Melatonin delayed release tablet and preparation method thereof

A melatonin and delayed-release technology is applied in the field of melatonin delayed-release tablets and the preparation thereof, which can solve the problems of inhibiting male gonad development, excessive administration dose, endocrine disorder, etc., and achieves a simple preparation process and a reduction in the dosage of medication. , the effect of maintaining complete sleep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

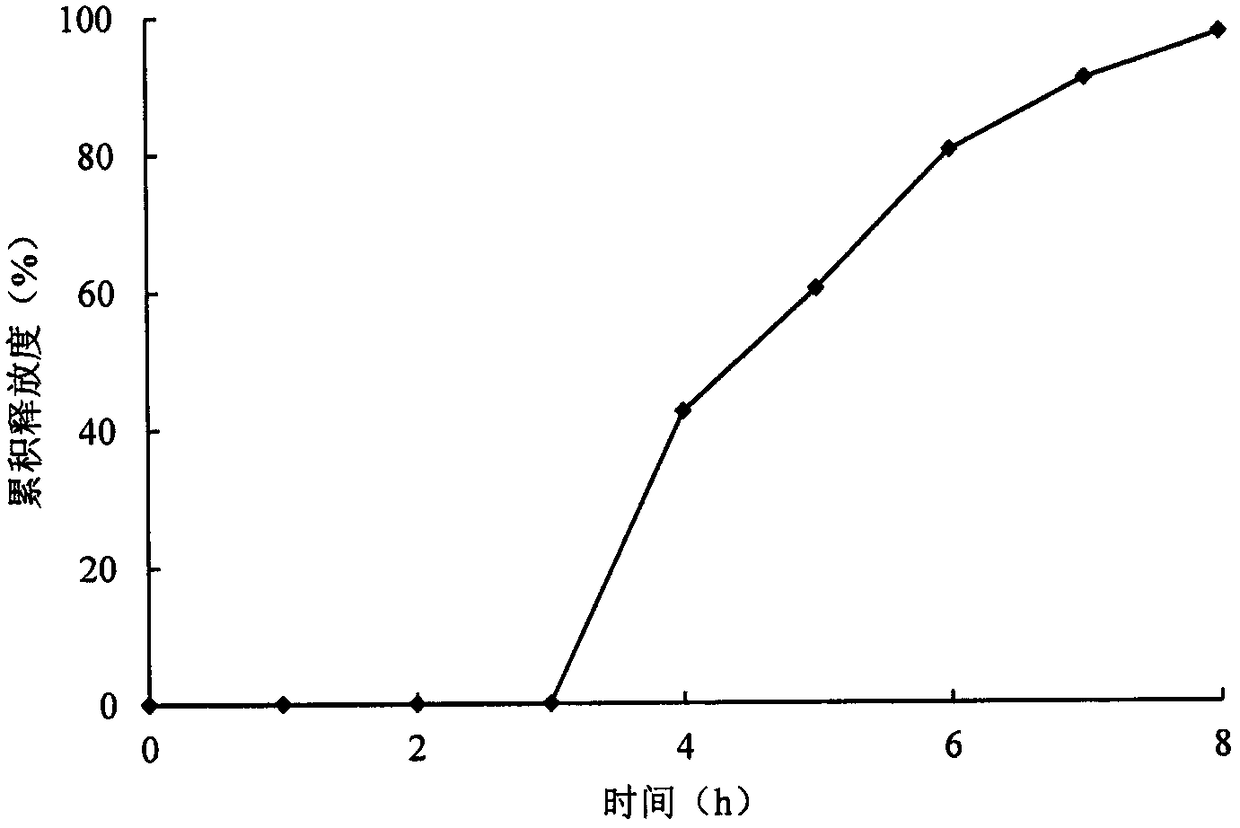

Embodiment 1

[0040]

[0041] Preparation Process:

[0042] (1) Preparation of double-layer tablet cores: Take the prescribed amount of tablet core drug-containing layer melatonin, lactose and behenic acid ester and pass through 80 mesh sieves respectively, mix well, add 10% starch slurry to make soft materials, and 30 mesh sieves granules, dried at 50°C for 2 hours, granulated with a 25-mesh sieve, mixed with micro-powdered silica gel; take the prescribed amount of tablet core expansion layer and each auxiliary material was passed through an 80-mesh sieve, mixed evenly, and added with 5% PVPK30 aqueous solution to make a soft material, 30 mesh Sieve to granulate, dry at 50°C for 2 hours, sieve through a 25-mesh sieve, add magnesium stearate and mix evenly; press to obtain a double-layer tablet core;

[0043] (2) Preparation of coated granules: take the prescription amount of HPMC 100LV and lactose and pass through a 60-mesh sieve respectively, mix well, add 95% ethanol as a binder to ma...

