Preparation method of foamed nickel-based oxide composite wave-absorbing material

A technology of composite absorbing materials and oxides, applied in chemical instruments and methods, other chemical processes, electrical components, etc., can solve the problems of prolonging the material preparation cycle, limiting practical applications, and cumbersome preparation processes, achieving repeatability and Strong controllability, short preparation cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Accurately weigh 1.45g Ni (NO 3 ) 2 ·6H 2 O and 0.4054g FeCl 3 ·6H 2 O and 1gF127 were placed in an agate mortar and ground for 10 minutes until the materials were mixed; the mixed materials were collected and dried in a blast drying oven at 80°C for 6 hours to obtain a foaming material precursor; Calcined at 500°C for 2h at °C / min to obtain a nickel-ferrite-supported foamed nickel-based oxide composite absorber.

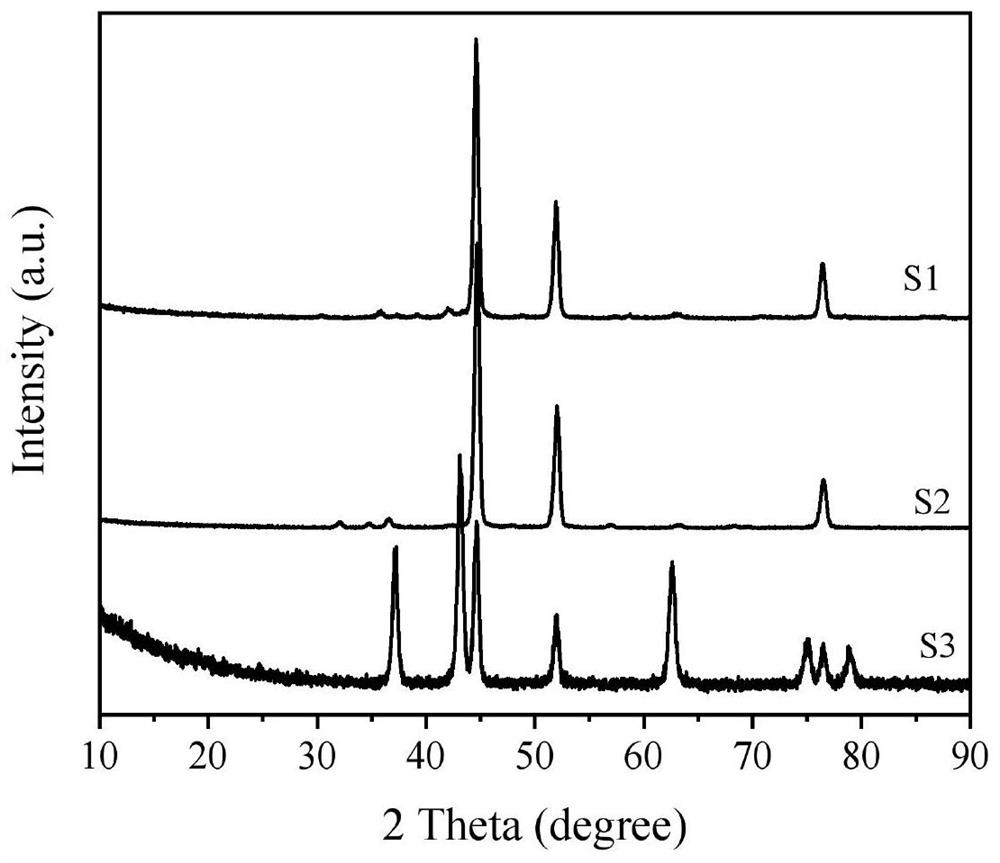

[0034] figure 1 S1 is the X-ray diffraction pattern of the prepared sample. The main peak is the peak of metallic nickel, and the diffraction peak of nickel ferrite can be observed by zooming in on the spectrum. The peak shape is good and has good crystallinity.

