Preparation method of compatibilizer for epoxy resin modified asphalt

A technology of epoxy resin and modified asphalt, used in building components, building insulation materials, buildings, etc., can solve problems such as restricting the development of thermosetting asphalt, and achieve the effects of high rigidity, simple operation, and expanded selection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

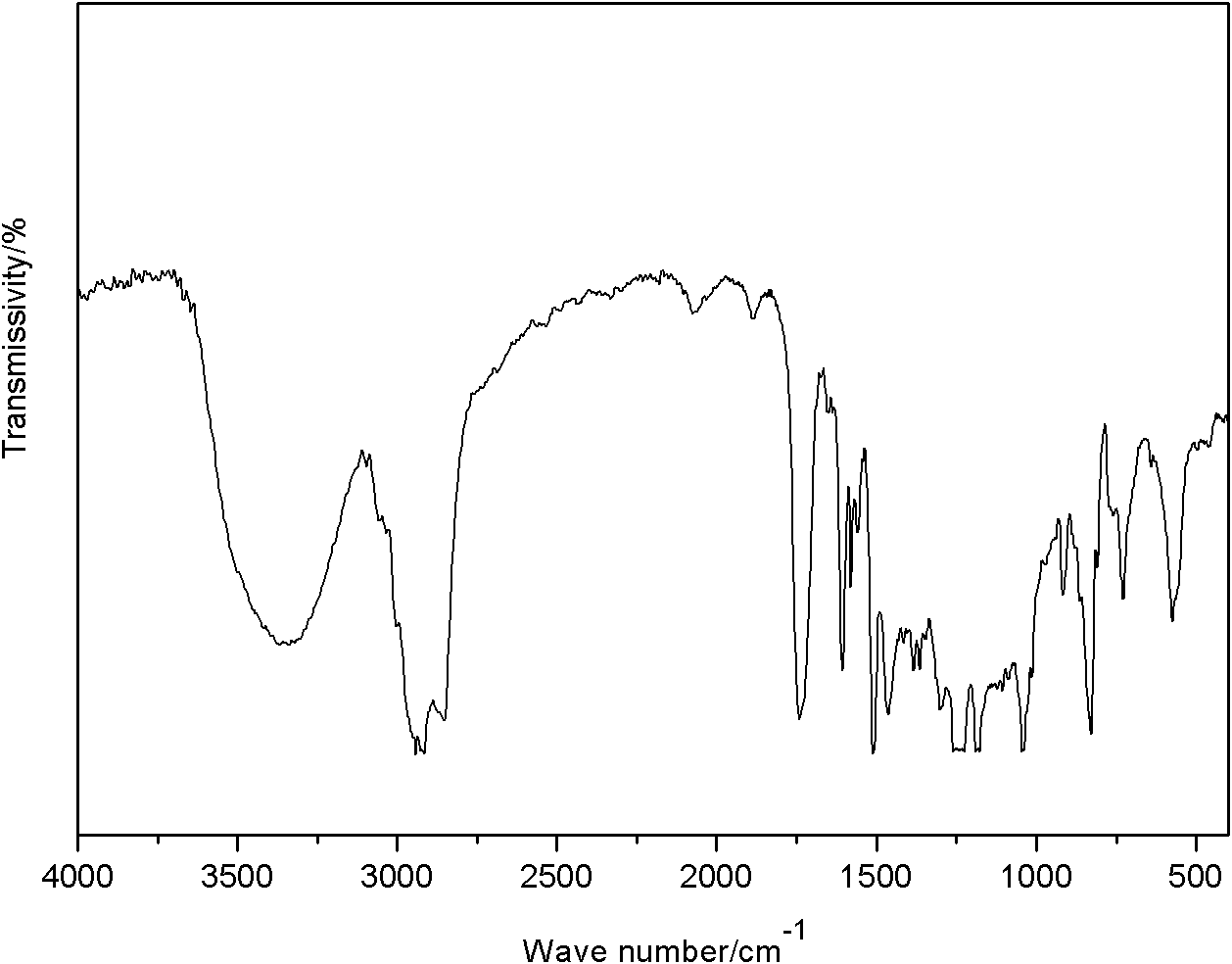

Image

Examples

Embodiment 1

[0045] The preparation method of the compatibilizer of epoxy resin modified asphalt, it comprises the steps:

[0046] In the constant temperature oil bath, add 100 gram ricinoleic acid, 155 gram E-44 epoxy resin, 595 gram chloroform, 3.1 gram tetrabutylammonium bromide, heat up and cause 100 ℃ of reaction 3 hours, evaporate solvent (three Chloromethane), a compatibilizer for epoxy modified asphalt.

[0047] The compatibilizer of the obtained epoxy resin modified asphalt, its structural formula comprises following structure:

[0048]

[0049] Wherein, A is a bisphenol A group.

[0050] The obtained compatibilizer application of present embodiment prepares epoxy resin modified asphalt, the preparation method of epoxy resin modified asphalt, it comprises the steps:

[0051] With No. 70 bitumen of 100 gram Shells, 35 gram epoxy resin E-44, 40 gram present embodiment obtained compatibilizer, 2 gram sulfur (vulcanizing agent), 0.002 gram smoke inhibitor (zinc hydroxystannate) ...