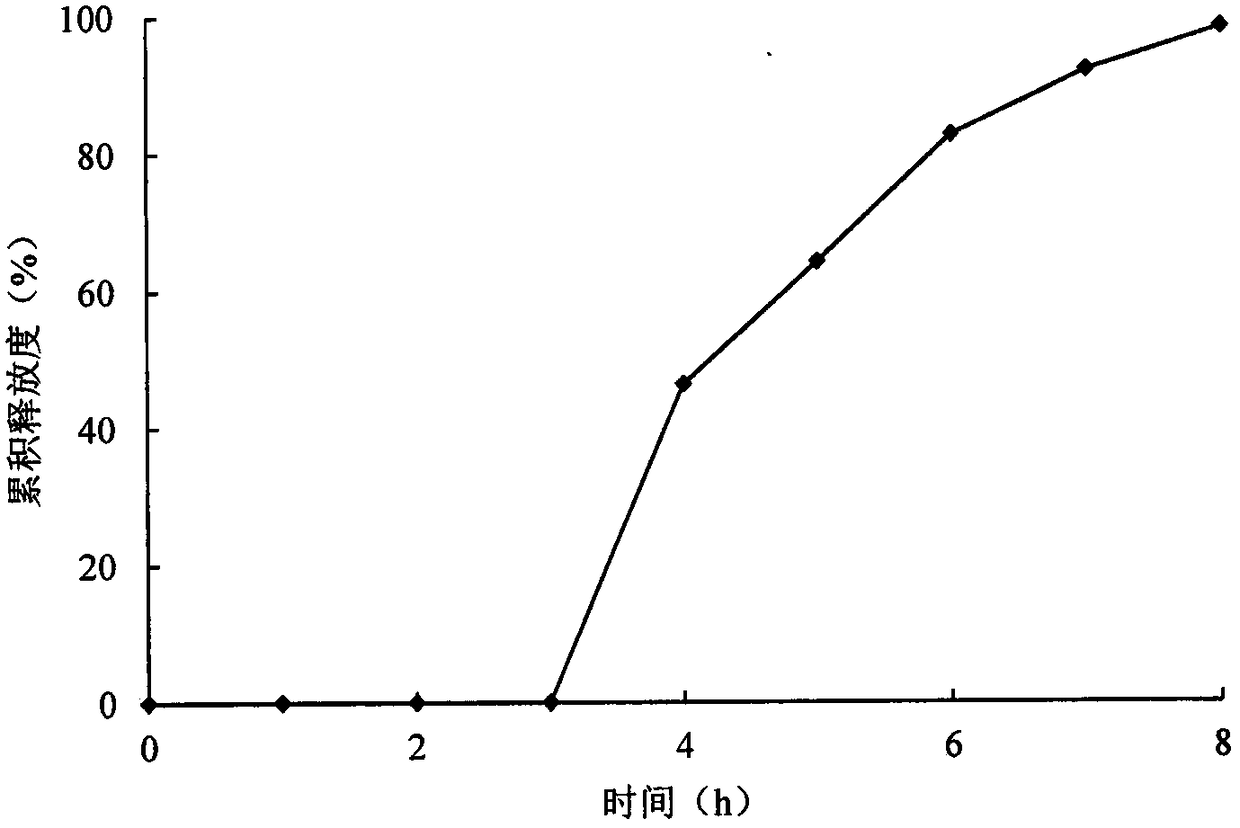

Embodiment 2

[0046]

[0047] Preparation Process:

[0048] (1) Preparation of double-layer tablet core: take the prescribed amount of tablet core drug-containing layer melatonin, EC and lactose and pass through 80 mesh sieve respectively, mix well, make soft material with 75% ethanol, granulate with 30 mesh sieve, at 50 ℃ Dry for 1 hour, granulate with a 25-mesh sieve, add magnesium stearate and mix evenly; take the prescription amount of each auxiliary material of the tablet core expansion layer and pass through an 80-mesh sieve, mix evenly, add 10% starch slurry to make a soft material, and granulate with a 30-mesh sieve , dried at 50°C for 2 hours, sieved with a 25-mesh sieve, mixed with stearic acid; pressed to obtain a double-layer tablet core;

[0049] (2) Preparation of coated granules: Take the prescribed amount of behenate, lactose and calcium hydrogen phosphate, pass through a 60-mesh sieve respectively, mix well, add 10% PVPK30 solution as a binder to make a soft material, an...

