtained in the step 1), slowly dropping a 2 mol L<-1> NaOH solution at a certain speed, adjusting pH to 10, stirring for 2-5 hours, and carrying out hydrothermal reaction to obtain the target product, Zn / Al-LDH @ CNTs. The method has the advantages of low synthesis cost, simple synthesis method, energy conservation, environmental protection, large adsorption capacity, high adsorption speed, wide application and practical applicability.

Owner:LIAONING UNIVERSITY

Az31b magnesium alloy golden yellow conversion coating treatment agent and az31b magnesium alloy surface treatment method

ActiveCN109536941BImprove corrosion resistanceImprove adhesionMetallic material coating processesAlloyPolluted environment

The invention discloses an AZ31B magnesium alloy golden conversion film treatment agent and an AZ31B magnesium alloy surface treatment method. The AZ31B magnesium alloy golden conversion film treatment agent comprises components with the following concentrations: 1-25 g / l of 98% of sulfuric acid, 1-25 g / l of 50% of manganese nitrate, 1-25 g / l of potassium permanganate, 0.1-1 g / l of metavanadate, 0.01-0.05 ml / l of dispersing agent, and the balance of water. After the AZ31B magnesium alloy golden conversion film treatment agent is applied to the surface treatment of AZ31B magnesium alloys, golden conversion films can be formed on the surfaces of the AZ31B magnesium alloys, so that the corrosion resistance of the AZ31B magnesium alloys can be improved. The formed golden conversion films havethe advantages of good adhesion, good salt mist performance and good film forming uniformity. In addition, the AZ31B magnesium alloy golden conversion film treatment agent contains no phosphorus and chromium, so that the problem of environmental pollution caused by common use of phosphorus and chromium in traditional alloy treatment agents is prevented, no environmental pollution is generated, andthe environmental protection is better.

Owner:广东东明新材科技有限公司

Efficient composite biological flocculant for sludge treatment and preparation method thereof

InactiveCN108892358AEasy to lockClear separation interfaceSludge treatment by de-watering/drying/thickeningFlocculationWastewater

The invention discloses an efficient composite biological flocculant for sludge treatment and a preparation method thereof. The efficient composite biological flocculant for sludge treatment comprises, by mass, 10-70 parts of polymerized amino acid, 10-50 parts of animal gelatin, 0.1-20 parts of uronic acid and 0.1-10 parts of composite sulphate chloride PBT. The flocculant is a net-shaped mixturecontaining organic and inorganic high-molecular compounds at the same time. The flocculant and colloidal particles in water form compact and uniform floc through charge neutralization, adsorption, bridging and sweeping. The flocculant has the advantages of being good in product stability, small in use amount, good in flocculation effect, high in treatment efficiency, small in sludge generation amount and the like, is more environmentally friendly compared with polyacrylamide, and can be widely applied to treatment of sewage and wastewater.