Embodiment 2

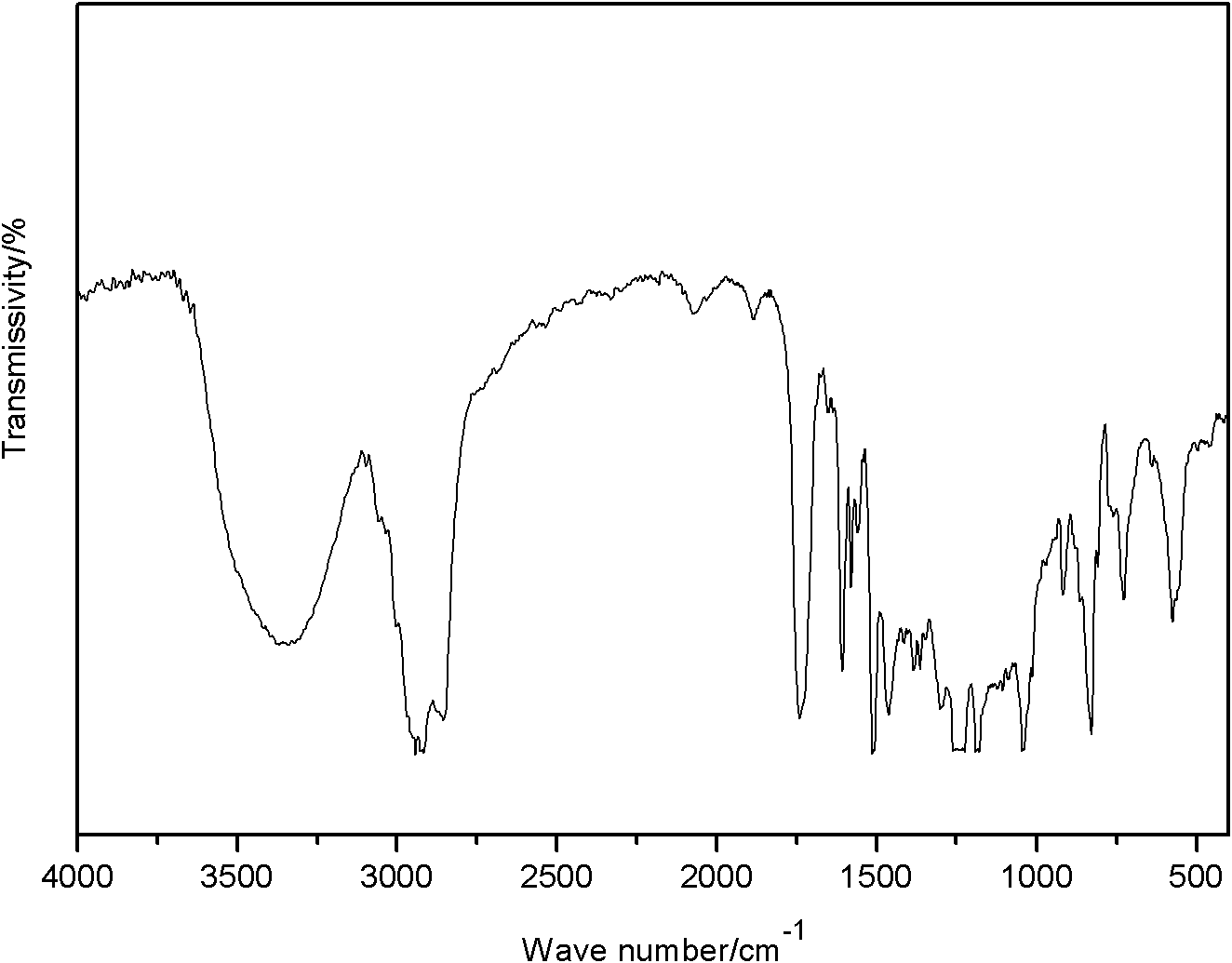

[0056] The preparation method of the compatibilizer of epoxy resin modified asphalt, it comprises the steps:

[0057] In the constant temperature oil bath, add 100 gram ricinoleic acid, 155 gram E-41 epoxy resin, 595 gram chloroform, 3.1 gram tetrabutylammonium bromide, heat up to 100 ℃ of reaction 3 hours, evaporate solvent (three Chloromethane), a compatibilizer for epoxy modified asphalt.

[0058] The compatibilizer of the obtained epoxy resin modified asphalt, its structural formula comprises following structure:

[0059]

[0060] Wherein, A is a bisphenol A group.

[0061] The obtained compatibilizer application of present embodiment prepares epoxy resin modified asphalt, the preparation method of epoxy resin modified asphalt, it comprises the steps:

[0062] With No. 90 bitumen of shell of 100 gram, 35 gram epoxy resin E-44, 40 gram present embodiment obtained compatibilizer, 2 gram vulcanizing agent (sulfur), 0.002 gram smoke inhibitor (zinc hydroxystannate) , 30 ...