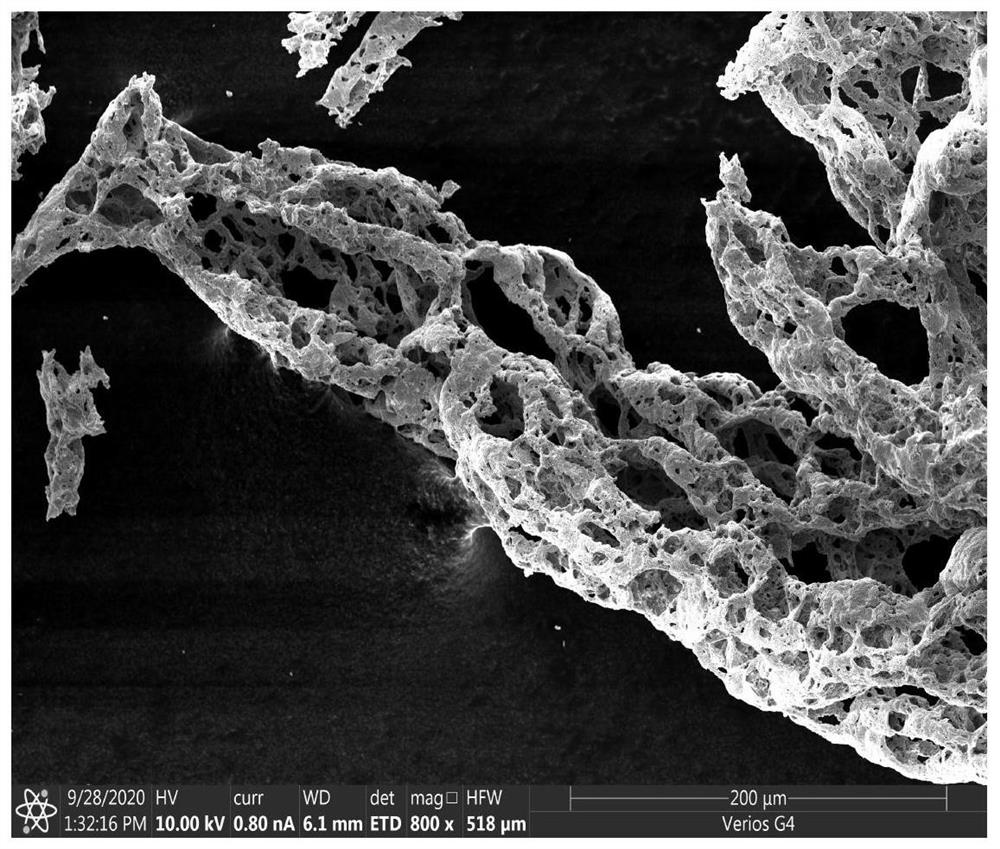

[0035] figure 2 This is the scanning electron microscope image of the synthesized absorbing material in this example, from which it can be seen that the material is in a regular porous shape.

Embodiment 2

[0037] Accurately weigh 1.45gNi(NO 3 ) 2 ·6H 2 O and 0.1488g Zn(NO 3 ) 2 ·6H 2 O and 0.5g P123 were placed in an agate mortar and ground for 15 minutes until the materials were evenly mixed. The mixed material was collected and dried in a blast drying oven at 60° C. for 12 hours to obtain a foam material precursor. Finally, it was calcined at 200°C for 3h at a heating rate of 1°C / min to obtain a zinc oxide-supported foamed nickel-based oxide composite absorber.

[0038] figure 1 S2 is the X-ray diffraction pattern of the prepared sample.

[0039] Figure 4 The scanning electron microscope image of the wave-absorbing material prepared for this example, it can be seen from the image that a porous zinc oxide-loaded porous nickel-based material is obtained.

Embodiment 3

[0041] Accurately weigh 1.45gNi(NO 3 ) 2 ·6H 2 O and 0.5948g CoCl 2 ·6H 2 O and 0.5g F127 were placed in an agate mortar and ground for 20 minutes until the materials were evenly mixed. The mixed material was collected and dried in a blast drying oven at 100° C. for 3 hours to obtain a foam material precursor. Finally, it was calcined at 400° C. for 30 minutes at a heating rate of 10° C. / min to obtain a foamed nickel-based oxide composite absorbing material supported by nickel oxide.

[0042] figure 1 S3 is the X-ray diffraction pattern of the prepared sample.

[0043] Figure 5 The scanning electron microscope image of the wave-absorbing material prepared for this example, it can be seen from the image that the nickel oxide-loaded porous nickel-based foam material exhibits a regular morphology.

[0044]In the preparation process of the foamed nickel-based oxide composite wave-absorbing material provided by the present invention, it is necessary to strictly control the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com