Owner:青岛博尔优生物科技有限公司

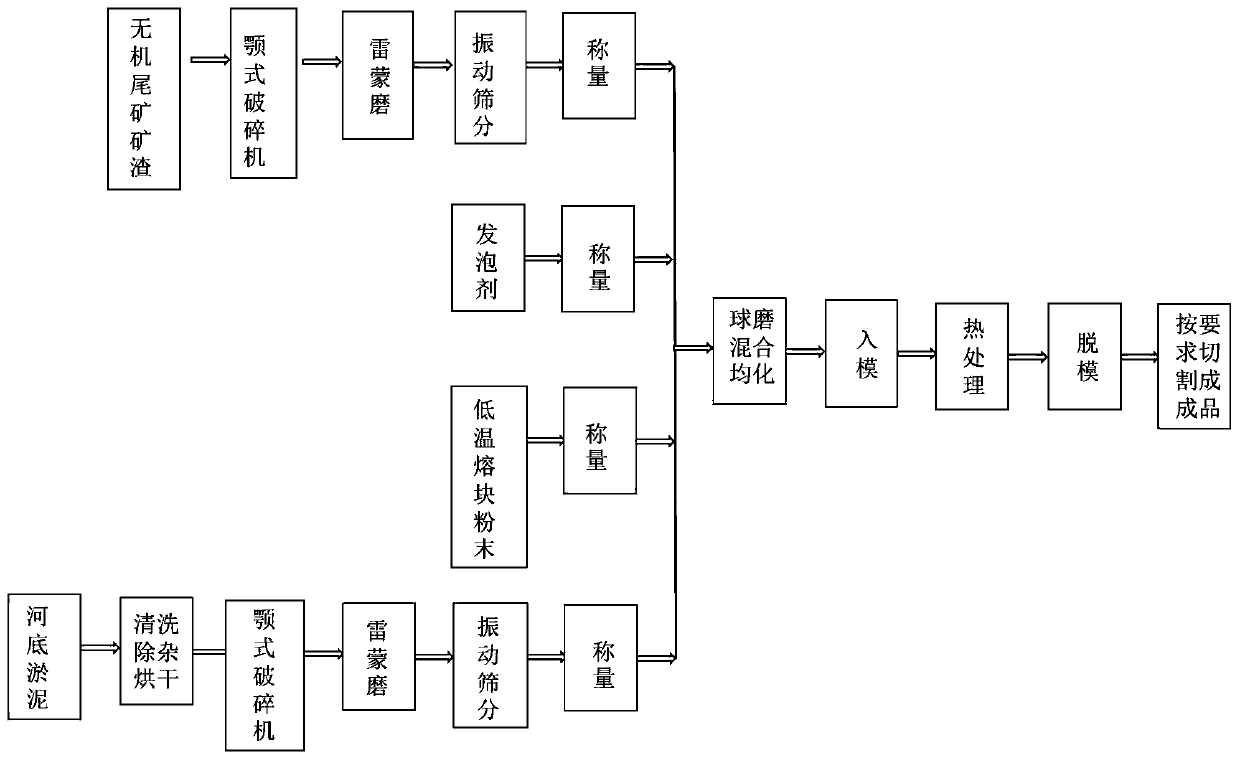

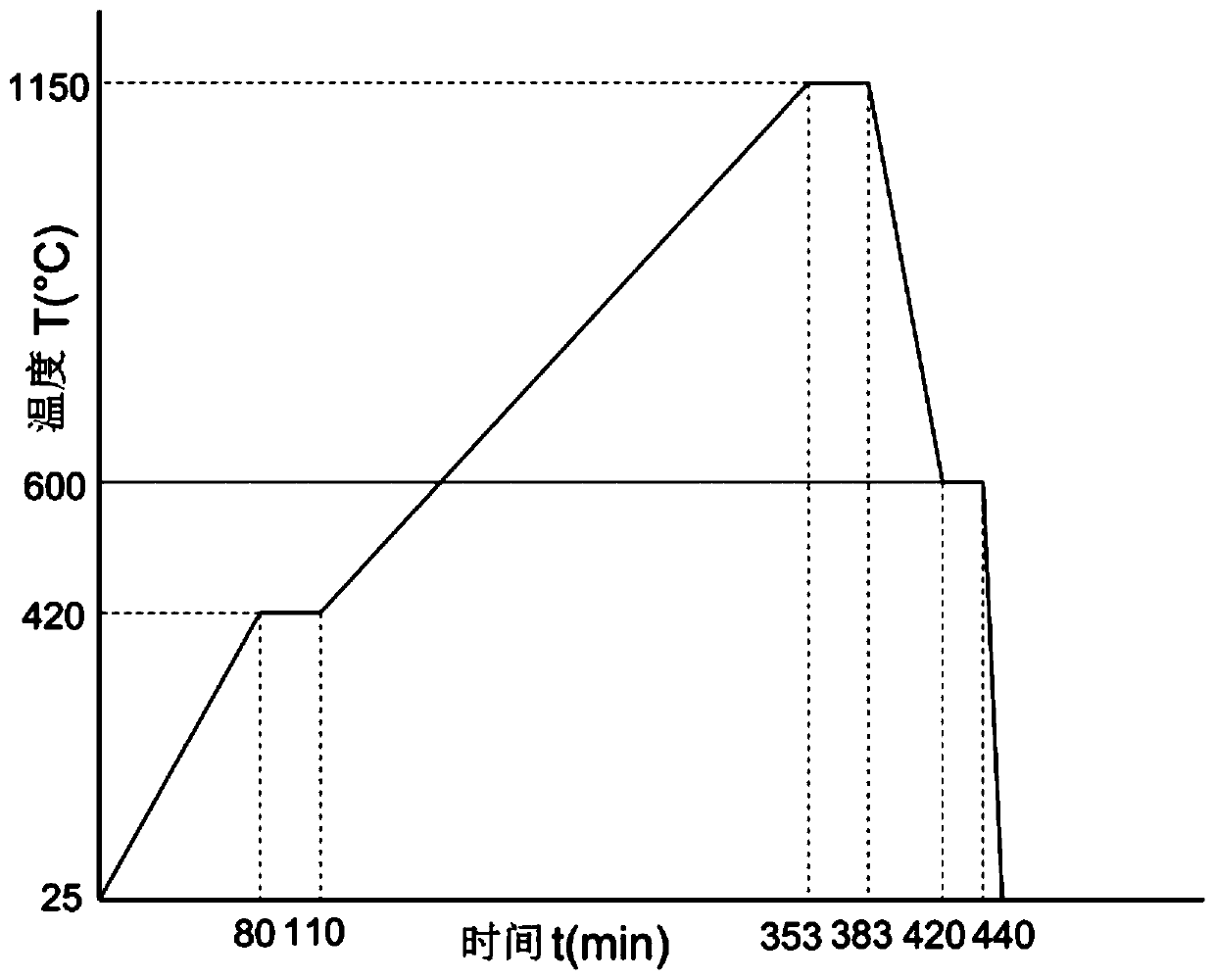

Foamed ceramic and ceramic composite integrated brick and preparation method thereof

InactiveCN110642594ASimple processLow costCeramic shaping apparatusCeramic materials productionHeat conservationProcess engineering

The invention discloses a foamed ceramic and ceramic composite integrated brick and a preparation method thereof, wherein mine tailing slag and urban river bottom sludge are used as main raw materials, and are added with a small amount of low-temperature frit and a foaming agent, and proper heat treatment is performed to prepare the foamed ceramic and ceramic composite integrated brick. Accordingto the invention, 90% of the raw materials are all from industrial tailing slag and urban river bottom sludge, so that waste is turned into wealth, no pollution is generated to the environment in theproduction and use process, environmental protection and energy conservation are unified, and the method is an effective method for recycling industrial solid waste and solving environmental pollutionof the industrial solid waste; the produced foamed ceramic-ceramic composite integrated brick has advantages of good adsorption, good water retention, good air permeability, fire resistance and heatresistance, can be directly used for heat insulation of exterior walls, and can avoid the defect of separated construction of heat insulation and water resistance of the traditional exterior wall; andthe preparation process is simple in operation process, low in cost and suitable for industrial large-scale production, and has obvious economic benefits and environmental protection benefits.

