Low-grade waste heat recovery and application technology

A waste heat recovery, low-grade technology, used in heat pumps, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of high economic cost, inability to balance the temperature of the ground source rock and soil layer, and high investment, and achieve the prospect of popularization and application. Wide, improve the secondary utilization rate, reduce the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

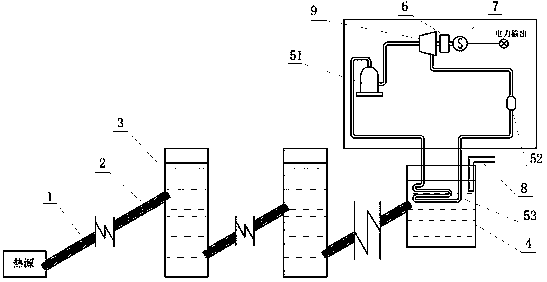

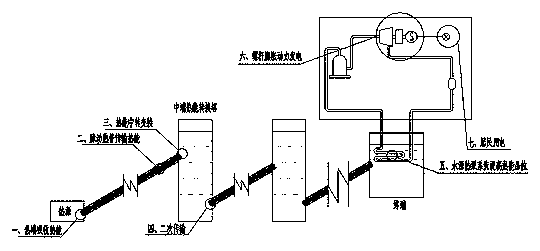

[0037] see figure 1 , the present invention provides a technical solution: a low-grade waste heat recovery utilization technology, comprising the following steps:

[0038] Step 1: Take a place from the waste heat cooling circulating water according to the temperature as the heat source recovery point, and connect a special vacuum heat pipe 1 here to collect waste heat;

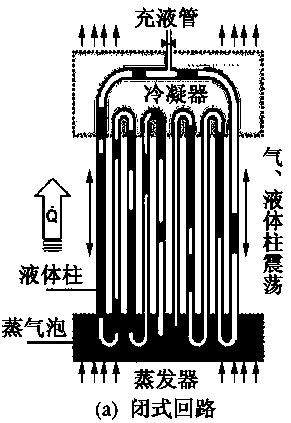

[0039] Step 2: The vacuum heat pipe 1 extends toward the end user in an upward slanting manner, and builds a middle-end heat exchange tower 3 filled with liquid at intervals. The inside of the vacuum heat pipe 1 is in a vacuum state, and the pipe wall is made of special materials to prevent The heat is lost, and the multi-circuit heat pipe 2 is arranged inside;

[0040] Step 3: The vacuum heat pipe 1 of the previous section transfers the heat energy from the heat source end to the water body of the middle heat exchange tower 3, and another vacuum heat pipe 1 of the same specification material is connected to ...

Embodiment 2

[0057] On the basis of Embodiment 1, replacing the vacuum heat pipe with a vacuum tube bundle has the same effect as using the vacuum heat pipe.

[0058] see figure 1 , the present invention provides a technical solution: a low-grade waste heat recovery utilization technology, comprising the following steps:

[0059] Step 1: Take a place from the waste heat cooling circulating water according to the temperature as the heat source recovery point, and connect a special vacuum tube bundle 1 here to collect waste heat;

[0060] Step 2: The vacuum tube bundle 1 is extended to the end user in an upward slanting manner, and a middle-end heat exchange tower 3 filled with liquid is built at intervals. The vacuum tube bundle 1 is in a vacuum state, and the tube wall is made of special materials to prevent The heat is lost, and the multi-circuit heat pipe 2 is arranged inside;

[0061] Step 3: The previous vacuum tube bundle 1 transfers the heat energy from the heat source end to the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com