Method for preparing alpha high-strength gypsum through atmospheric pressure salt solution method by using chlor-alkali by-product salt gypsum and chemical waste salt

A high-strength gypsum and by-product salt technology, applied in chemical instruments and methods, inorganic chemistry, calcium/strontium/barium compounds, etc., can solve the problems of no research and attempts, achieve good crystallinity, smooth surface, and reduce risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

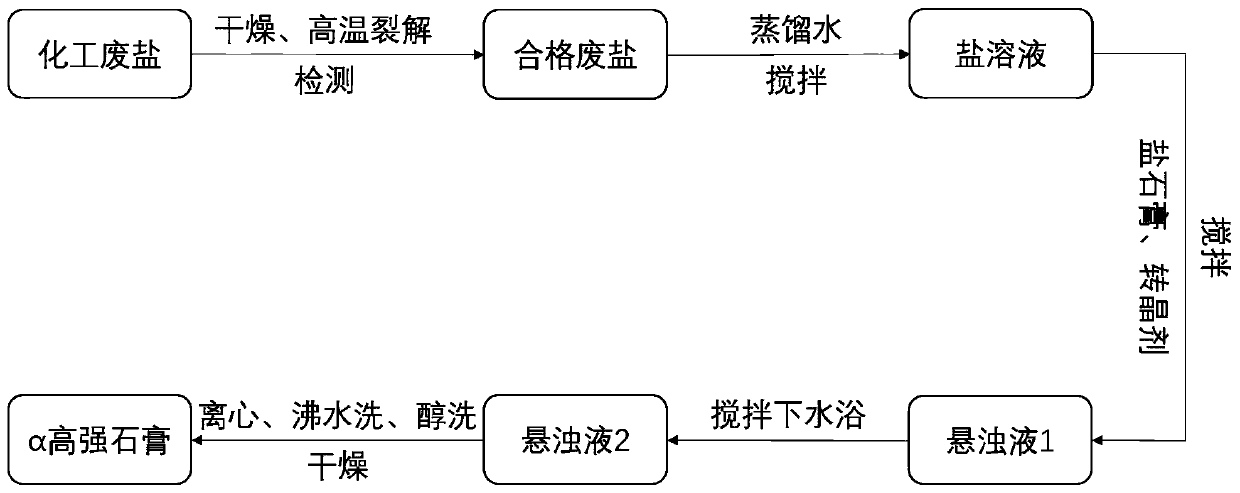

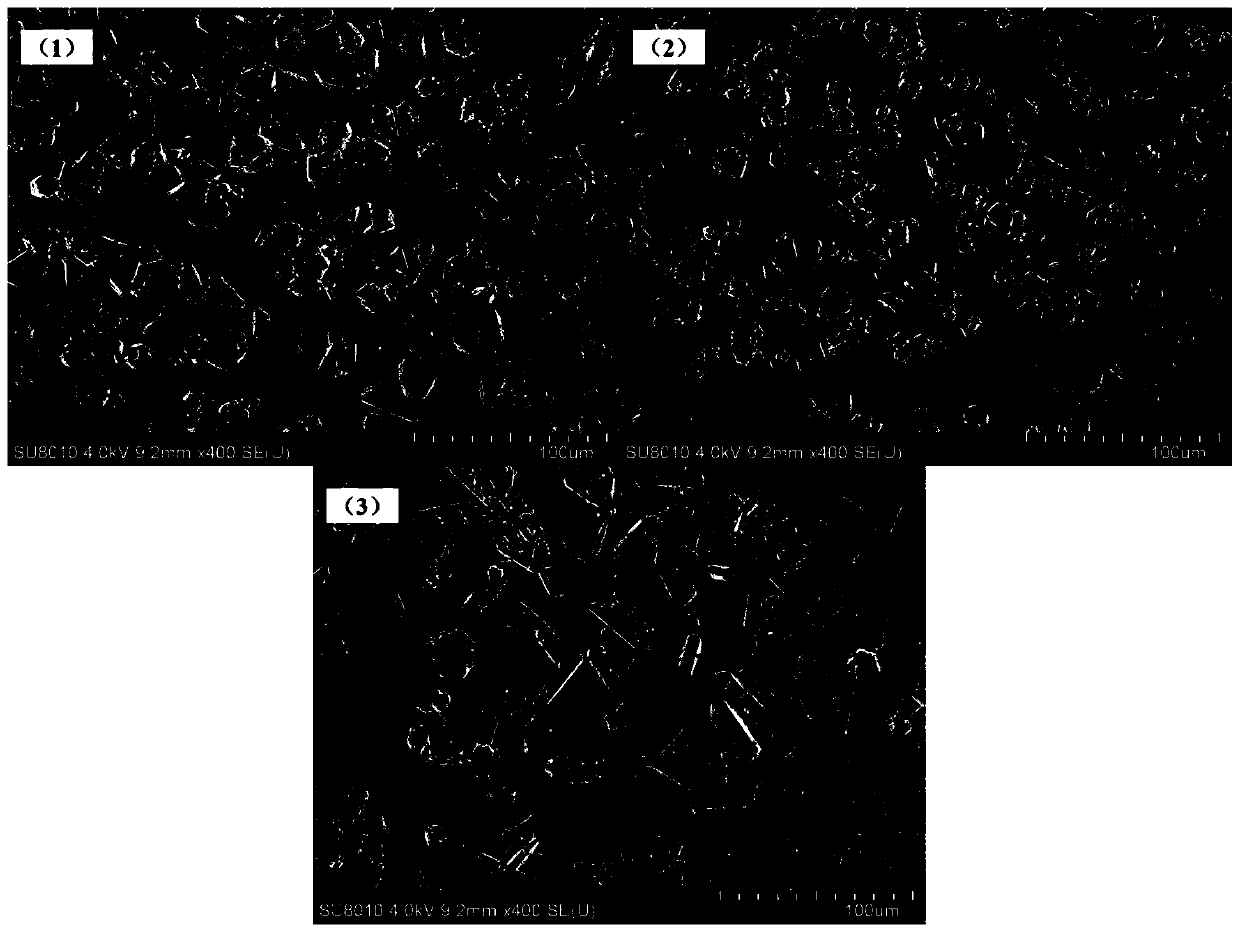

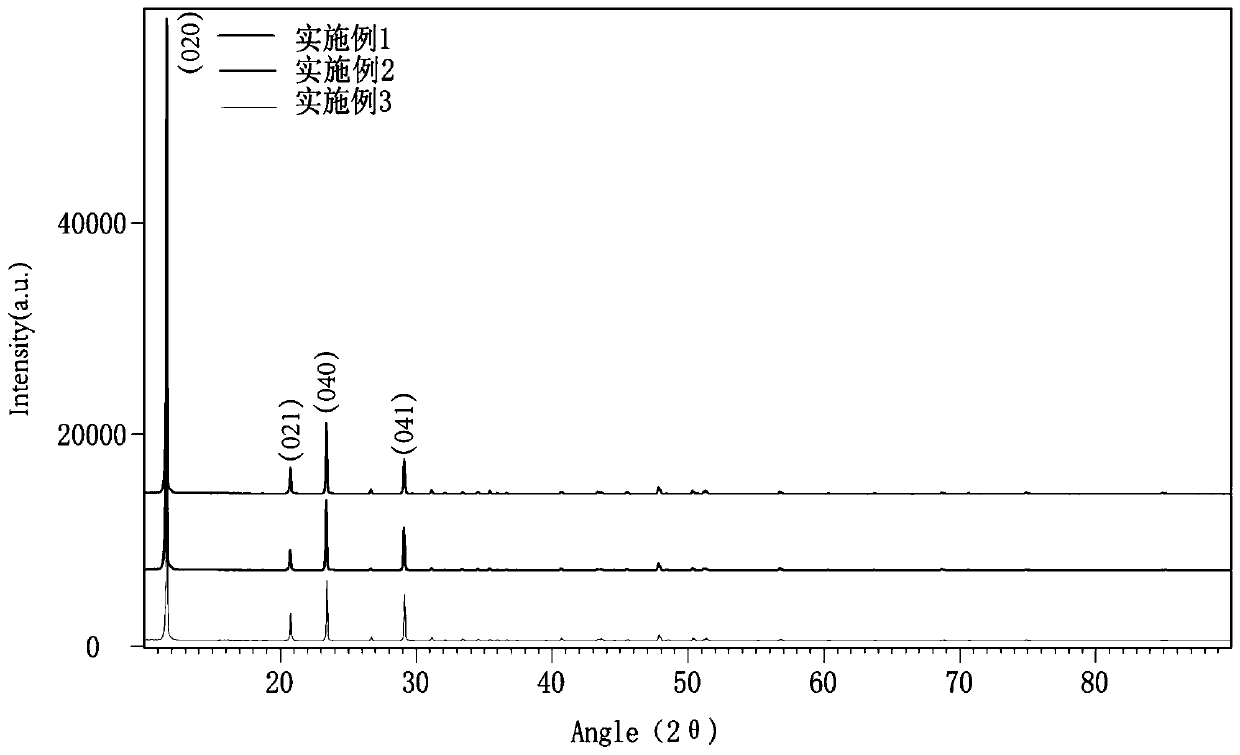

[0033] The invention provides a method for preparing α high-strength gypsum by using chlor-alkali by-product salt gypsum and chemical waste salt in the normal-pressure salt solution method (see flow chart figure 1 ), including the following steps: dry chemical waste salt at 80°C for 2h to remove free water and part of crystal water, then send it to a muffle furnace for high temperature cracking at 600°C for 3h, weigh 30g of waste salt and 70g of distilled water in a cone Mix the saline solution in a flask. Add 20 g of by-product salt gypsum and 0.06 g of anhydrous citric acid to the obtained salt