Owner:HUBEI UNIV OF TECH

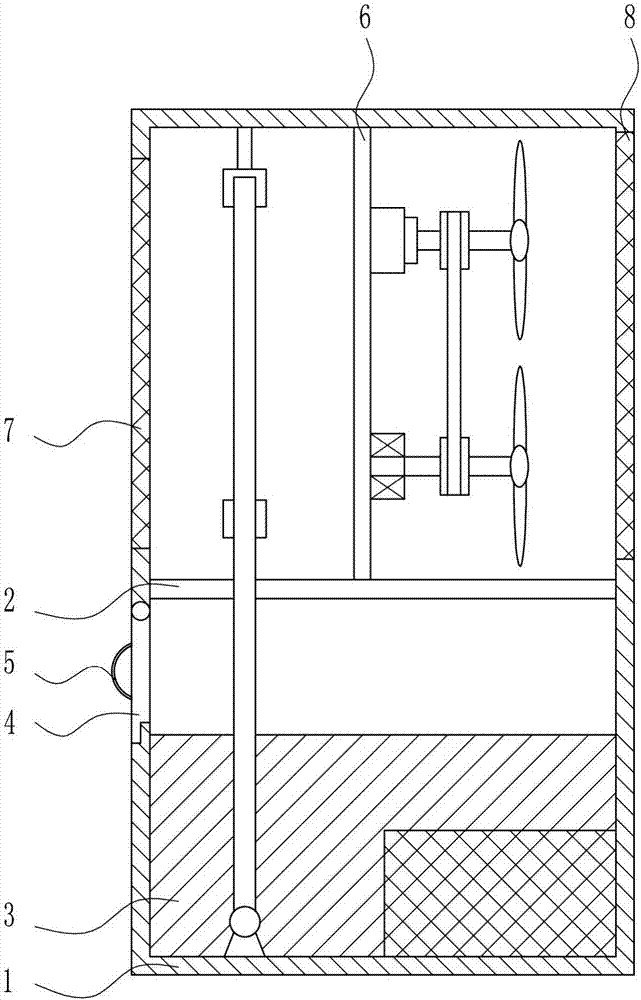

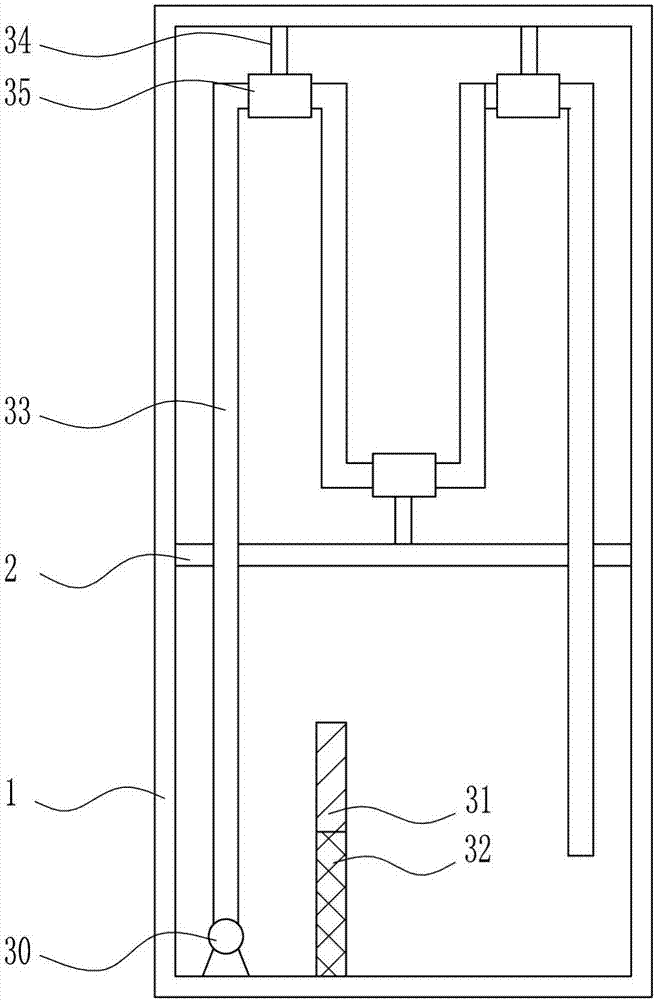

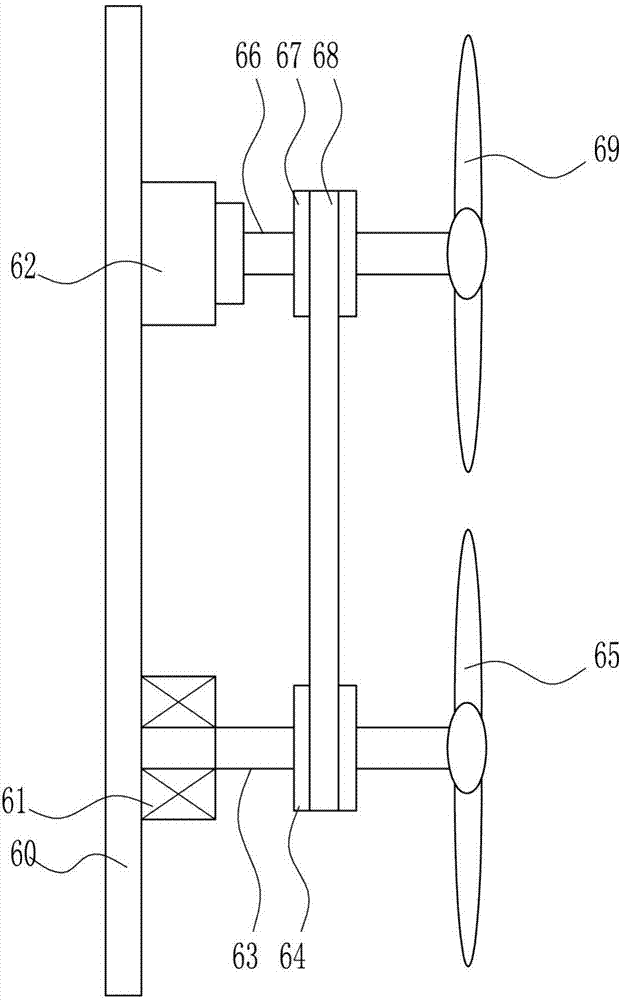

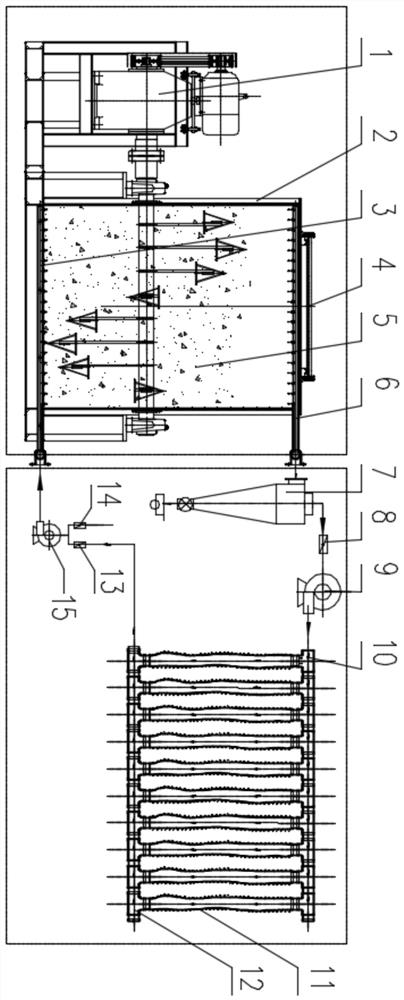

Environment-friendly cooling fan

InactiveCN107543263ANo pollutionPollution generationLighting and heating apparatusHeating and ventilation casings/coversWater circulationEngineering

The invention relates to cooling fans, in particular to an environment-friendly cooling fan. The environment-friendly cooling fan can blow out cool air and be free of polluting the environment. The environment-friendly cooling fan comprises a box body, a partition plate, a water circulating device, a box door, a handle, a blowing device and the like. The partition plate is arranged in the middle,between the left wall and the right wall, in the box body; the water circulating device is arranged at the bottom in the box body and penetrates through the partition plate; the lower portion of the left wall of the box body is rotatably connected with the box door; the box door is located on the lower portion of the partition plate; the handle is arranged on the left side of the box door; the blowing device is arranged on the top of the partition plate and located on the upper-right portion of the water circulating device. The environment-friendly cooling fan can blow out the cool air and befree of polluting the environment.

