Zinc-aluminum hydrotalcite/carbon nanotube composite adsorption material, preparation method thereof and application in gallium recovery

A carbon nanotube composite and zinc-aluminum hydrotalcite technology, which is applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of easy dispersion and unstable structure of hydrotalcite materials, and achieve good results. Separation and enrichment effect, fast adsorption speed, and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

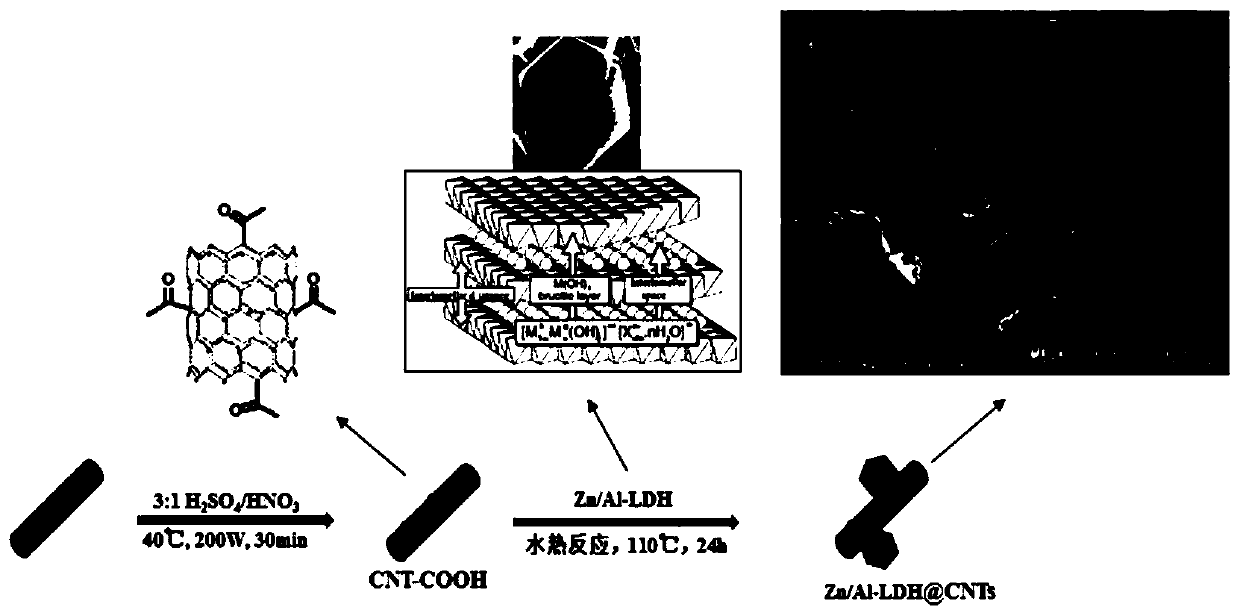

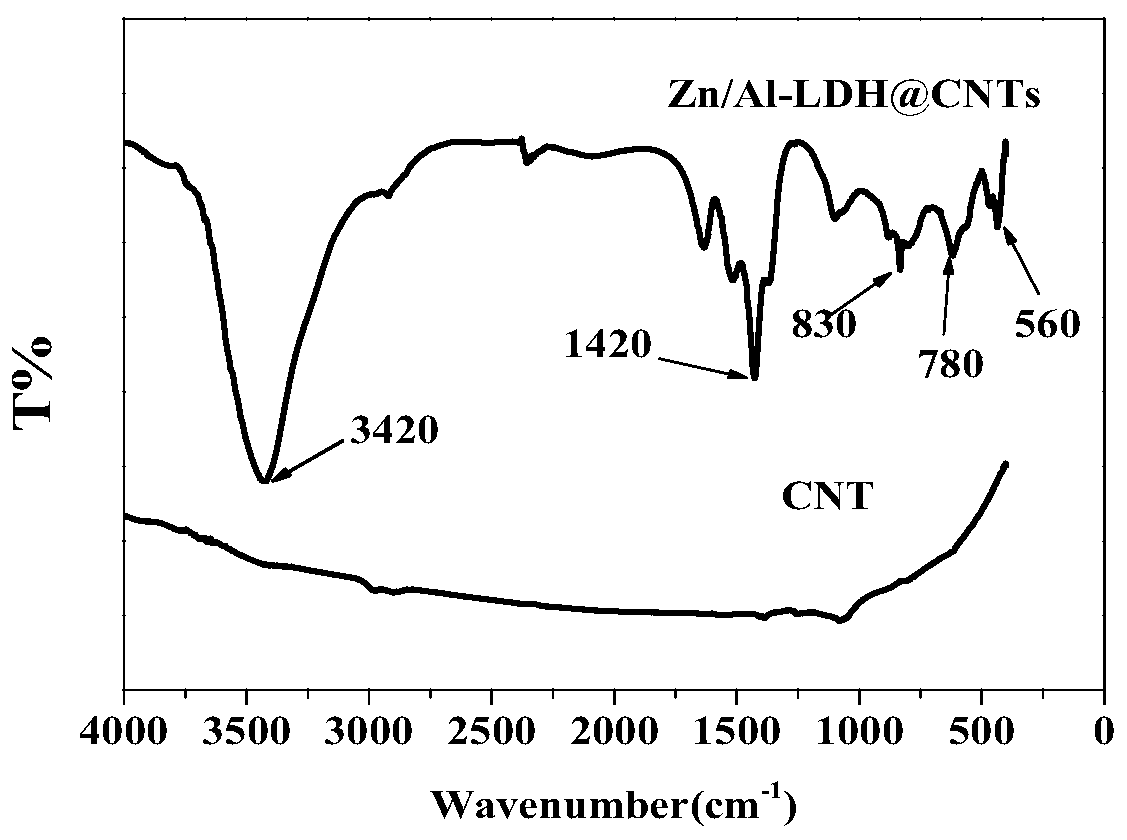

[0034] The preparation of embodiment 1 zinc aluminum hydrotalcite / carbon nanotube composite material