solution and stir with a magnetic stirrer for 1 h (stirring speed is 500 r / min), then seal the mouth of the Erlenmeyer flask and put it in a 90°C constant temperature water bath React in a water bath for 3 hours (stirring while reacting, the stirring rate is 300r / min). After the water bath reaction is completed, the obtained suspension is centrifuged at a speed of 3000r / min to separa...

Embodiment 1

[0039] (1) Dry chemical waste salt at 70°C for 3 hours to remove free water and part of crystal water, then send it to a muffle furnace for high temperature cracking at 600°C for 5 hours, and use it as an atmospheric pressure salt solution method after passing the test of organic harmful substances (completely harmless) Prepare the salt solution raw materials of α high-strength gypsum for standby;

[0040] (2), weigh 30g chemical industry waste salt after the organic harmful substance detection is qualified, mix and prepare 30% saline solution with 70g distilled water in conical flask;

[0041](3), add 20g chlor-alkali by-product salt gypsum powder and 0.06g anhydrous citric acid in 30% saline solution, stir with magnetic stirrer, stirring speed is 500r / min, and stirring time is 3h;

[0042] (4), after the stirring is completed, seal the mouth of the Erlenmeyer flask and put it into a 95°C constant temperature water bath for 5 hours of water bath reaction, stirring while react...

Embodiment 2

[0045] (1) Dry chemical waste salt at 90°C for 1 hour to remove free water and part of crystallization water, then send it to a muffle furnace for 650°C high-temperature cracking for 3 hours, and use it as an atmospheric pressure salt solution method after passing the test of organic harmful substances (completely harmless) Prepare the salt solution raw materials of α high-strength gypsum for standby;

[0046] (2), weigh 35g chemical industry waste salt after the organic harmful substance detection is qualified, mix and prepare 35% saline solution with 65g distilled water in conical flask;

[0047] (3), add 25g chlor-alkali by-product salt gypsum powder and 0.03g anhydrous citric acid, 0.03g aluminum potassium sulfate in 35% saline solution, stir with magnetic stirrer, stirring speed is 400r / min, and stirring time is 4h;

[0048] (4), after the stirring is completed, seal the mouth of the Erlenmeyer flask and then put it into a 98°C constant temperature water bath for 3 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com