Owner:查健春

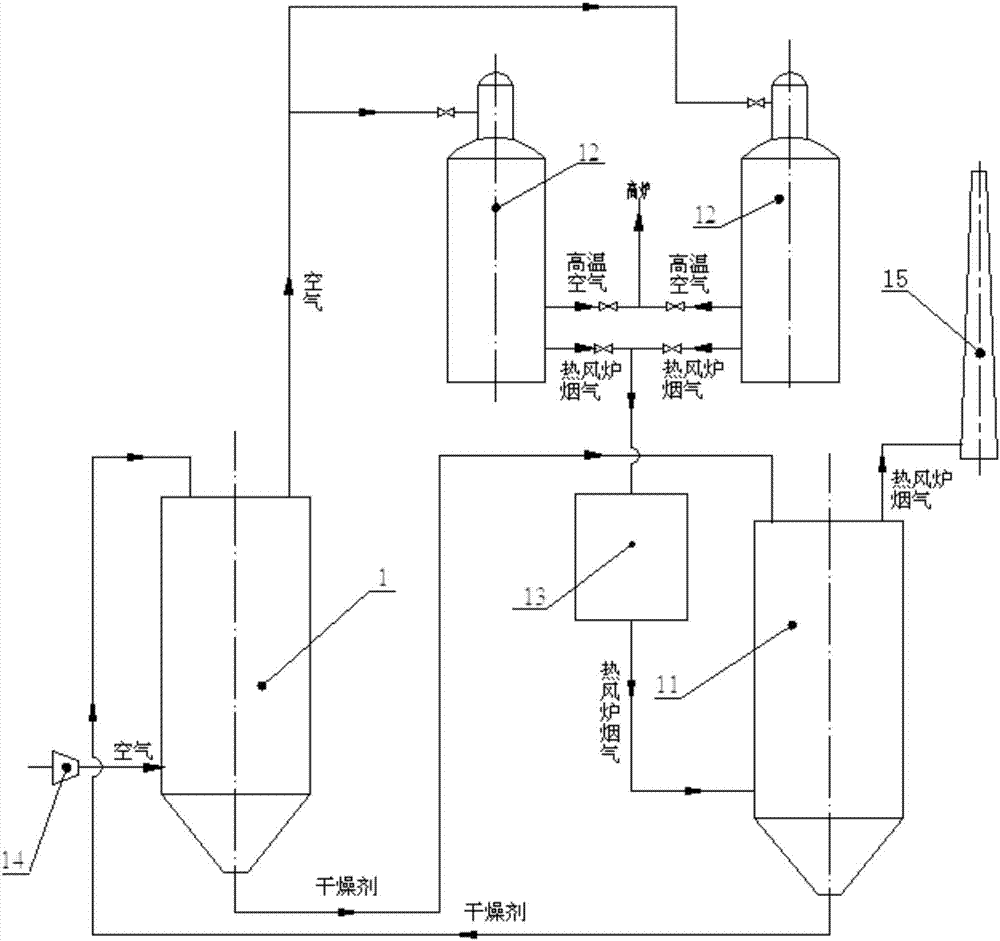

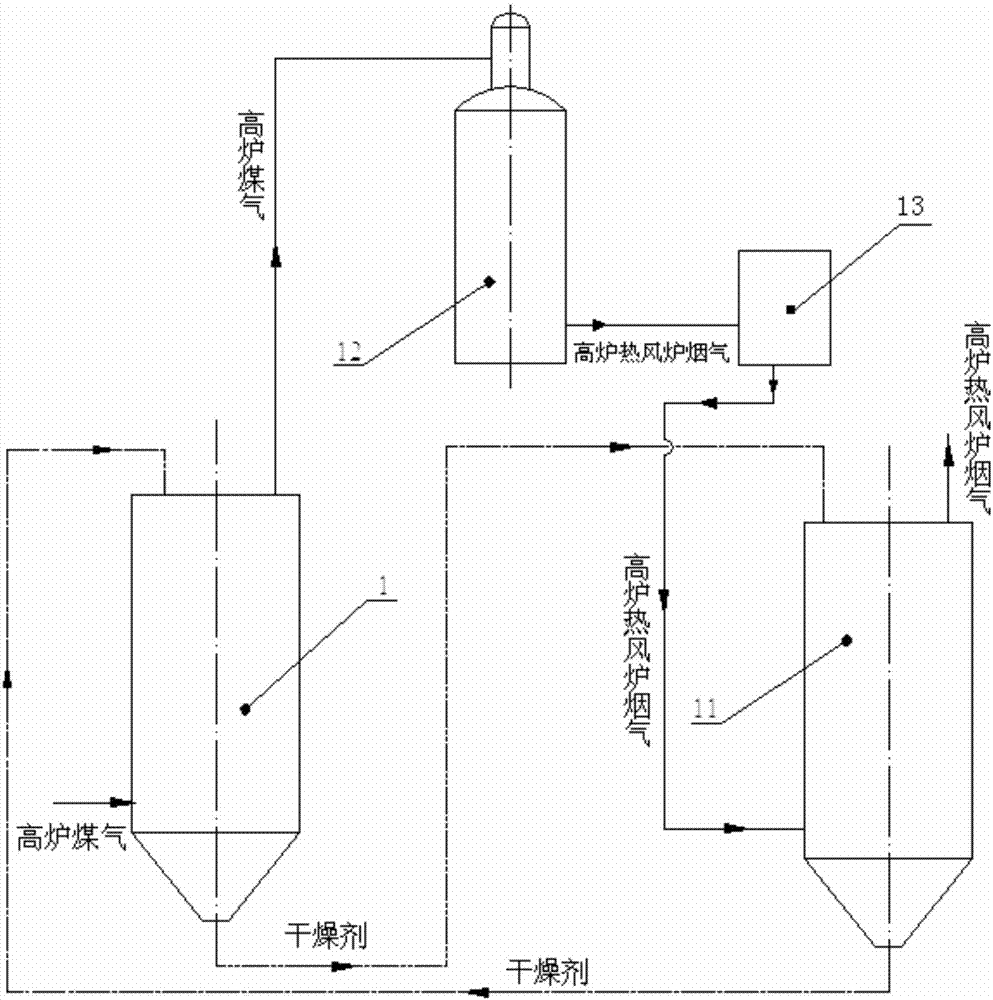

Process system for drying blast furnace gas through smoke waste heat of hot blast stove

ActiveCN107119164AIncrease contact timeReduce the overall heightBlast furnace detailsHeating stovesProcess systemsProcess engineering