[0035] 1. Preparation of zinc-aluminum hydrotalcite / carbon nanotube composites

[0036] 1) Disperse carbon nanotubes (0.5g) in a 250mL three-necked flask equipped with concentrated nitric acid (20mL) and concentrated sulfuric acid (60mL), the concentration of the concentrated nitric acid is 16mol / L, the concentration of the concentrated sulfuric acid It is 18.4mol / L. Stir ultrasonically for 1.5 h in an ultrasonic water bath at 40°C. After the solution was cooled to room temperature, the above concentrated acid solution was diluted, filtered and washed to obtain carboxylated carbon nanotubes, and dried in an oven at 50°C to obtain an intermediate product, which was named CNT-COOH.

[0037] 2) The dried carboxylated carbon nanotubes (0.40 g), aluminum chloride hexahydrate (0.02 mol, 4.83 g), and zinc chloride (0.06 mol, 8.18 g) were dissolved in 25 mL of water. Slowly add 2m...

Embodiment 2

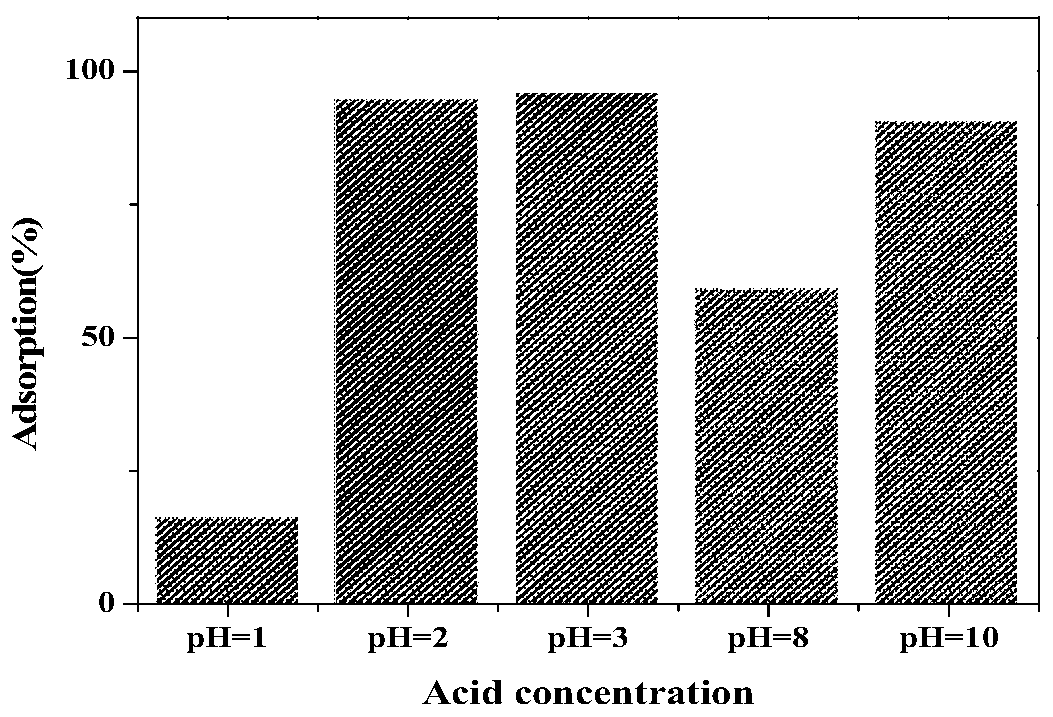

[0041]Example 2 The adsorption effect of zinc-aluminum hydrotalcite / carbon nanotube composite adsorbent on gallium at different acidities

[0042] Take 10 mg of the Zn / Al-LDH@CNTs composite material prepared in Example 1 and add it to 10 mL of gallium solutions with a concentration of 20 mg / L and a pH of 1, 2, 3, 8, and 10, and then put it into the 180r / min, shake in a shaking box with a temperature of 303K for 24h, filter, take the filtrate and stock solution to measure its concentration, and calculate the adsorption rate.

[0043] Adsorption results such as image 3 As shown, the zinc-aluminum hydrotalcite / carbon nanotube composite adsorbent has the highest adsorption rate of gallium at pH 3, reaching more than 96%. The reason for this phenomenon may be that the hydrogen ions in the phenolic hydroxyl group and the Ga(OH) 2+ and Ga(OH) 2 + Cation exchange occurs, so as to achieve the purpose of adsorbing Ga(Ⅲ), while Ga(OH) 2+ and Ga(OH) 2 + It is the main form at pH 3...

Embodiment 3

[0044] Example 3 The adsorption capacity of zinc-aluminum hydrotalcite / carbon nanotube composite adsorbent to gallium

[0045] Weigh 10 mg of the Zn / Al-LDH@CNTs composite material prepared in Example 1, add it to Ga(III) solutions of different concentrations under the condition of pH 3, shake at a temperature of 303K for 24h, filter, and measure Stock solution and filtrate concentration.

[0046] Isotherms such as Figure 4 shown, from Figure 4 It can be seen from the figure that the adsorption isotherm type is Langmuir type, and the adsorption slope gradually decreases with the increase of concentration until reaching the adsorption equilibrium, which is in line with the characteristics of chemical adsorption. When the pH value of the Ga(III) solution is 3, the maximum adsorption capacity of Ga(III) by the adsorbent Zn / Al-LDH@CNTs is 314.43 mg g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com