Embodiment 3

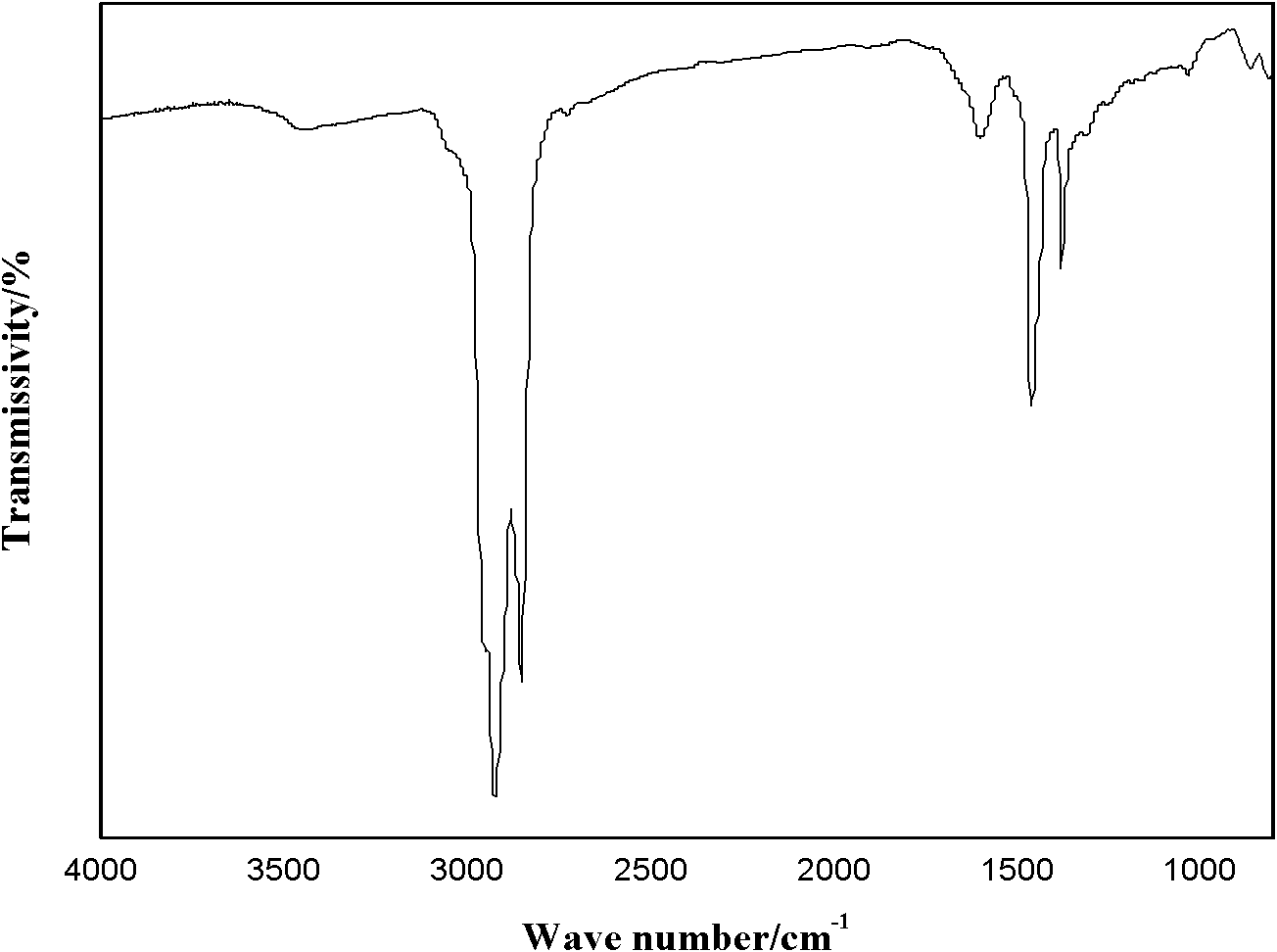

[0066] The preparation method of the compatibilizer of epoxy resin modified asphalt, it comprises the steps:

[0067] 100 grams of oleic acid and 160 grams of E-41 epoxy resin are dispersed in 606 grams of organic solvent chloroform, and 3.2 grams of catalysts (inorganic salt anion catalyst, CaCl 2 ), heated at 100°C for 3 hours to obtain a compatibilizer for epoxy resin modified asphalt.

[0068] The application of compatibilizer of the present invention: application prepares epoxy resin modified asphalt, the preparation method of epoxy resin modified asphalt, it comprises the following steps: with 100 grams of Shell No. 70 pitches, 20 grams of epoxy resin E-41 , 20 grams of curing agent diethylenetriamine, 4 grams of vulcanizing agent tetramethylthiuram disulfide and 20 grams of compatibilizer are mixed, heated to 80 ° C and stirred evenly, cured at 100 ° C for 2 hours, and then heated at 150 ° C Curing for 7 hours at lower temperature to obtain epoxy resin modified asphalt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com