Pyrochlore-based glass ceramic for solidifying radioactive waste and preparation method of pyrochlore-based glass ceramic

A technology of radioactive waste and glass ceramics, applied in radioactive purification, nuclear engineering and other directions, can solve problems such as slow temperature adjustment, reduce energy consumption, reduce the time for crystal nucleation and growth, and achieve good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a pyrochlore-based glass-ceramic for solidifying radioactive waste and a preparation method thereof, the preparation method comprising the following steps:

[0051] (1) Mix lanthanum oxide, yttrium oxide, zirconium oxide, titanium oxide, and aluminum oxide in a molar ratio of 1:1:2:2:1, and add absolute ethanol as a grinding medium to the material, and grind until the absolute ethanol is fully Volatilize, dry the material, repeat the grinding process, and press with a pressure of 10MPa to obtain a block sample;

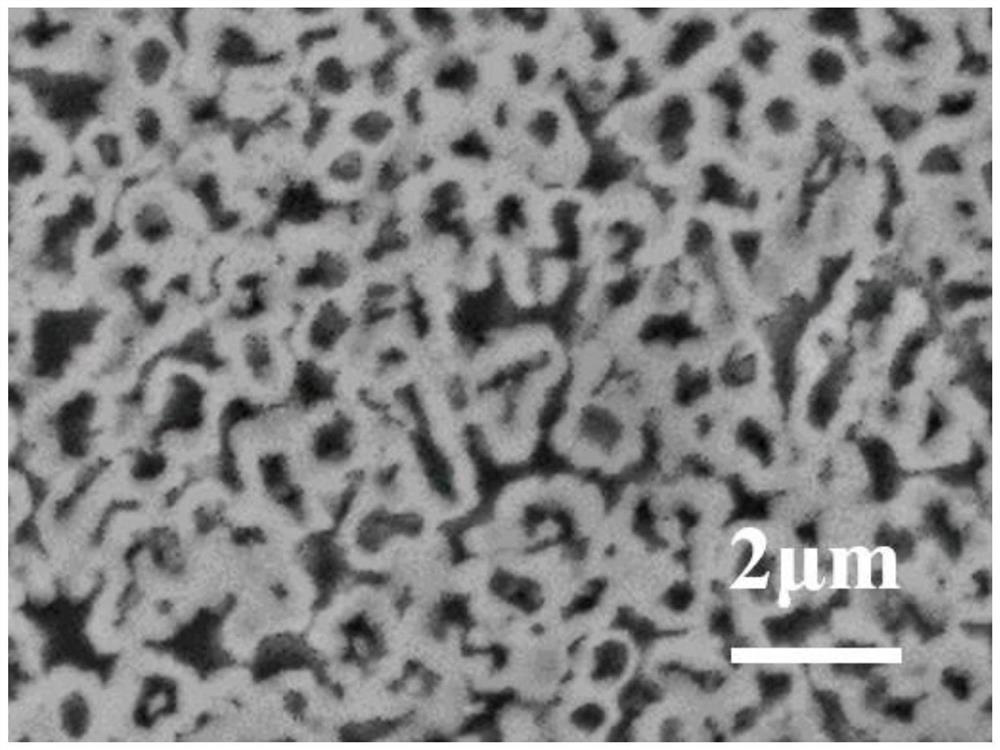

[0052] (2) Place the block sample obtained in step (1) at the nozzle of the pneumatic suspension containerless heating equipment, use oxygen as the carrier gas to keep the sample in a suspended state, use a carbon dioxide laser to directly heat the sample, and wait until the sample is heated to a molten state and then Keep for 1 min until the materials are evenly mixed, and then cool and solidify at a cooling rate of 500K / s to obtain py...

Embodiment 2

[0055] This embodiment provides a pyrochlore-based glass-ceramic for solidifying radioactive waste and a preparation method thereof. In the preparation method, except that the cooling rate in step (2) is changed to 400K / s, the rest of the conditions are the same as in Example 1. So I won't go into details here.

[0056] The ceramic phase and glass phase of the pyrochlore-based glass ceramics obtained in this example are similar to those in Example 1.