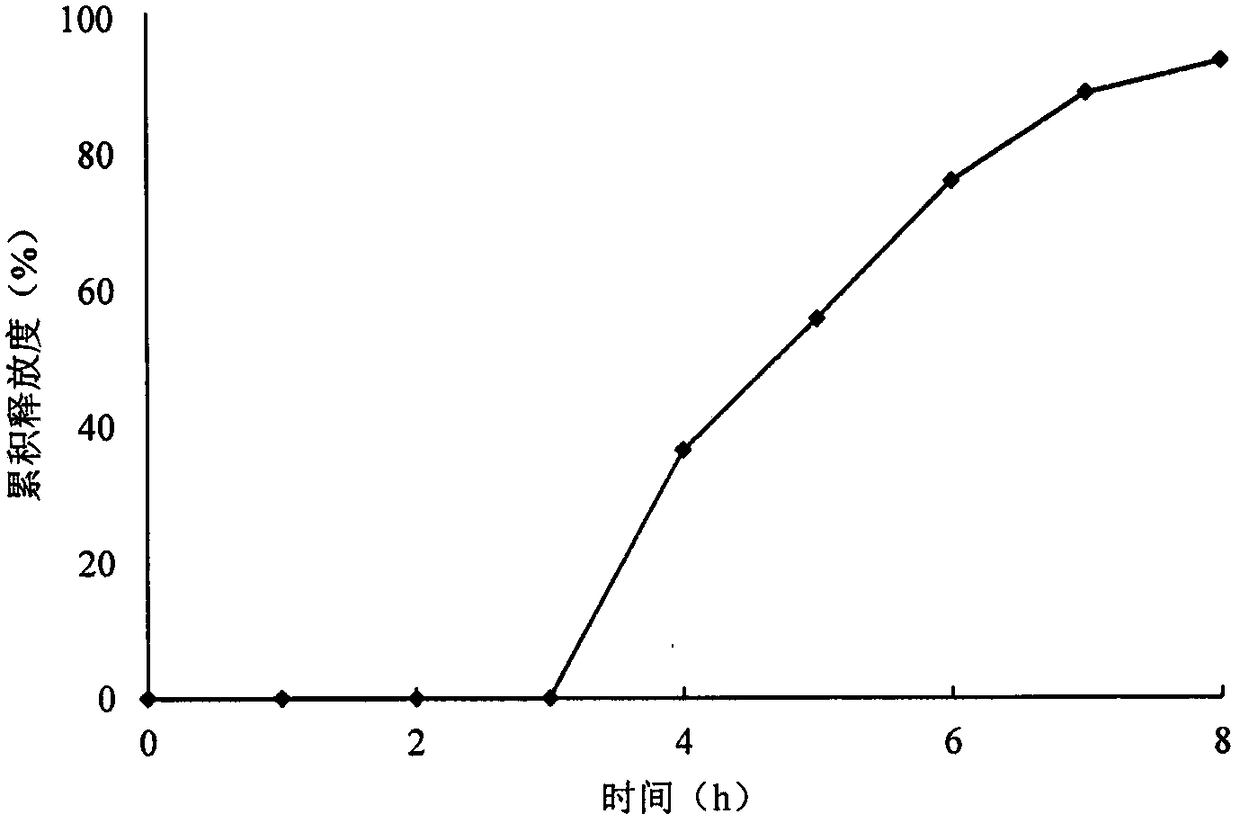

Embodiment 3

[0052]

[0053] Preparation Process:

[0054] (1) Preparation of double-layer tablet core: take the raw and auxiliary materials of the drug-containing layer of the tablet core and the auxiliary materials of the expansion layer of the tablet core to pass through an 80-mesh sieve respectively, fully mix the components of each layer, and press to obtain a double-layer tablet core;

[0055] (2) Preparation of coated granules: take the prescription amount of glyceryl monostearate, beeswax, and mannitol and mix, heat and melt, cool to room temperature and solidify, grind and pulverize, pass through a 30-mesh sieve, add talcum powder and mix, and set aside;

[0056] (3) Press coated tablets: first add half of the coated granules to the bottom of the die, place the double-layer tablet core in the center, then add the remaining half of the coated granules, and press to get the tablet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com