Accordion-shaped NiCo2O4 wave-absorbing material and preparation method thereof

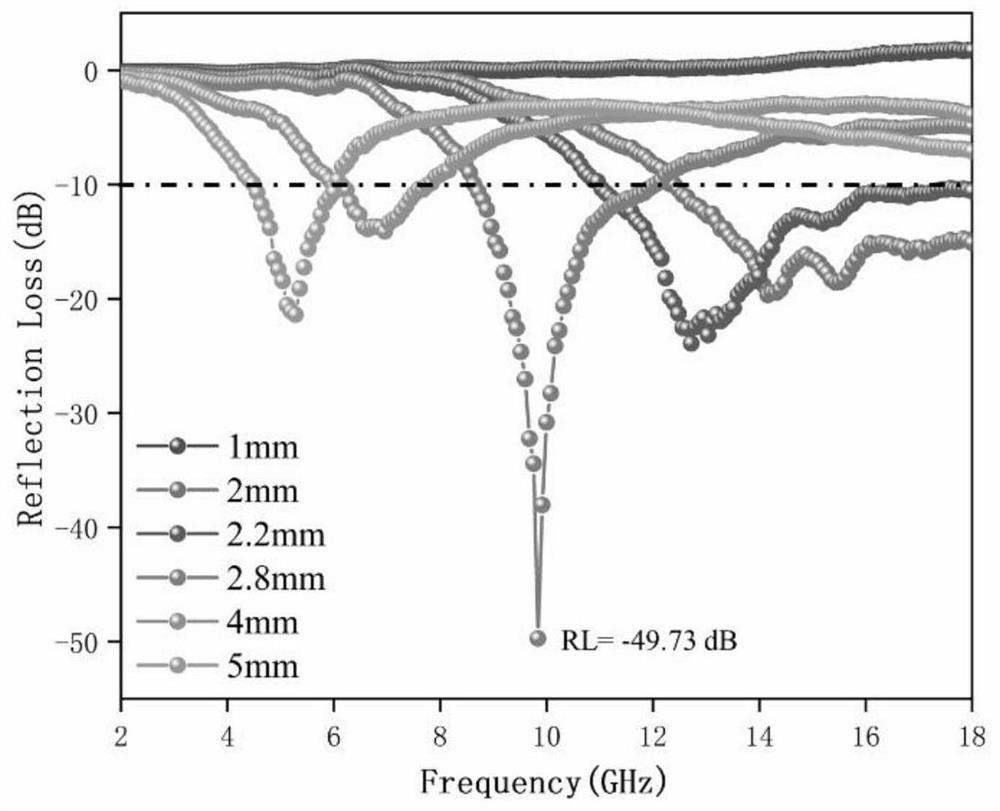

A wave-absorbing material and accordion technology, applied in chemical instruments and methods, inorganic chemistry, nickel compounds, etc., can solve the problems of high cost and cumbersome preparation process, and achieve small thickness, cheap and easy-to-obtain raw materials, and strong controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Accurately weigh 0.1426g NiCl according to the stoichiometric ratio 2 ·6H 2 O and 0.2855 g CoCl 2 ·6H 2 O, added to 60mL of deionized water; another accurately weighed 0.3528g sodium oxalate was added to the above solution, stirred rapidly for 10min to make it a homogeneous liquid; sequentially added 0.1621g anhydrous glucose and 0.1462g urea, stirred at high speed for 30min; The above solution was transferred to a stainless steel reactor, and the temperature was raised to 220°C for 10 hours; after the reaction, it was naturally cooled to room temperature, filtered, washed, and dried to obtain the precursor of the wave-absorbing material; finally, it was calcined at 400°C for 2 hours to obtain an accordion-shaped NiCo 2 o 4 Absorbing material.

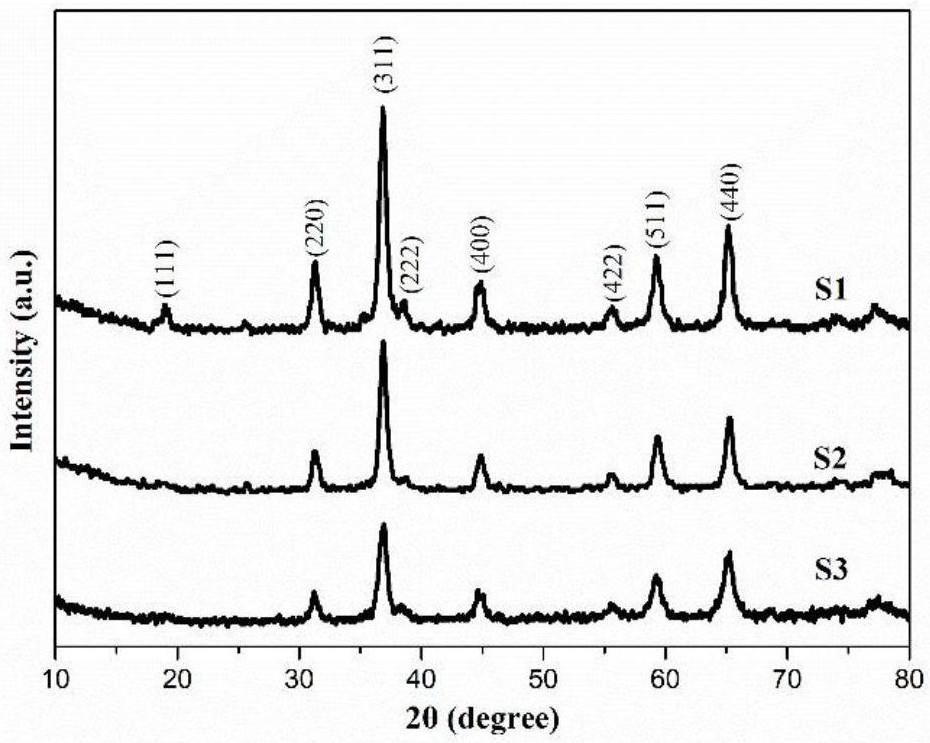

[0033] figure 1 S1 is the X-ray diffraction pattern of the prepared sample. All the diffraction peaks are sharp and consistent with the spinel NiCo 2 o 4 (JCPDS No.20-0718) is consistent, indicating that NiCo 2 o 4 The...