Embodiment 3

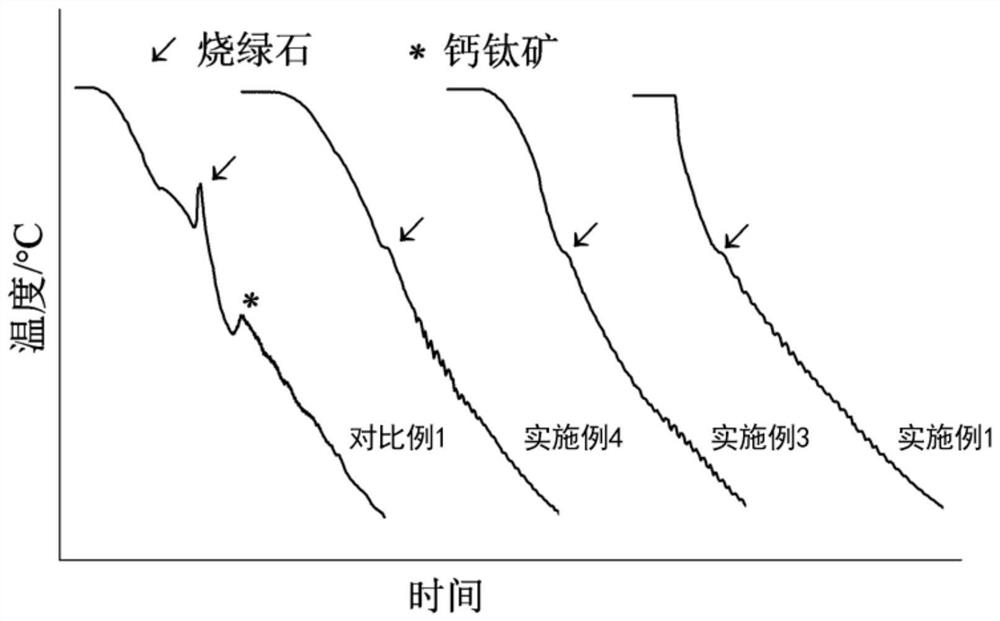

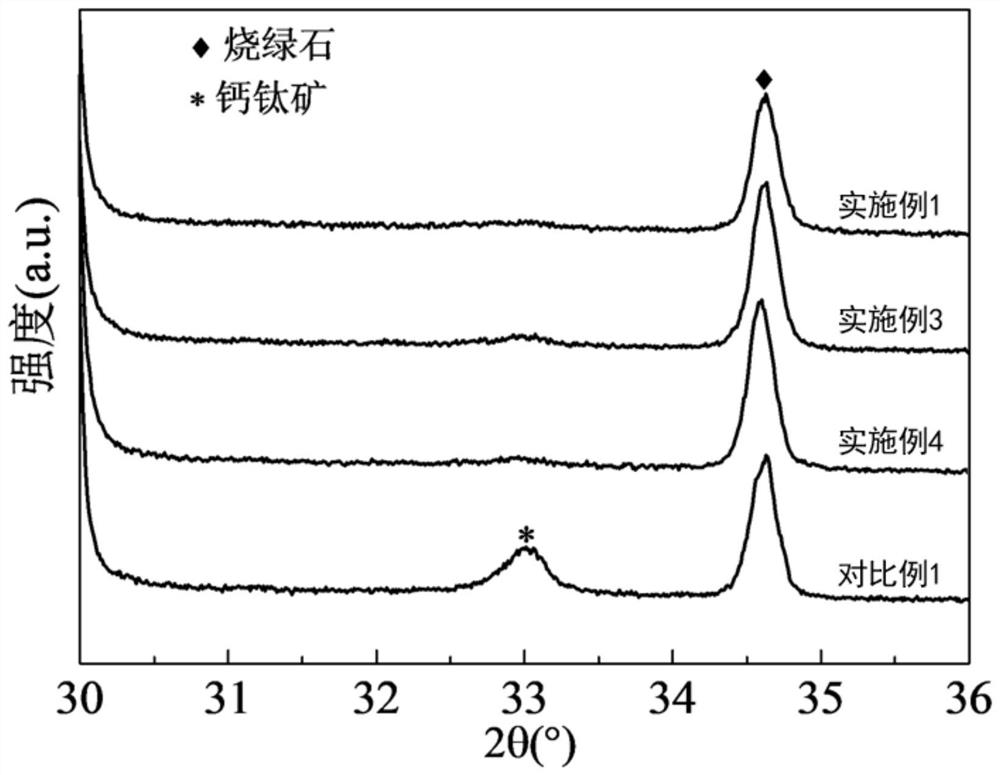

[0058] This embodiment provides a pyrochlore-based glass-ceramic for solidifying radioactive waste and its preparation method. In addition to changing the cooling rate in step (2) to 300K / s in the preparation method, and the solidification cooling curve of the glass-ceramic solidified body Spectrum see figure 2 , and the rest of the conditions are the same as in Example 1, so details are not repeated here.

[0059] The ceramic phase and glass phase of the pyrochlore-based glass ceramics obtained in this example are similar to those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com