The invention relates to a process system for drying blast furnace gas through smoke waste heat of a hot blast stove. The process system comprises a dryer, a regenerator, two sets of conveying and lifting devices and a drying agent. A drying agent discharging port is formed in the bottom of the dryer, a blast furnace gas inlet is formed in the lower portion of the dryer, a drying channel is formed in the middle portion of the dryer, and a drying agent feeding port and a blast furnace gas outlet are formed in the top of the dryer. A drying agent discharging port is formed in the bottom of the regenerator, a hot blast stove smoke inlet is formed in the lower portion of the regenerator, a drying agent regeneration channel is formed in the middle portion of the regenerator, a drying agent feeding port and a hot blast stove smoke outlet are formed in the top of the regenerator. The blast furnace gas outlet is connected to the hot blast stove, the hot blast stove is connected with the hot blast stove smoke inlet through a preheater, the drying agent discharging port of the dryer is connected to the drying agent feeding port of the regenerator through one set of conveying and lifting device, and the drying agent discharging port of the regenerator is connected with the other set of conveying and lifting device. The process system indirectly dries the blast furnace gas through the smoke waste heat of the hot blast stove, no pollution is caused for the blast furnace gas, energy sources are saved, and the calorific value of the blast furnace gas is increased.

Owner:WISDRI ENG & RES INC LTD

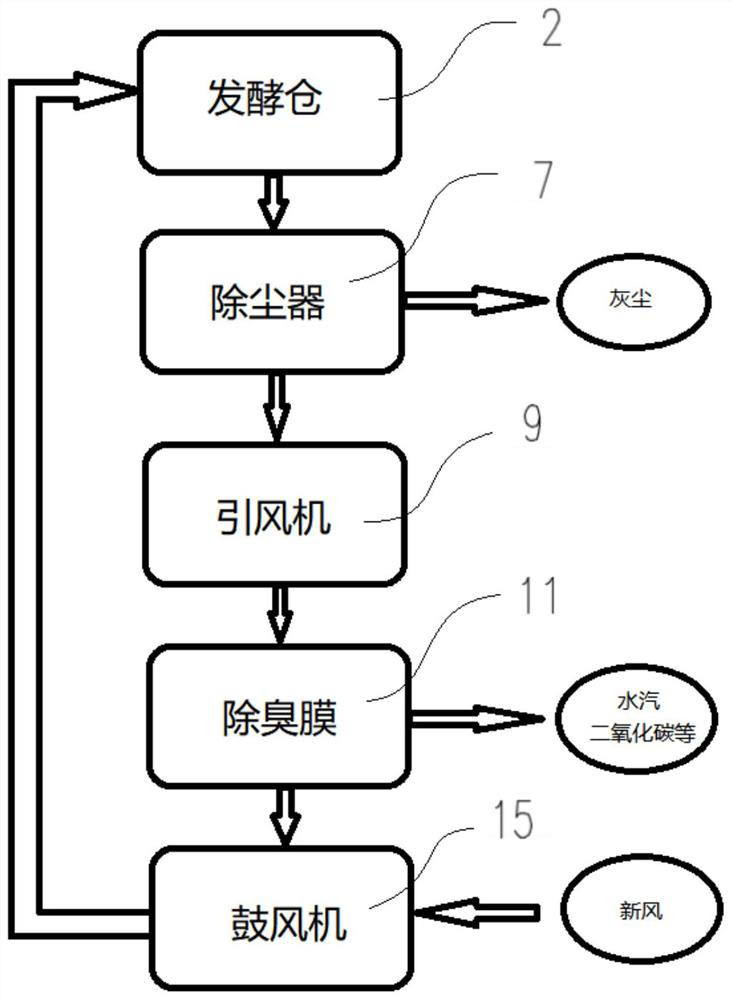

Dynamic fermentation system and process for membrane treatment waste gas

PendingCN112209755ASolve secondary pollutionSolve addBio-organic fraction processingOrganic fertiliser apparatusMicroorganismWater vapor

The invention discloses a dynamic fermentation system and process for membrane treatment waste gas, the system is mainly composed of a dynamic fermentation unit and a waste gas treatment unit, the dynamic fermentation unit and the waste gas treatment unit are connected through a pipeline to form a dynamic circulation loop, and the waste gas treatment unit comprises a deodorization unit and a blower unit. The dynamic fermentation unit is provided with a fermentation bin. The fermentation bin is provided with a first air inlet and a first air outlet, and the air blowing unit is communicated withthe first air inlet and the first air outlet. The deodorization unit is installed in the dynamic circulation loop, water vapor and carbon dioxide in the waste gas are removed through a deodorizationfilm, then microorganisms and the remaining waste gas are blown into the fermentation bin through the air blowing unit, and finally the microorganisms and the remaining waste gas are automatically absorbed by a pile body. The dynamic fermentation unit is communicated with the waste gas treatment unit, so that the dynamic fermentation system for membrane treatment of the waste gas forms a dynamic fermentation system, dynamic circulation of the waste gas is realized, and the waste gas absorption speed of the pile body is greatly increased. The system can be widely applied to a warehouse storagetype organic raw material fermentation process.

