Composite modified banana peel biochar as well as preparation method and application thereof

A composite modification and biochar technology, applied in chemical instruments and methods, water pollutants, and other chemical processes, can solve problems such as unstable chemical properties, easy deactivation, and adsorbent pollution, and achieve enhanced physical adsorption capacity, enhanced chemical adsorption capacity, and the effect of adsorption and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Preparation of composite modified banana peel biochar (P-S-Fe-BC)

[0057] 1. Provide banana peel biochar

[0058] The dried banana peel waste is subjected to high temperature carbonization treatment and pulverization to obtain banana peel biochar.

[0059] 2. Preparation of the first pretreatment biochar

[0060] (1) 9.446g Ca(NO 3 ) 2 ·4H 2 O and 3.169g (NH 4 ) 2 HPO 4 40 mL of calcium salt solution and 40 mL of phosphate solution were prepared as starting materials.

[0061] (2) At room temperature (25°C), add 10 g of banana peel biochar to the calcium salt solution, and use magnetic stirring (150 rpm, continuous stirring for 30 min) to evenly mix to obtain mixed solution A.

[0062] (3) Mix the above-mentioned mixed solution A with the above-mentioned phosphate solution (stir for 2h at room temperature), and use NH 4 OH adjusts the pH value of the solution to keep the pH between 10-10.5 to obtain mixed solution B.

[0063] (4) performing hydroth...

