High-heat environment-friendly biomass and preparation method therefor

A high-calorie, biomass technology, used in biofuels, waste fuels, solid fuels, etc., can solve the problems of slagging, incomplete combustion of polluting gas emissions, and achieve low pollution, resource saving, and high combustion value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

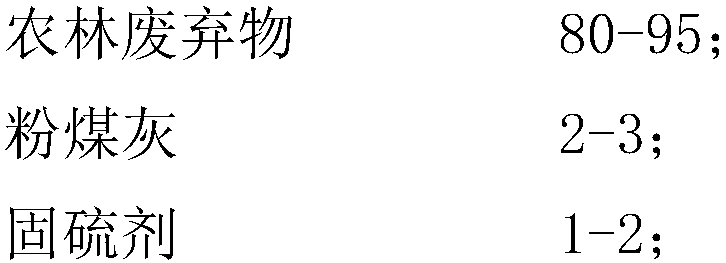

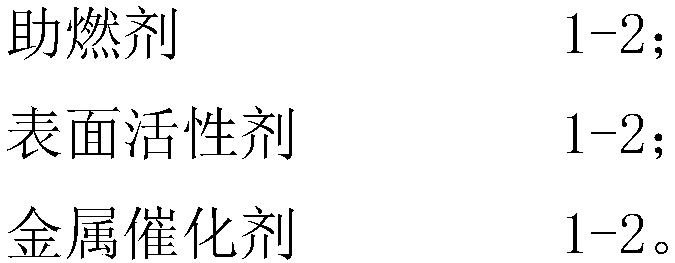

[0029] Step 1) After screening 80 parts by weight of agricultural and forestry wastes, they are sent to a primary pulverizer via a conveyor belt for primary pulverization; the primary pulverizer is provided with a primary bag vacuum cleaner;

[0030] Step 2) 80 parts by weight of the primary crushed agricultural and forestry wastes are sent to the fine processing pulverizer through a conveyor belt, and the diameter of the finely processed and crushed agricultural and forestry wastes is ≤ 8mm;

[0031] Step 3) Send the finely processed pulverized material into the material adjustment mixing bin through the pumping machine, and simultaneously add 2 parts by weight of fly ash, 1 part by weight of sulfur-fixing agent, 1 part by weight of combustion aid, and 1 part by weight in the mixer. The surfactant of weight part is mixed with the metal catalyst of 1 weight part, obtains mixture;

[0032] Step 4) Mix the obtained mixture with the pulverized material in the material adjustment ...

Embodiment 2

[0039] Step 1) After screening 90 parts by weight of agricultural and forestry wastes, they are sent to a primary pulverizer via a conveyor belt for primary pulverization; the primary pulverizer is provided with a primary bag vacuum cleaner;

[0040] Step 2) 90 parts by weight of the primary crushed agricultural and forestry wastes are sent to the fine processing pulverizer through the conveyor belt, and the diameter of the agricultural and forestry wastes after the fine processing and crushing is equal to 8mm;

[0041] Step 3) Send the finely processed pulverized materials into the material adjustment mixing bin through the pumping machine, and simultaneously add 2.5 parts by weight of fly ash, 1.5 parts by weight of sulfur-fixing agent, 1.5 parts by weight of combustion enhancer, 1.5 parts by weight in the mixer The tensio-active agent of weight part is mixed with the metal catalyst of 1.5 weight part, obtains mixture;

[0042] Step 4) Mix the obtained mixture with the pulve...

Embodiment 3

[0049] Step 1) After screening 95 parts by weight of agricultural and forestry wastes, they are sent to a primary pulverizer via a conveyor belt for primary pulverization; the primary pulverizer is provided with a primary bag vacuum cleaner;

[0050] Step 2) 95 parts by weight of the primary crushed agricultural and forestry wastes are sent to the finishing grinder through the conveyor belt, and the diameter of the finished and crushed agricultural and forestry wastes is less than 8mm;

[0051] Step 3) Send the finely processed pulverized material into the material adjustment mixing bin through the pumping machine, and simultaneously add 3 parts by weight of fly ash, 2 parts by weight of sulfur fixing agent, 2 parts by weight of combustion enhancer, 2 parts by weight in the mixer. The tensio-active agent of weight part is mixed with the metal catalyst of 2 weight parts, obtains mixture;

[0052] Step 4) Mix the obtained mixture with the pulverized material in the material adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com