Owner:GUANGDONG PROVINCE MODERN AGRI EQUIP RES INST

Production method of dry-mixed mortar

The invention provides a production method of dry-mixed mortar. The production method comprises the following steps: step 1: removing steel bar materials in building waste materials; then crushing thebuilding waste materials and sieving, wherein an oversize material is aggregate and an undersize material is building waste sand after sieving, and the grain diameter of the aggregate is less than orequal to 55mm; step 2: proportioning a mixture in parts by weight: 3 to 5 parts of cement, 13 to 18 parts of natural sand, 1 to 2 parts of fly ash, 42 to 55 parts of the building waste sand and 20 to30 parts of the aggregate; step 3: adding the mixture and an additive into a dry-mixed mortar mixing machine, and sufficiently stirring by the dry-mixed mortar mixing machine and uniformly mixing toobtain dry-mixed mortar powder. By adopting the method provided by the invention, the dry-mixed mortar can be produced by sufficiently utilizing the building waste materials and the environment pressure caused by building wastes can be effectively alleviated.

Owner:翟孝东

Irradiation crosslinked chitosan/gelatin/polyvinyl alcohol hydrogel dressing as well as preparation method and application thereof

The invention discloses an irradiation crosslinking chitosan / gelatin / polyvinyl alcohol hydrogel dressing as well as a preparation method and an application thereof. The preparation method comprises the steps that a chitosan, gelatin and polyvinyl alcohol solution is prepared by using ultrapure water serving as a solvent; the solution is stirred and mixed uniformly and then irradiated, and original hydrogel is obtained; the original hydrogel is put into the ultrapure water to be soaked; and the chitosan / gelatin / polyvinyl alcohol hydrogel dressing is prepared. The hydrogel dressing is extensive in raw material source, simple in preparation technology and stable in performance, and has the advantages of inflammation diminishing, wound pain relieving, scar reduction, wound healing promotion, wound seepage absorption, and excellent biocompatibility. The hydrogel dressing is easy to degrade after abandoned, and has a smaller influence on an environment. The hydrogel dressing can be applied to the fields of trauma hemostasis, inflammation diminishing, scald, postoperative wound healing and the like.

Owner:江西金思康药业有限公司

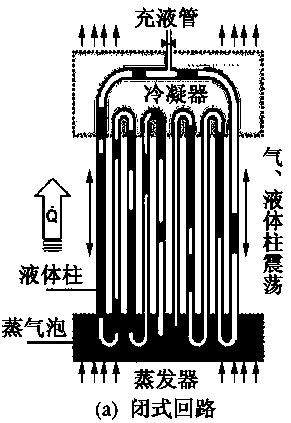

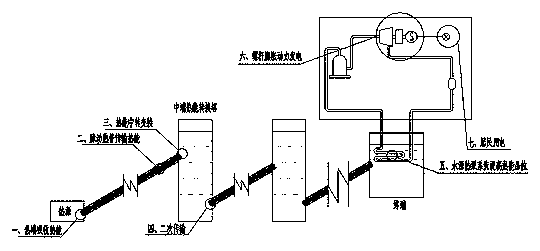

Low-grade waste heat recovery and application technology

InactiveCN110793237ARealize long-distance transmissionReduce energy consumptionHeat pumpsIndirect heat exchangersThermodynamicsProcess engineering

The invention discloses a low-grade waste heat recovery and application technology. A special vacuum heat pipe is introduced to the hot source end for collecting waste heat, the vacuum heat pipe extends towards a terminal user in an upward oblique-pulling mode, middle-end heat exchanging towers are built at certain intervals, the vacuum heat pipe at the previous period transmits the heat energy from the hot source end into the liquid in each middle-end heat exchanging tower, another vacuum heat pipe with the same specification material is additionally introduced in the heat exchanging tower toabsorb the heat energy of the liquid after heating, and cascade heat energy transmission is conducted continuously in the same way; and during storing and using of the terminal, the long-distance transmission can be achieved through cascade heat energy exchanging and transmission, the heat energy transmission of each heat pipe is high in speed and less in system energy consumption, a heat transmitting structure of each heat pipe is simple and easy to operate, automatic and continuous operation can be achieved, a screw-rod-type expansion power generator can still obtain higher internal efficiency under lower volume flow conditions, the fuel is not only saved, the secondary utilization rate of the energy is improved, the environmental pollution can also be reduced, and the energy using andconverting efficiency is high.

Owner:祁同刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com