Embodiment 2

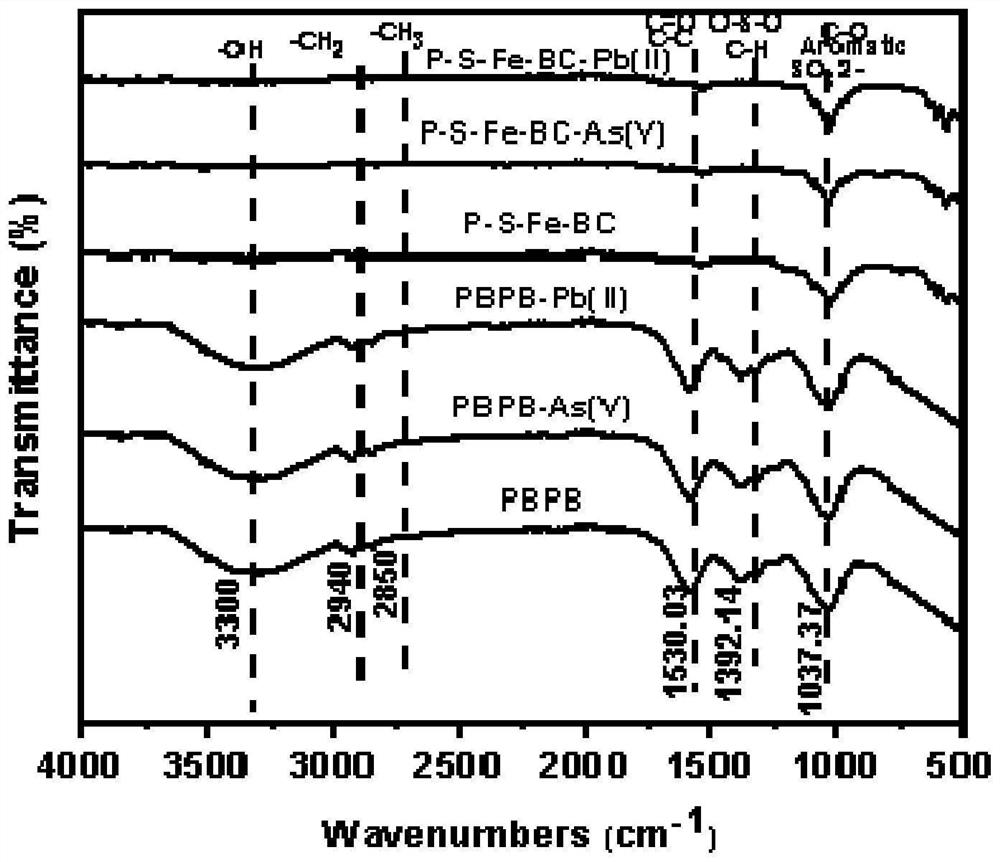

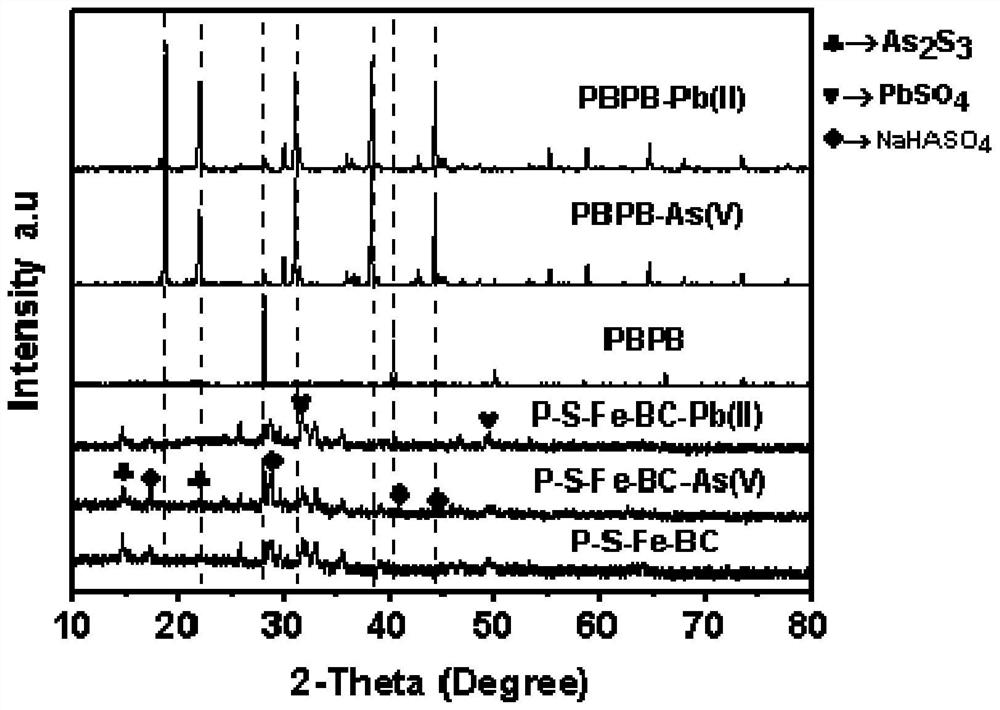

[0071] Example 2: Characterization of composite modified banana peel biochar (P-S-Fe-BC) and second pretreatment biochar (PBPB), and comparative analysis of their products acting on heavy metals

[0072] In this embodiment, the comparative analysis of products acting on heavy metals takes the removal of Pb(II) and As(V) as an example.

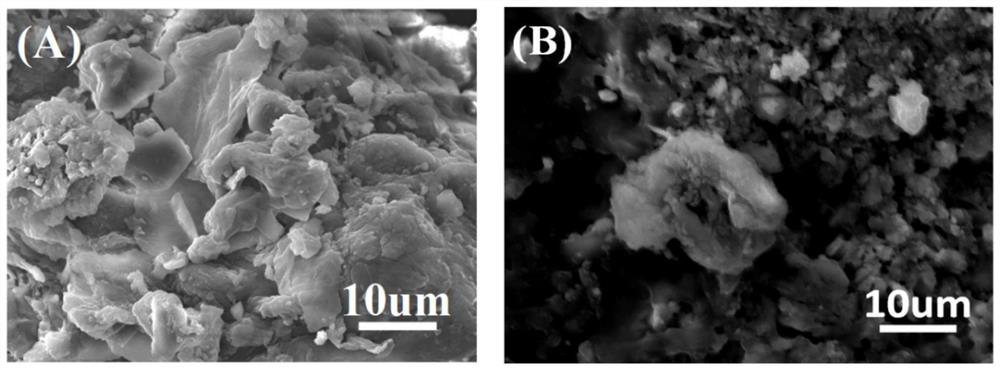

[0073] (1) Scanning electron microscope (SEM) comparative analysis of the second pretreatment biochar (PBPB) and the composite modified banana peel biochar (P-S-Fe-BC)

[0074] The SEM results of PBPB and P-S-Fe-BC are as follows figure 1 shown.

[0075] The surface of PBPB exists in the form of large and smooth minerals, and has a unique adsorption pore structure, which is conducive to the adsorption of heavy metals. Many smaller particles with uneven and rough morphology appeared on the surface of P-S-Fe-BC after mixing treatment, and these small particles adhered in the form of aggregates, which made P-S-Fe-BC further enhance the biologica...

Embodiment 3

[0087] Example 3: Removal of Tl(I), As(V) and Pb(II) by composite modified banana peel biochar (P-S-Fe-BC)

[0088] To the Erlenmeyer flask containing Tl(I), As(V) and Pb(II) at 10 ppm, 30 ppm and 30 ppm, respectively, 0.25 g of P-S-Fe-BC prepared in Example 1 was added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com