Embodiment 2

[0036] Accurately weigh 0.1426g NiCl according to the stoichiometric ratio 2 ·6H 2 O and 0.2855 g CoCl 2 ·6H 2 O, added to 60mL of deionized water; another 1.1790g of sodium sulfosalicylate was accurately weighed and added to the above solution, and stirred rapidly for 10min to make it a homogeneous liquid; sequentially added 0.9720g of anhydrous glucose and 0.38mL of ammonia water, and Stir for 30 minutes; transfer the above solution to a stainless steel reactor, raise the temperature to 40°C for 24 hours; after the reaction, naturally cool to room temperature, suction filter, wash, and dry to obtain the precursor of the wave-absorbing material; finally calcinate at 600°C for 0.5h, Accordion-shaped NiCo 2 o 4 Absorbing material.

[0037] figure 1 S2 is the X-ray diffraction pattern of the prepared sample.

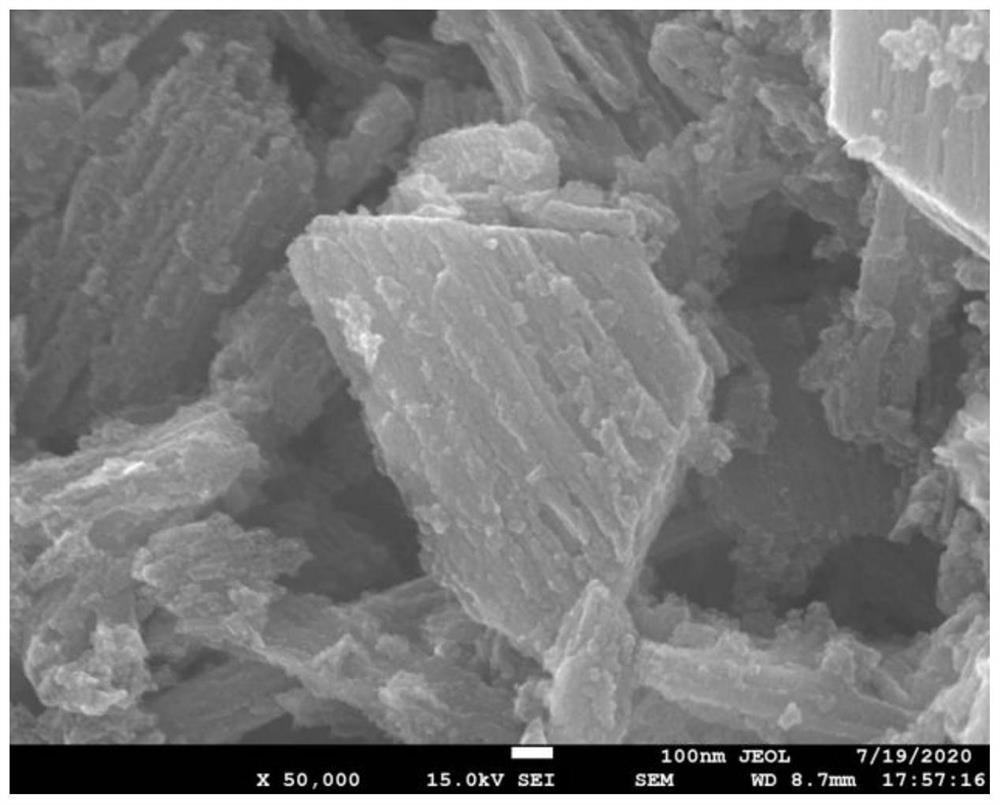

[0038] Figure 4 It is the scanning electron microscope picture of the synthetic wave-absorbing material of this embodiment, can find out from this figure that NiC...

Embodiment 3

[0040] Accurately weigh 0.1426g NiCl according to the stoichiometric ratio 2 ·6H 2 O and 0.2855 g CoCl 2 ·6H 2 O, added to 60mL of deionized water; another accurate measure of 12μL ethylenediamine was added to the above solution, stirred rapidly for 10min to make it a homogeneous liquid; sequentially added 0.6552g cetyltrimethylammonium bromide and 0.0711g Ammonium bicarbonate, stirred at high speed for 30 minutes; transferred the above solution to a stainless steel reaction kettle, raised the temperature to 220°C and reacted for 10 minutes; naturally cooled to room temperature after the reaction, filtered, washed, and dried to obtain the precursor of the wave-absorbing material; ℃ calcined for 3h to obtain accordion-shaped NiCo 2 o 4 Absorbing material.

[0041] figure 1 S3 is the X-ray diffraction pattern of the prepared sample.

[0042] Figure 5 It is the scanning electron microscope picture of the synthetic wave-absorbing material of this embodiment, can find out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption bandwidth | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com