Method for controlling long-periodic structure to strengthen magnesium alloy matrix crystallization texture through direct current magnetic field

A long-period structure and reinforced magnesium alloy technology, which is applied in the field of DC magnetic field control of long-period structure to enhance the crystal texture of magnesium alloy matrix, can solve the problem of not considering the solidification rate of the alloy and the inability to fully exert the control effect of the DC magnetic field on the crystal texture of the alloy , DC magnetic field strength is small and other problems, to achieve the effect of easy control, stable liquid hole, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

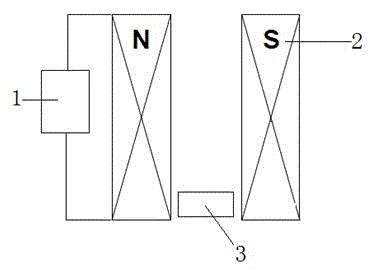

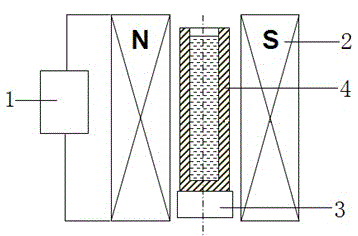

Image

Examples

Embodiment 1

[0015] Mg 97 Y 2 Cu 1 The magnesium alloy is melted in a resistance furnace, kept at a superheat of 50°C for 10 minutes, and then the alloy melt is poured into a mold with a preheating temperature of 200°C in a DC magnetic field solidification device. T is completely solidified under the action of a DC magnetic field. According to XRD analysis, the magnesium matrix of the alloy has an obvious preferred orientation on the (002) plane.

Embodiment 2

[0017] Mg 97 Y 2 Zn 1 The magnesium alloy is melted in a resistance furnace, kept at a superheat of 80°C for 10 minutes, and then the alloy melt is poured into a mold with a preheating temperature of 400°C in a DC magnetic field solidification device. T is completely solidified under the action of a DC magnetic field. According to XRD analysis, the magnesium matrix of the alloy has an obvious preferred orientation on the (101) plane.

Embodiment 3

[0019] Mg 97 Y 2 Cu 1 The magnesium alloy is melted in a resistance furnace, and kept at a superheat of 90°C for 10 minutes, and then the alloy melt is poured into a mold with a preheating temperature of 600°C in a DC magnetic field solidification device, and the alloy is cooled at 0.5 T is completely solidified under the action of a DC magnetic field. According to XRD analysis, the magnesium matrix of the alloy has an obvious preferred orientation on the (100) plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com